Steam distributor and moisture separator reheater

A technology of steam distributor and steam channel, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., and can solve the problem of direct connection between the anti-scouring plate and the deflector, and the lack of drainage between the anti-scouring plate and the deflector Structure, water cannot be drained away, etc., to achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

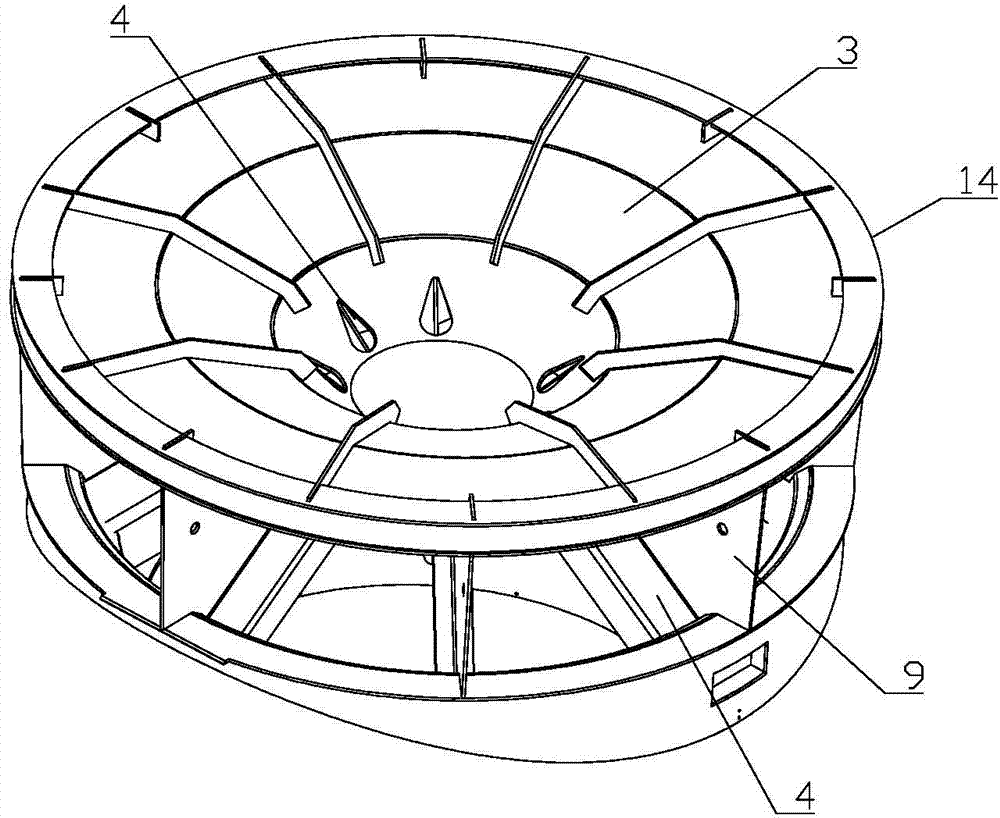

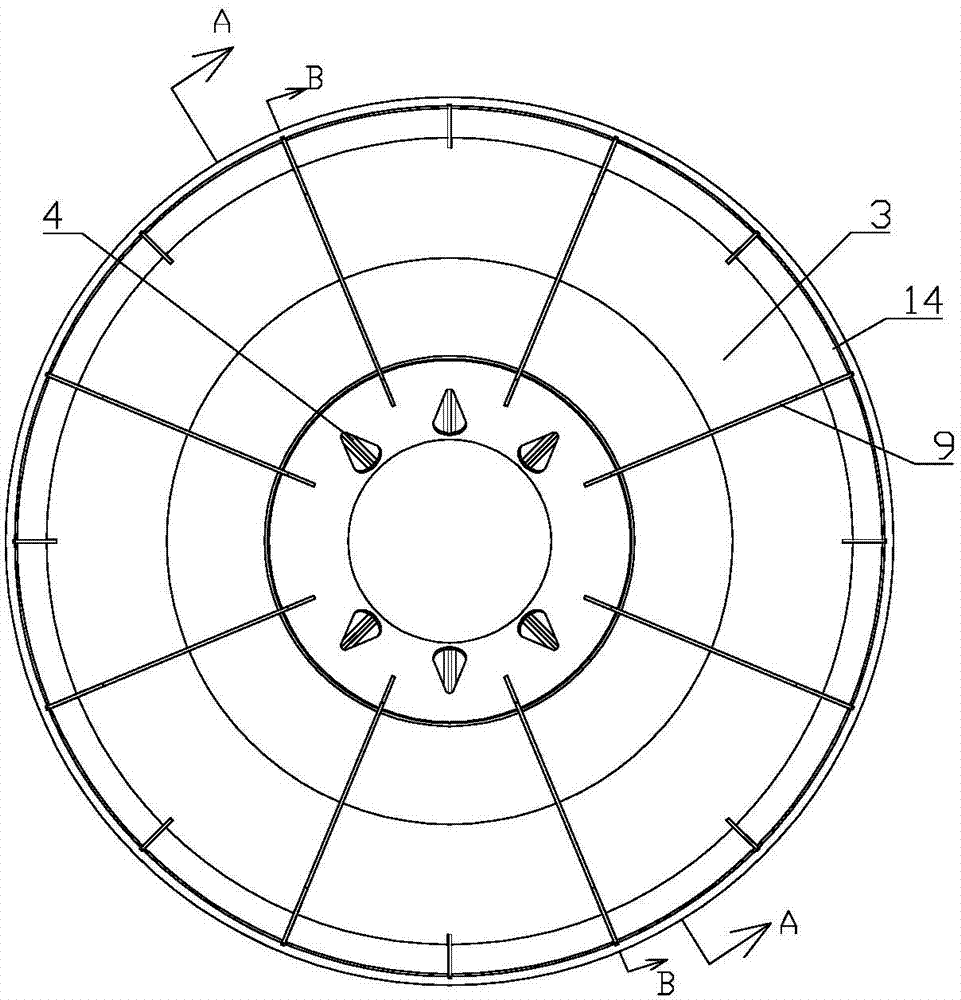

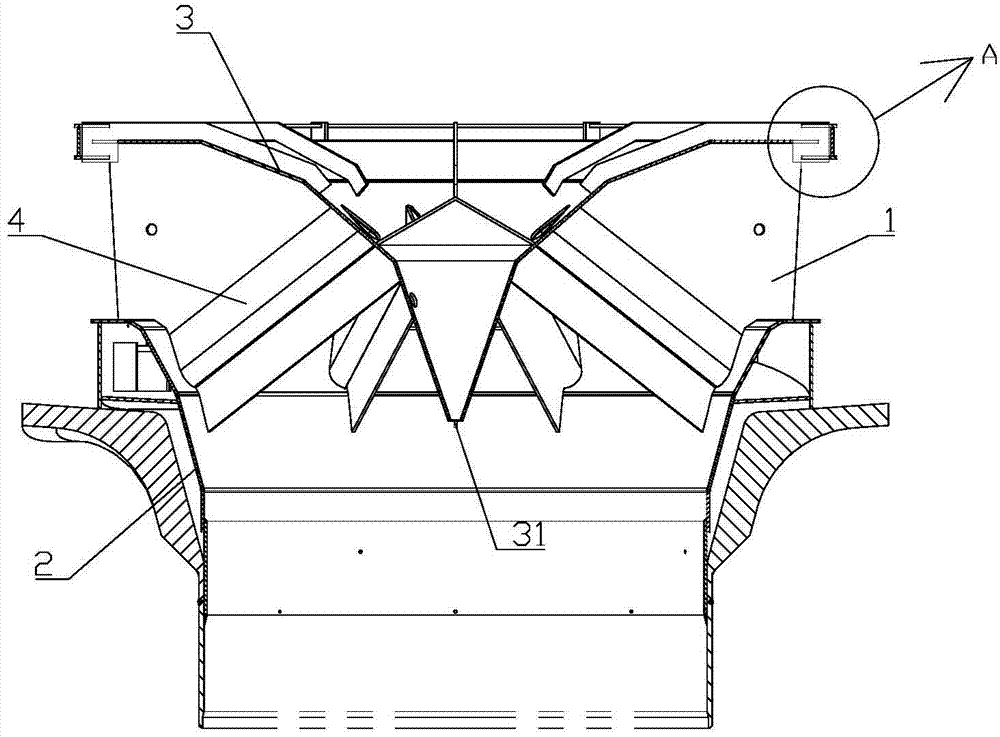

[0029] like Figure 1 to Figure 8 The shown steam distributor includes a steam passage 1 that enters from the bottom and diffuses around. The steam passage 1 is surrounded by a lower deflector 2 and an upper deflector 3 above the lower deflector 2 . The steam passage 1 is provided with a hydrophobic passage 4 connecting the lower deflector 2 and the upper deflector 3. The hydrophobic passage 4 connects the space above the upper deflector 3 with the peripheral space of the lower deflector 2, and condenses on the upper deflector. The water on the upper surface of the plate 3 is collected and discharged out of the steam distributor.

[0030] In this embodiment, both the lower deflector 2 and the upper deflector 3 are annular and concentric, and there are reinforcing ribs 9 between them to increase the strength of the structure and prevent the steam distributor from being damaged by the impact of steam. Structural damage occurs. Among them, the lower deflector 2 is welded end to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com