Universal fixture for horizontal clamping of fuel injection pump body

A fuel injection pump and clamping technology, which is used in clamping, manufacturing tools, positioning devices, etc., can solve the problems of high manufacturing cost of positioning fixtures, irregular shapes, and jamming during clamping, so as to reduce manufacturing costs and be widely used. flexibility and applicability, and the effect of reducing the labor intensity of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

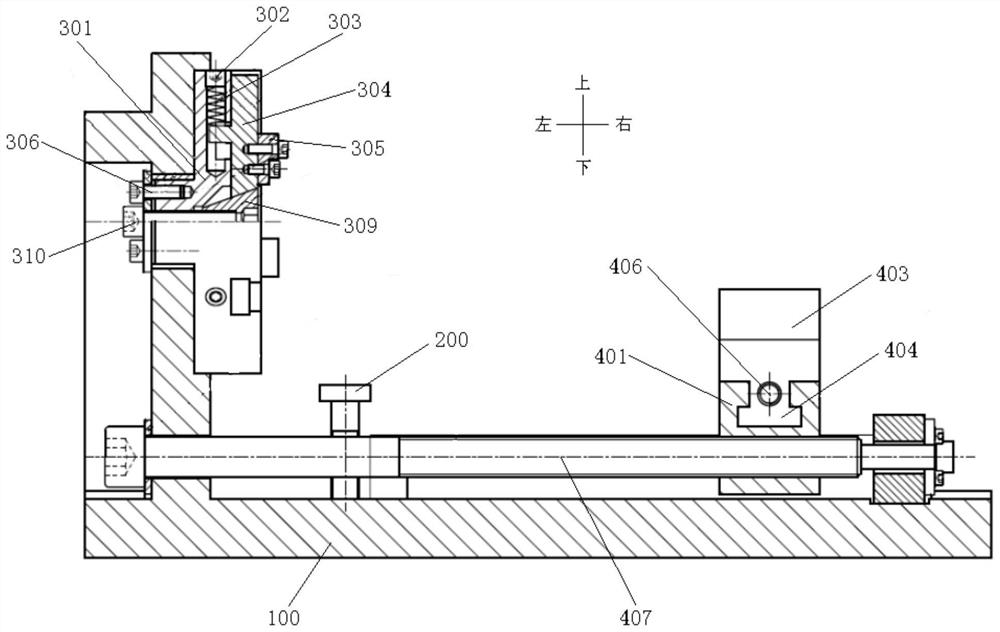

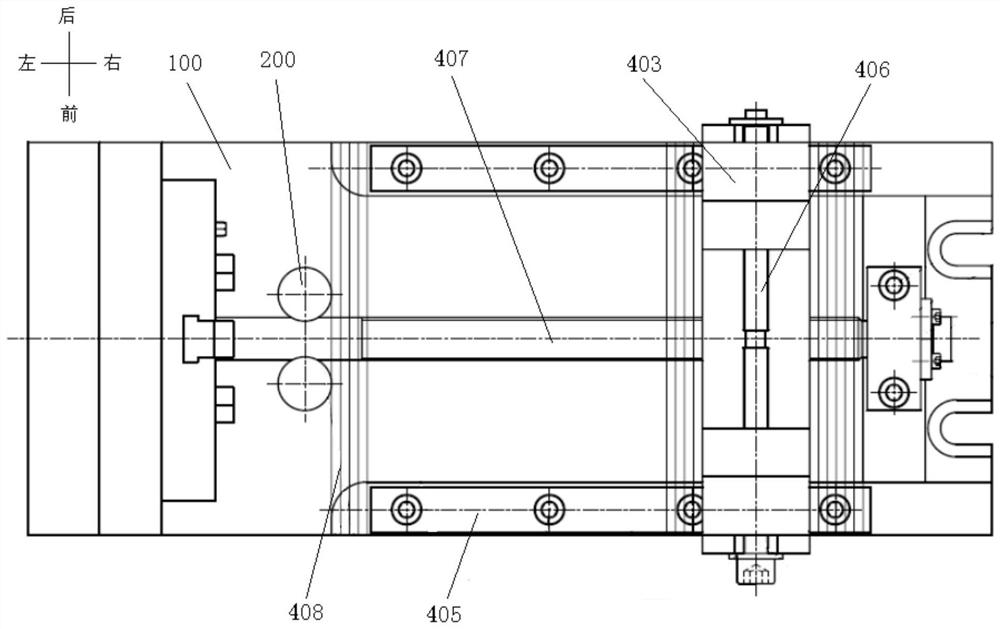

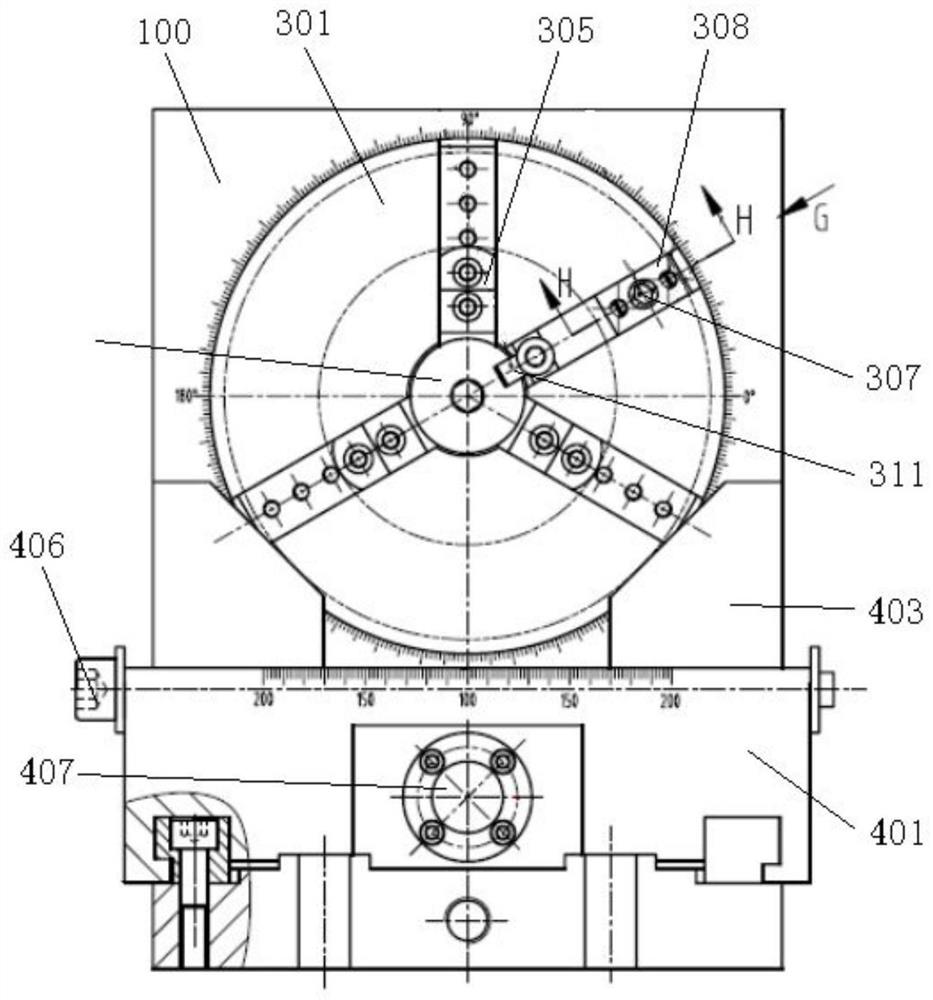

[0027] like Figure 1-Figure 10As shown, the universal fixture for horizontal clamping of the fuel injection pump body in this embodiment includes a base 100, and also includes a positioning mandrel device, an adjusting push rod 200 and a V-shaped frame fixed on the base 100 in sequence from left to right; The positioning mandrel device includes a centering chuck for positioning the center hole of the fuel injection pump body 500 and a positioning pin 307 for positioning the positioning hole of the fuel injection pump body 500, and the centering chuck includes a chuck The disc body 301, the claw drive mechanism and N movable claws, the claw drive mechanism is arranged on the chuck body 301, and the N movable claws are arranged on the chuck body 301 in a circumferential distribution , the jaw drive mechanism can drive N movable jaws to move synchronously in the radial direction; the chuck body 301 is arranged on the base 100, and the positioning pin 307 can adjust the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com