Tramcar basalt fiber composite road surface structure

A technology of basalt fiber and composite pavement, applied in roads, roads, special pavements, etc., can solve problems such as endangering the overall stability and safety of the pavement, interrupting traffic during maintenance and repair, affecting driving comfort, etc., and achieves convenient maintenance and repair in the later stage. , reduce maintenance costs, improve the effect of anti-cracking and anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Describe in detail below in conjunction with embodiment according to accompanying drawing:

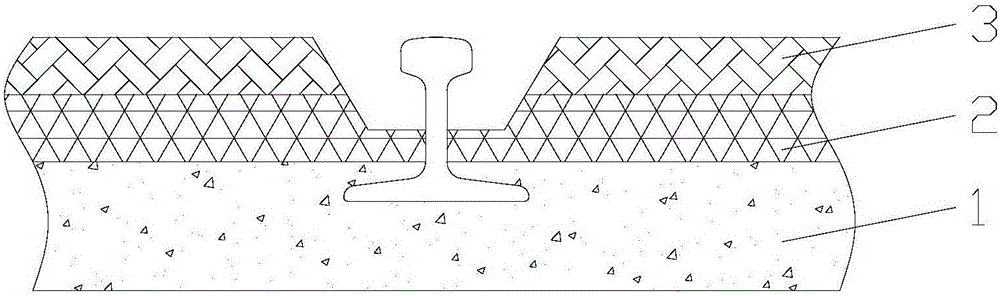

[0018] figure 1 It is a schematic diagram of a tram basalt fiber composite pavement structure of the present invention. The figure shows:

[0019] A tram basalt fiber composite pavement structure, which is sequentially provided with a basalt fiber concrete base (1), a basalt fiber medium-grain asphalt concrete layer (2), and a basalt fiber asphalt mastic macadam mixture layer from bottom to top (3); the basalt fiber concrete base (1) is mixed with chopped basalt fiber in concrete; the basalt fiber medium-grain asphalt concrete layer (2) is in the medium-grain asphalt concrete It is mixed with chopped basalt fiber; the basalt fiber asphalt mastic macadam mixture layer (3) is mixed with chopped basalt fiber in the flame-retardant asphalt mastic macadam mixture. made.

[0020] When a tram basalt fiber composite pavement structure of the present invention is specifically applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com