System for preparing hydrogen and biochar from biomass based on steel slag extract

A technology of biomass and extracts, which is applied in the field of hydrogen and biochar preparation systems, can solve the problems of high price of Ni-based catalysts, difficult separation and circulation, etc., and achieve the effect of simplified pretreatment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

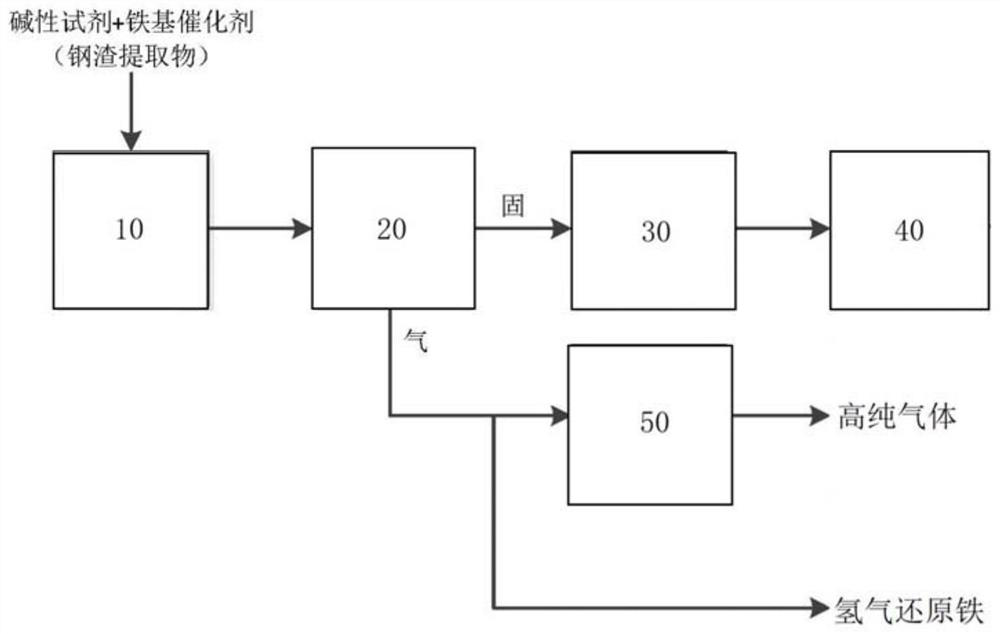

[0040] Such as figure 1 As shown, in one of the embodiments of the present application, a system for preparing hydrogen and biochar from biomass based on iron and steel slag extract, the system includes:

[0041] The pretreatment system 10 is used to pretreat the biomass, iron-based catalyst and alkaline reagent and mix them according to a mixing ratio;

[0042] A heat treatment system 20, the mixed reactants are fully reacted in the heat treatment system 20;

[0043] A solid collection system 40, which is arranged in communication with the slag outlet of the heat treatment system 20, and is used to collect the above-mentioned solid residues reacted by the heat treatment system 20;

[0044] And a gas collection system, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com