Patents

Literature

54 results about "Calcium magnesium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dolomite (/ ˈ d ɒ l ə m aɪ t /) is an anhydrous carbonate mineral composed of calcium magnesium carbonate, ideally CaMg(CO 3) 2. The term is also used for a sedimentary carbonate rock composed mostly of the mineral dolomite.

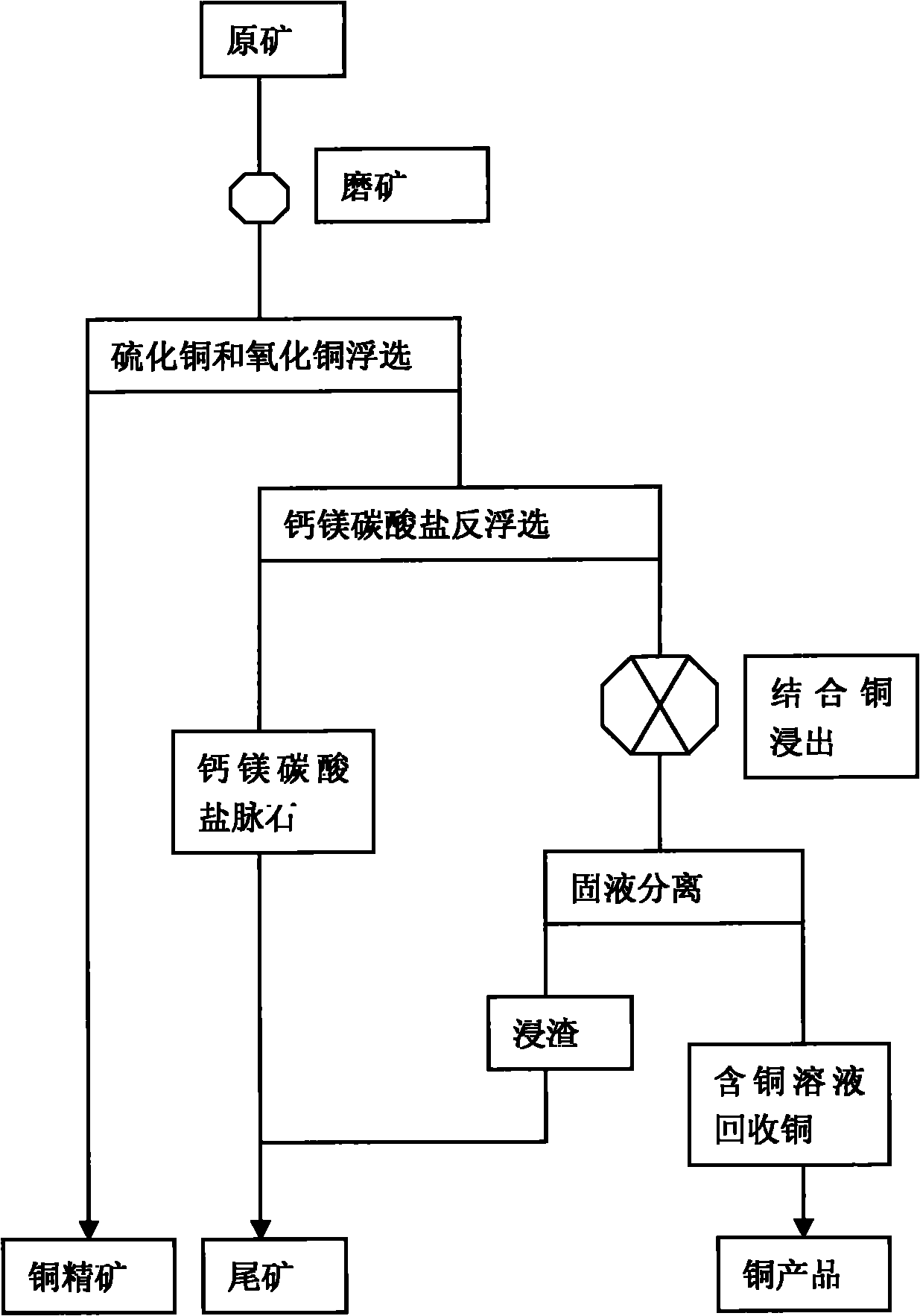

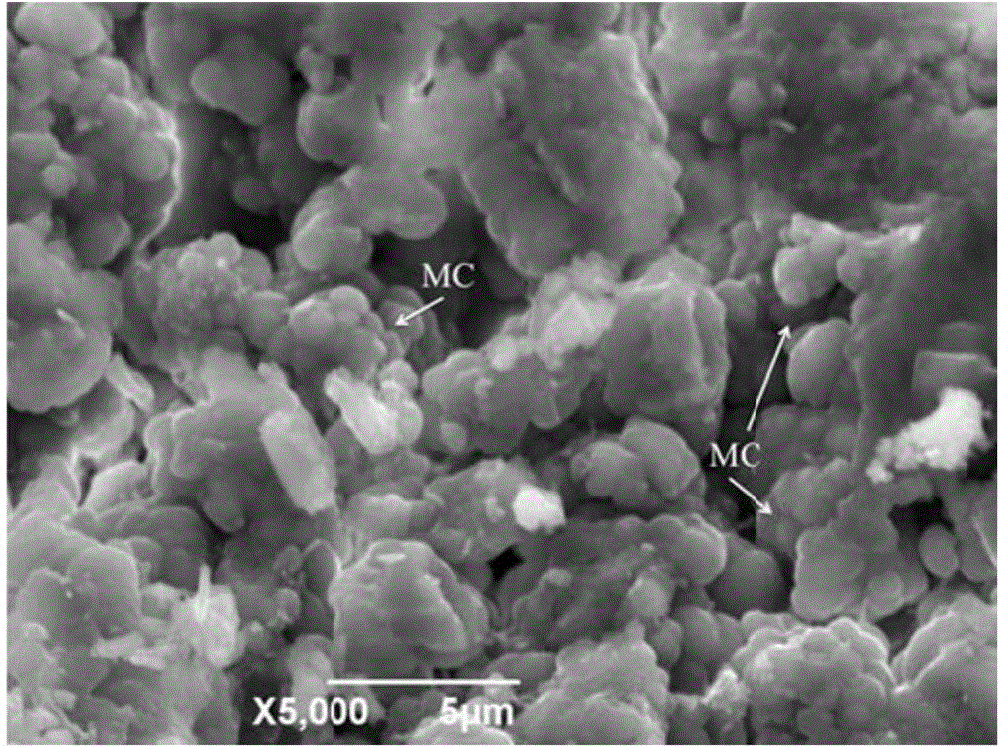

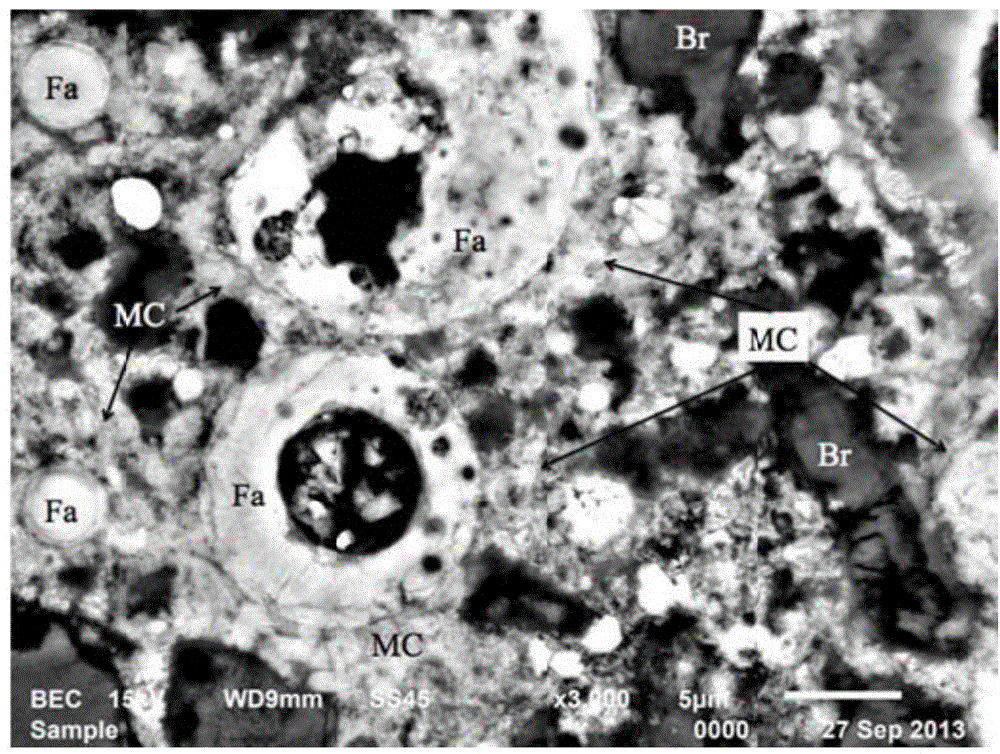

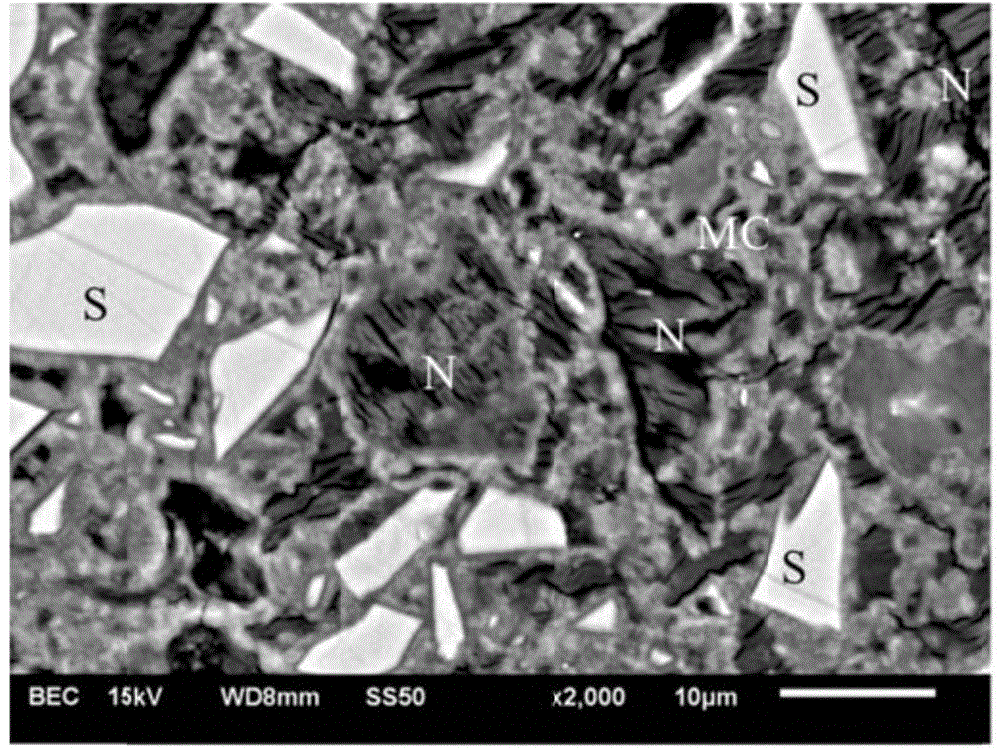

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

Calcium-magnesium carbonate gel material and preparation method thereof

ActiveCN104478256APromote energy saving and emission reductionLow costBreaking strengthCarbonization

The invention discloses a calcium-magnesium carbonate gel material and a preparation method thereof. The gel material is prepared from the following components in percentage by mass: not smaller than 60% and not greater than 100% of industrial alkaline wastes, not smaller than 0 and not greater than 20% of cement and not smaller than 0 and not greater than 20% of active magnesium oxide through CO2 carbonization. According to the calcium-magnesium carbonate gel material and the preparation method thereof disclosed by the invention, a great deal of solid wastes is utilized, so that the calcium-magnesium carbonate gel material is environmentally friendly, low in cost, excellent in breaking strength and compressive strength; and the greenhouse gas CO2 is recycled to promote the energy conservation and emission reduction in the building material industry.

Owner:苏州博纽强新材料科技有限公司

Low titianium dioxide coatings

Owner:AKZO NOBEL COATINGS INT BV

Simultaneous phosphorus and nitrogen removal light material, preparation method and application thereof

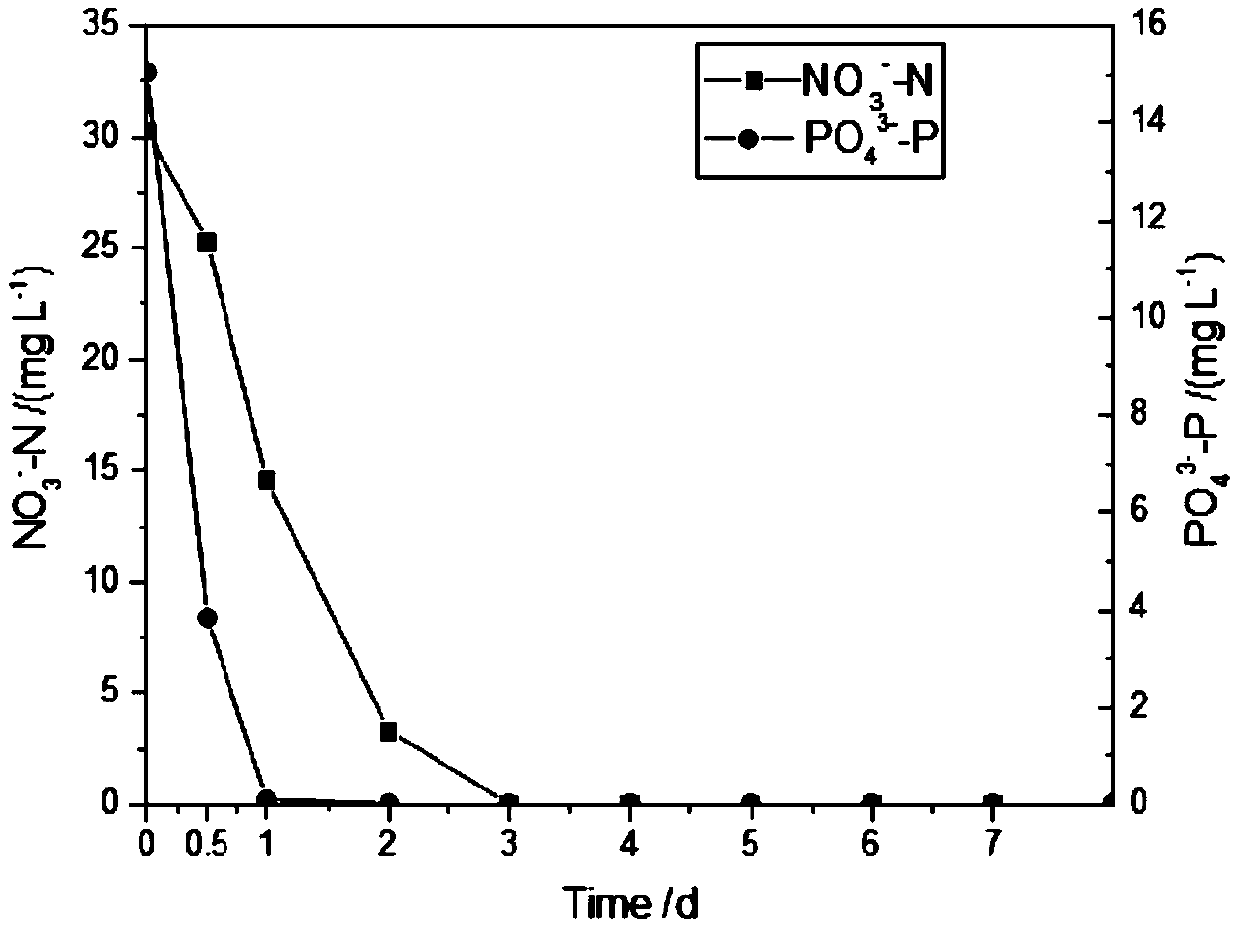

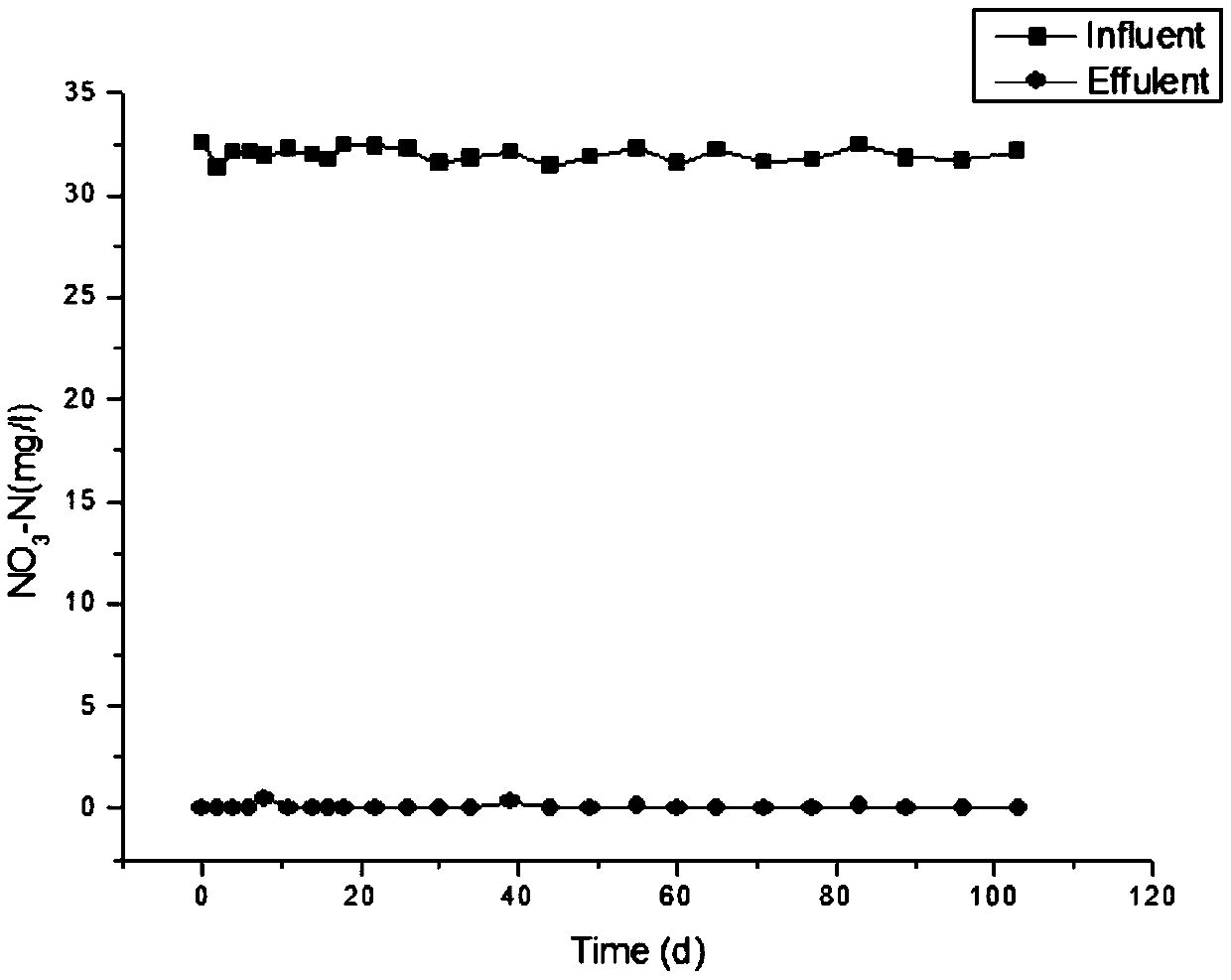

PendingCN110078221ALarge specific surface areaQuality improvementWater treatment parameter controlGas treatmentPorosityElectron donor

The invention discloses a simultaneous phosphorus and nitrogen removal light material, a preparation method and the application thereof, and belongs to the technical field of environment function materials and sewage disposal. A fusion mixture is obtained by sufficiently fusing and dispersing sulfur and an iron-based component, wherein the iron-based component is a pyrite and calcium magnesium carbonate mixture; and foaming treatment is carried out on the fusion mixture to form the simultaneous phosphorus and nitrogen removal light material. The simultaneous phosphorus and nitrogen removal light material disclosed by the invention has the characteristics of high porosity, large specific surface area, light weight and high reaction activity. The obtained light material, as a microbial carrier and an electron donor of biochemical reactions, is applied to the reactors, such as fixed beds and fluidized beds, for sewage disposal, and has the advantages of good microorganism adhesion property, high denitrification speed and good phosphorous removal effect.

Owner:NANJING UNIV +1

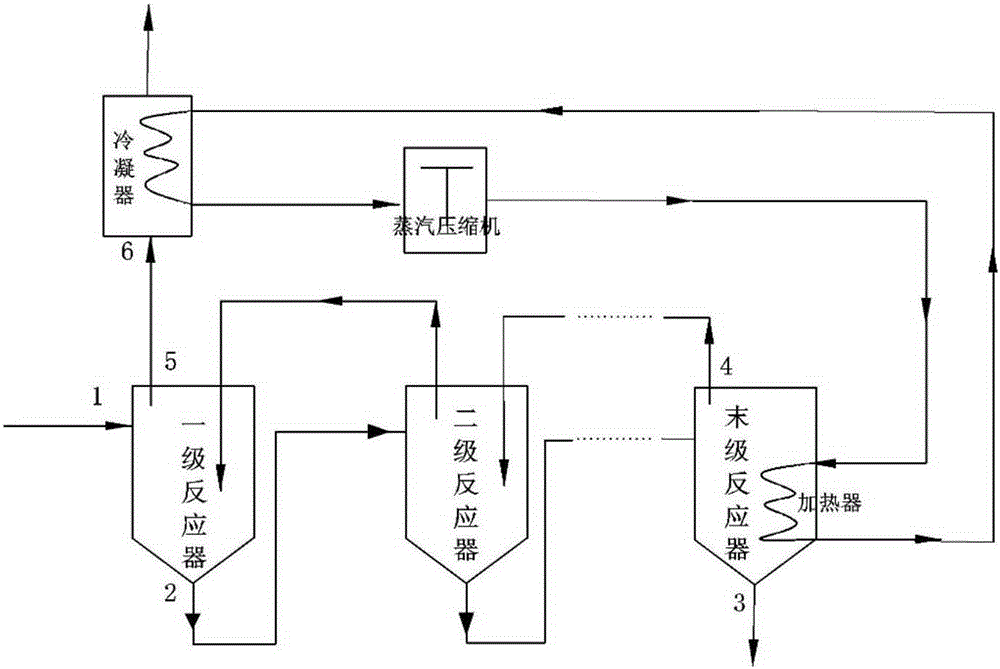

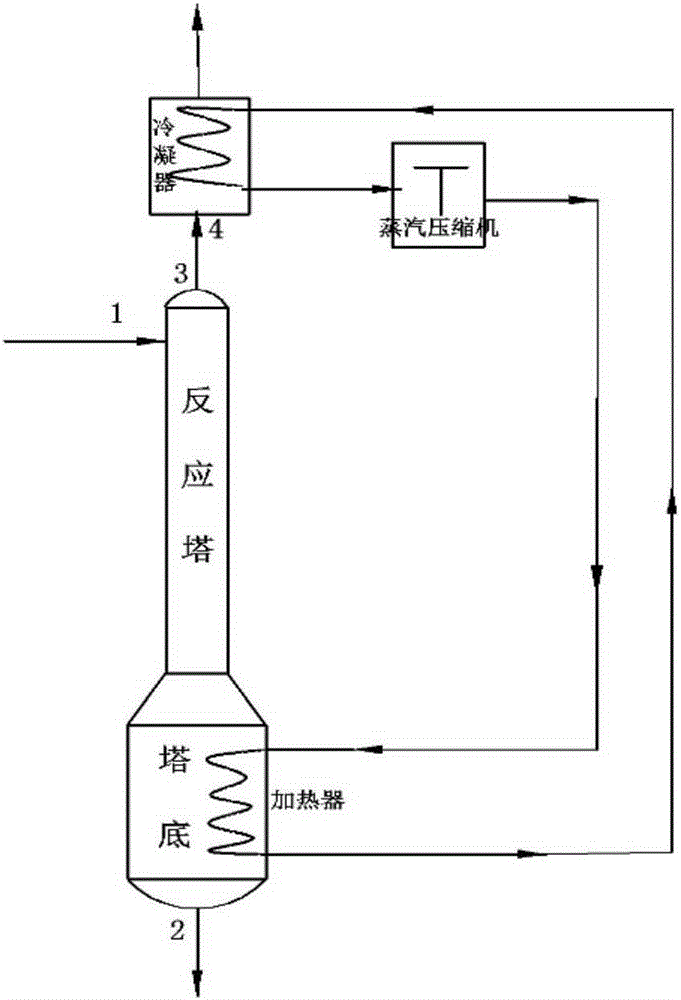

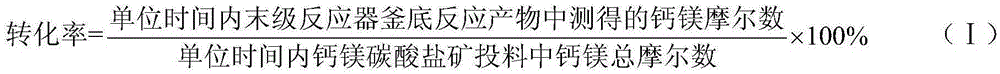

Calcium magnesium carbonate salt mine decomposition method

ActiveCN105347703AAchieve decompositionDecomposition is efficient and stableLime productionEvaporationAmmonium uranyl carbonate

The invention provides a calcium magnesium carbonate salt mine decomposition method which comprises the following steps: an ammonium salt solution is adopted to decompose calcium magnesium carbonate salt mine, the decomposition reaction is conducted in a series-connected multistage reactor or a tower-type reactor, heat carried by mixed gas generated by decomposition reaction of the ammonium salt solution and the calcium magnesium carbonate salt mine through heating are used as heat sources for recycling. According to the provided calcium magnesium carbonate salt mine decomposition method, through the introduction of the multistage countercurrent series-connected reaction kettle or the tower-type reactor, not only are the problems that a single-stage reaction kettle is large in water evaporation amount, the energy consumption is wasted, and ammonium carbonate is relatively low in concentration and unstable solved, but also the efficient and stable reaction of decomposition of the calcium magnesium carbonate salt mine by ammonium salt is realized, the energy consumption cost is reduced, and the method is energy-saving and economical.

Owner:LONGYAN ZIYUN CHEM TECH

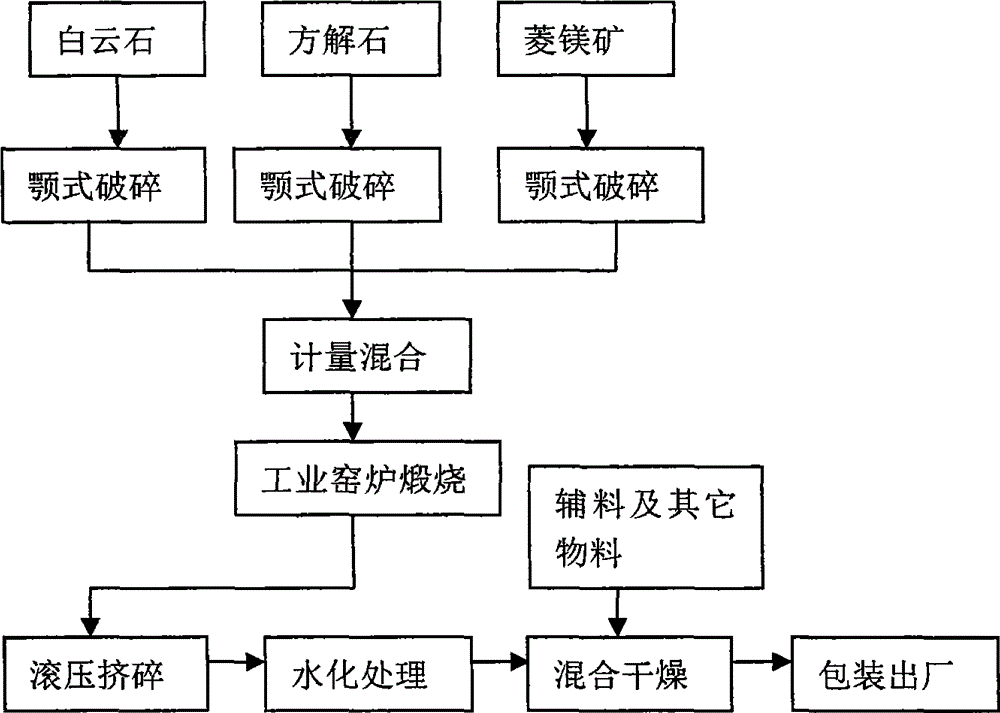

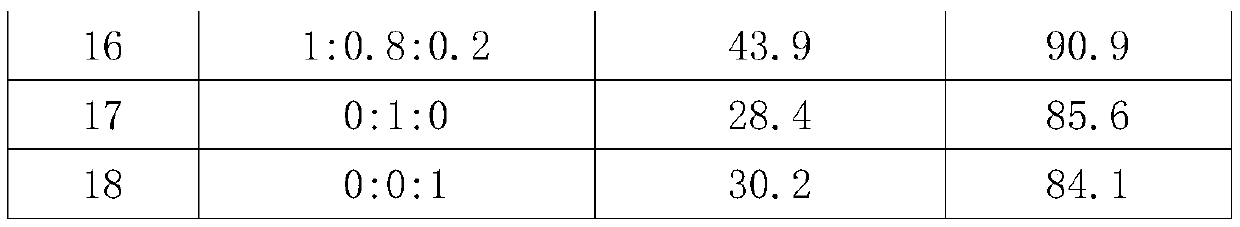

Acid soil conditioner and preparation method thereof

InactiveCN105295930ANeutral and strongHigh activityOrganic fertilisersSoil conditioning compositionsDecompositionCalcite

The invention relates to an acid soil conditioner and a preparation method thereof. The preparation method comprises the following steps: taking dolomite as the main raw material, calcite or magnesite as an auxiliary material to adjust the product calcium and magnesium proportions, then mixing the main raw material and the auxiliary material at proportion, and calcining in an industrial kiln; taking the upper limit of the raw material decomposition temperature interval as the boundary of the calcining temperature, wherein the duration generally does not exceed 40 min; immediately performing material surface hydration treatment after the obtained product is discharged out of the kiln so as to obtain a porous loose compound alkali material which includes the main ingredients of calcium and magnesium oxides and hydroxides and contains a small quantity of calcium magnesium carbonate and carbon dioxide gas. The acid soil conditioner is used for improving acid soil and repairing heavy-metal-polluted soil, and can also serve as an intermediate raw material for producing a functional compound fertilizer.

Owner:山西云大中天环境科技有限公司 +1

Low titianium dioxide coatings

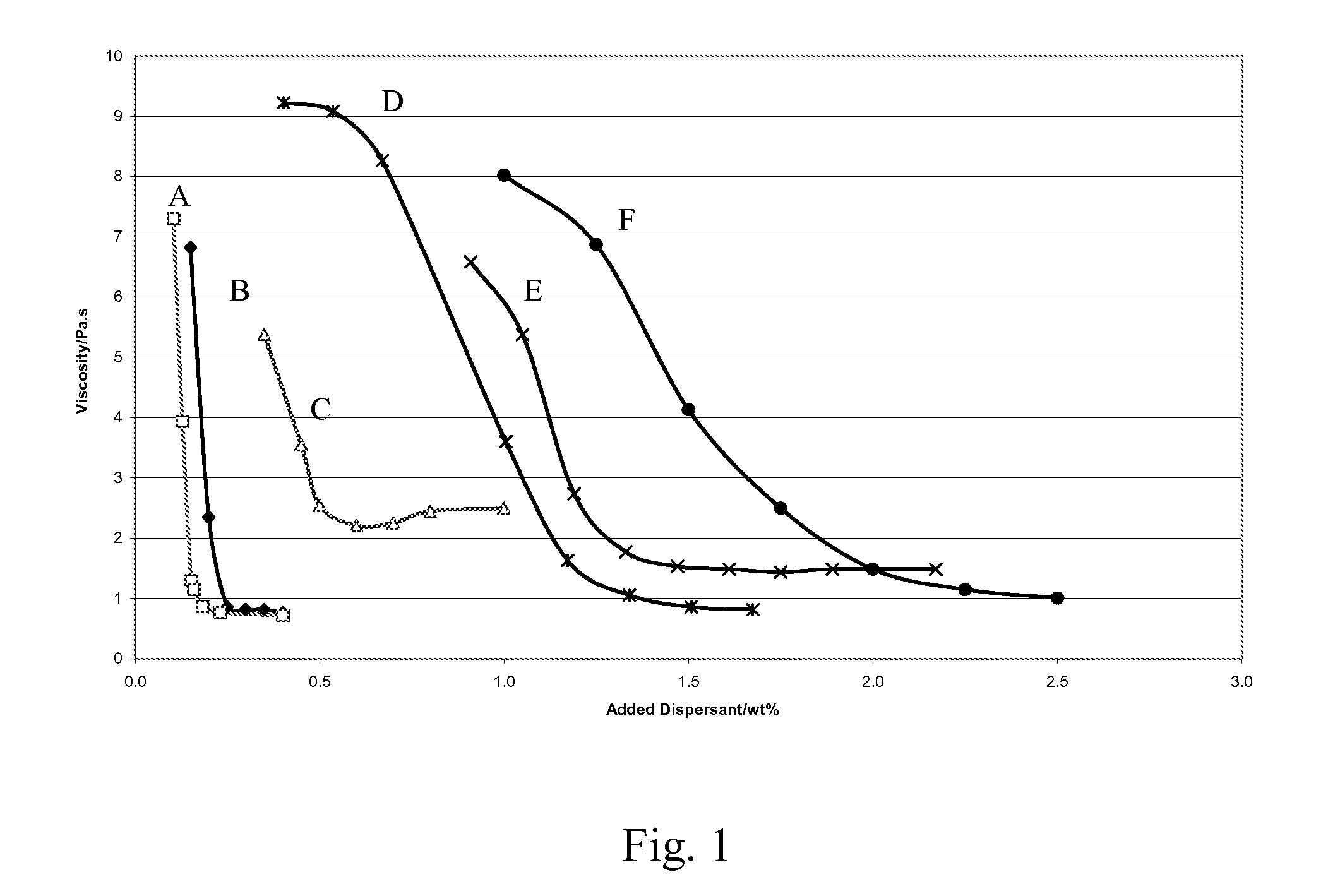

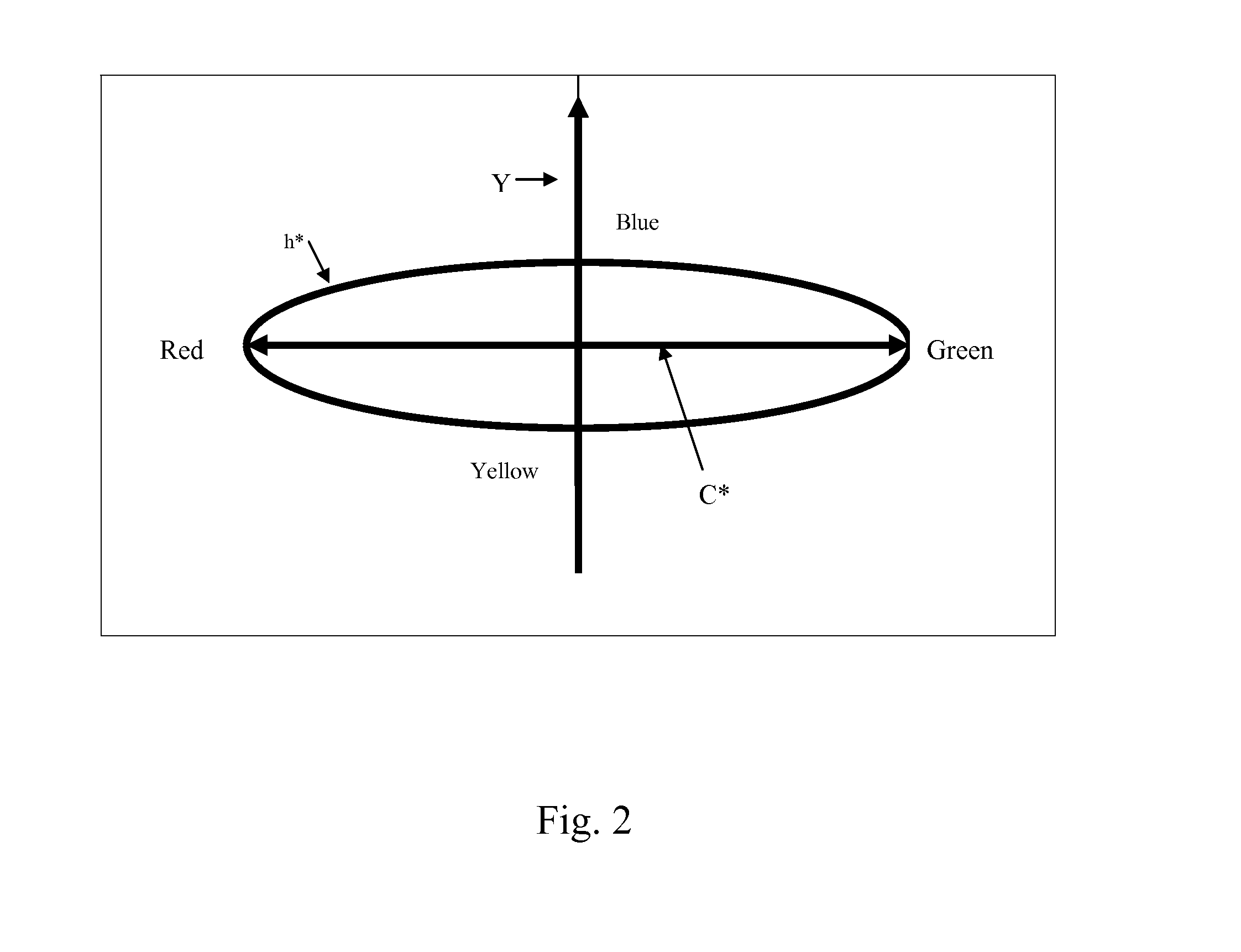

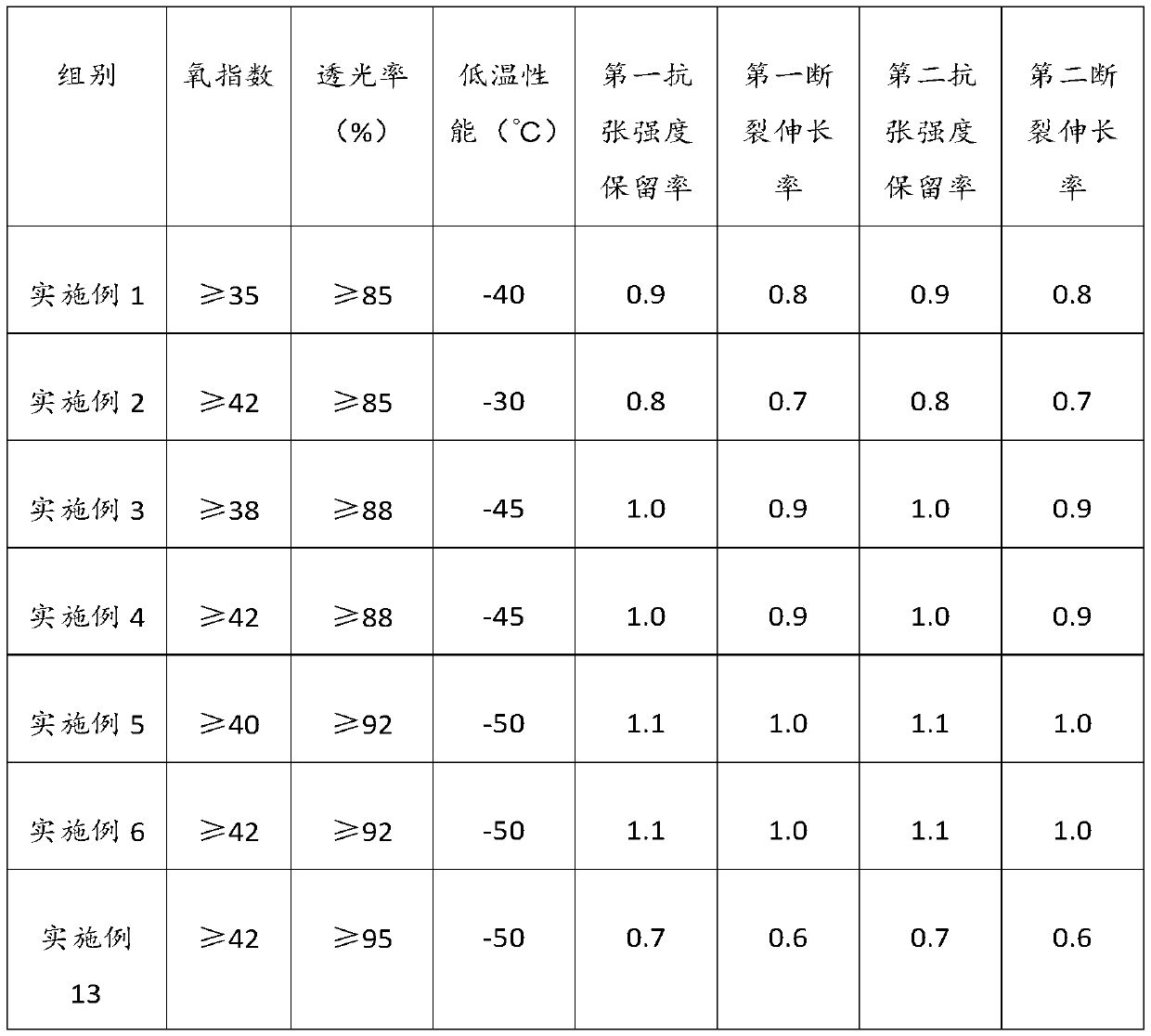

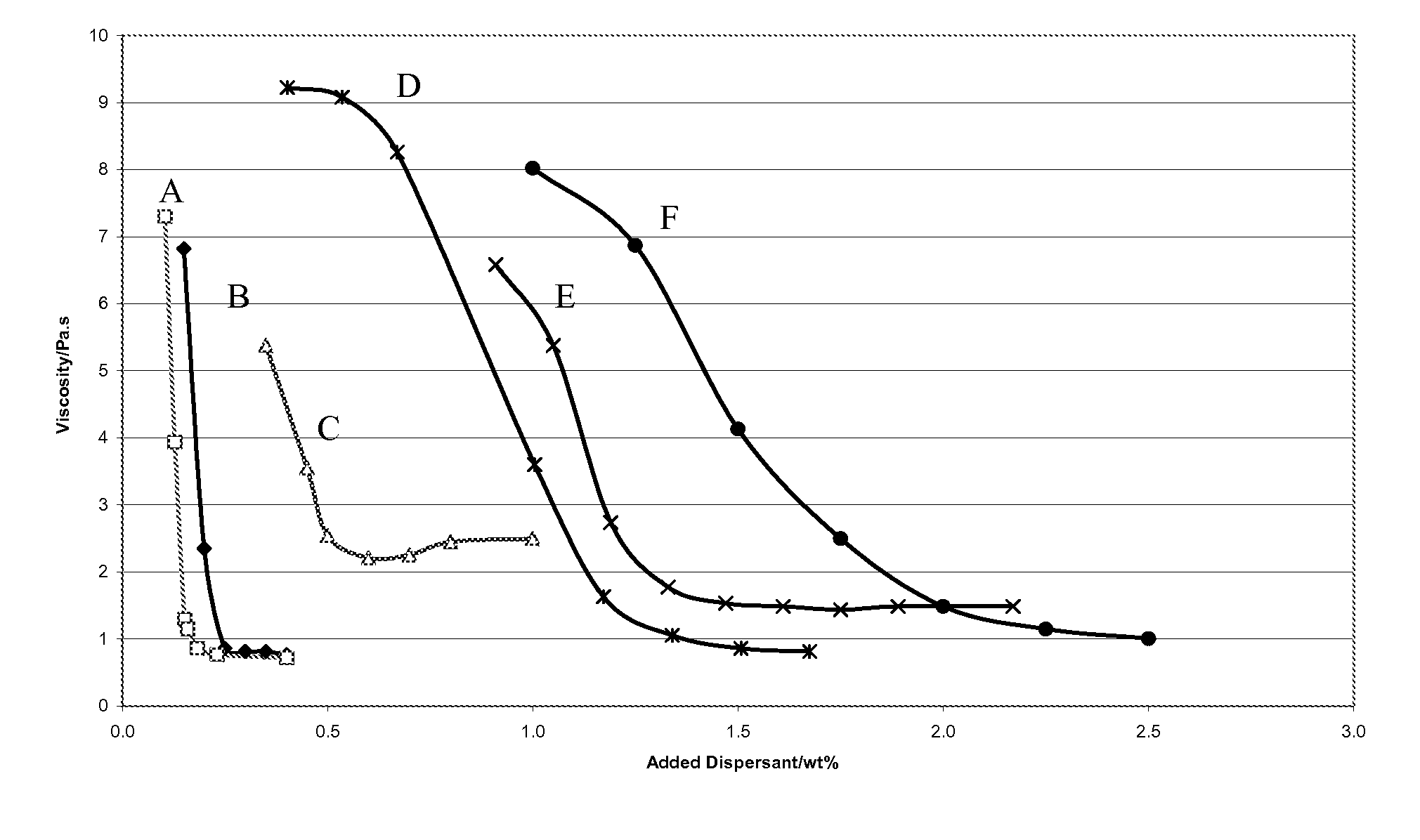

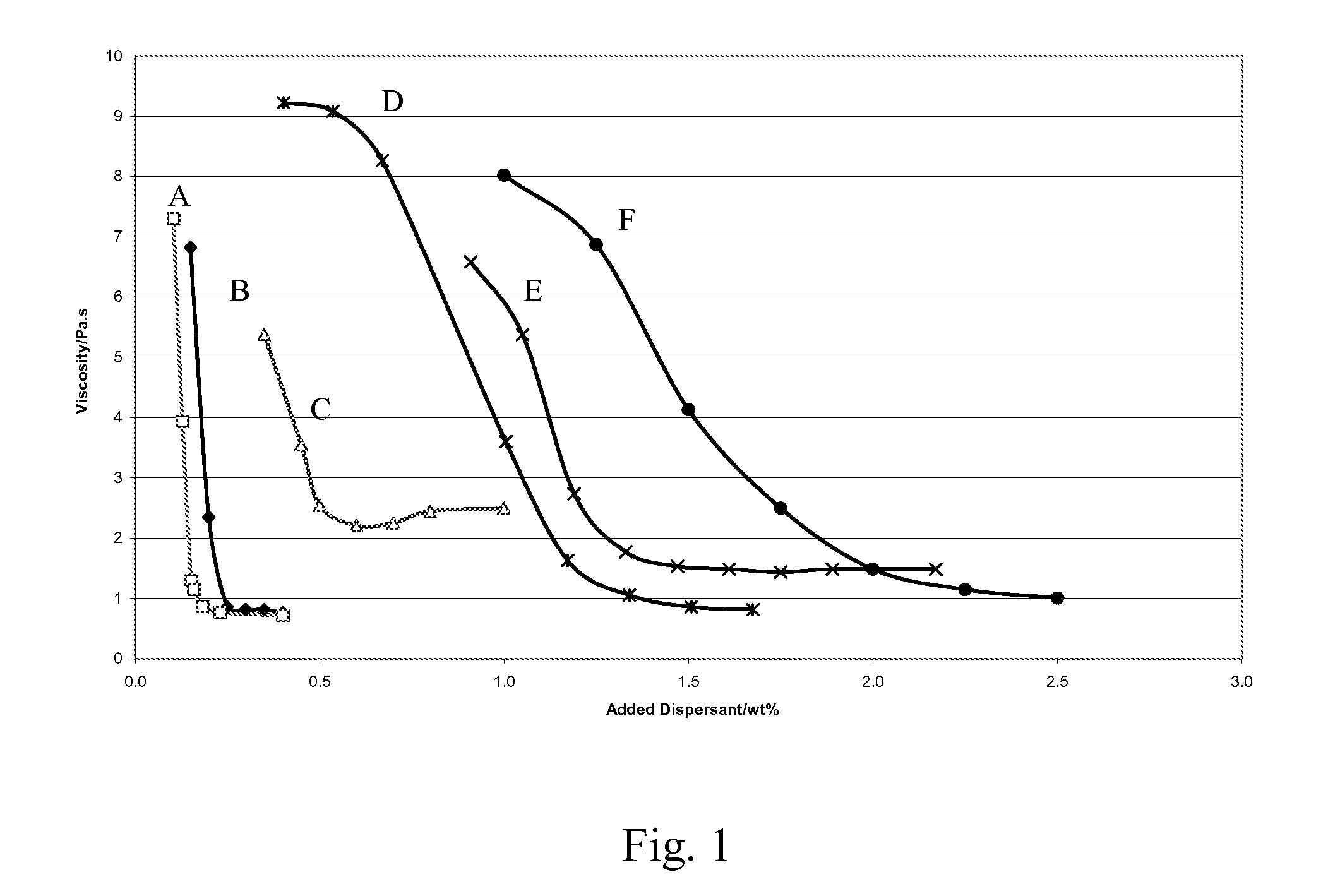

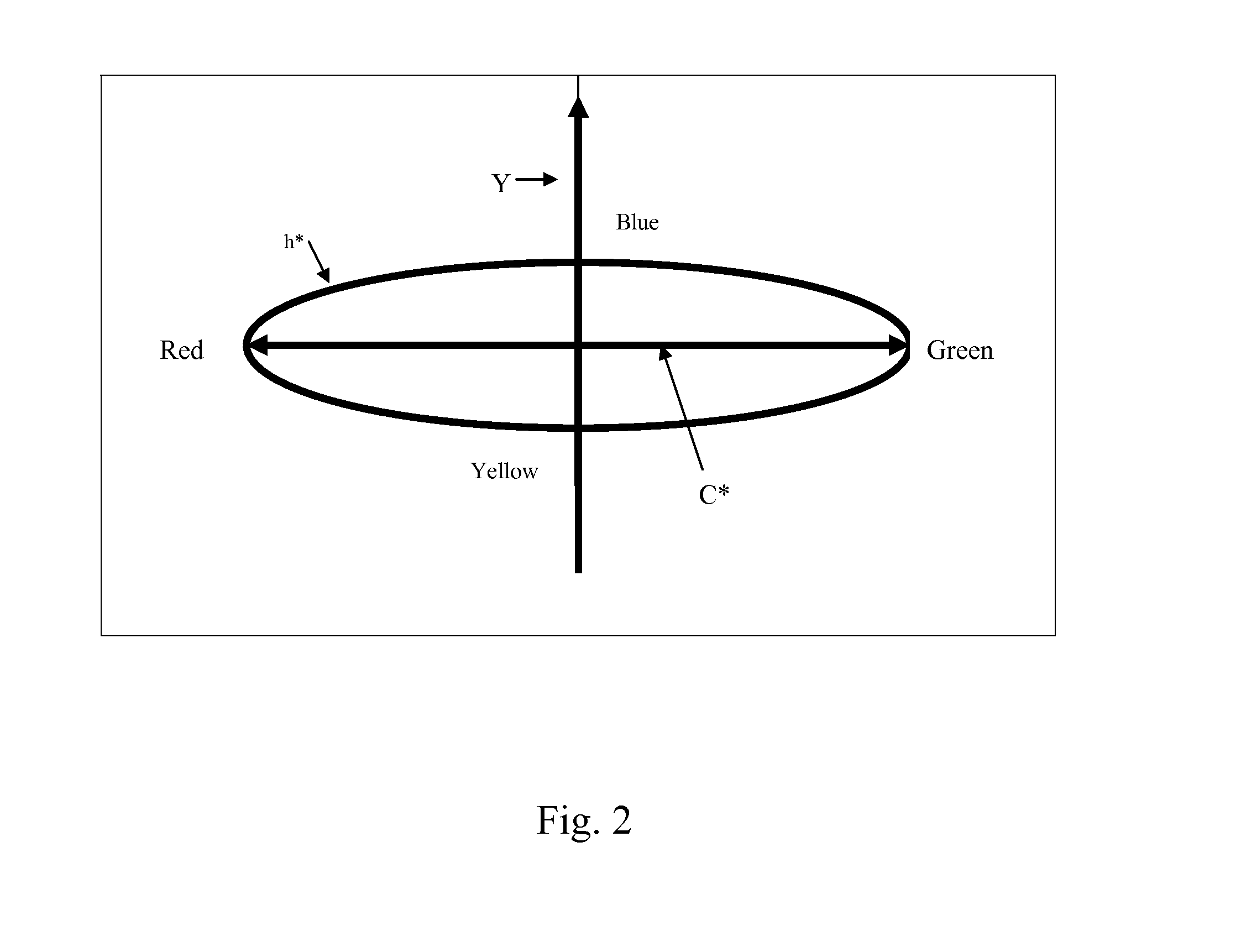

Aqueous coating composition having a PVC from 78 to 85% and free of non-fugitive coalescing solvent, comprising, based on the total volume solids of the dry coating unless otherwise stated,a) opacifying pigment particles comprising from 3 to 10% titanium dioxide and from 0 to 20% of hollow polymeric particles;b) non-opacifying extender particles comprising calcium magnesium carbonate and / or calcium carbonate and / or nepheline syenite and / or kaolin;c) polymer binder particles of calculated Fox Tg of from 5 to 25° C. having an acid value of from 15 to 65 mg KOH / g of polymer;d) dispersant having weight average molecular weight of at least 3500 Daltons, and wherein the dispersant demand of a mixture of the opacifying pigment particles, other than the hollow polymeric particles, of a) and the extender particles of b) is greater than 0.35 wt %, calculated on the weight of the titanium dioxide and extender particles;e) fugitive coalescing solvent.

Owner:AKZO NOBEL COATINGS INT BV

Environment-friendly water-based ceramic simulating coating

InactiveCN105199552ASimplify the preparation processSimple processEpoxy resin coatingsFilling materialsFirming agent

The invention relates to an environment-friendly water-based ceramic simulating coating. The ceramic simulating coating is a bicomponent water-based ceramic simulating coating. The ceramic simulating coating contains filling materials of titanium dioxide, zincite powder, calcium magnesium carbonate powder, heavy calcium powder, light calcium carbonate and the like, and contains a leveling agent, a defoaming agent, a wetting agent, a thixotropic agent and a dispersant at the same time. The water-based ceramic simulating coating, different from a traditional single-component ceramic simulating coating, is prepared by adopting two components namely water-based epoxy resin and a water-based epoxy curing agent as a film forming agent, adding a water-based color paste, a water dispersion type pigment and a filling material and additionally adding a certain amount of auxiliary agents. The prepared water-based ceramic simulating coating is high in glossiness, good in overall effect and high in film hardness, is water-resistant and scrub-resistant after formed into a film, and is low in cost and clean and environmentally friendly in production and construction processes.

Owner:张进 +2

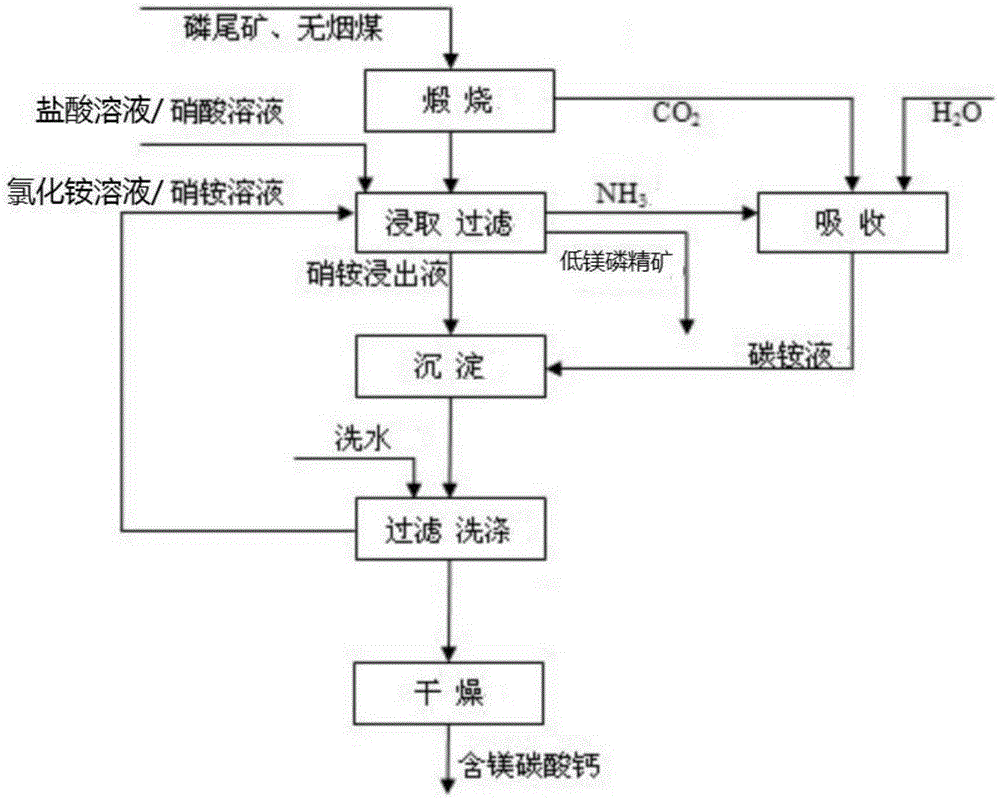

Method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate

ActiveCN105399068AIncrease added valueReduce difficultyCalcium/strontium/barium carbonatesMagnesium carbonatesEcological environmentDecomposition

The invention relates to the technical field of phosphate rock tailing processing and treatment, in particular to a method for processing phosphate rock tailings and producing magnesium-containing calcium carbonate. First the calcium-magnesium carbonate decomposition process is accelerated through calcination digestion treatment, magnesium element is fully extracted by combination with compound extraction of ammonium nitrate solution and nitric acid solution and compound extraction of ammonium chloride solution and hydrochloric acid solution, the magnesium element is separated out of the phosphate rock tailings massively, and the quality of recycled phosphate rock is improved. Waste liquid and waste gas which are generated in the process are recycled, a treated solvent is reused, magnesium-containing calcium carbonate is prepared while the high-quality phosphate rock is obtained, not only are calcium and magnesium elements effectively reused, but also the discharge of the waste liquid and the waste gas and the accumulation of the tailings are avoided, and the method is favorable for ecological environment improvement.

Owner:贵州盛源新材料股份有限公司

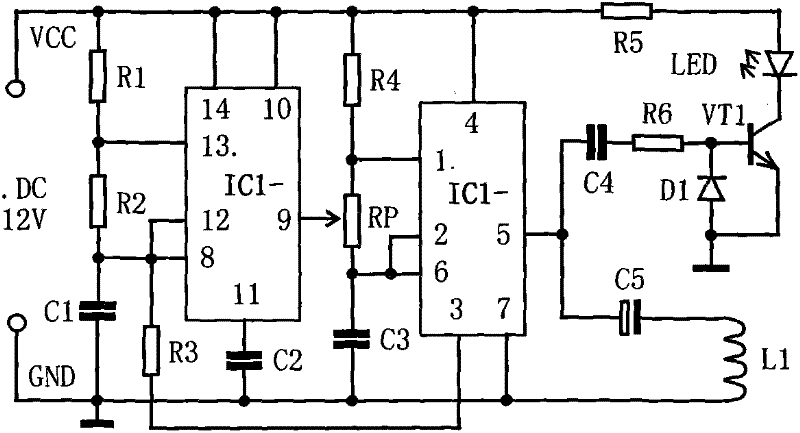

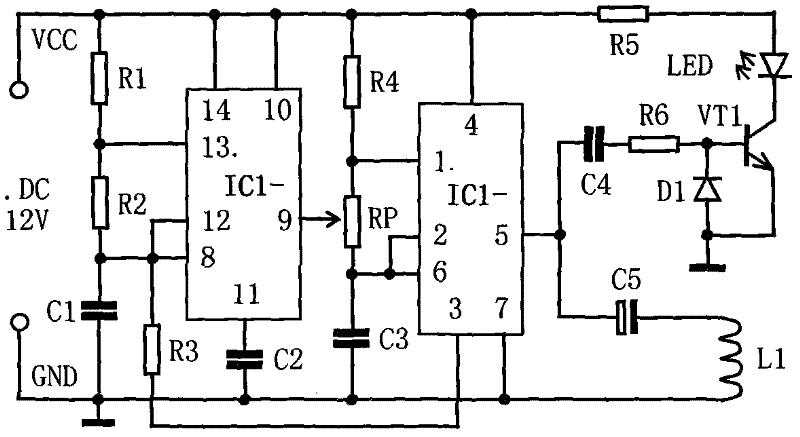

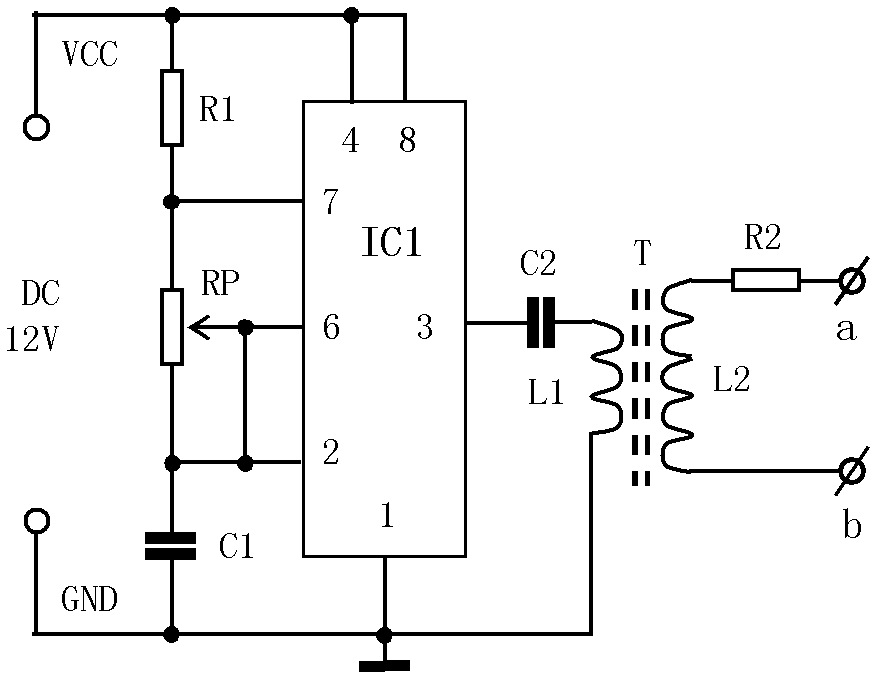

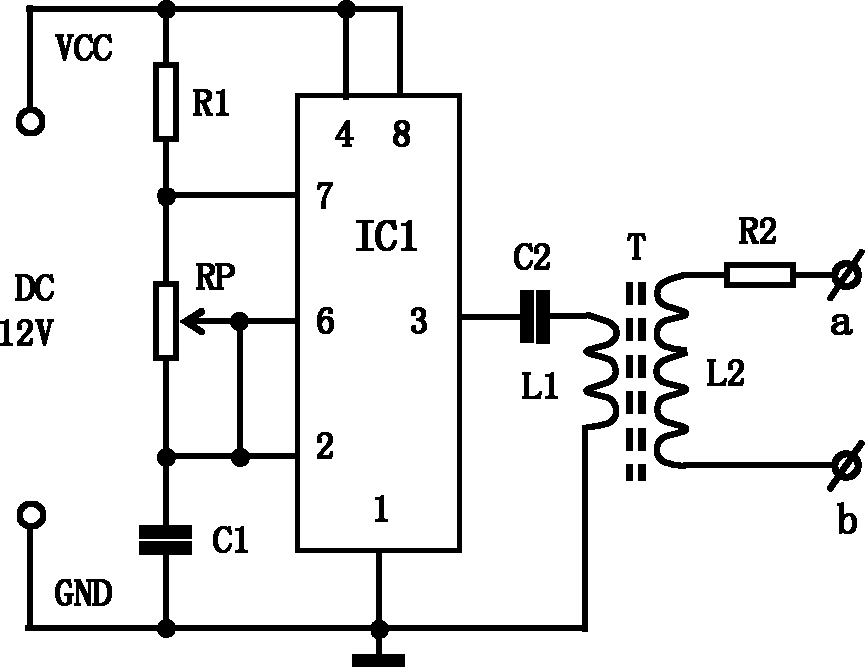

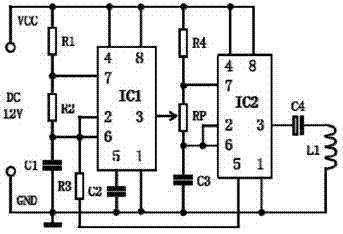

Device to electronically soften hard water

InactiveCN102267764AAchieve the goal of softeningLow costScale removal and water softeningElectromagnetic fieldCalcium magnesium carbonate

The invention belongs to the technical field of electronic technology and water treatment, and relates to a device for softening hard water by electronic means. The device is composed of 12V direct current power supply DC, astable multivibrator, square wave oscillator, alternating electromagnetic field forming circuit and working state indicating circuit. When the hardness of the water is greater than 450 mg / L, if the softening treatment is not carried out in time, it will affect industrial production and people's daily life. The hardness of the water is too high, and it is easy to form scale in the container. If it is not removed in time, repeated drinking of the water in the container will cause health problems. In order to solve the softening problem of hard water, the present invention applies an appropriate electromagnetic field to the hard water at the entrance of the water supply system or hot water appliance by means of the alternating electromagnetic field generated by electronic means, so as to reorganize or interfere with the calcium and magnesium plasma in the water, and change the absolute value of the water in the water. Most of the original characteristics of calcium magnesium carbonate, calcium magnesium carbonate and mercury, cadmium, lead and arsenic ions make hard water achieve the goal of softening. Softening hard water electronically is far less expensive than applying chemical methods, and is environmentally friendly without any pollution.

Owner:殷丽芳

Aqueous polyurethane

InactiveCN103613921AReasonable formulaImprove water resistancePhenylketonesCalcium magnesium carbonate

The invention discloses an aqueous polyurethane, which is composed of following raw materials: polyether type polyurethane prepolymer, dibutyl phthalate, calcium carbonate, calcium magnesium carbonate, 1,4-butylene glycol, and 1-hydroxyl-cyclohexyl-phenylketone. The aqueous polyurethane has the advantages of reasonable formula, and good waterproofness and weatherability; the adhesive performance will not degrade even under a long term using in the external environment, furthermore, the cost is low, and the application range is wide.

Owner:SUZHOU CITY WUZHONG DISTRICT TAIHU LIGHT TEXTILE

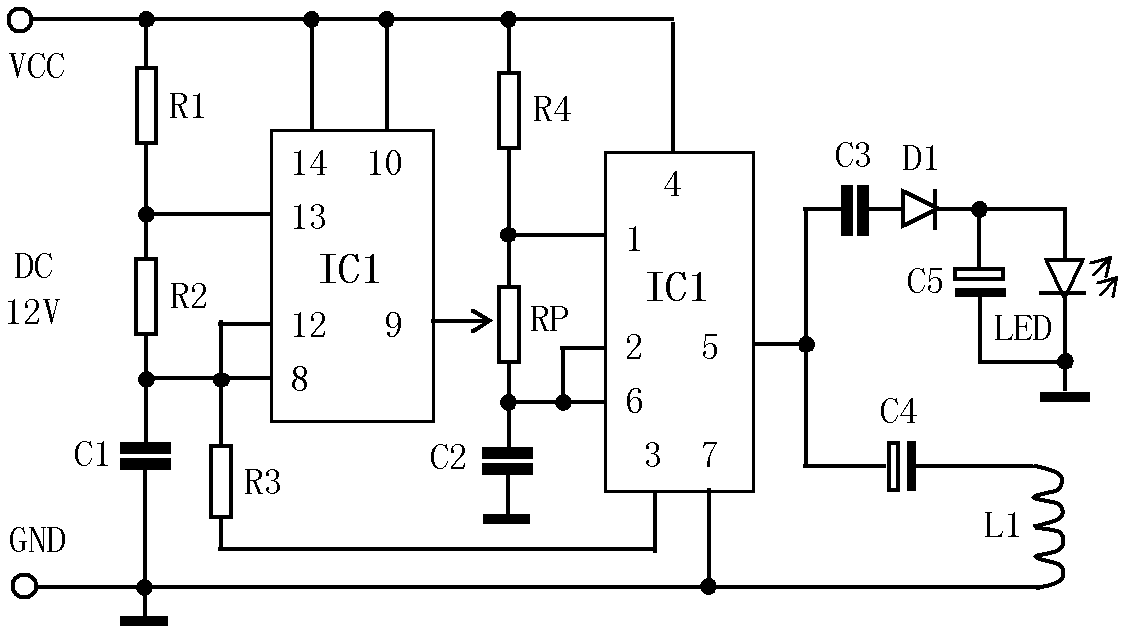

Hard water softener

InactiveCN102583784AAchieve the purpose of softeningLow costScale removal and water softeningDouble-timeEngineering

The invention relates to a hard water softener, which consists of a 12V direct current power supply, a multivibrator, a square-wave oscillator, an alternating electromagnetic field forming circuit and a work state indicating circuit. Double time-base circuits IC1 in the multivibrator and the square-wave oscillator adopt model NE556. When the hardness of water is greater than 450mg / l, if softening treatment is not preformed, industrial production and daily life of people will be directly influenced. Hard water will influence results of chemical tests and product quality in industry. In domestic life, repeated drinking of the water in such a container will influence on the health of people. In order to solve the problem of softening hard water, an alternating electromagnetic field is generated electronically, that is to say, applying an appropriate electromagnetic field to hard water at the inlet of a water supply system for recombining or interfering or changing original characteristics of the vast majority of calcium magnesium carbonate, calcium magnesium carbonate and mercury, cadmium, lead and arsenic ions in water so as to soften the hard water. Water softening in an electrical manner much lower cost than the cost of water softening in a chemical manner and is environment-friendly and free from any pollution.

Owner:何林

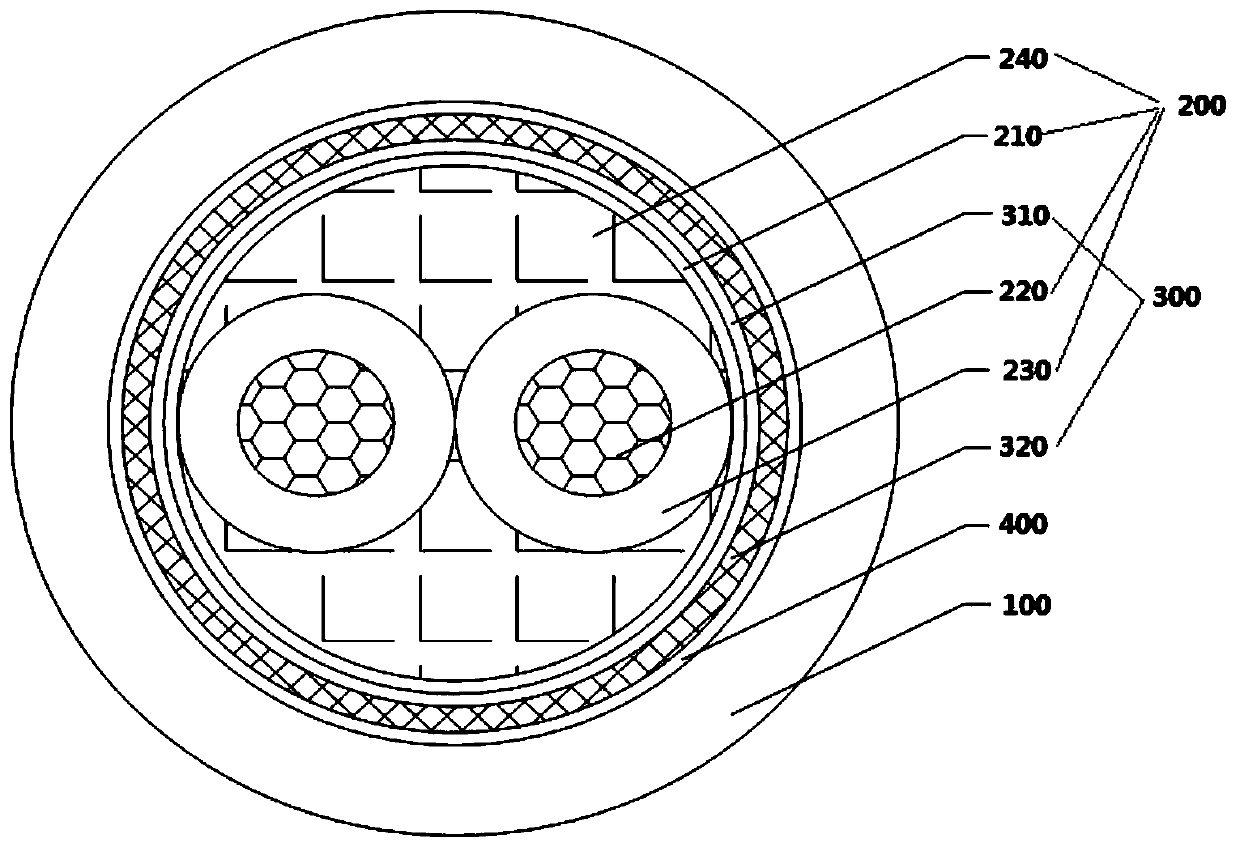

Irradiation cross-linked halogen-free low-smoke insulation material for photovoltaic electric cables

InactiveCN106519405AProtects against thermo-oxidative degradationExcellent discoloration resistanceLow-density polyethyleneCross-link

The present invention relates to an irradiation cross-linked halogen-free low-smoke insulation material used for photovoltaic electric cables and having characteristics of no halogen, high mechanical property, strong high-temperature resistance, strong ozone resistance, strong weather resistance and strong ultraviolet resistance, wherein the components comprise 20-40% of an ethylene-vinyl acetate copolymer, 0-20% of low density polyethylene, 10-20% of aluminum hydroxide, 0-10% of calcium magnesium carbonate, 1-10% of a coupling agent and a cross-linking agent, 1-10% of a compatibilizer, 0.1-1% of an antioxidant, 0.1-1% of a lubricant, and 0.1-1% of a stabilizer. According to the present invention, the irradiation cross-linked halogen-free low-smoke insulation material has the following advantages that the harms of the traditional PVC insulation material on the environment and the human body are overcome, and the irradiation cross-linked halogen-free low-smoke insulation material is non-toxic, green and environmental protection; and the irradiation cross-linked halogen-free low-smoke insulation material has characteristics of high mechanical property, strong high-temperature resistance, strong ozone resistance, strong weather resistance and strong ultraviolet resistance.

Owner:HANGZHOU GAOXIN RUBBER & PLASTIC MATERIALS CO LTD

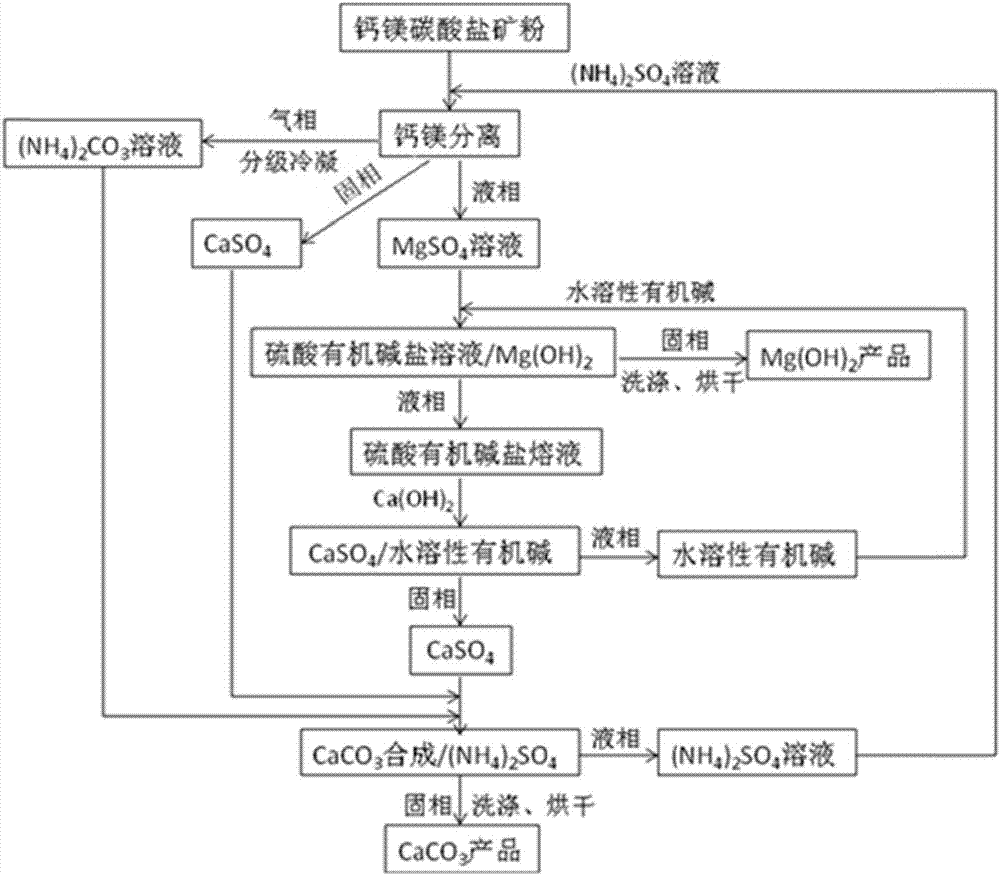

Method for preparing magnesium hydroxide from calcium-magnesium-carbonate-containing ore

InactiveCN106986360AReduce high energy consumptionLow costCalcium/strontium/barium carbonatesMagnesium hydroxideGas phaseCalcium magnesium carbonate

The invention provides a method for preparing magnesium hydroxide from calcium-magnesium-carbonate-containing ore. The method includes the steps of (1), adding ammonium sulfate aqueous solution and carbonate ore into a reactor, separating reaction products to obtain a gas phase, a liquid phase and a solid phase; (2), subjecting the gas phase to fractional condensation to obtain ammonium carbonate solution; (3), adding the liquid phase to a water-soluble organic alkali solution while stirring, and then filtering to obtain a filter cake and filter liquor; (4), adding calcium hydroxide to the filter liquor obtained in the step (3) for reaction, filtering after finishing reaction to obtain a filter cake and filter liquor, and taking at least a part of the filter liquor as a raw material for the step (1); (5), subjecting the ammonium carbonate solution obtained in the step (2) and the filter cake obtained in the step (4) to reaction, filtering after finishing reaction to obtain filter liquor, and taking at least a part of the filter liquor as a raw material for the step (1). Compared with the conventional synthesis technique of magnesium hydroxide by ammonia-soda process, the method has the advantage of increasing utilization rate of magnesium ion greatly.

Owner:LONGYAN ZIYUN CHEM TECH

A method for calcining dolomite and separating calcium and magnesium in water to produce magnesium hydroxide and calcium carbonate

ActiveCN103738986BSimple processLow costCalcium/strontium/barium carbonatesMagnesium hydroxideCooking & bakingCalcium carbonate precipitation

Owner:贵州胜威化工新材料研究院有限公司

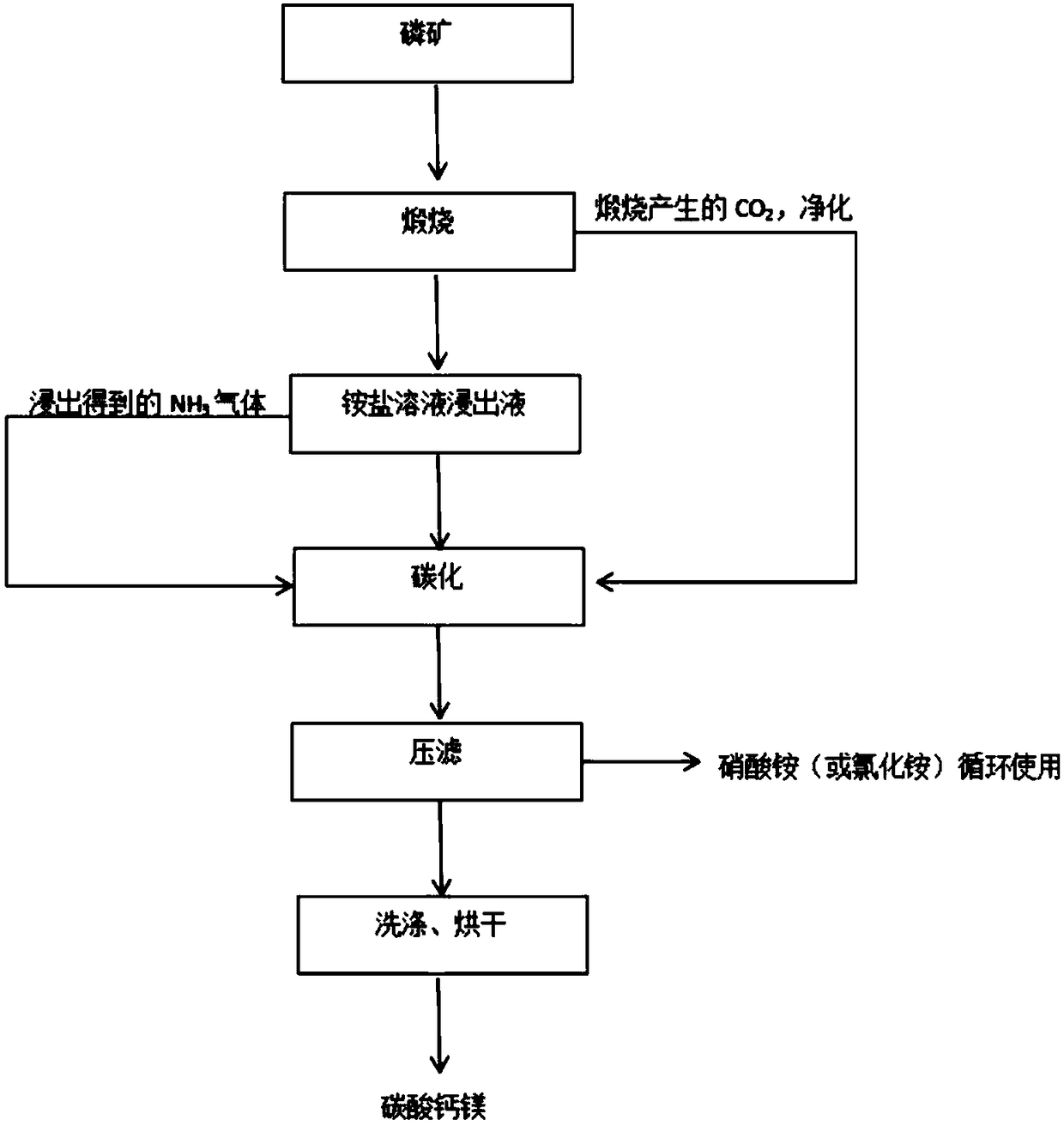

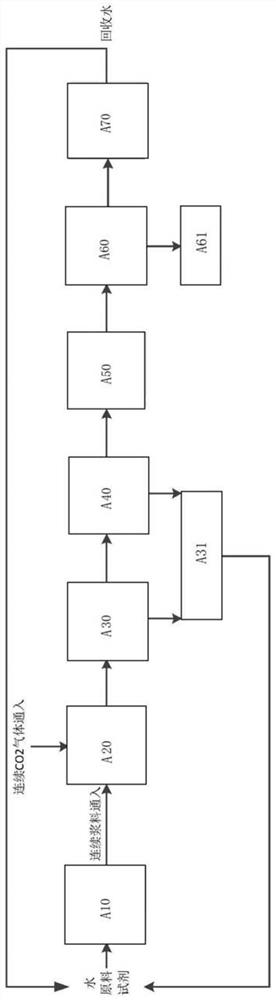

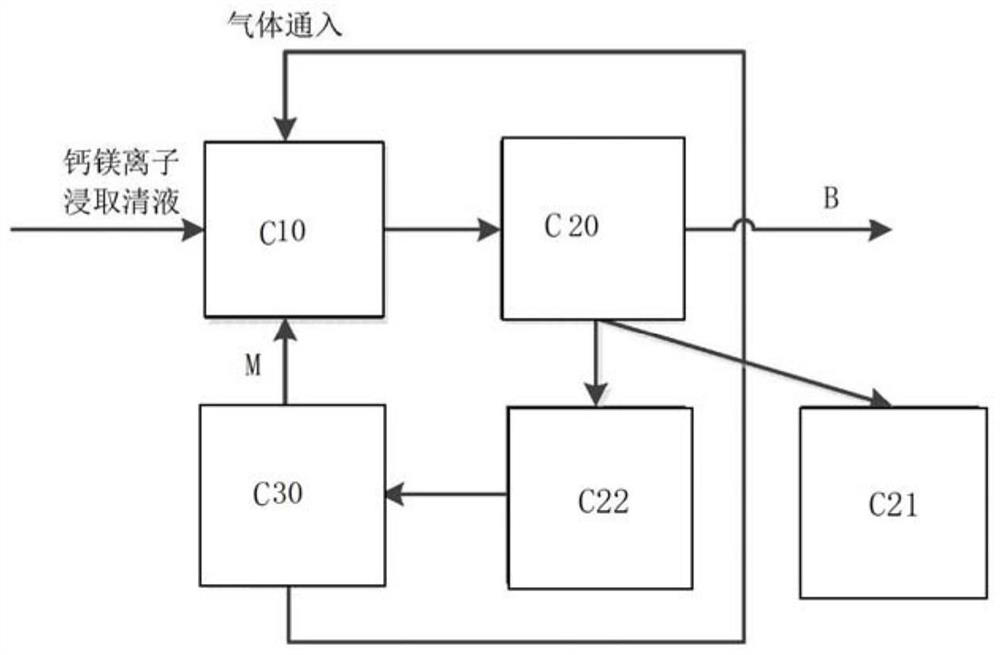

Method for directly carbonizing calcinated mid and low grade phosphate ore ammonium salt lixivium to prepare calcium magnesium carbonate

InactiveCN108358230ANo lossEasy particle size controlCalcium/strontium/barium carbonatesMagnesium carbonatesAmmonium nitrateMoisture

The invention relates to the technical field of inorganic chemical engineering, in particular to a method for directly carbonizing calcinated mid and low grade phosphate ore ammonium salt lixivium toprepare calcium magnesium carbonate. The method utilizes CO2 gas obtained through calcination of phosphate ores, NH3 gas produced in the extracting process of a phosphate ore pyrolysis product to jointly react with the calcinated mid and low grade phosphate ore ammonium salt lixivium, calcium and magnesium in the calcinated mid and low grade phosphate ore ammonium salt lixivium can form calcium magnesium carbonate sediment. The method only uses ammonium nitrate or ammonium chloride solutions to achieve circulation, no loss of ammonium nitrate is caused, and meanwhile, the situation that moisture is newly introduced into a circulation system is avoided; granularity control in the synthesis process of calcium magnesium carbonate is facilitated, and the production capability of filter pressing and washing is improved; the NH3 gas used in the method comes from the reaction of the pyrolysis product and the ammonium nitrate or ammonium chloride solution, CO2 comes from calcinations of the phosphate ores, and the pyrolysis product is obtained, the waste gas needing to be emitted in the original production process is recycled, not only is emission of the waste gas reduced, but also the cost of the raw materials is reduced.

Owner:贵州盛源新材料股份有限公司 +1

Tap water scale eliminator

The invention relates to a tap water scale eliminator, which consists of a 12V direct current power supply, an astable multivibrator, a voltage booster circuit and a high-frequency electric field module. If not cleared in time, water scales in tap water directly influence industrial production and daily life of people. Water scales industrially influence chemical test results in industries such as papermaking, pharmacy, electronics, chemical industry, foods and beverages, and the like; and due to boiler scaling, fuels are wasted, and the service life of a boiler is shortened. In daily life, water scales are easily formed in a container if the hardness of tap water is too high, and over one third of fuel is wasted during water boiling once water scales are formed. An alternate high-frequency electric field generated by an electron eliminating device is used for interfering or recombining the original characteristics of most calcium magnesium carbonate, mercury ions, cadmium ions, lead ions and arsenic ions in tap water, so that precipitates are prevented from being formed easily in a container in the boiling process of tap water. The tap water scale eliminator can be used for treating water for industries, laboratories, households and diets.

Owner:王寅寅

Composite material for locomotive cable outer sheath, preparation method of the composite material, the cable outer sheath and locomotive cable

ActiveCN110607022AImprove flame retardant performanceGood high and low temperature resistanceInsulated cablesInsulated conductorsLow-density polyethyleneElastomer

The invention discloses a composite material for a locomotive cable outer sheath, a preparation method of the composite material, the cable outer sheath and a locomotive cable, and relates to the technical field of industrial cables. The composite material for the locomotive cable outer sheath is prepared from the following raw materials in parts by weight: 12 to 23 parts of ethylene-vinyl acetatecopolymer resin, 2 to 7 parts of polyolefin elastomer resin, 13-25 parts of linear low-density polyethylene resin, 1-4 parts of high-density polyethylene resin, 3-10 parts of maleic anhydride graftedPOE, 0.1-0.8 part of an antioxidant, 0.1-0.8 part of an irradiation crosslinking agent, 1-13 parts of an organophosphorus flame retardant, 20-50 parts of calcium magnesium carbonate and 1-7 parts ofan organosilicon flame retardant. The material can be endowed with good flame retardant property and high and low temperature resistance. The preparation method takes materials in the formula as raw materials. The material of the outer sheath of the locomotive cable is the composite material for the outer sheath of the locomotive cable, and the outer sheath can work at ultralow temperature and ultrahigh temperature and has good flame retardant property.

Owner:凯布斯工业电气线缆(苏州)有限公司 +1

Low titanium dioxide coatings

Aqueous coating composition having a PVC from 78 to 85% and free of non-fugitive coalescing solvent, comprising, based on the total volume solids of the dry coating unless otherwise stated,a) opacifying pigment particles comprising from 3 to 10% titanium dioxide and from 0 to 20% of hollow polymeric particles;b) non-opacifying extender particles comprising calcium magnesium carbonate and / or calcium carbonate and / or nepheline syenite and / or kaolin;c) polymer binder particles of calculated Fox Tg of from 5 to 25° C. having an acid value of from 15 to 65 mg KOH / g of polymer;d) dispersant having weight average molecular weight of at least 3500 Daltons, and wherein the dispersant demand of a mixture of the opacifying pigment particles, other than the hollow polymeric particles, of a) and the extender particles of b) is greater than 0.35 wt %, calculated on the weight of the titanium dioxide and extender particles;e) fugitive coalescing solvent.

Owner:AKZO NOBEL COATINGS INT BV

Powder for disks

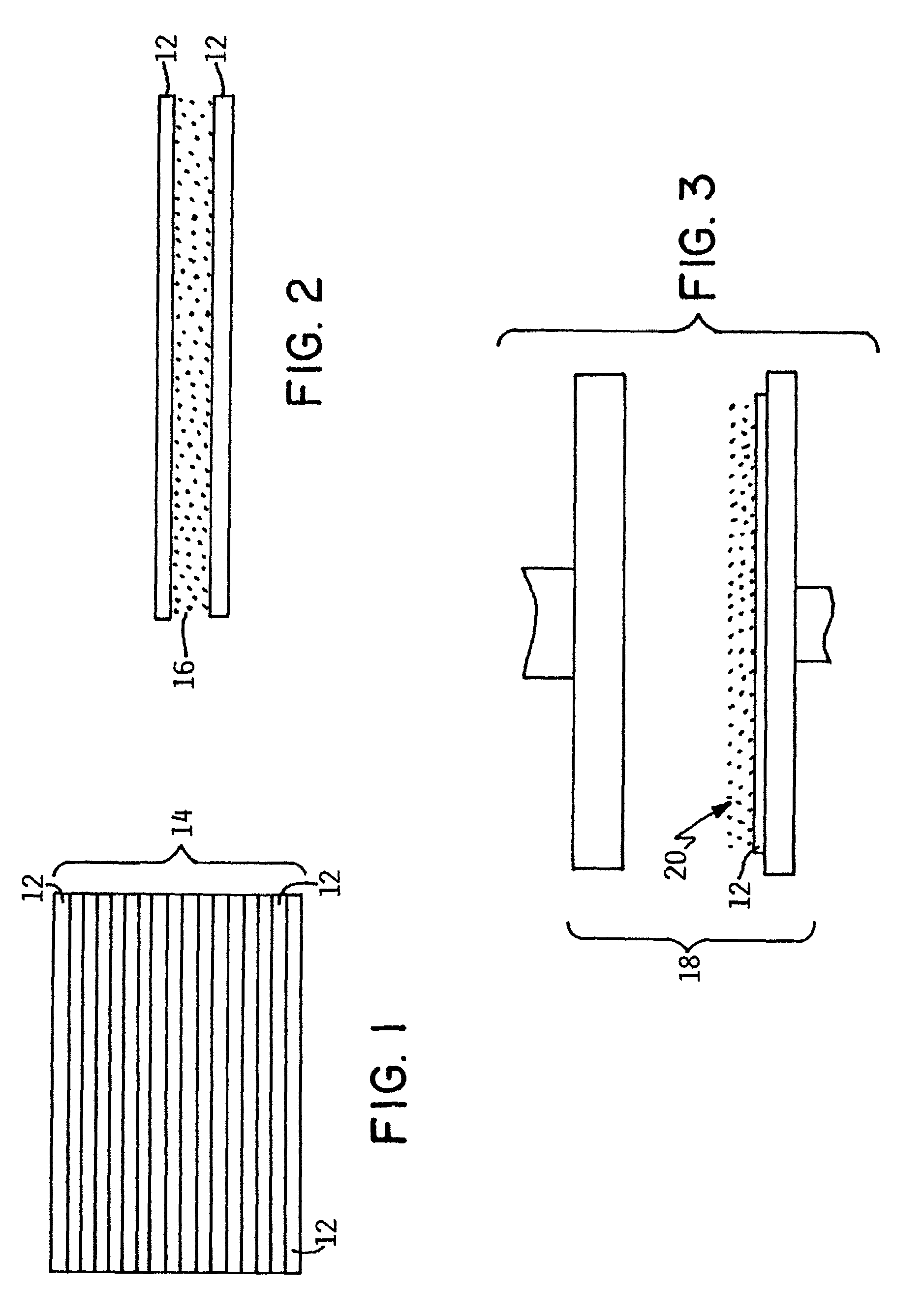

InactiveUS7201639B2Avoid breakingAvoid damageStampsLiquid surface applicatorsCalcium biphosphateMagnesium phosphate

A plurality of disks include a first disk and a second disk stacked upon the first disk. The first disk and the second disk are each formed from glass or glass-ceramic. A powder is disposed between the first disk and the second disk. The powder is selected from the group including calcium carbonate, calcium magnesium carbonate, calcium phosphate, magnesium carbonate, magnesium borate, magnesium oxide, magnesium phosphate, and clay.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

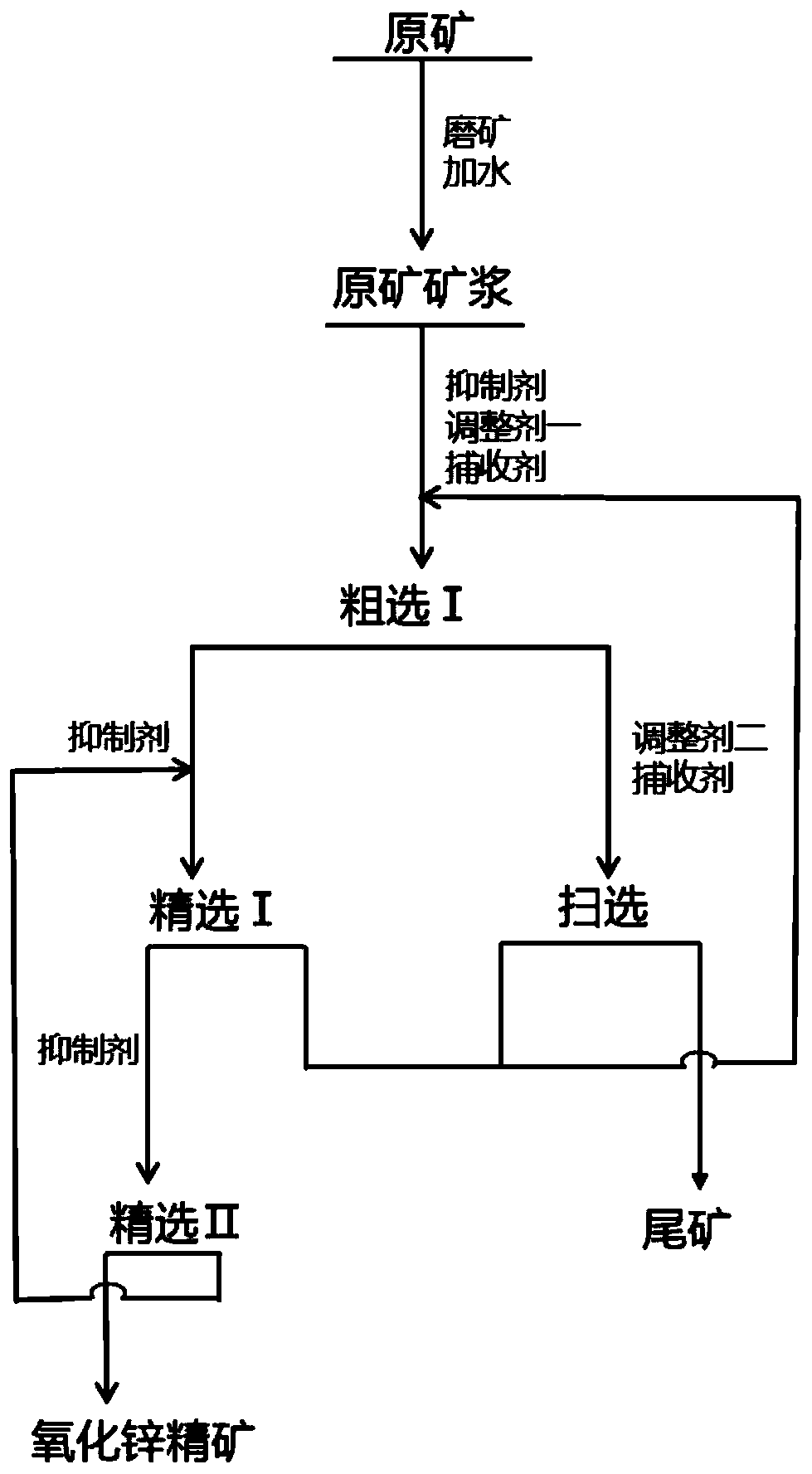

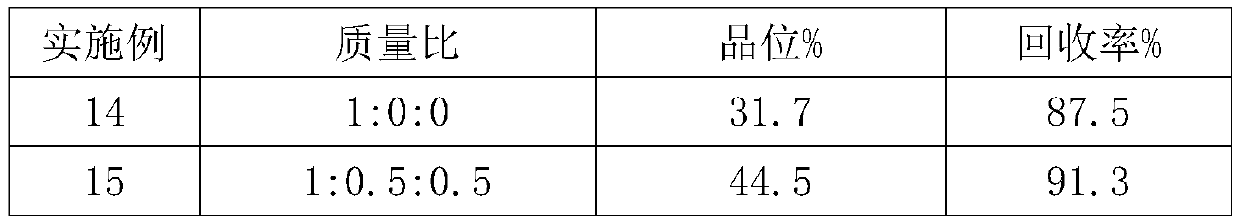

Flotation method for zinc oxide in sulphide ore tailings

The invention discloses a flotation method for zinc oxide in sulphide ore tailings. Sodium hexametaphosphate and sodium silicate which have a remarkable inhibiting effect on gangue minerals such as quartz, calcium magnesium carbonate and magnesium silicate and slime in sulfide ore tailings are used as a combined inhibitor, and meanwhile a combined collecting agent formed by mixing CA-1, N-nitroso-benzene nuclear ammonium salt and E-5 according to the proportion of 1: (0.5-0.8): (0.2-0.5) is used. The combined collecting agent is adopted, a one-roughing, two-concentrating and one-sweeping closed-loop non-desliming direct flotation process flow is adopted, the dosage ratio of the inhibitor to the regulator in the flotation process is reasonably optimized, the flotation reagent consumption can be effectively reduced, the separation index is improved, and the recovery rate and the grade of the zinc oxide concentrate in the sulphide ore tailings are remarkably improved, so that the zinc oxide concentrate of which the zinc grade is 46.7% and the zinc recovery rate is as high as 92.4% is obtained, and efficient utilization of low-grade refractory zinc oxide ore resources in the sulphide ore tailings is realized.

Owner:NANHUA UNIV

Irradiation crosslinked halogen-free low-smoke cable sheath material used for photovoltaic cables

InactiveCN106496754AAvoid harmImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

The invention relates to an irradiation crosslinked halogen-free low-smoke cable sheath material used for photovoltaic cables. The irradiation crosslinked halogen-free low-smoke cable sheath material possesses high temperature resistance, ozone resistance, weather resistance, ultraviolet resistance, and excellent flame resistance, and is harmless for the environment and human body. The irradiation crosslinked halogen-free low-smoke cable sheath material is prepared from 20 to 40% of ethylene / vinyl acetate copolymer, 0 to 20% of low density polyethylene, 30 to 60% of aluminium hydroxide, 0 to 10% of calcium magnesium carbonate, 1 to 10% of a coupling agent and a cross-linking agent, 1 to 10% of a compatilizer, 0.1 to 1% of an antioxidant, 0.1 to 1% of a lubricating agent, and 0.1 to 1% of a stabilizing agent. The irradiation crosslinked halogen-free low-smoke cable sheath material is capable of solving a problem that conventional PVC sheath material is harmful for the environment and human body, is nontoxic, is green, is friendly to the environment, and possesses high temperature resistance, ozone resistance, weather resistance, ultraviolet resistance, and excellent flame resistance.

Owner:HANGZHOU GAOXIN RUBBER & PLASTIC MATERIALS CO LTD

Heavy metal repair and treatment material and preparation method thereof

PendingCN114405478AImprove adsorption capacityImprove passivation effectOther chemical processesWater contaminantsPolyethylene glycolChemical adsorption

The invention discloses a heavy metal repair and treatment material and a preparation method thereof. The heavy metal repair and treatment material has hydroxyl on the surface of a mineral modified by a dry method and is grafted with sulfydryl; the preparation method comprises the following steps: weighing potassium feldspar, montmorillonite, calcium magnesium carbonate and calcium carbonate, and mixing; adding polyethylene glycol, grinding in a planetary ball mill, calcining at high temperature, and naturally cooling; h2O and mercaptopropyltrimethoxysilane are sequentially sprayed to the calcined material, extrusion is conducted through a roller press, air drying and smashing are conducted, and the heavy metal repairing and treating material is obtained. The heavy metal repair and treatment material has a good adsorption effect in a solution, can adsorb heavy metals through surface complexation reactions such as chemical adsorption, and has an excellent adsorption effect on heavy metal elements such as cadmium and mercury in the solution. The heavy metal remediation and treatment material has a good passivation effect on heavy metals in soil, can improve the pH of the soil, enhance the adsorption and fixation of the soil on the heavy metals and remarkably reduce the bioavailability of the soil, and can be used as an efficient passivation material for cadmium pollution of the acid soil.

Owner:四川津蜀生态科技有限公司

High-viscosity building waterproof material

The invention discloses a high-viscosity building waterproof material which is prepared from the following raw materials in parts by weight: 15 to 20 parts of silicate cement, 5 to 10 parts of low-calcium fly ash, 3 to 8 parts of modified shale, 6 to 10 parts of sepiolite, 12 to 17 parts of dolomite, 4 to 8 parts of calcium magnesium carbonate, 3 to 6 parts of gallium nitride, 5 to 9 parts of vanadium pentoxide, 2 to 5 parts of chromic boride, 2 to 6 parts of tantalum silicide, 5 to 8 parts of calcium oxide, 4 to 9 parts of a calcium silicate powder, 7 to 9 parts of stearyl alcohol, 3 to 7 parts of precipitated barium sulphate, 2 to 6 parts of fibroin fiber, 2 to 8 parts of a mixed solvent, 4 to 9 parts of polybutyl acrylate, 7 to 9 parts of an epoxy resin emulsion, 4 to 8 parts of tackifying resin, 5 to 12 parts of a surfactant, 3 to 10 parts of an antioxidant, 4 to 9 parts of a flame retardant and 150 to 180 parts of water. Due to the addition of the antioxidant, the surfactant and the tackifying resin, the oxidization resistance and the adhesive property of the building waterproof material are improved favorably; by coating the surface of a building material with the high-viscosity building waterproof material, oxidization of the building material can be effectively prevented, and the service life of the building material is prolonged.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

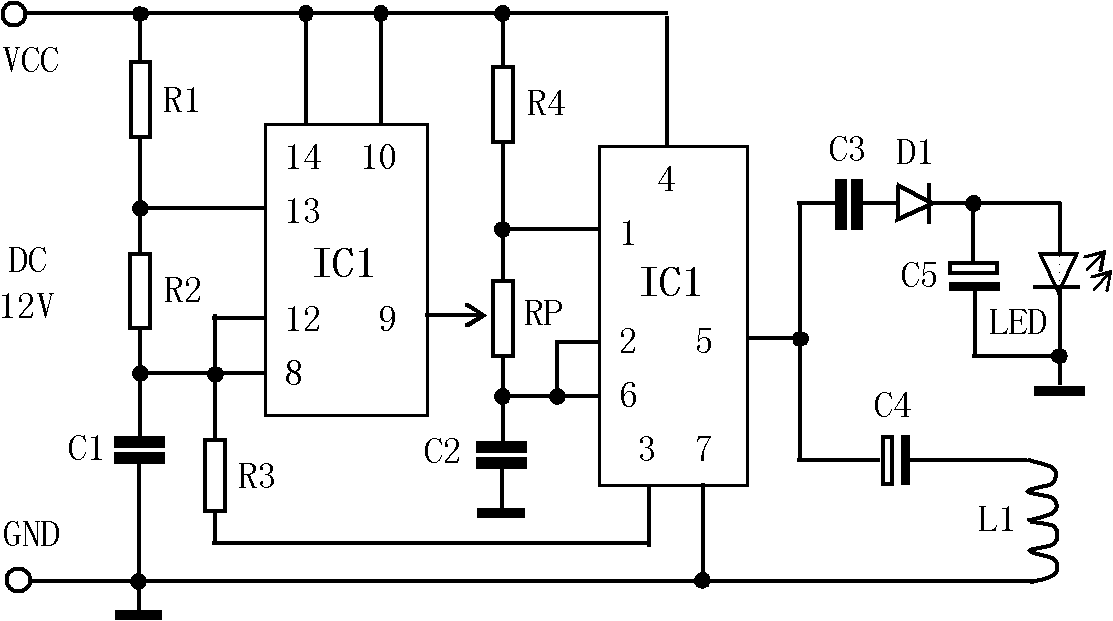

Electronic hard water softener

InactiveCN102730844ALow costNo pollution in the processScale removal and water softeningElectromagnetic fieldCalcium magnesium carbonate

The invention discloses an electronic hard water softener which is composed of a 12V direct current power supply, a multivibrator, a square wave-form vibrator and an alternating electromagnetic field formation circuit. The invention is characterized in that the type of a time base circuit IC1 and a time base circuit IC2 in the multivibrator and the square wave-form vibrator is NE555. The alternating electromagnetic field generated by the electronic mode recombines or disturbs calcium, magnesium and other ions in water, and changes the primary characteristics of most calcium magnesium carbonate, and mercury, cadmium, lead and arsenic ions in water. The test indicates that calcium carbonate and other minerals contained in hard water can be combined into a large crystal grain precipitate or flushed away by running water under the action of the electromagnetic field. Therefore, in order to soften the hard water, a proper electromagnetic field can be applied to the hard water at the water inlet of a water supply system or water heater. Compared with the chemical method for softening hard water, the electronic method disclosed by the invention has the advantages of lower cost, environmental protection and no pollution.

Owner:周芸

Environmentally-friendly building composite material and preparation method thereof

The invention discloses an environmentally-friendly building composite material and a preparation method thereof, wherein the environmentally-friendly building composite material is prepared from thefollowing raw materials by weight: 20-35 parts of waste ceramic material, 20-30 parts of calcium magnesium carbonate, 15-30 parts of paraffin, 10-20 parts of isoprene rubber, 8-15 parts of an inorganic filler, 20-35 parts of calcium silicate powder, 11-22 parts of pearl sand, 10-12 parts of chlorosulfonated polyethylene, 10-15 parts of ethylenediaminetetraacetic acid, 2-6 parts of a flame retardant agent, 8-15 parts of an antioxidant, and 5-10 parts of a polycarboxylate cement dispersant. According to the present invention, the building composite material is prepared by using the effective ratio of the raw materials such as waste ceramic material, calcium magnesium carbonate, paraffin, isoprene rubber, inorganic filler, calcium silicate powder, pearl sand and the like so as to improve theimpact resistance and the crack resistance of the product; the prepared environmentally-friendly building composite material has characteristics of cracking resistance, impact resistance, easy transportation, low maintenance cost and the like; and the preparation method has characteristics of simple preparation process, high yield, material recycling, environmental protection, energy saving, consumption reducing and the like.

Owner:安徽嘉中金属材料有限公司

A method for preparing calcium magnesium carbonate mineral ca1-xmgxco3 under high temperature and high pressure

InactiveCN107640781BNot easy to absorb waterGood chemical stabilityCalcium/strontium/barium carbonatesUltra-high pressure processesHigh pressureCalcium magnesium carbonate

The invention discloses a method for preparing calcium-magnesium carbonate mineral Cal-xMgxCO3 at a high temperature under high pressure. The method includes evenly grinding and mixing analytically-pure calcium carbonate, magnesium oxalate powder and anhydrous oxalic acid to obtain a mixture serving as an initial raw material, pressing the mixture into a cylinder by a tablet machine, inserting a cylindrical sample into a platinum tube, sealing two ends of the platinum tube by a welding gun, putting the sample sealed by platinum in an h-BN tube by taking h-BN as a pressure transfer medium, assembling the sample in the h-BN tube in a high-pressure combined assembly block, putting the high-pressure combined assembly block in a cubic press for high-temperature high-pressure reaction, taking out the reacted sample, opening the platinum tube by a diamond cutter, and naturally air-drying the sample to obtain calcium-magnesium carbonate minerals. By the method, the technical problems such as operation process complexity, long reaction time, and low purity, low chemical stability and proneness to water absorption of obtained samples in existing calcium-magnesium carbonate mineral preparation methods are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Therapeutic Compositions and Uses Thereof

ActiveUS20200000768A1Hydrocarbon active ingredientsPharmaceutical delivery mechanismLycoperseneVitamin b6

The present invention discloses a composition and method of use for the general improvement of hypertension, high cholesterol, and cardiovascular health. The novel composition is comprised of thiamin (vitamin B1), vitamin B2 (as riboflavin-5′-phosphate), niacin (vitamin B3, as niacinamide), vitamin B6 (as pyridoxine hydrochloride), folic acid, vitamin C, vitamin D, calcium (as calcium carbonate), magnesium (as magnesium taurate), aged garlic extract, olive leaf extract (as 20% oleuropein), coenzyme Q10 (as ubiquinol), L-Arginine (as hydrochloride), L-Citrulline (as malate), and lycopene.

Owner:STAMPALIA ANTHONY

Flame-retardant film

A flame retardant film comprising a polyester-containing film, the polyester-containing film comprising a flame retardant layer on a side thereof. The flame retardant layer includes a colloidal metal oxide in an amount of 6 g / m or more, an inorganic binder in an amount of 2 g / m or more, the first flame retardant being a phosphorus-containing compound in an amount of 10 g / m or more, and the second flame retardant being a phosphorus-containing compound in an amount of 10 g / m or more. And the second flame retardant is an inorganic compound selected from the group consisting of aluminum hydroxide, aluminum trihydrate, magnesium hydroxide, calcium magnesium carbonate, magnesium carbonate hydrate, alumina hydroxide, a boron compound, antimony trioxide, and combinations thereof in an amount of 6 g / m or more.

Owner:AGFA GEVAERT AG

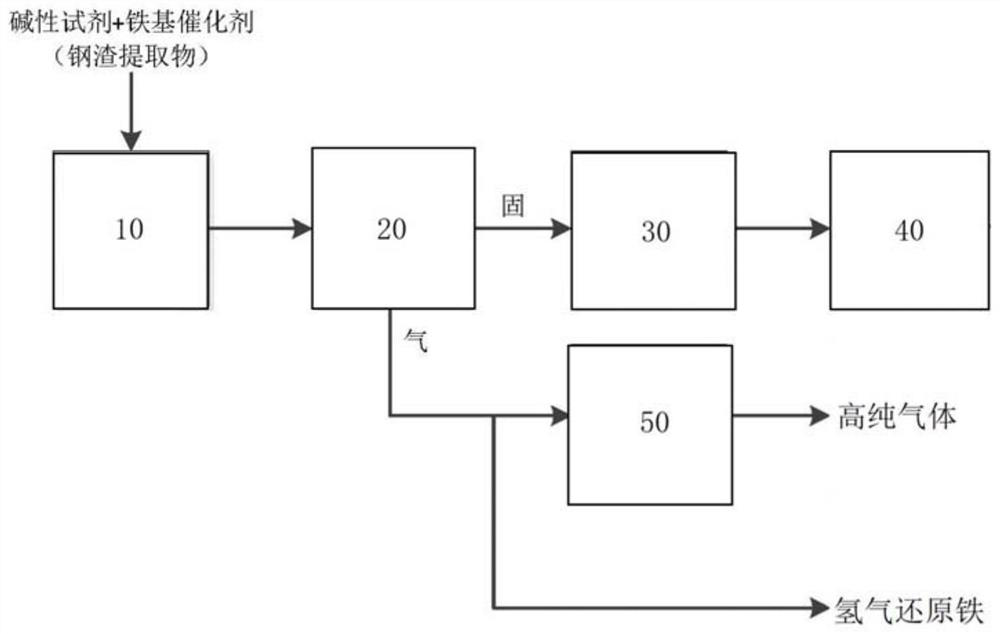

System for preparing hydrogen and biochar from biomass based on steel slag extract

PendingCN111676037AThe pre-processing process is simpleEasily damagedBiofuelsCatalyst activation/preparationPtru catalystSlag

The invention discloses a system for preparing hydrogen and biochar from biomass based on a steel slag extract. The system comprises a pretreatment system, a heat treatment system in which mixed reactants fully react, a solid collection system used for collecting solid residues obtained after the reaction in the heat treatment system, and a gas collection system used for collecting gas obtained after the reaction in the heat treatment system. According to the method, a calcium-magnesium alkaline reagent in the steel slag extract is used as one of reactants and can absorb moisture in the biomass raw material, so that the damage to the biomass structure and the hydrogen production reaction are facilitated, and the pretreatment of the biomass raw material is simplified. An iron-based catalystextracted from the stainless steel slag is used as a byproduct and is low in price, and batch production can be achieved. The solid residues obtained after biomass hydrogen production are mixed in sintering raw materials for iron making for use, and meanwhile biochar, calcium magnesium carbonate and an iron-based catalyst in the solid residues can be fully recycled.

Owner:瀜矿环保科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com