Pin splitter applied to narrow space and using method thereof

A pin splitter and space technology, which is applied in the field of hand-held special fastening tools, can solve the problems that the radian cannot meet the acceptance standard, the bending section of the lock pin is not bent in place, and the efficiency is low, so as to achieve the purpose of strengthening the split pin The effect of quality and acceptance efficiency, simplification of operation process, and ease of popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The present invention will be further described in detail below with reference to the accompanying drawings.

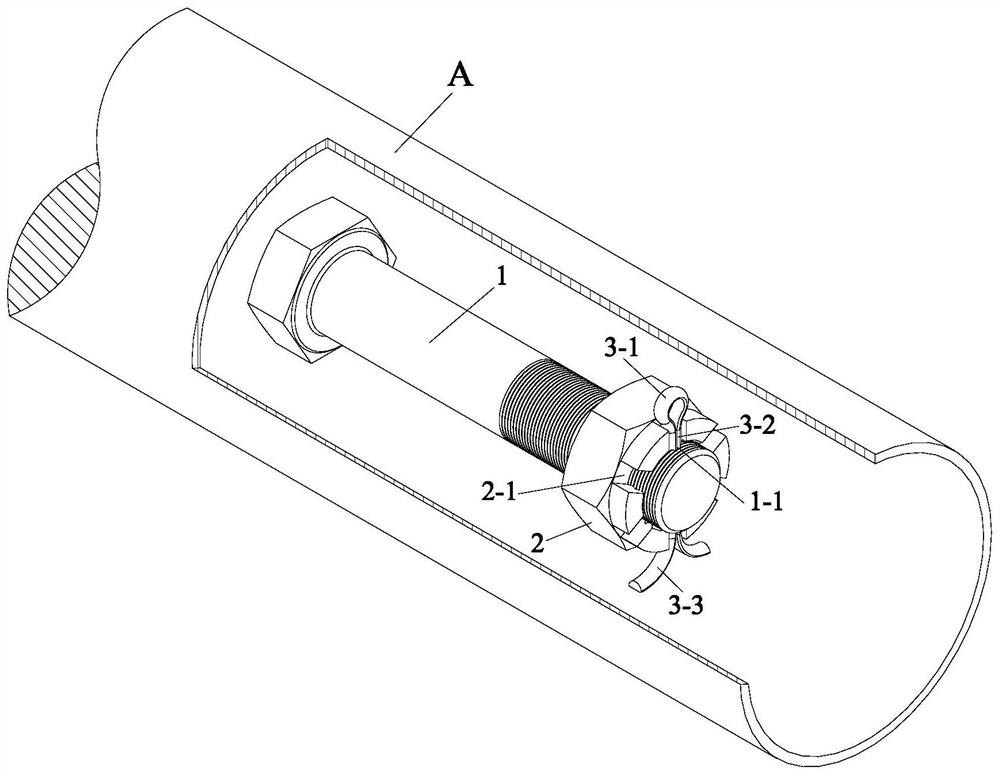

[0043]Such asFigure 4 to 17 As shown, the 销销器 of the present invention is applied to the narrow space includes: coaxial positioning sleeve 4, cleaning striker mechanism 5, hand-held probe 6, latch ring positioning rod 7, hand-held probe 6 includes handle 6-1, chute Base 6-2, open card ring 6-3, positioning rod socket 6-4, striker guide sliding slot 6-5, hit needle tie through hole 6-6 and sleeve jack 6-7, chute pedestal 6 -2 The front end of the handle 6-1, the sleeve jack 6-7 is sequentially penetrating the slot base 6-2 and the handle 6-1 along the center line of the front end surface of the slot base 6-2, and the handle guide The chute 6-5 is opened at the edge of the front end surface of the slot base 6-2; the opening card ring 6-3 is solidly connected to the outer portion of the sleeve jack 6-7; parallel to the sleeve jack 6-7 The strike bar through holes 6-6 are op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com