Micro-stroke, double-redundancy torsion-preventive LVDT displacement sensor

A displacement sensor and anti-rotation technology, which is applied in the field of displacement sensors, can solve the problems of narrow installation space, strong vibration and strong shock resistance, and short travel of displacement sensors, so as to improve the ability of pressure resistance, strong vibration and strong shock resistance, and improve Effects of airtightness and pressure resistance, improvement of electrical connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

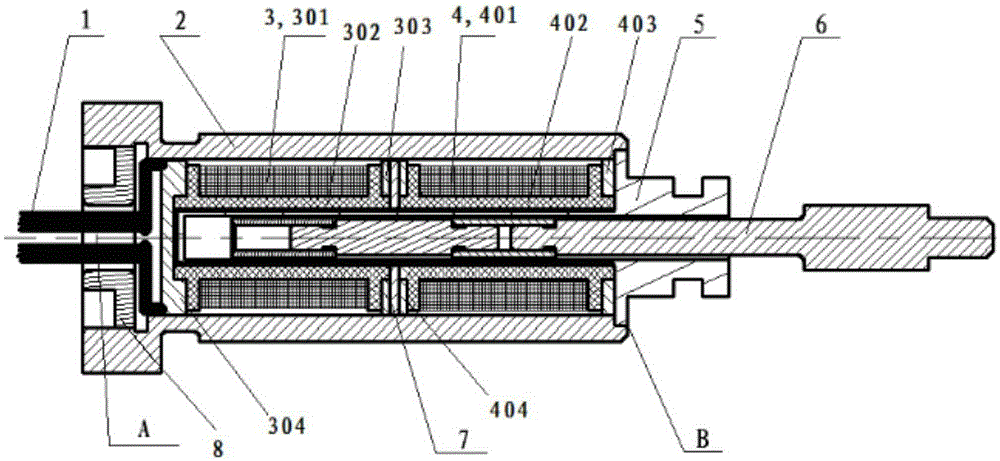

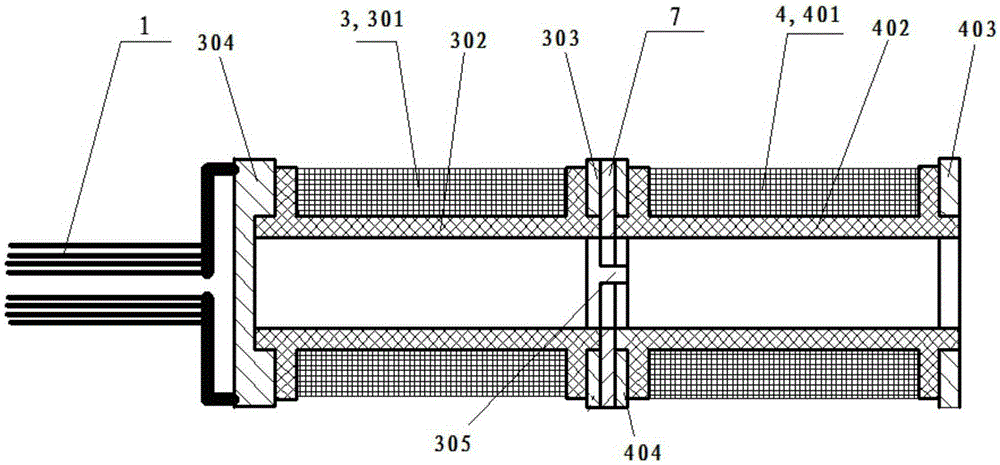

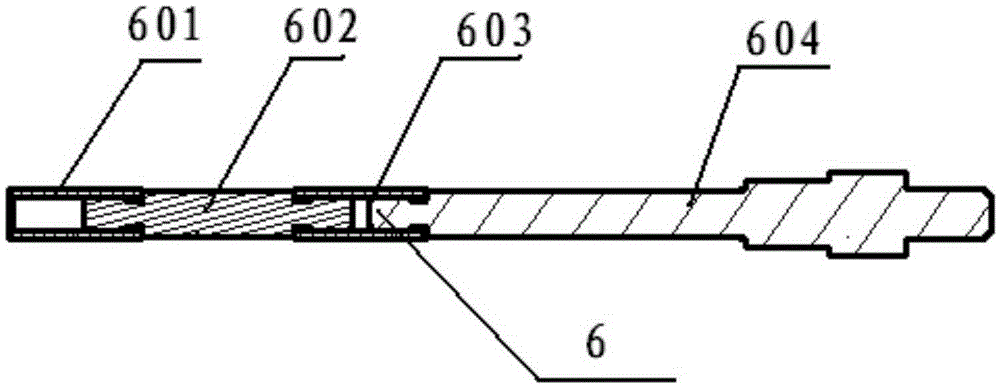

[0028] Such as figure 1 As shown, a small stroke double redundant anti-rotation LVDT displacement sensor provided by the present invention includes a first coil assembly 3, a second coil assembly 4, a magnetic isolation spacer 7, an iron core assembly 6, and a sleeve 5 , Shell 2, lead wire 1 and end cap 8.

[0029] The first coil assembly 3, the second coil assembly 4 and the magnetic isolation spacer 7 are installed in the cylindrical shell 2, and one end of the iron core assembly 6 is sleeved inside the first coil assembly 3 and the second coil assembly 4, and the iron core assembly The other end of 6 is suspended outside the housing 2, one end of the sleeve 5 is sleeved between the iron core assembly 6, the first coil assembly 3, the second coil assembly 4, and the magnetic isolation spacer 7, and the other end of the sleeve 5 Suspended o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com