Conveniently-disassembled mounting structure in small rudder cabin

A technology that facilitates disassembly and installation of the structure, applied in the field of machinery, can solve the problems of reducing the positioning accuracy of rudder installation, affecting the service life of the rudder shaft, and limiting the installation space of the rudder shaft, and achieves a compact structure, reliable bearing capacity, and simple processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

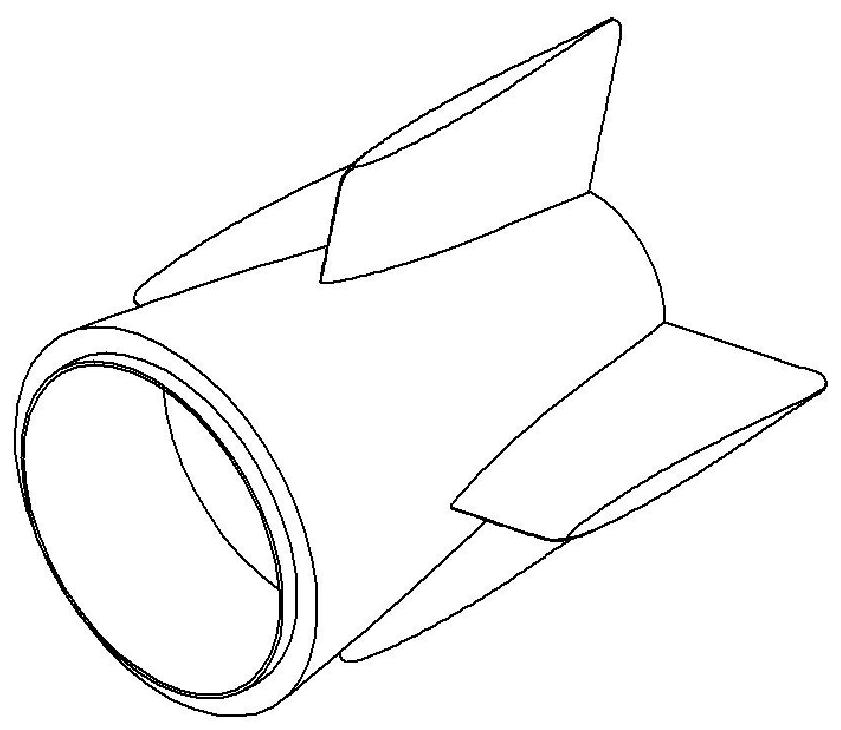

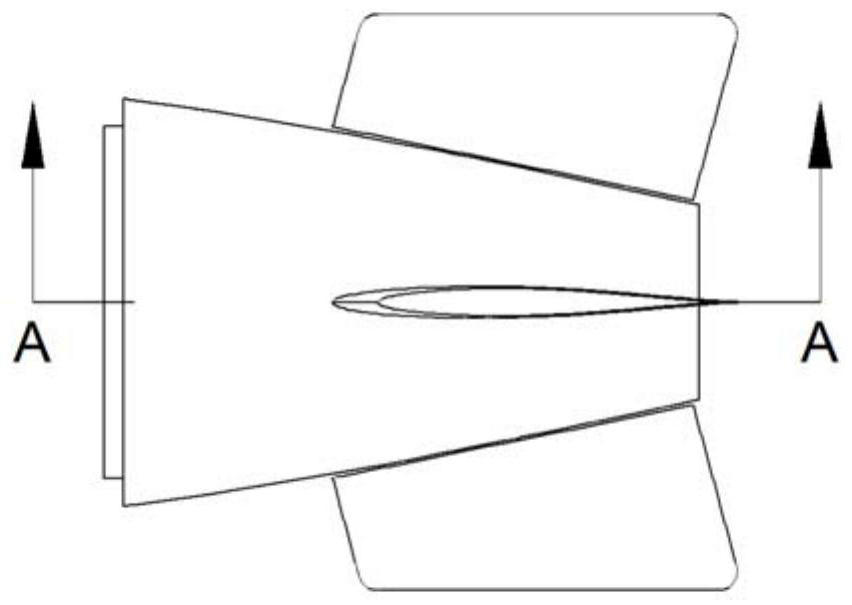

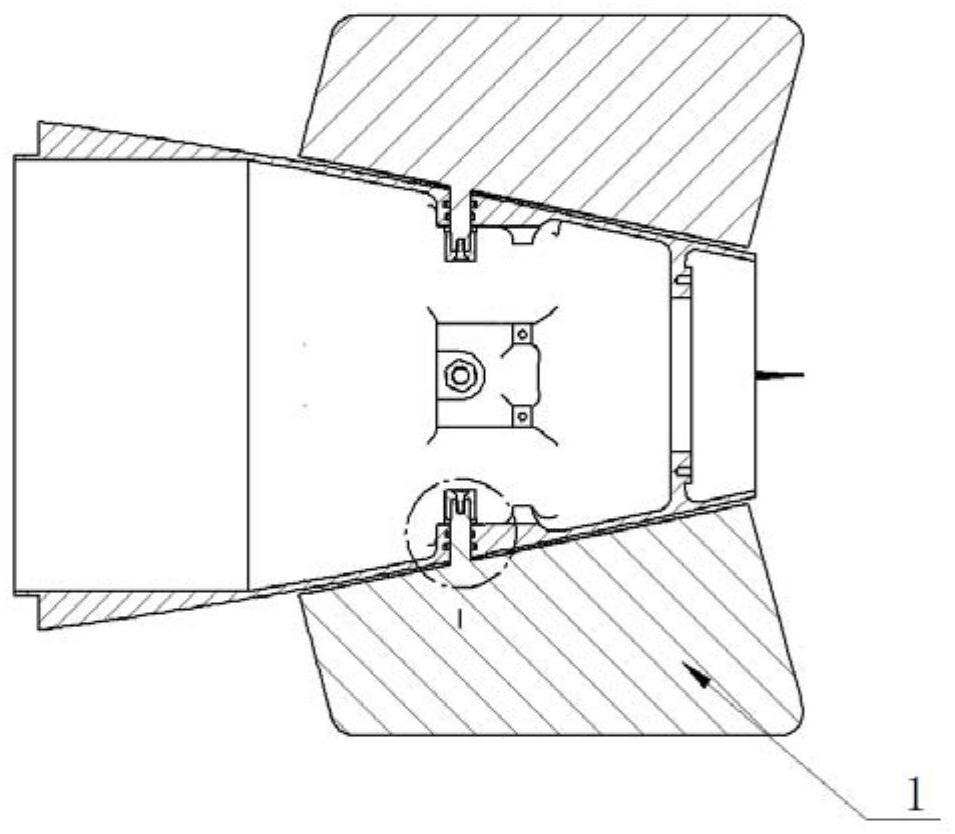

[0028] like figure 1 As shown, the present invention provides a small rudder cabin installation structure that is convenient to disassemble, including rudder blade 1, rudder shaft 2, housing 3, rotating grid ring 4, O-shaped sealing ring 5, lubricating gasket 7, rudder shaft Set 8, countersunk head screw 9 and steering gear.

[0029] There are multiple rudder blades, and they are evenly distributed on the outer side of the shell in the circumferential direction, and are used to control the overall flight depth, heading and roll. Each rudder blade is driven by the steering gear, and the rudder shaft transmits torque to drive it to rotate, and all the steering gears are installed inside the housing. The lower end of the rudder shaft is connected with the rudder blade, and the rudder shaft and the rudder blade are integrally processed. The upper end of the rudder shaft passes through the shell respectively, and is connected with the rudder shaft sleeve after lubricating the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com