Bracket for use in processing of heavy spindle of large turbine generator

A hydro-generator, heavy-duty technology, used in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of the left end wooden block can not be fixed, the rotation of the main shaft is difficult to control, and the efficiency is low. The effect of clamping labor intensity, high production efficiency, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

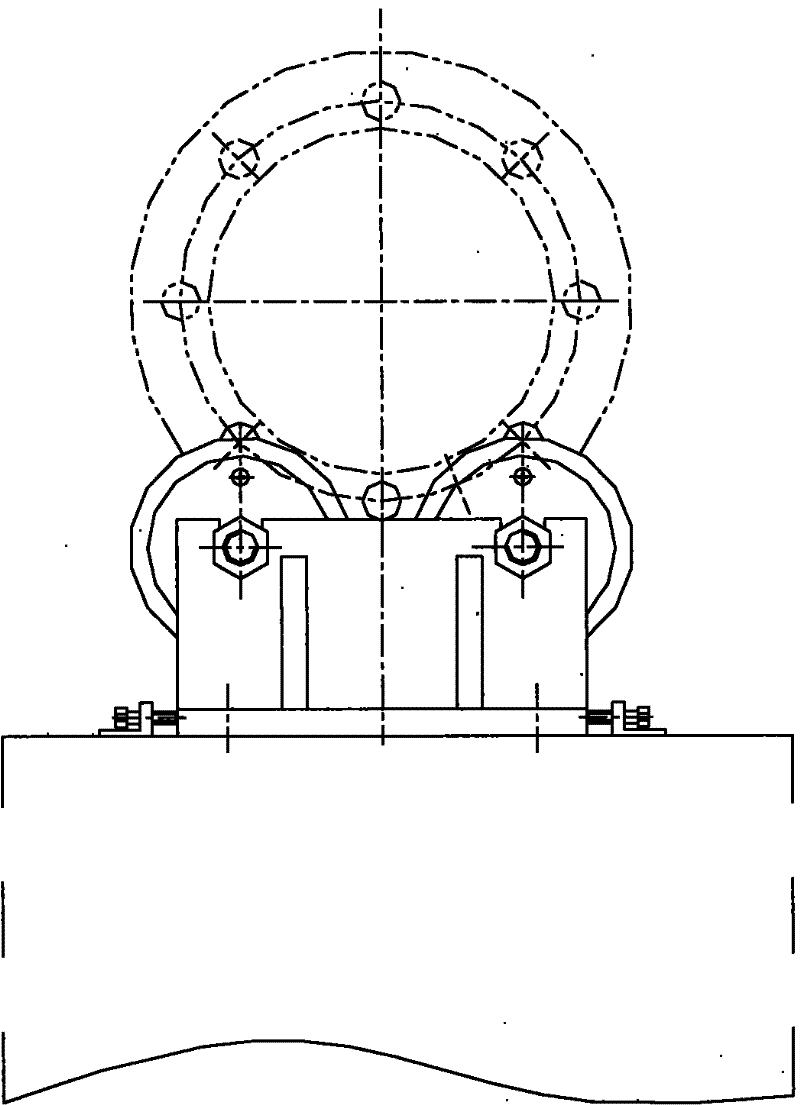

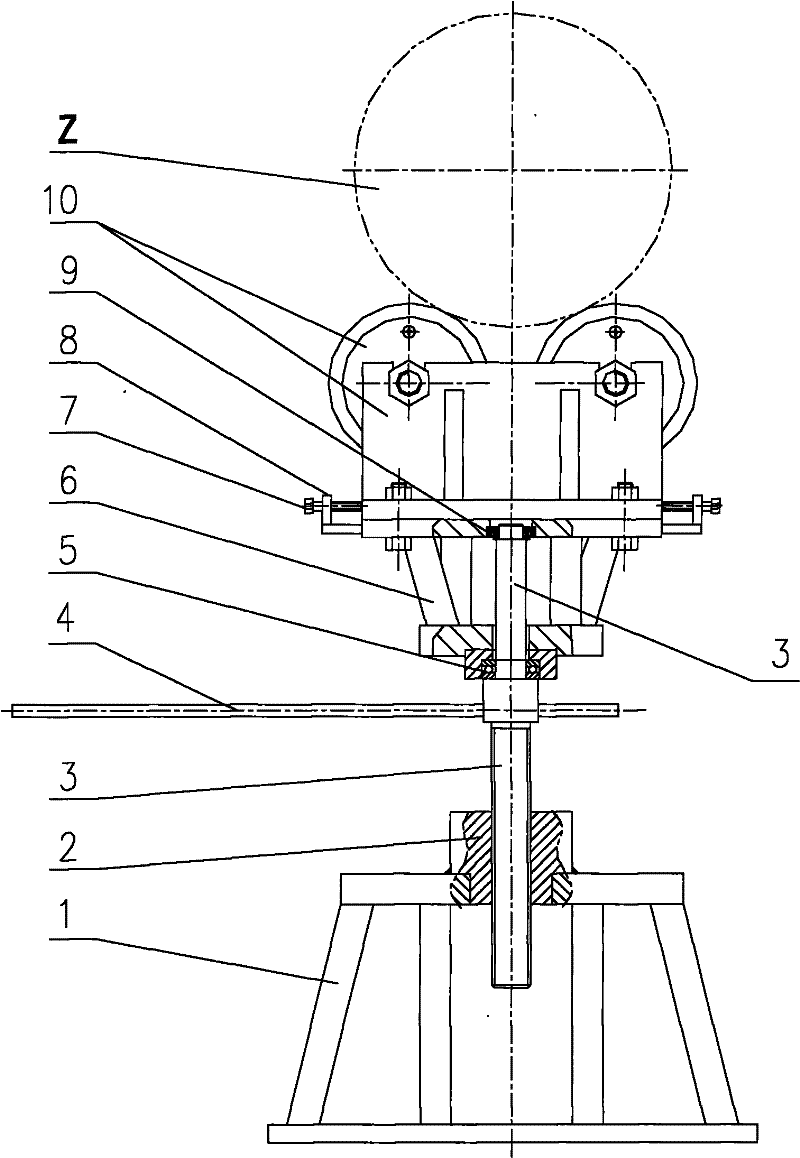

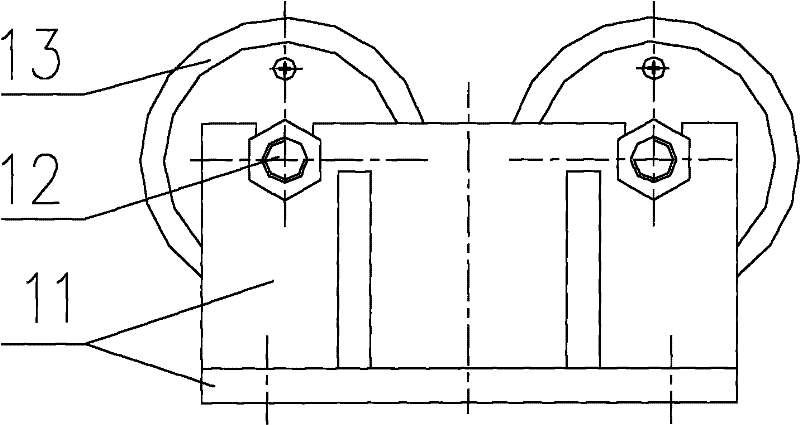

[0018] Example 1 is attached Figure 1-5 Shown: a bracket for processing the heavy-duty main shaft of a large hydroelectric generator, the screw at the bottom of the vertical shaft (3) engages with the nut (2) on the bracket base (1), and adopts an M64X6 thread that can bear a weight of 16t; horizontal The horizontal hole in the middle part of the lever (4) is slidably fitted with the vertical shaft (3). The center of the lower plate of the slewing seat (6) is equipped with a mutually matched bearing seat and an 8310 thrust ball bearing (5) with a load capacity of 164KN, and the center of the upper plate of the slewing seat (6) is equipped with a 7208E tapered roller with a load capacity of 43KN Bearing (9), thrust ball bearing (5) and tapered roller bearing (9) share same center line with vertical shaft (3). Thrust ball bearing (5) and tapered roller bearing (9) are installed on the upper end of vertical shaft (3). The upper and lower parts of the bracket are separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com