Crab binding aiding equipment

A kind of auxiliary equipment, crab technology, applied in the parts, packaging and other directions of strapping machinery, can solve the problems of easy breakage, high cost of quick boxing, damage to crab claws, etc., and achieves easy installation and use, convenient processing and manufacturing, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

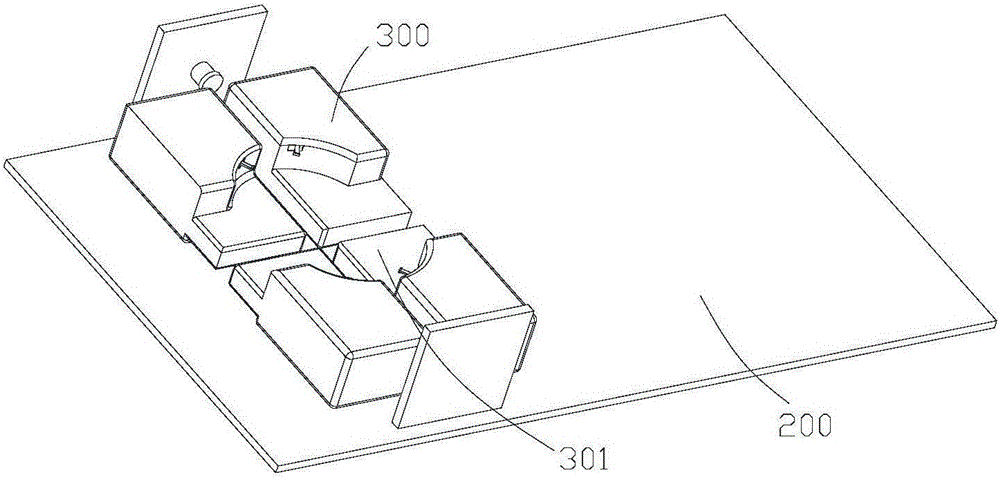

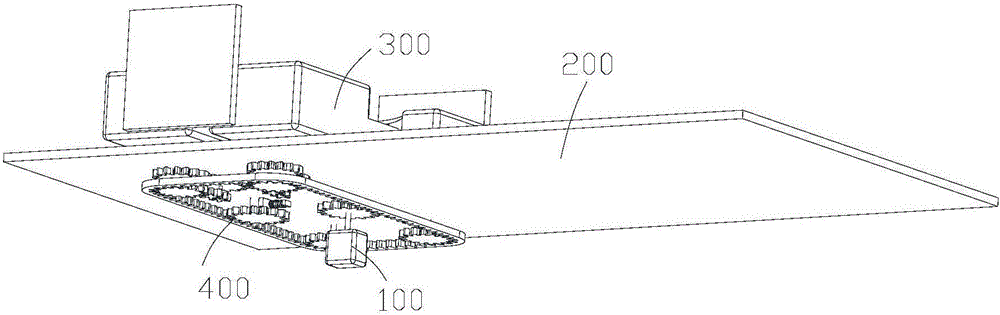

[0050] see Figure 1-Figure 3 , the present embodiment provides an auxiliary device for strapping crabs, including a driving assembly 100 , a mounting plate 200 , a fixing table 300 and a crab fixing assembly 400 .

[0051] see Figure 4 and Figure 5 , the driving assembly 100 provides power for the entire auxiliary equipment, specifically, the driving assembly 100 provides power for the crab fixing assembly 400, drives the crab fixing assembly 400 to position and fix the crab, and provides a good environment for tying. The drive assembly 100 is preferably configured to include a transmission belt 102 and a motor 101, the motor 101 may be a servo motor 101, which is convenient to control the rotation speed and is more flexible and reliable during operation. Drive wheel 103 is installed on the output end (output shaft) of motor 101, and drive wheel 103 is meshed with drive belt 102, and drive belt 102 is closed shape, is annular, and drive wheel 103 is positioned at drive be...

Embodiment 2

[0065] see Figure 9 and Figure 10 , this embodiment provides a crab strapping auxiliary device, this embodiment is a further improvement on the basis of the technical solution of the first embodiment, the technical solution already disclosed in the first embodiment is also applicable to this embodiment, in order to avoid repetition of description To be cumbersome, the technical solution already described in Embodiment 1 will not be described again.

[0066] Specifically, this embodiment is a further improvement of the driving assembly 100 in order to improve the transmission efficiency of the transmission belt 102 . The driving assembly 100 also includes a tensioning device 500 for adjusting the tightness of the transmission belt 102 . The tensioning device 500 comprises a pressing tooth 503, a pressing member 501 and a pressing spring 502, the pressing tooth 503 is connected with the transmission belt 102, the pressing member 501 is pressed against the rotating shaft of th...

Embodiment 3

[0068] see Figure 11 and Figure 12 , this embodiment provides a crab strapping auxiliary device, this embodiment is a further improvement on the basis of the technical solution of the second embodiment, the technical solution already disclosed in the second embodiment is also applicable to this embodiment, in order to avoid repetition of description To be cumbersome, the technical solution already described in Embodiment 2 will not be described again.

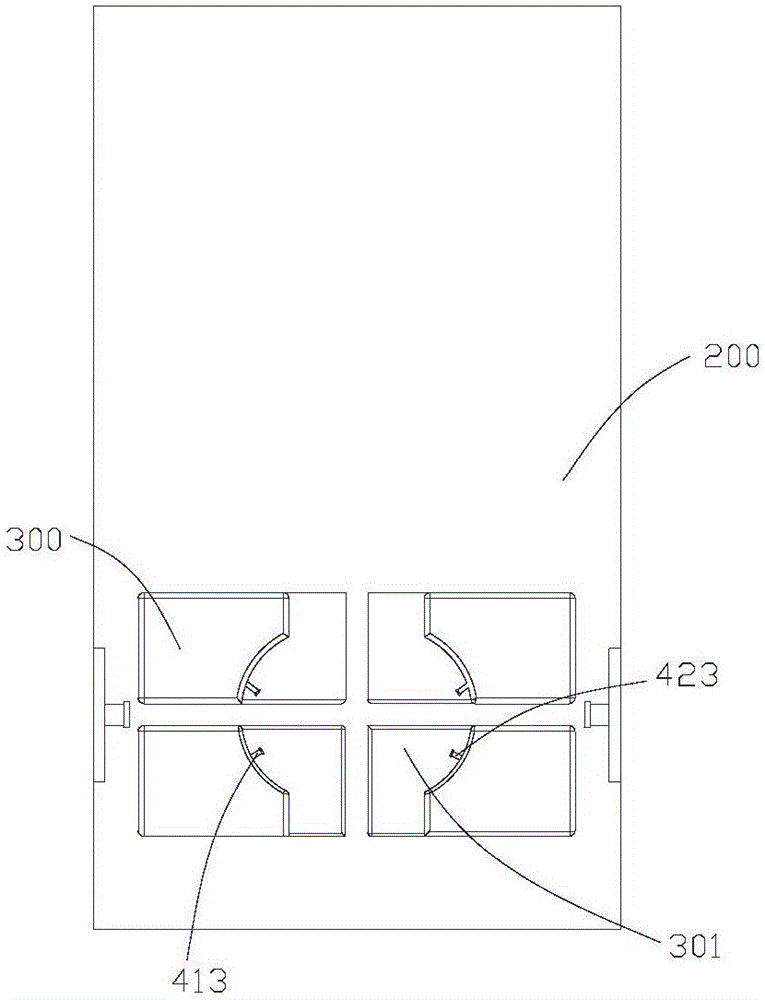

[0069] Specifically, this embodiment is an improvement to ensure that the crabs are easily taken out after the crabs are bound. The crab binding auxiliary equipment also includes a push-out mechanism. Launched within 301.

[0070] There is a groove 301 on the fixed platform 300, and the crab is placed in the groove 301. In order to facilitate the release of the crab, the fixed platform 300 is provided with an opening 302. The opening 302 communicates with the groove 301. The opening 302 is located between the first cam 411 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com