Acid soil conditioner and preparation method thereof

A soil conditioner and acidic soil technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve problems such as difficulty in releasing active calcium and magnesium ions, low soil activity, and affecting agronomic effects, etc., to achieve Conducive to soil improvement, increase utilization rate, meet the effect of soil improvement and plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

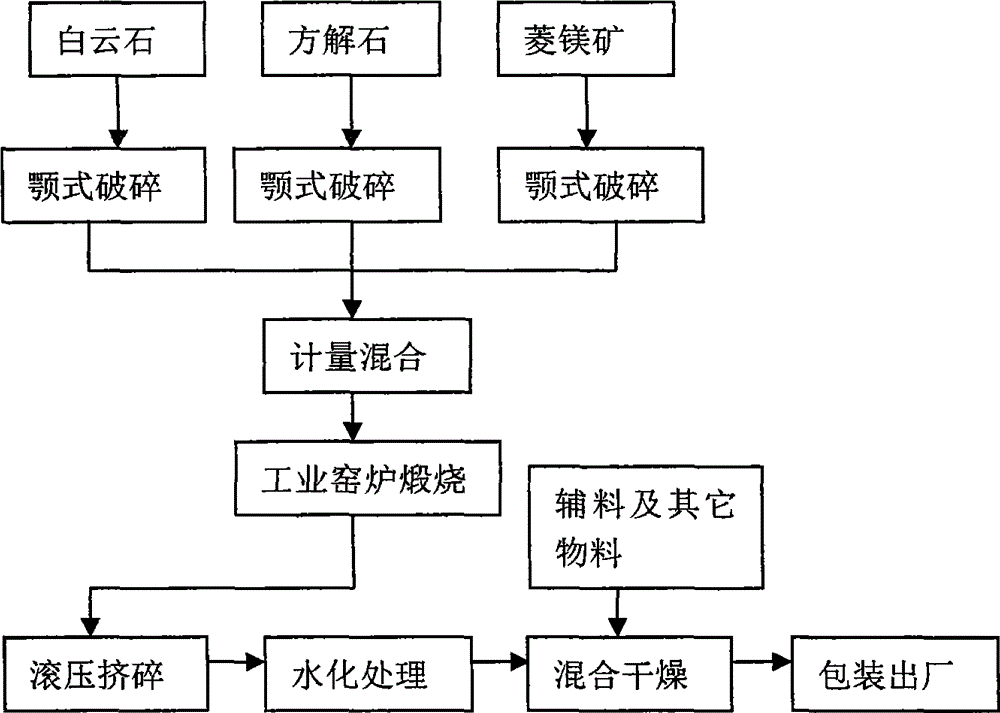

Method used

Image

Examples

Embodiment 1

[0064] Raw materials: Dolomite with a purity of more than 95%, the feeding ratio is 100%; use a jaw crusher to crush the dolomite material to a particle size of 20-50mm; pass through a vertical preheater, and the preheating temperature is 260-300 degrees; The preheated material is sent to the rotary kiln for calcination, and a ball mill extrusion device is installed in the high temperature zone inside the rotary kiln and the heat preservation zone in the rear section. The calcination temperature is 910 degrees, the holding time is 30 minutes, and the loss-of-fire rate is controlled at about 38%; the material is hydrated after leaving the kiln, and the material in the stirring state is sprayed with water to make the hydration reaction of the surface oxide of the material The ratio is controlled so that it does not exceed 10% of the material after cooling; a single dolomite-type calcined product is obtained, and its active ingredients are: calculated as oxides, CaO+MgO≥40%, of wh...

Embodiment 2

[0066] Raw material 1: dolomite with a purity of more than 95%; the feeding ratio is 59%; raw material 2: calcite with a purity of more than 95% and a feeding ratio of 41%; use a jaw crusher to crush the dolomite to a particle size of 20- 50mm; through the vertical preheater, the preheating temperature is 260-300 degrees; the preheated material is sent to the rotary kiln for calcination, and a ball mill extrusion device is installed in the high temperature zone inside the rotary kiln and the rear heat preservation zone. The calcination temperature is 960 degrees, the holding time is 40 minutes, and the loss-of-fire rate is controlled at about 35%. The material is hydrated after leaving the kiln. The ratio is controlled so that it does not exceed 10% of the material after cooling; the high-calcium ratio calcined product is obtained, and its active ingredients are: calculated as oxides, CaO+MgO≥40%, of which, CaO30%, MgO10%, CaO / MgO The content ratio is 3.0; the compound ratio: ...

Embodiment 3

[0068]Raw material 1: dolomite with a purity of more than 95%; the feeding ratio is 45%; raw material 2: magnesite with a purity of more than 95%; the feeding ratio is 55%; the dolomite ore is crushed to the particle size with a jaw crusher 20-50mm; through the vertical preheater, the preheating temperature is 260-300 degrees; the preheated material is sent to the rotary kiln for calcination, and a ball mill extrusion device is installed in the high temperature zone inside the rotary kiln and the rear insulation zone . The calcination temperature is 910 degrees, the holding time is 30 minutes, and the loss-of-fire rate is controlled at about 38%. The material is hydrated after it leaves the kiln, and water is sprayed on the material in the stirring state to cause the hydration reaction of the surface oxide of the material. The ratio is controlled so that it does not exceed 10% of the material after cooling; a high-magnesium ratio calcined product is obtained, and its active in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com