Cable for charging facility of electric automobile

A technology for charging facilities and electric vehicles, applied in the direction of power cables, bendable cables, insulated cables, etc., can solve problems that have not been seen in technical revelations, and achieve the effects of avoiding damage, prolonging service life, and good pressure-bearing support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

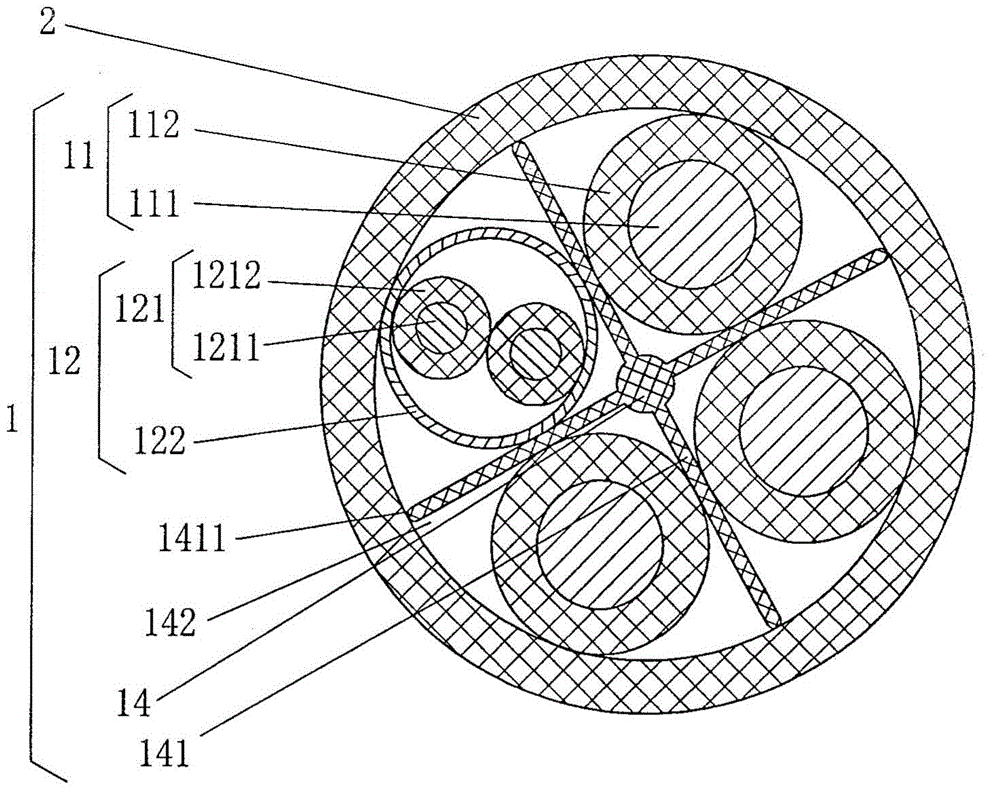

[0030] See figure 1 , figure 1 It is a cross-sectional schematic diagram of a cable used for electric vehicle charging facilities of the present invention, including a cable core 1 and a sheath layer 2 outside the cable core 1, and the cable core 1 includes a power line 11 and a signal line pair 12, and the power line 11 and the signal line The pairs 12 are located in the sheath layer 2 together, that is to say, the sheath layer 2 is extruded outside the power line 11 and the signal line pair 12 according to the usual sheath extrusion process in the production of electric wires and cables.

[0031]As the technical gist of the technical solution provided by the present invention: the aforementioned cable core 1 also includes a cable core supporting framework 14, which is located on the sheath layer 2 in the state accompanied by the aforementioned power line 11 and signal line pair 12 Inside, and the cable core support frame 14 has a group of support frame wings 141, the number...

Embodiment 2

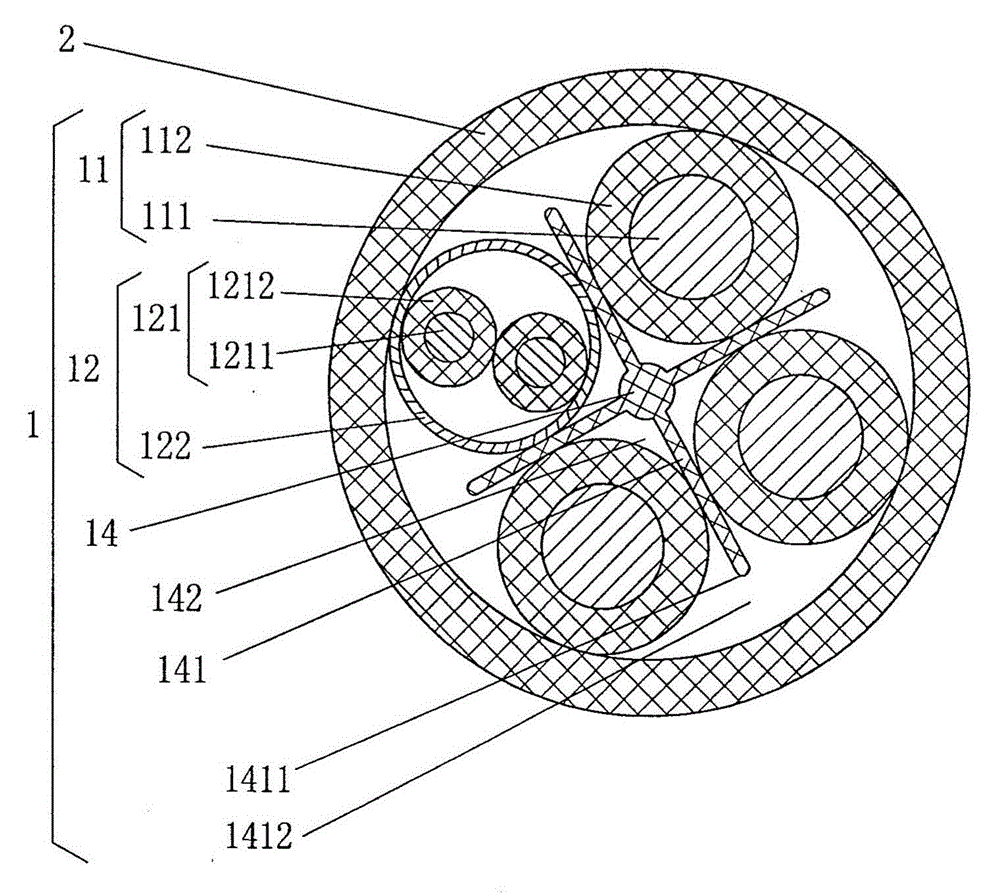

[0039] See figure 2 , in this embodiment, since the support skeleton wing space 1412 is maintained between the aforementioned support skeleton wing end face 1411 and the sheath layer 2, the support skeleton wing 141 is formed into a half-section support skeleton wing, thereby separating the wire into the cavity 142 constitutes a semi-closed cavity. All the other are the same as the description to embodiment 1.

Embodiment 3

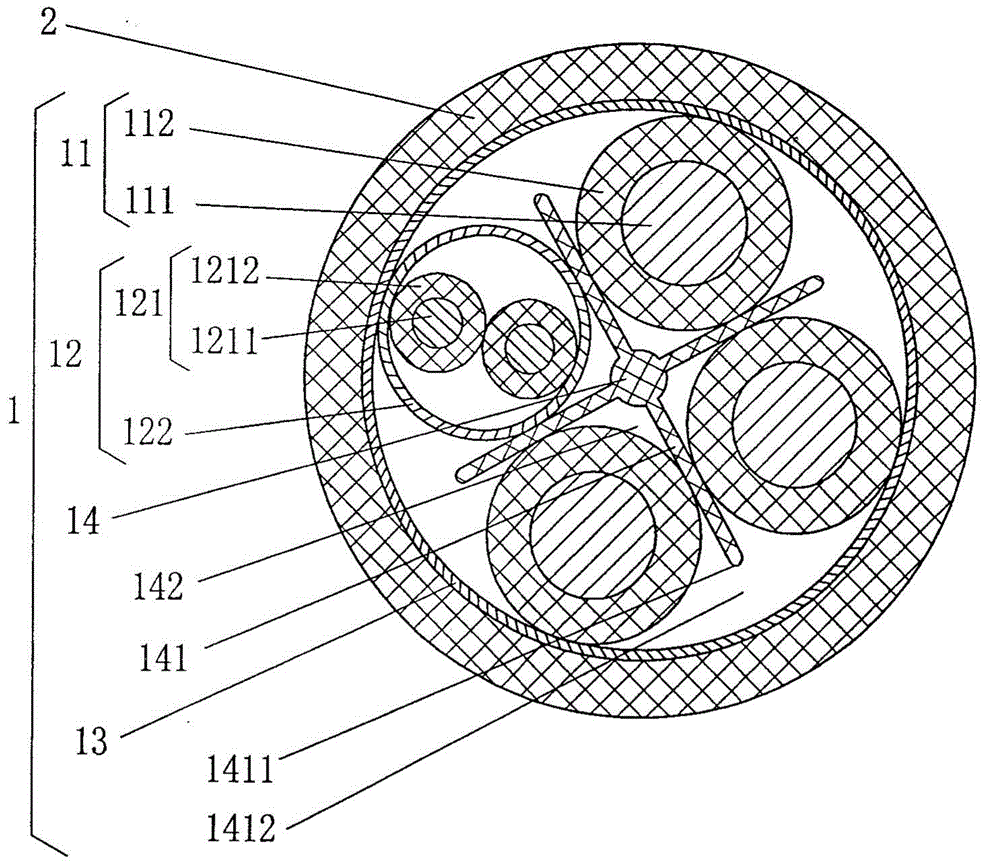

[0041] See image 3 A shielding layer 13 is added to the structural system of the aforementioned cable core 1, and the aforementioned power line 11, signal line pair 12 and cable core support frame 14 are located in the shielding layer 13 together. Due to the existence of the shielding layer 13, the aforementioned sheath Layer 2 is extruded outside the shielding layer 13. Since the supporting frame wing end face 1411 of a group of supporting frame wings 141 of the cable core supporting frame 14 and the shielding layer 13 maintain a supporting frame wing space 1412, thereby making a group of supporting frame wings 141 is formed as a half-section supporting frame wing, and the wire separation cavity 142 is formed as a semi-closed cavity, that is, a semi-closed cavity. The aforementioned shielding layer 13 is a wire braided shielding layer. What the applicant needs to explain is that if the aforementioned support frame wing space 1412 is abandoned and the support frame wing end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com