Composite material for locomotive cable outer sheath, preparation method of the composite material, the cable outer sheath and locomotive cable

A technology for locomotive cables and composite materials, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems that the combustion performance and ultra-high and low temperature resistance cannot meet the requirements, and achieve the effect of good flame retardant performance and high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention also provides a preparation method of a composite material used for the outer sheath of a locomotive cable, which includes: mixing the components in the raw materials. The obtained outer sheath has very excellent flame retardancy and high and low temperature resistance performance after being used in cables.

[0033] Further, the mixing temperature is 130-170° C., and the mixing time is 5-15 minutes; preferably, the mixing temperature is 140-160° C., and the mixing time is 7-9 minutes. It is advisable to control the mixing temperature and mixing time within the above range, so that all components can be fully mixed and uniform, and the flame retardancy and high and low temperature resistance of the material can be guaranteed.

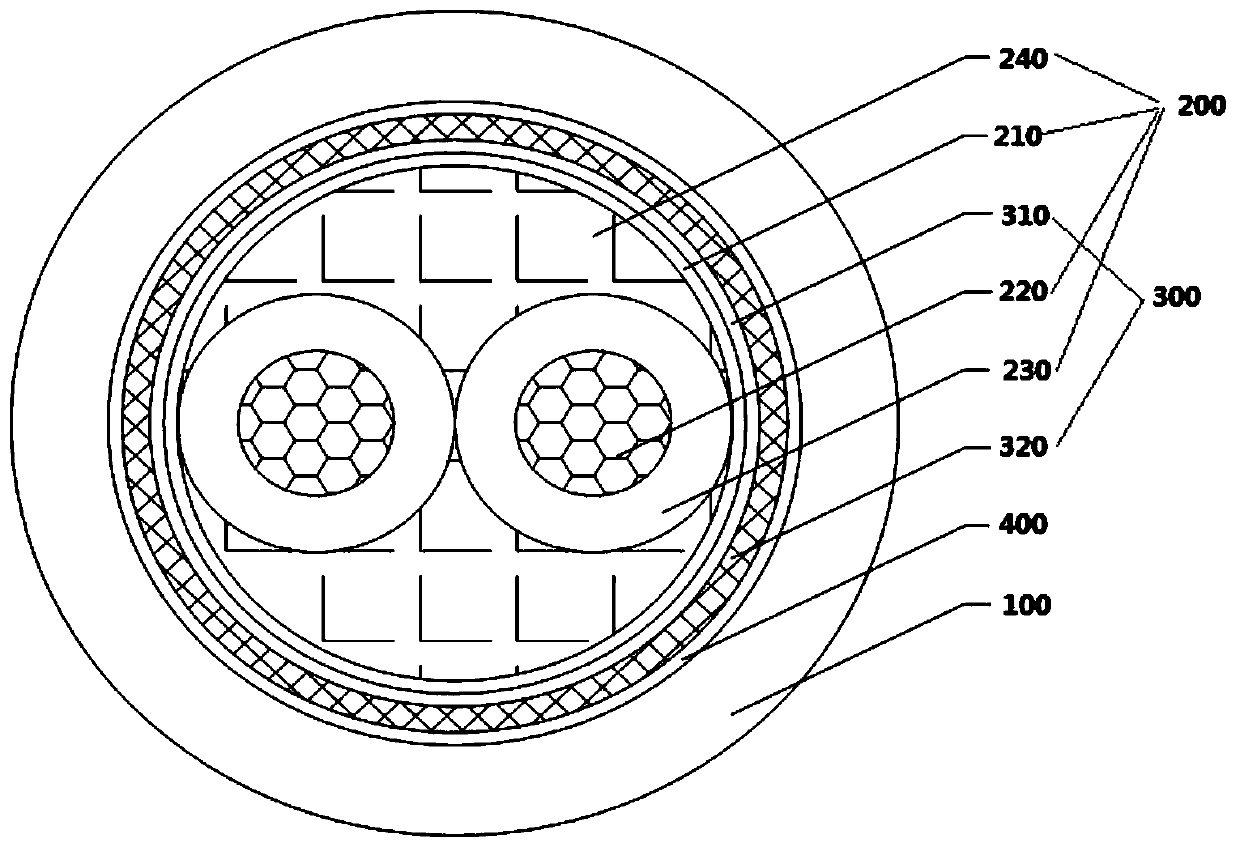

[0034]The embodiment of the present invention also provides a cable outer sheath, which is prepared from the above-mentioned composite material. The preparation method of the cable outer sheath belongs to ...

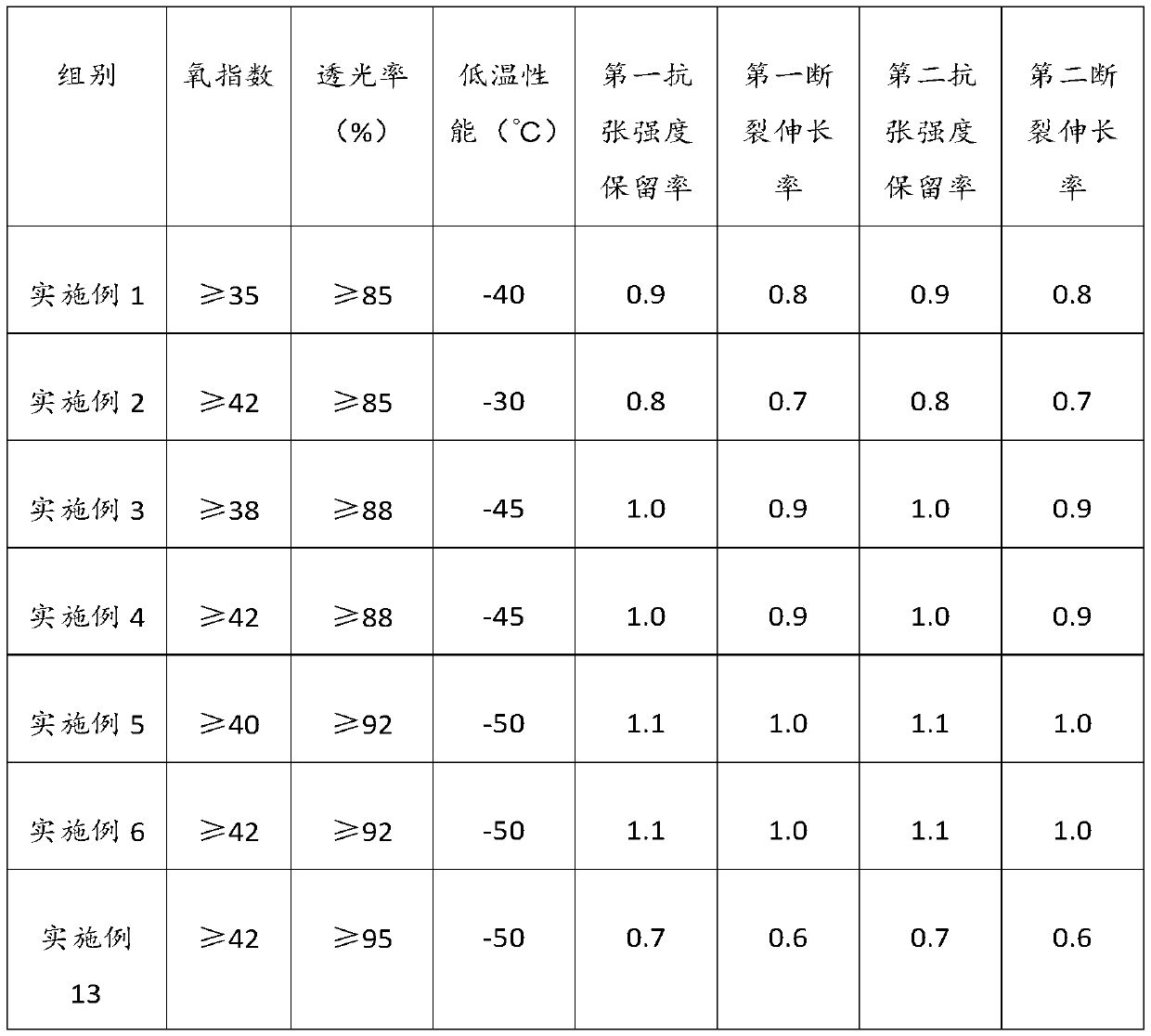

Embodiment 1

[0046] This embodiment provides a composite material for the outer sheath of a locomotive cable, and its raw materials include 12 parts of ethylene-vinyl acetate copolymer resin, 2 parts of polyolefin elastomer resin, linear low-density polyethylene 13 parts of resin, 1 part of high-density polyethylene resin, 3 parts of maleic anhydride grafted POE, 0.1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, triene 0.1 part of propyl isocyanurate, 1 part of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 20 parts of calcium magnesium carbonate and polysiloxane flame retardant 1 serving.

[0047] This embodiment provides a method for preparing a composite material for the outer sheath of a locomotive cable, comprising mixing the above-mentioned raw materials provided in this embodiment in proportion, and stirring at 130° C. for 15 minutes.

[0048] This embodiment provides a cable outer sheath, which is extruded from the composite materia...

Embodiment 2

[0051] This embodiment provides a composite material for the outer sheath of a locomotive cable, and its raw materials include 23 parts of ethylene-vinyl acetate copolymer resin, 7 parts of polyolefin elastomer resin, linear low-density polyethylene 25 parts of resin, 4 parts of high-density polyethylene resin, 10 parts of maleic anhydride grafted POE, 0.8 parts of dilauryl thiodipropionate, 0.8 parts of triallyl isocyanurate, 9,10-dihydro -13 parts of 9-oxa-10-phosphaphenanthrene-10-oxide, 50 parts of calcium magnesium carbonate and 7 parts of polysilaboroxane flame retardant.

[0052] This embodiment provides a method for preparing a composite material for the outer sheath of a locomotive cable, comprising mixing the above-mentioned raw materials provided in this embodiment in proportion, and stirring at 170° C. for 5 minutes.

[0053] This embodiment provides a cable outer sheath, which is extruded from the composite material prepared by the above preparation method.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com