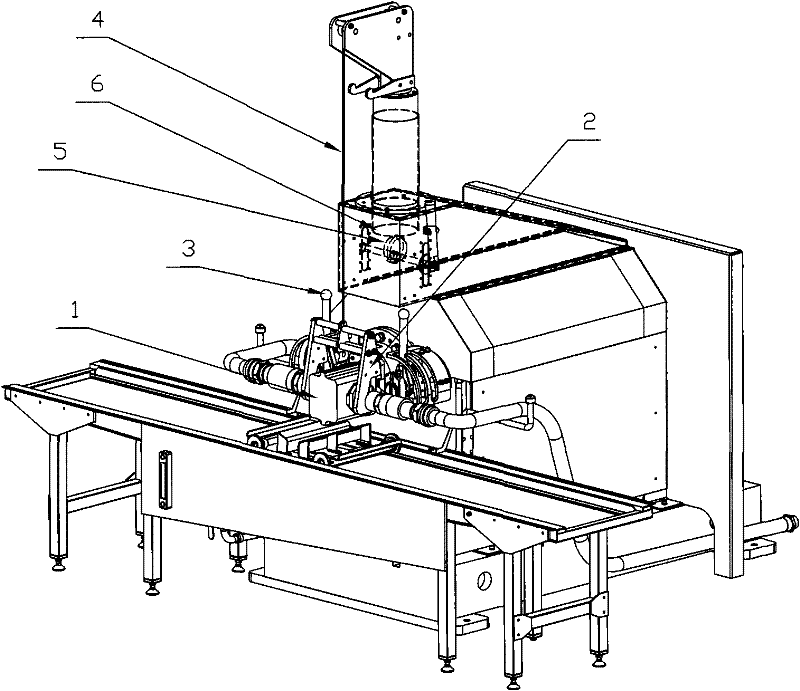

Clamping device

A clamping device and clamp locking technology, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of low efficiency and high labor intensity, and achieve fast and powerful clamping, free alignment, and reduced clamping labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

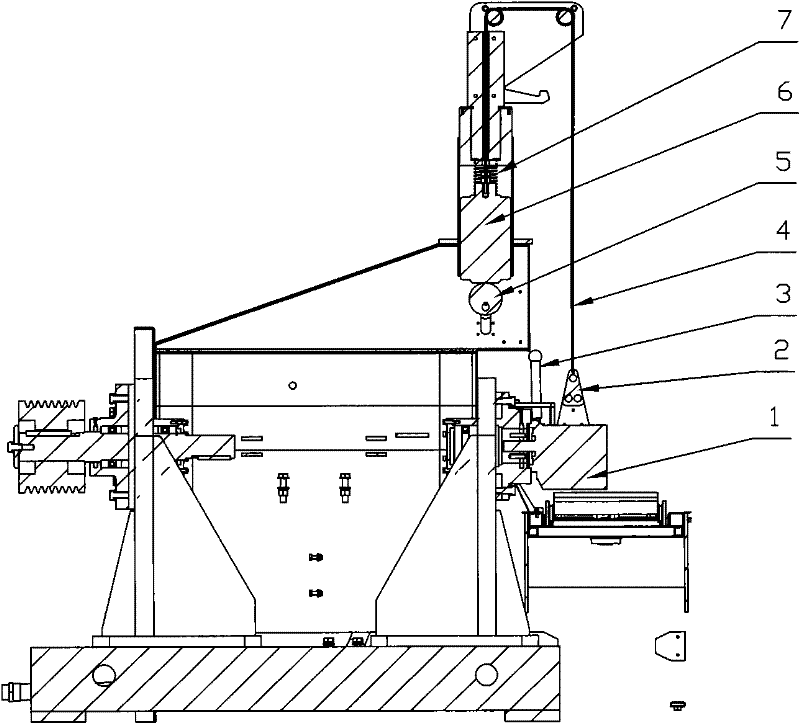

[0014] Install the alignment device and use the counterweight principle to hoist the hydraulic pump 1 through the steel wire rope 4. One end of the steel wire rope 4 is connected to the counterweight 6, and the other end is connected to the hydraulic pump 1 through the transition through the fixed pulley. The softness of the steel wire rope 4 is used. The six degrees of freedom of the hydraulic pump 1 are not restricted to achieve the purpose of convenient operation; the counterweight 6 is supported on the cam 5, and the stroke of the cam 5 is just equal to the initial position of the hydraulic pump 1 when it is placed on the station. The height difference from the location to the installation location. The cam 5 is coaxially connected with the operating handle 3, and the cam 5 is driven to rotate by rotating the handle 3, thereby lifting or lowering the counterweight 6 to realize switching of the counterweight and non-counterweight states of the hydraulic pump 1;

[0015] Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com