Cable for ocean platform and production process thereof

An offshore platform and cable technology, which is used in insulated cables, cable/conductor manufacturing, and conductor/cable insulation, etc., can solve problems such as cable damage, intrusion into cables, and easy to be ignored.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

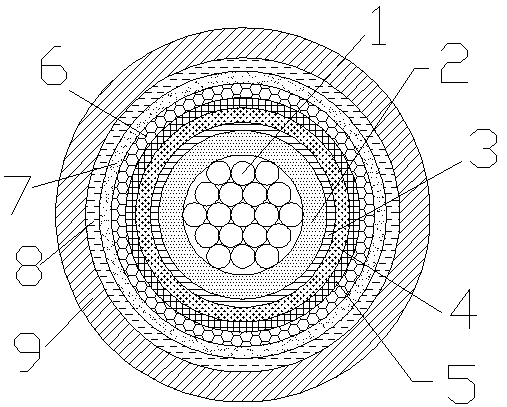

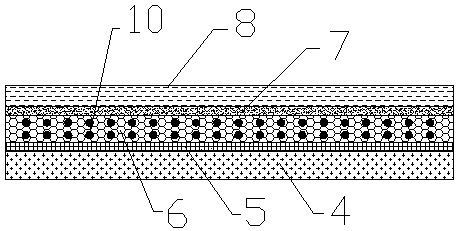

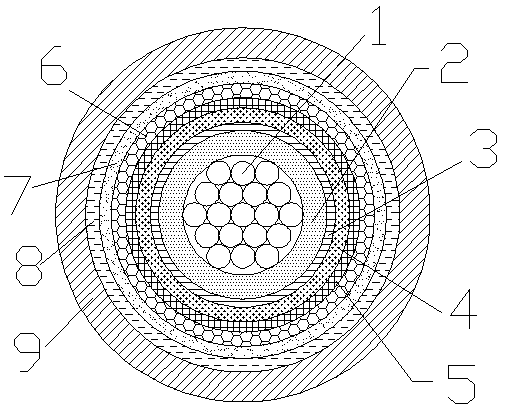

[0030] figure 1 and figure 2 Among them, a cable for offshore platforms, in the figure 1. copper single wire, 2. polytetrafluoroethylene layer, 3. polypropylene film layer, 4. water-blocking yarn, 5. water-soluble film layer, 6. dyed layer, 7. High-density polyethylene film layer, 8. Ceramic fiber layer, 9. Polyurethane outer sheath layer, 10. Dyed slow-release particles. The structure of the cable is: the innermost layer is a conductor, the conductor is twisted by several copper single wires, the conductor is provided with a polytetrafluoroethylene layer, and the polytetrafluoroethylene layer is provided with a polypropylene film layer, so The polypropylene film layer is provided with a water-blocking yarn layer, the water-blocking layer yarn is provided with a water-soluble film layer, the water-soluble film layer is provided with a dyed layer, and the dyed layer is provided with a high-density polyethylene film layer , the high-density polyethylene film layer is provided...

example 2

[0046] figure 1 and figure 2 A cable for offshore platforms, in the figure 1. copper single wire, 2. polytetrafluoroethylene layer, 3. polypropylene film layer, 4. water-blocking yarn, 5. water-soluble film layer, 6. dyed layer, 7. high density Polyethylene film layer, 8. Ceramic fiber layer, 9. Polyurethane outer sheath layer, 10. Dyed slow-release particles. The structure of the cable is: the innermost layer is a conductor, the conductor is twisted by several copper single wires, the conductor is provided with a polytetrafluoroethylene layer, and the polytetrafluoroethylene layer is provided with a polypropylene film layer, so The polypropylene film layer is provided with a water-blocking yarn layer, the water-blocking layer yarn is provided with a water-soluble film layer, the water-soluble film layer is provided with a dyed layer, and the dyed layer is provided with a high-density polyethylene film layer , the high-density polyethylene film layer is provided with a cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com