Cavity polyhedron filling block and method of processing the same

A technology of filling blocks and polyhedrons, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of waste of resources, complex processing, fragmentation, etc., and achieve improved overall strength, good bearing performance, and strong integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

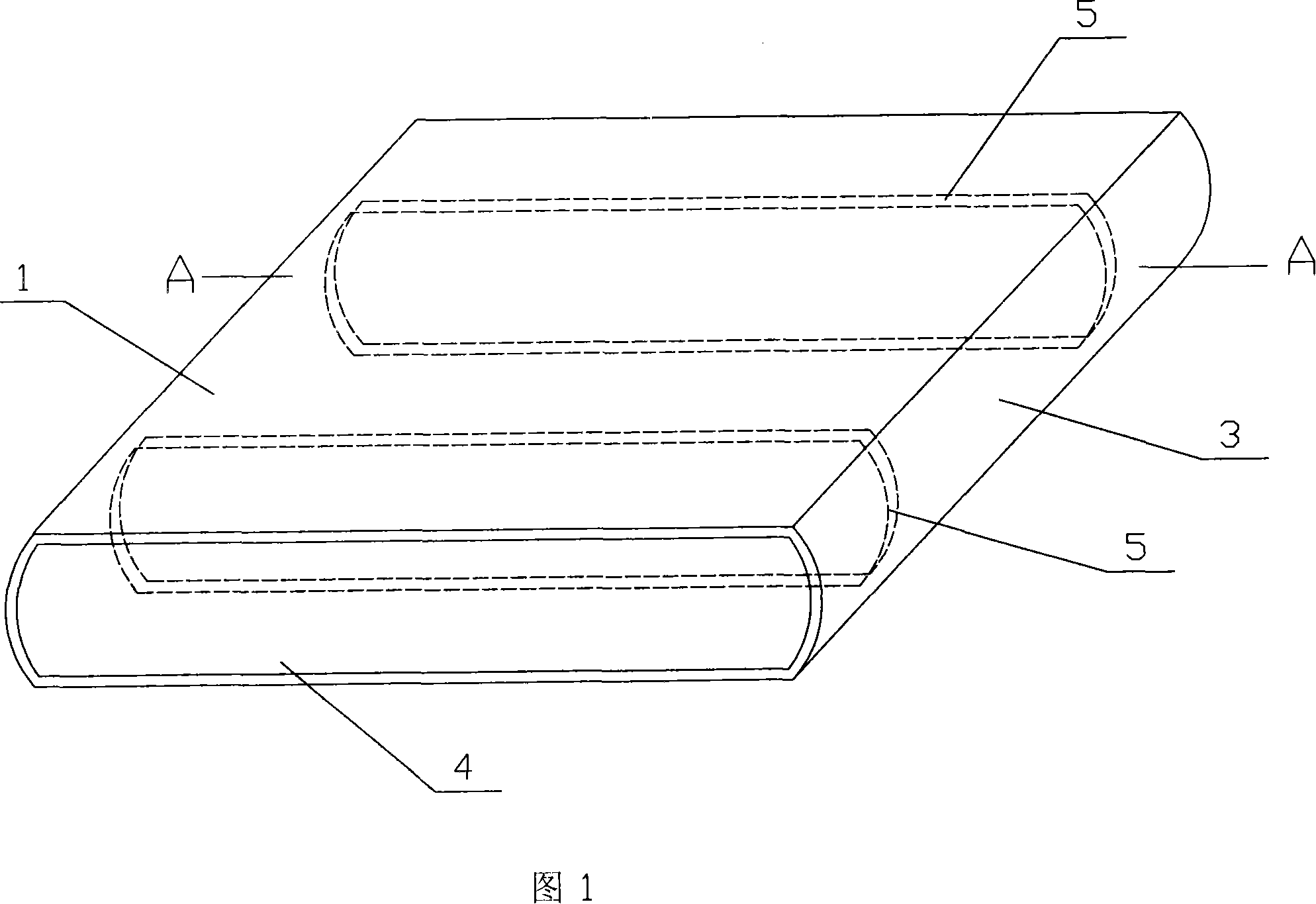

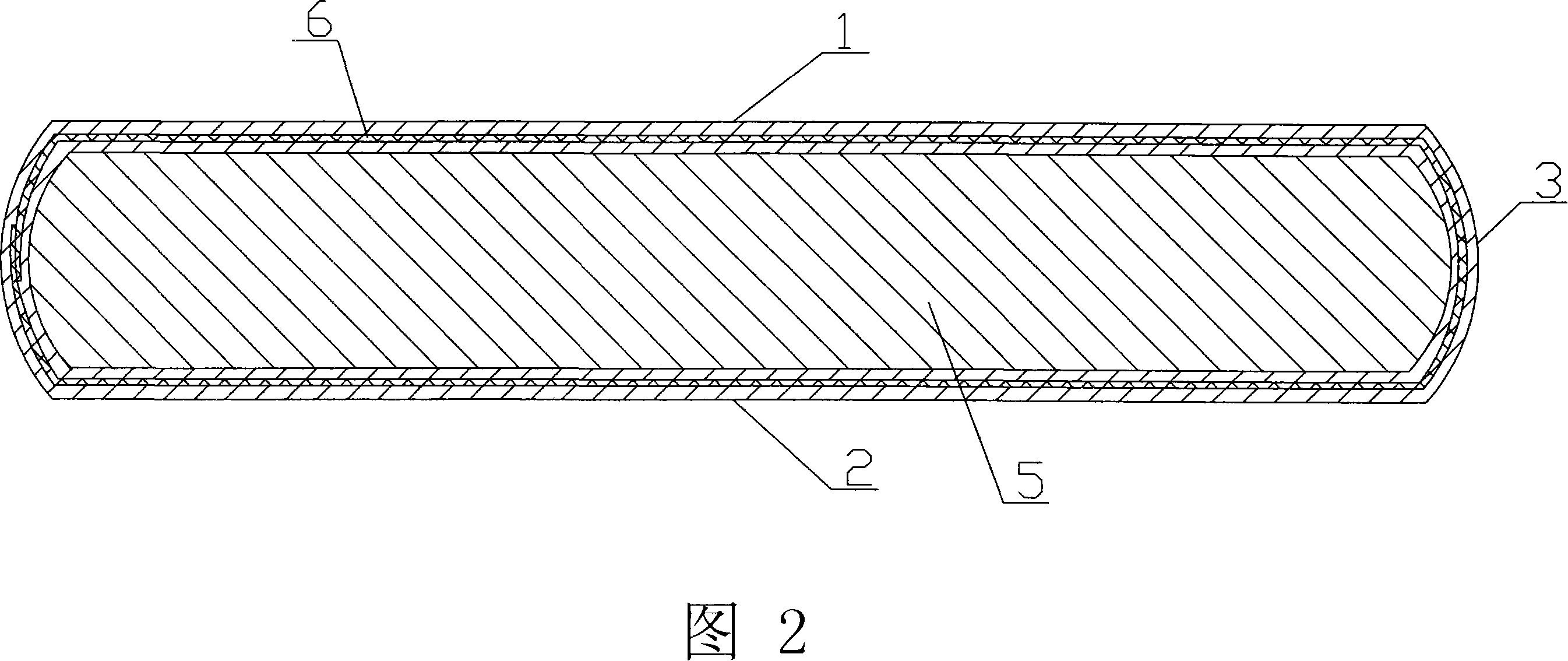

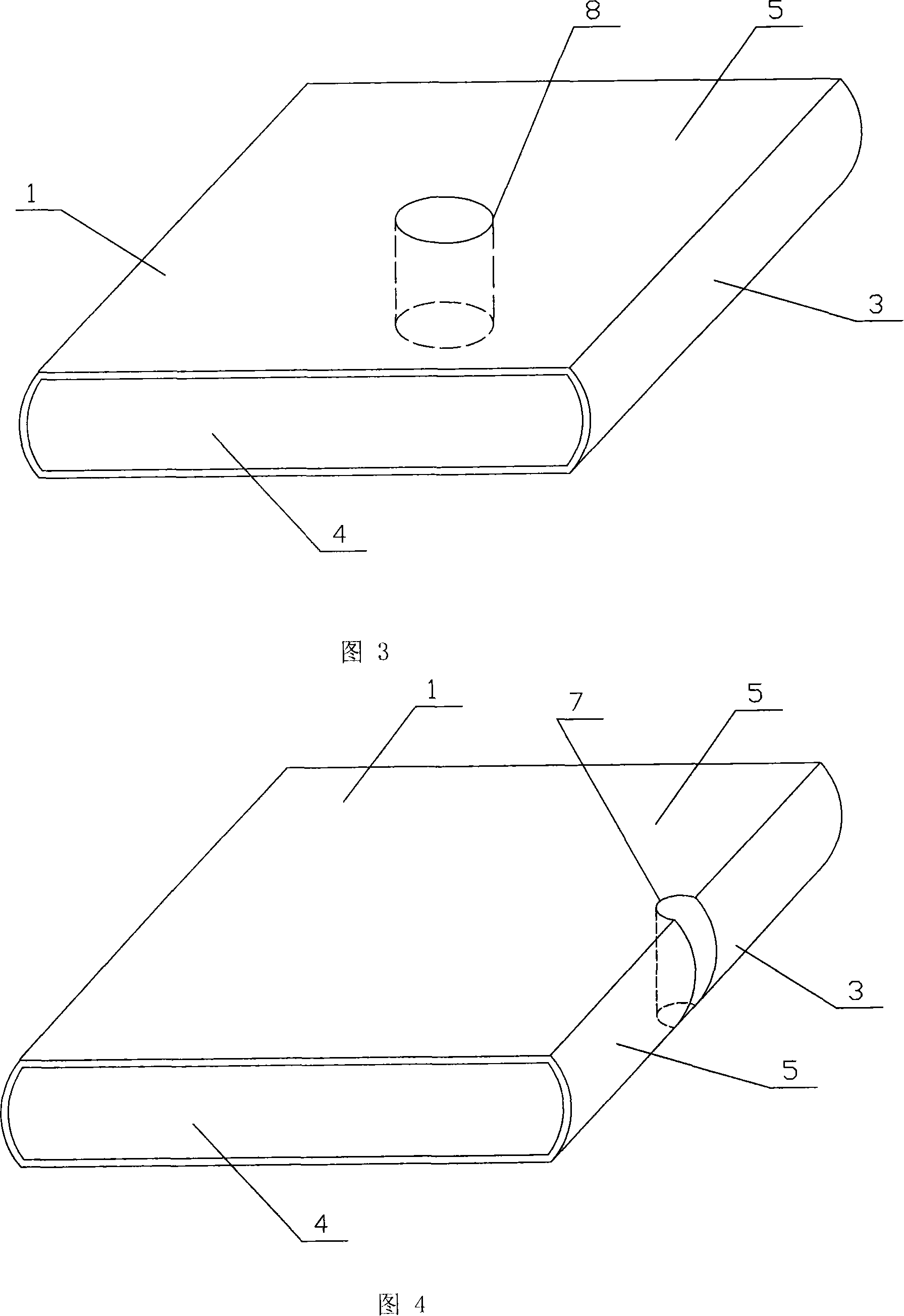

[0031] Embodiment 1 of the cavity polyhedron filling block of the present invention is shown in Fig. It is arc-connected with the top surface 1 and the bottom surface 2, and the top surface 1, the side surface 3 and the bottom surface 2 form an integrally formed non-cylindrical body. The two ends of the cylinder body are provided with prefabricated end plates 4 vertically connected to the top and bottom surfaces. The shape is rectangular in the middle, and the two ends are convex circular arcs, and the inner walls at both ends of the cylinder wrap the outer edge of the end plate 4 . The cavity of the cylinder body is provided with a prefabricated auxiliary board support body 5 vertically connected to the top and bottom surfaces. Its shape is a rectangular shape with convex arcs at both ends. A whole piece of reinforcing rib net 6 is stacked between them, the material of reinforcing rib net 6 is glass fiber net, and the cementitious material is cement mortar.

[0032] The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com