Stirring shaft mounting structure of stirring device

A stirring device and installation structure technology, applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve problems such as the loosening of the stirring shaft, and achieve the effect of firm installation and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

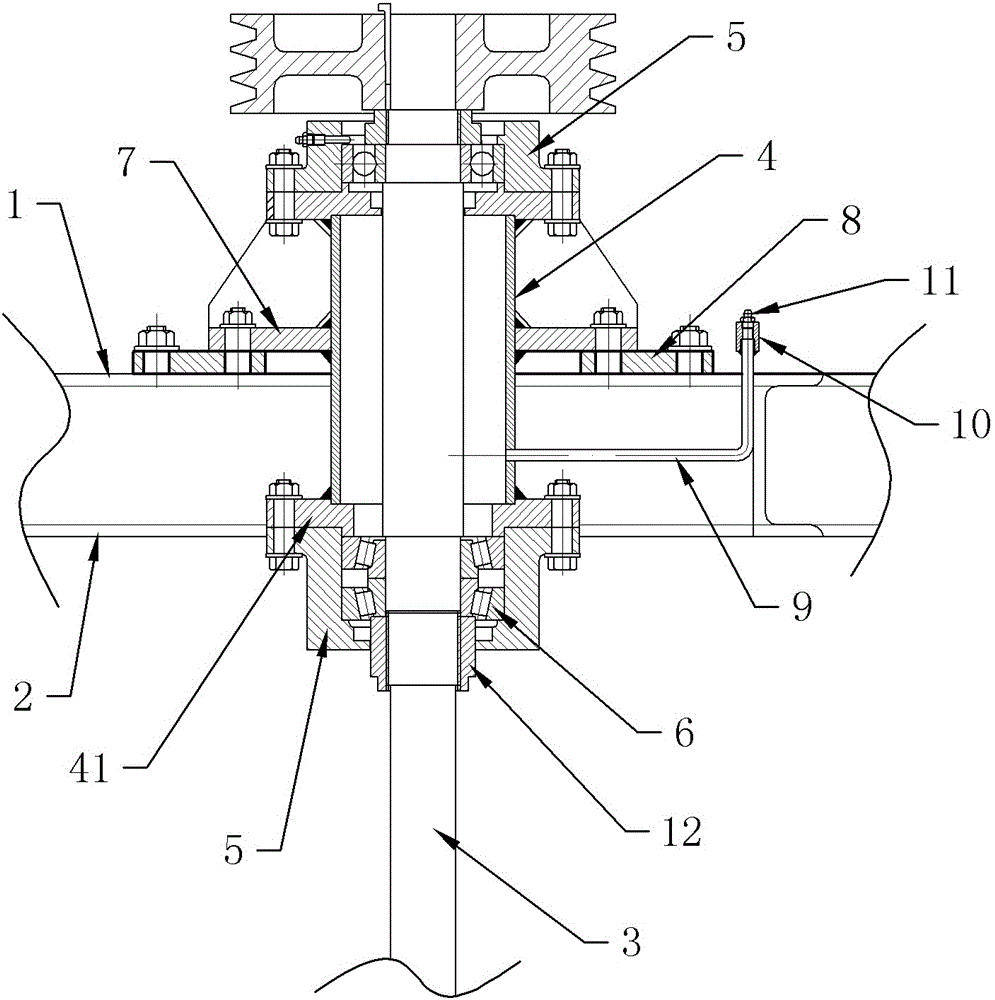

[0019] The embodiment is basically as attached figure 1 Shown: a stirring shaft installation structure of a stirring device, including a stirring shaft 3 and a mixing barrel, a support seat 7, a bearing seat 5 and a connecting cylinder 4 with flanges 41 at both ends, and the stirring barrel is provided with upper and lower The first mounting plate 1 and the second mounting plate 2 are arranged, the connecting cylinder 4 runs through the first mounting plate 1 and the second mounting plate 2, the support base 7 is connected to the first mounting plate 1 by bolts, and the support base 7 is connected to the first mounting plate 2. An anti-vibration pad 8 is provided between the mounting plate 1, flange-connected bearing housings 5 are installed at the upper and lower ends of the connecting cylinder 4 respectively, the bearing housing 5 at the upper end of the connecting cylinder 4 is connected to the supporting base 7 by bolts, and the stirring shaft 3 runs through The connecti...

Embodiment 2

[0023] The difference from Embodiment 1 is that the sealing structure is a sealing plug matched with the oil injection pipe 9 . The structure of sealing with a sealing plug is simple.

[0024] Specific working principle:

[0025] Let’s take Embodiment 1 as an example to illustrate: when installing, firstly insert the stirring shaft 3 into the connecting cylinder 4, respectively install the bearings into the bearing housing 5, and then connect the corresponding bearing housings 5 to the upper and lower ends of the connecting cylinder 4 respectively. Then connect the support seat 7 to the first mounting plate 1, and penetrate the connecting cylinder 4 into the first mounting plate 1 and the second mounting plate 2, and finally connect the bearing seat 5 on the upper end of the connecting cylinder 4 to the supporting seat 7 can be connected. This program is additionally equipped with a connecting cylinder 4 and a support seat 7. The bearing seat 5 mainly bears force through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com