Support pile tensioning device

A technology of tensioning devices and supporting piles, applied in the direction of strengthening and forming, can solve the problems of poor reliability, many parts, and the overall structure of the tensioning device is not compact enough, so as to avoid interference, the overall structure is compact and reasonable, and the operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

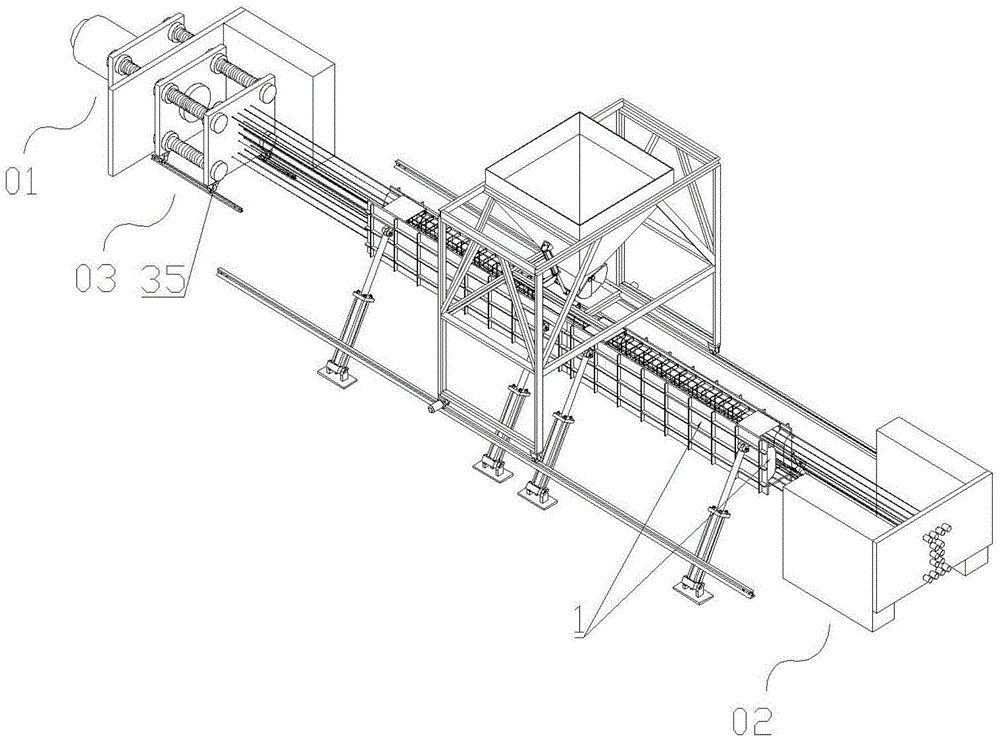

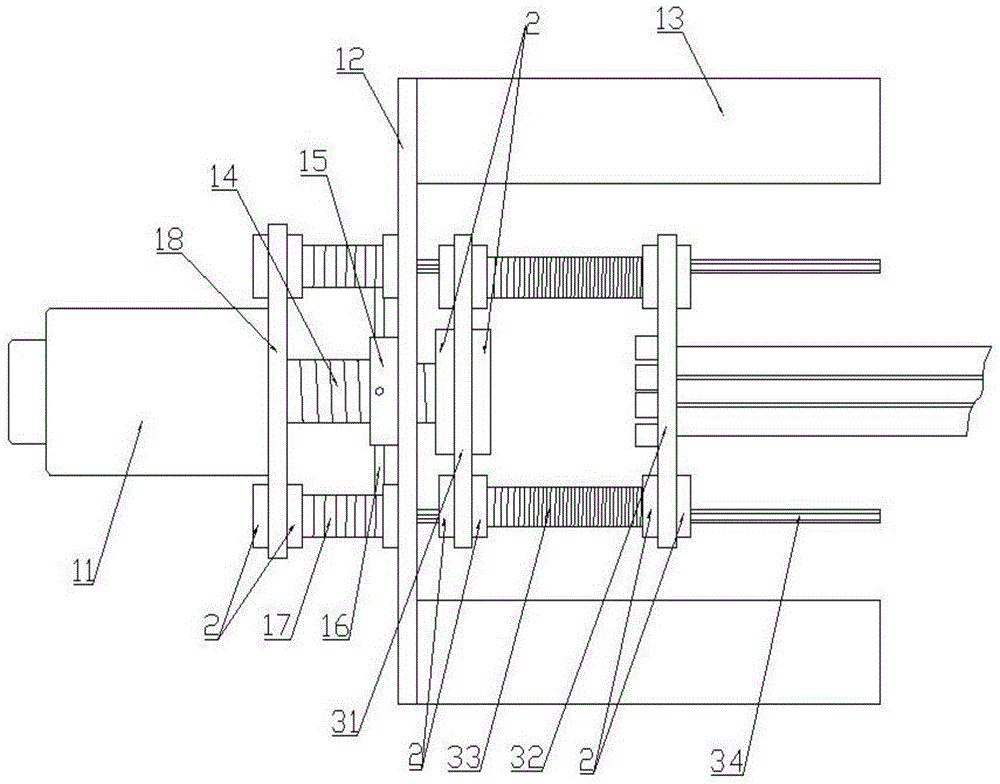

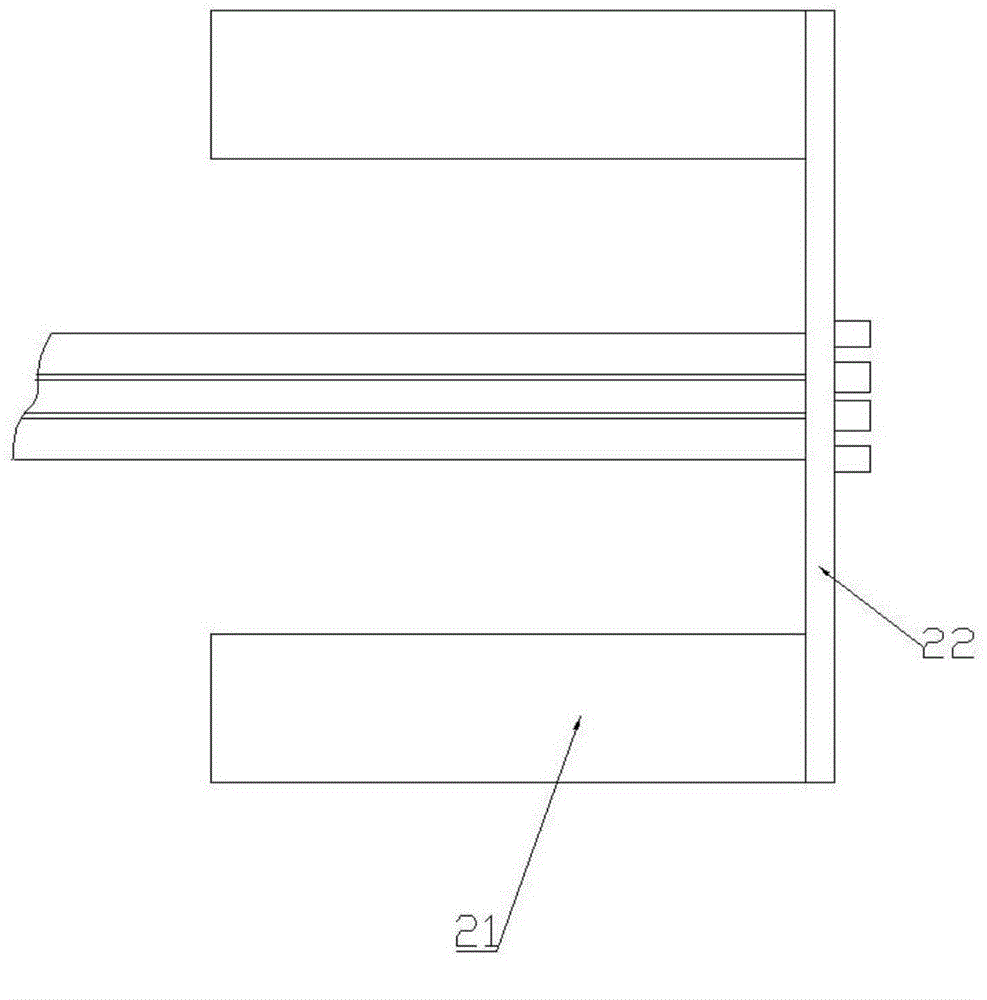

[0020] As shown in the figure, a supporting pile tensioning device includes a tensioning drive mechanism 01 and a locking mechanism 02 for locking the prestressed tendons at the rear end of the pile formwork 1. In this embodiment: the prestressed tendons Adopt prestressed steel bar, certainly also can adopt other types of prestressed tendon, as prestressed steel strand etc.; It is used for tensioning other irregular solid support piles, such as U-shaped support piles, V-shaped support piles and other irregular solid support piles.

[0021] The support pile tensioning device also includes a pre-tensioning mechanism 03 for pre-tensioning the front end of the pile formwork 1, and the pre-tensioning mechanism 03 includes a connecting plate 31, a front anchoring plate 32, a connecting front anchoring plate 32 and a connecting plate 31 a plurality of connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com