A rice and wheat harvester threshing drum multi-process automatic welding tool

A fully automatic welding and threshing drum technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. problems, to achieve the effect of reducing the labor intensity of clamping, easy operation, and improving welding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

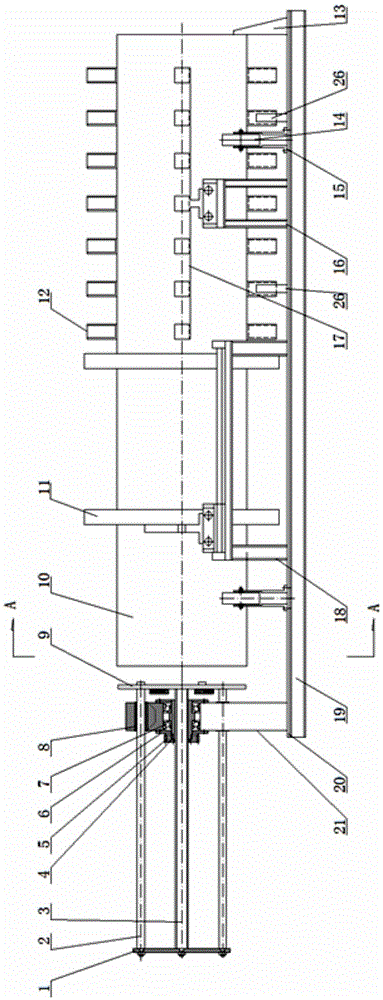

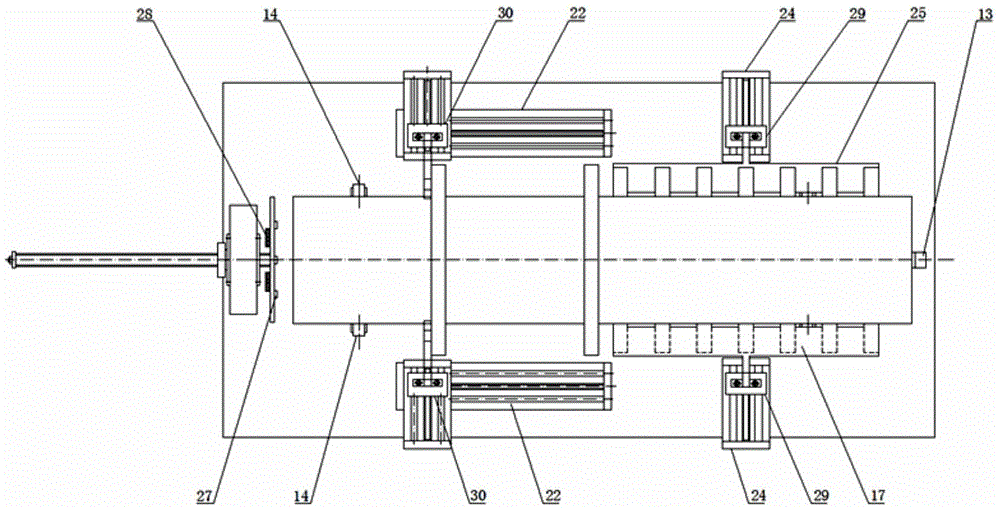

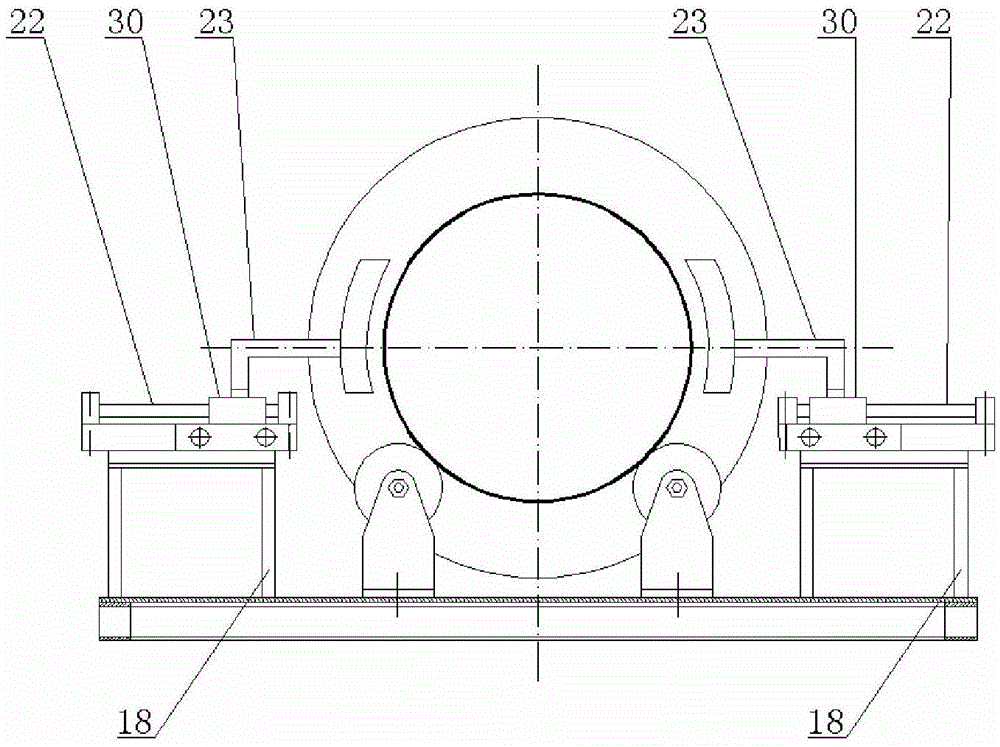

[0036] Such as figure 1 As shown, a rice and wheat harvester threshing drum multi-process automatic welding tooling includes a base system, an inner disk feeding system, a threshing drum rotation system, an outer disk positioning system and a gear seat positioning system.

[0037] The base system includes a base 19 and a bottom plate 20 . Among them, the base 19 is welded by channel steel, and the bottom plate 20 is fixed on the base 19 by bolts. The connection of this part constitutes the base system of the multi-process automatic welding tool for the threshing drum of the rice and wheat harvester, which is used for bearing and fixing the entire equipment. .

[0038] The inner disk feeding system includes a first connecting plate 1, a slide rod 2, a feed screw 3, a transmission gear 4, a large nut 5, a bearing end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com