Long beam part machining deformation control method

A technology for part processing and deformation control, applied in metal processing and other directions, can solve the problems of small buffering effect of side bending deformation, the amount of deformation cannot be ignored, the number of stress relief grooves, size constraints, etc., to ensure processing quality and reduce manual intervention. point, the effect of reducing the amount of side bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

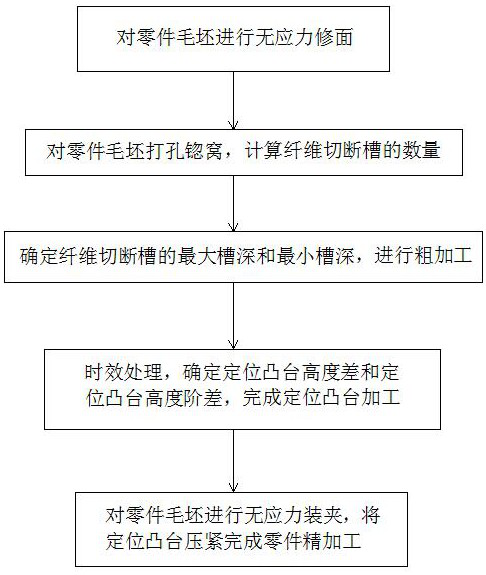

[0054] see Figure 1-Figure 5 , a processing deformation control method for long beam parts, comprising the following steps:

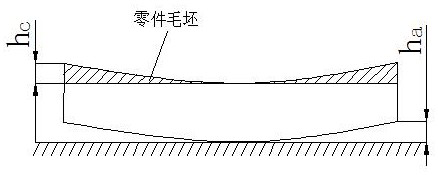

[0055] a. Place the part blank horizontally and observe the deformation of the part blank. The maximum deformation is h a , and then carry out stress-free shaving on the part blank, the amount of stress-free shaving is , so that h c ≥ h a ;

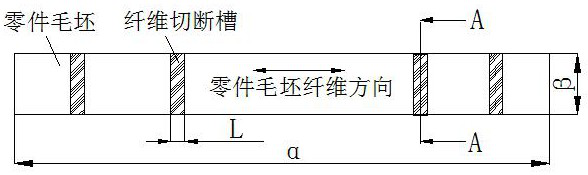

[0056] b. Punch and spot-face the blank of the part, according to the length of the blank of the part and part blank width Calculate the number n of the fiber cutting grooves, and arrange the fiber cutting grooves evenly;

[0057] c. According to the maximum groove depth allowance distribution of the part blank D 1 and the minimum groove depth margin distribution D 2 Determine the maximum groove depth h of the fiber cutting groove e and minimum groove depth h f , select a tool with a diameter of D for rough machining, and the width of the rough machining fiber cutting groove is L, so that D<L≤2D;

[...

Embodiment 2

[0062] see Figure 1-Figure 5 , a processing deformation control method for long beam parts, comprising the following steps:

[0063] a. Place the part blank horizontally and observe the deformation of the part blank. The maximum deformation is h a , and then carry out stress-free shaving on the part blank, the amount of stress-free shaving is , so that h c ≥ h a ;

[0064] b. Punch and spot-face the blank of the part, according to the length of the blank of the part and part blank width Calculate the number n of the fiber cutting grooves, and arrange the fiber cutting grooves evenly;

[0065] c. According to the maximum groove depth allowance distribution of the part blank D 1 and the minimum groove depth margin distribution D 2 Determine the maximum groove depth h of the fiber cutting groove e and minimum groove depth h f , select a tool with a diameter of D for rough machining, and the width of the rough machining fiber cutting groove is L, so that D<L≤2D;

[...

Embodiment 3

[0071] see Figure 1-Figure 5 , a processing deformation control method for long beam parts, comprising the following steps:

[0072] a. Place the part blank horizontally and observe the deformation of the part blank. The maximum deformation is h a , and then carry out stress-free shaving on the part blank, the amount of stress-free shaving is , so that h c ≥ h a ;

[0073] b. Punch and spot-face the blank of the part, according to the length of the blank of the part and part blank width Calculate the number n of the fiber cutting grooves, and arrange the fiber cutting grooves evenly;

[0074] c. According to the maximum groove depth allowance distribution of the part blank D 1 and the minimum groove depth margin distribution D 2 Determine the maximum groove depth h of the fiber cutting groove e and minimum groove depth h f , select a tool with a diameter of D for rough machining, and the width of the rough machining fiber cutting groove is L, so that D<L≤2D;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com