A method for detecting the stiffness of automatic laying prepreg

A technology of automatic wire laying and detection method, applied in non-electric variable control, simultaneous control of multiple variables, instruments, etc., can solve the problems of detecting the performance of prepreg tow, cannot be directly applied, and increase the test cost, and achieve detection Fast, intuitive results and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example discloses an automatic paving prepreg constant detection method, and specifically includes the following steps:

[0040] S1, from the cold storage of 1000 mm long prepreg wire, place the prepreg wire in the constant temperature and humidity test chamber;

[0041] S2, after 60min, the prepreg silk beam is removed from the constant temperature and humidity test chamber, and the three-piece length of the three-piece length is 60 mm, and the excess material is re-placed back to the test chamber;

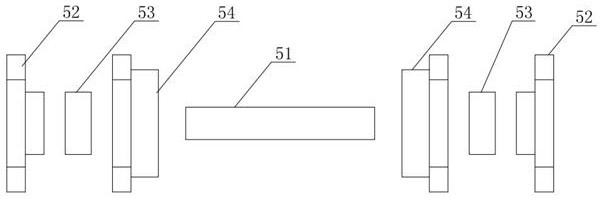

[0042] S3, remove the two prepreg yovings on the automatic paving test platform, adjust the position of the two slice buttons to completely cover the prepreg tow;

[0043] S4, the placing pressure of the test platform is 100 N, the release speed is 10 m / min, the release temperature is 35 ° C, the automatic paving test platform is activated, and two prepreg wire is bonded;

[0044] S5, placed on the prepreg stack formed in step S4, which also ensures that the wire beam i...

Embodiment 2

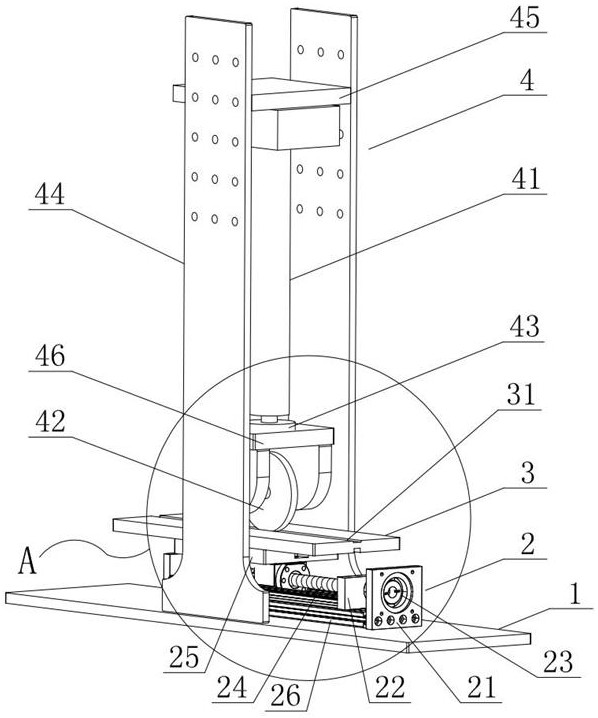

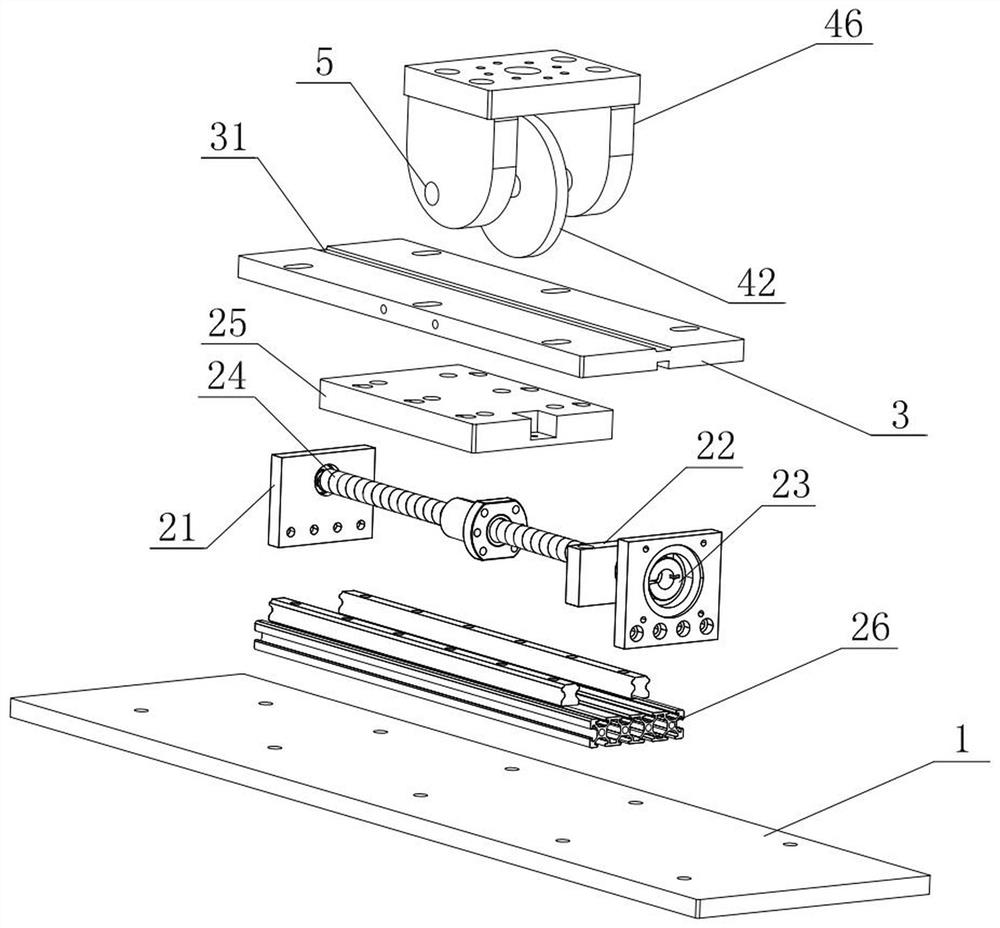

[0050] This example discloses an automatic paving test platform for realizing the paving fitting of the prepreg tow, referring to the accompanying drawings Figure 1 - Figure 3 The automatic paving test platform mainly includes a base 1, an SR80 double-wire rail ribbar slide 2, a laying platform 3, a placing pressure control unit 4, a laying temperature control unit, and a PLC controller; further, The two-wire rail roller slide 2 includes a lead screw support plate 21, a motor support plate 22, a servo motor 23, a ball screw 24, a working platform 25, and a wire rail 26, a lead screw support plate 21, a motor support plate 22, and a motor support plate 22. The line rail 26 is disposed on the base 1, and the finite-up switch is provided on both ends of the wire rail 26, which is the first limit switch and the second limit switch, and the two limit switches are connected to the PLC controller, the limit switch. The entire working platform and the spreading platform are separated from...

Embodiment 3

[0055] This example discloses a control method of an automatic paving test platform, and the entire control process includes a paving pressure closed loop control, a laying temperature closed loop control, and a lapse speed closed loop control. When the automatic paving test platform is activated, people The machine interface first transmits the electric cylinder 41 and the two-wire rail ribs slide 2 zero command to the PLC controller, and the PLC controller sends the zero command to the electric cylinder driver and the servo motor driver, each driver receives the zero command. And perform a zero operation, the entire process determines whether the electric cylinder 41 and the two-wire pulling bead bar slide 2 are returned by the corresponding limit switch.

[0056] In the present embodiment, the placing pressure control and the temperature control are simultaneously performed simultaneously, specific:

[0057] Paving pressure closed loop control:

[0058] The user first sets the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com