Anti-cracking type high-flame-retardance low-smoke halogen-free material for optical cable as well as preparation method and application thereof

An anti-cracking, high flame retardant technology, applied in the field of cables, can solve the problems of low flame retardant effect, large content of flame retardants, and the mechanical properties of the sheath cannot meet the laying conditions of optical cables, so as to improve mechanical properties and flame retardant. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

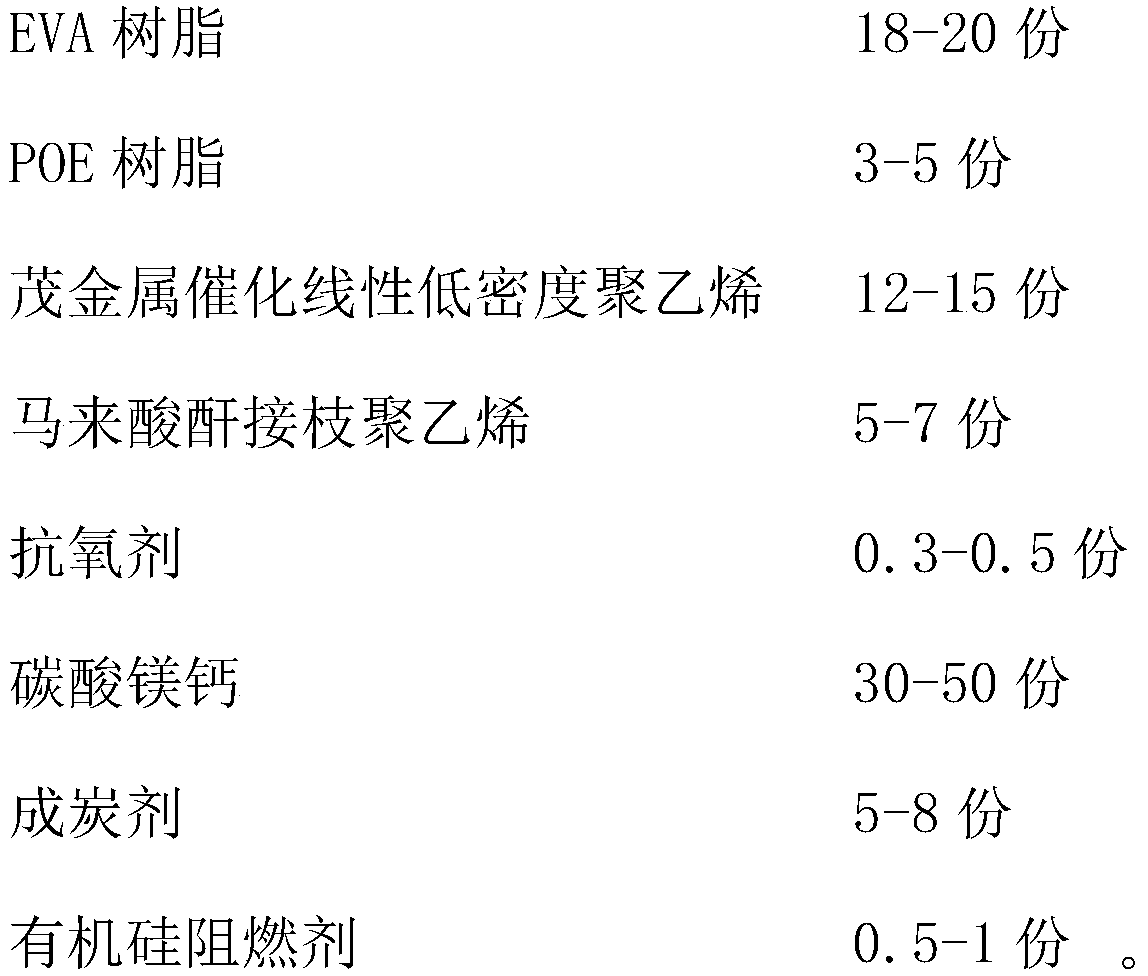

[0021] A crack-resistant high flame-retardant low-smoke and halogen-free material for optical cables in this embodiment includes the following components in parts by weight:

[0022]

[0023] Wherein, the VA content of EVA resin is 15%.

[0024] The carbon forming agent is a nanoscale powder.

[0025] The mesh number of calcium magnesium carbonate is 2500 mesh, and calcium magnesium carbonate is surface pretreated calcium magnesium carbonate.

[0026] A method for preparing an anti-cracking type high flame-retardant low-smoke and halogen-free material for an optical cable, comprising the following steps:

[0027] S1: Add EVA resin, POE resin, metallocene-catalyzed linear low-density polyethylene, maleic anhydride grafted polyethylene, antioxidant, calcium magnesium carbonate, char-forming agent, silicone flame retardant to a high-mixer for mixing and plasticizing ;

[0028] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion pr...

Embodiment 2

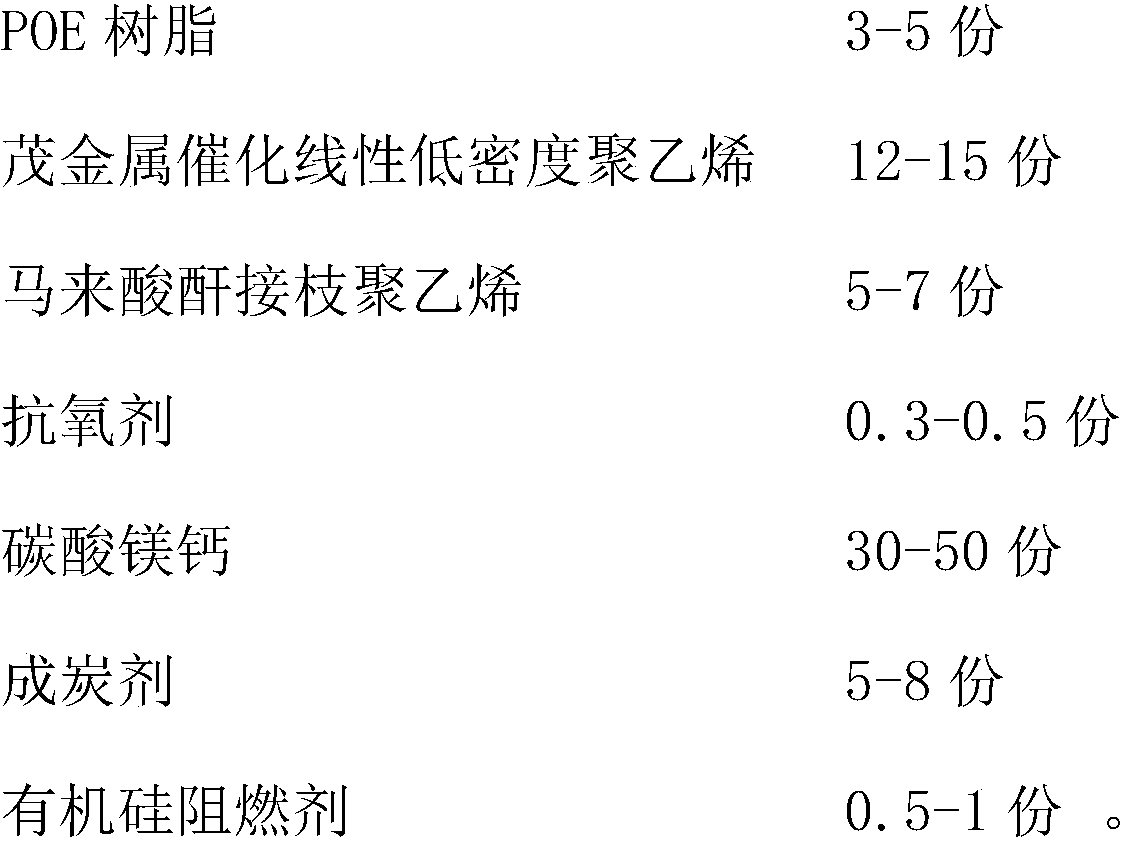

[0031] A crack-resistant high flame-retardant low-smoke and halogen-free material for optical cables in this embodiment includes the following components in parts by weight:

[0032]

[0033] Wherein, the VA content of EVA resin is 18%.

[0034] The carbon forming agent is a nanoscale powder.

[0035] The mesh number of calcium magnesium carbonate is 2600 mesh, and calcium magnesium carbonate is surface pretreated calcium magnesium carbonate.

[0036] A method for preparing an anti-cracking type high flame-retardant low-smoke and halogen-free material for an optical cable, comprising the following steps:

[0037] S1: Add EVA resin, POE resin, metallocene-catalyzed linear low-density polyethylene, maleic anhydride grafted polyethylene, antioxidant, calcium magnesium carbonate, char-forming agent, silicone flame retardant to a high-mixer for mixing and plasticizing ;

[0038] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion pr...

Embodiment 3

[0041] A crack-resistant high flame-retardant low-smoke and halogen-free material for optical cables in this embodiment includes the following components in parts by weight:

[0042]

[0043] Wherein, the VA content of EVA resin is 20%.

[0044] The carbon forming agent is a nanoscale powder.

[0045] The mesh number of calcium magnesium carbonate is 2700 mesh, and calcium magnesium carbonate is surface pretreated calcium magnesium carbonate.

[0046] A method for preparing an anti-cracking type high flame-retardant low-smoke and halogen-free material for an optical cable, comprising the following steps:

[0047] S1: Add EVA resin, POE resin, metallocene-catalyzed linear low-density polyethylene, maleic anhydride grafted polyethylene, antioxidant, calcium magnesium carbonate, char-forming agent, silicone flame retardant to a high-mixer for mixing and plasticizing ;

[0048] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com