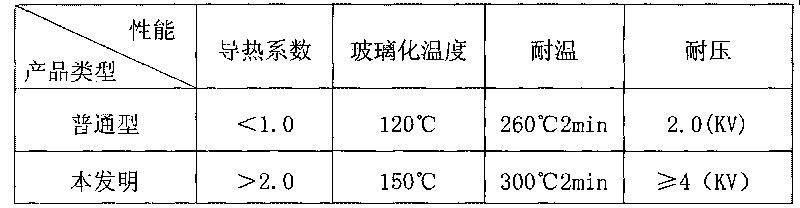

High-Tg high-thermal conductivity aluminium-based copper-clad laminate

An aluminum-based copper cladding, high thermal conductivity technology, applied in layered products, metal layered products, chemical instruments and methods, etc. and other problems, to achieve the effect of large thermal conductivity and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] A high Tg high thermal conductivity aluminum-based copper-clad laminate, including a copper layer and an aluminum layer, an insulating layer is coated between the copper layer and the aluminum layer, and the composition of the insulating layer includes epoxy resin, dimethyl Imidazole, propylene glycol methyl ether and filler, wherein the mass percentage of each composition is: epoxy resin 55-73%, dimethylimidazole 0.06-0.20%, propylene glycol methyl ether 10-22.94% and filler 10-22%.

[0018] Above-mentioned epoxy resin is the epoxy resin of a kind of brominated multifunctional two-component system, wherein, the two-component of described epoxy resin is component A and component B, wherein component A and component The mass percentage between B is: 1:0.45~0.56, and the appearance of component A is dark yellow or brownish yellow liquid, epoxy equivalent is 200~220g / eq, solid content is 82±1wt%, bromine content is 0 , the viscosity is 2000-3000; the appearance of the comp...

Embodiment 1

[0021] A high Tg high thermal conductivity aluminum-based copper-clad laminate, including epoxy resin, dimethylimidazole, propylene glycol methyl ether and fillers, wherein the mass percentage of each composition is: epoxy resin 55.00%, dimethyl Imidazole 0.06%, propylene glycol methyl ether 22.94%, filler 22.00%, and epoxy resin includes component A and component B, wherein, the mass percentage of component A and component B is 1: 0.45, and filler is 100% Silica powder.

Embodiment 2

[0023] A high Tg high thermal conductivity aluminum-based copper-clad laminate, including epoxy resin, dimethylimidazole, propylene glycol methyl ether and fillers, wherein the mass percentage of each composition is: epoxy resin 73.00%, dimethyl Imidazole 0.20%, propylene glycol methyl ether 10.00%, filler 17.80%, and epoxy resin comprises component A and component B, wherein, the mass percent of component A and component B is 1: 0.50, and filler is silicon micropowder and The mixture of boron nitride, the mass percentage of silicon micropowder and boron nitride is 0.7:0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com