Patents

Literature

115results about How to "Improve anti-crack and anti-seepage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

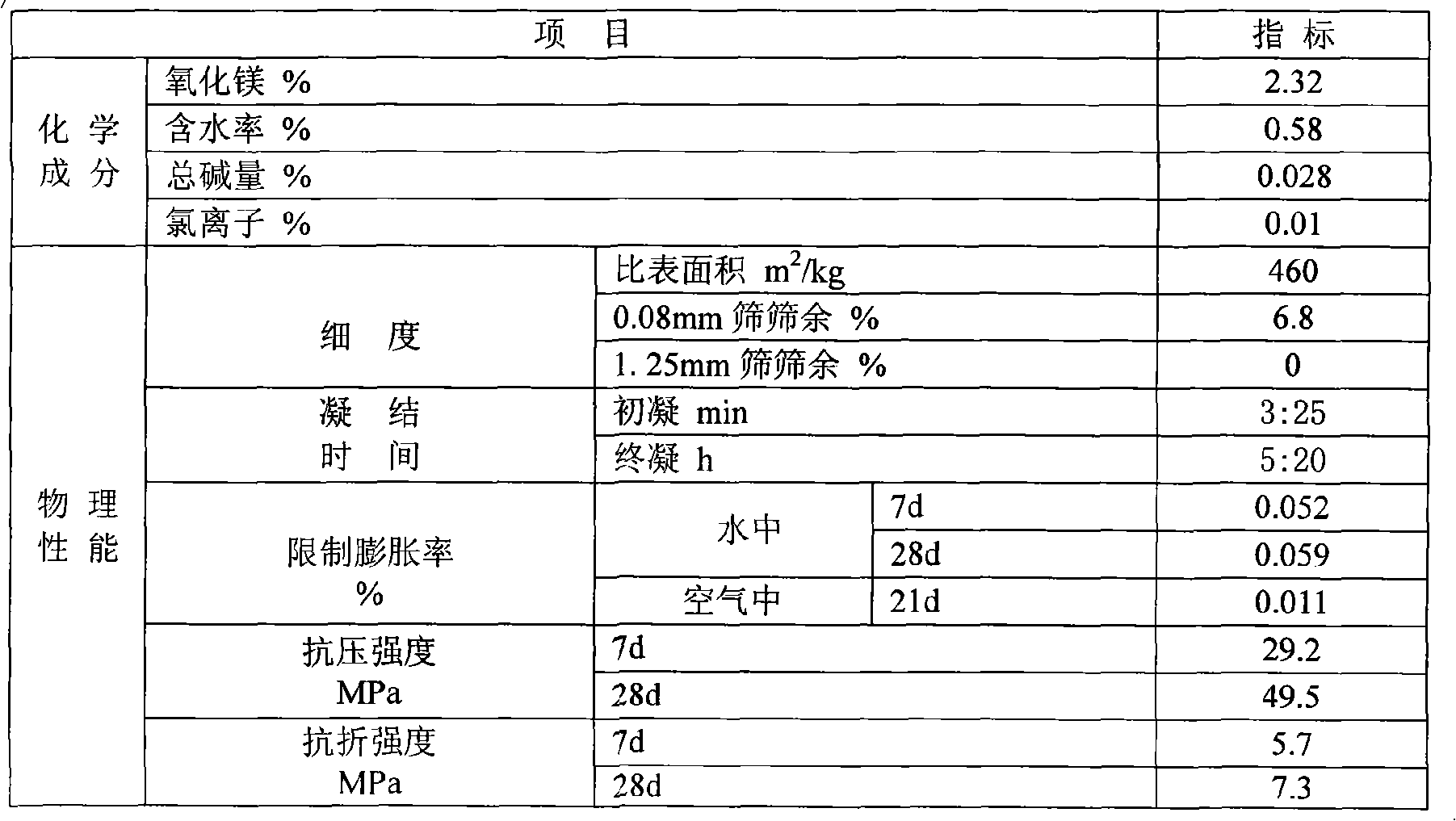

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

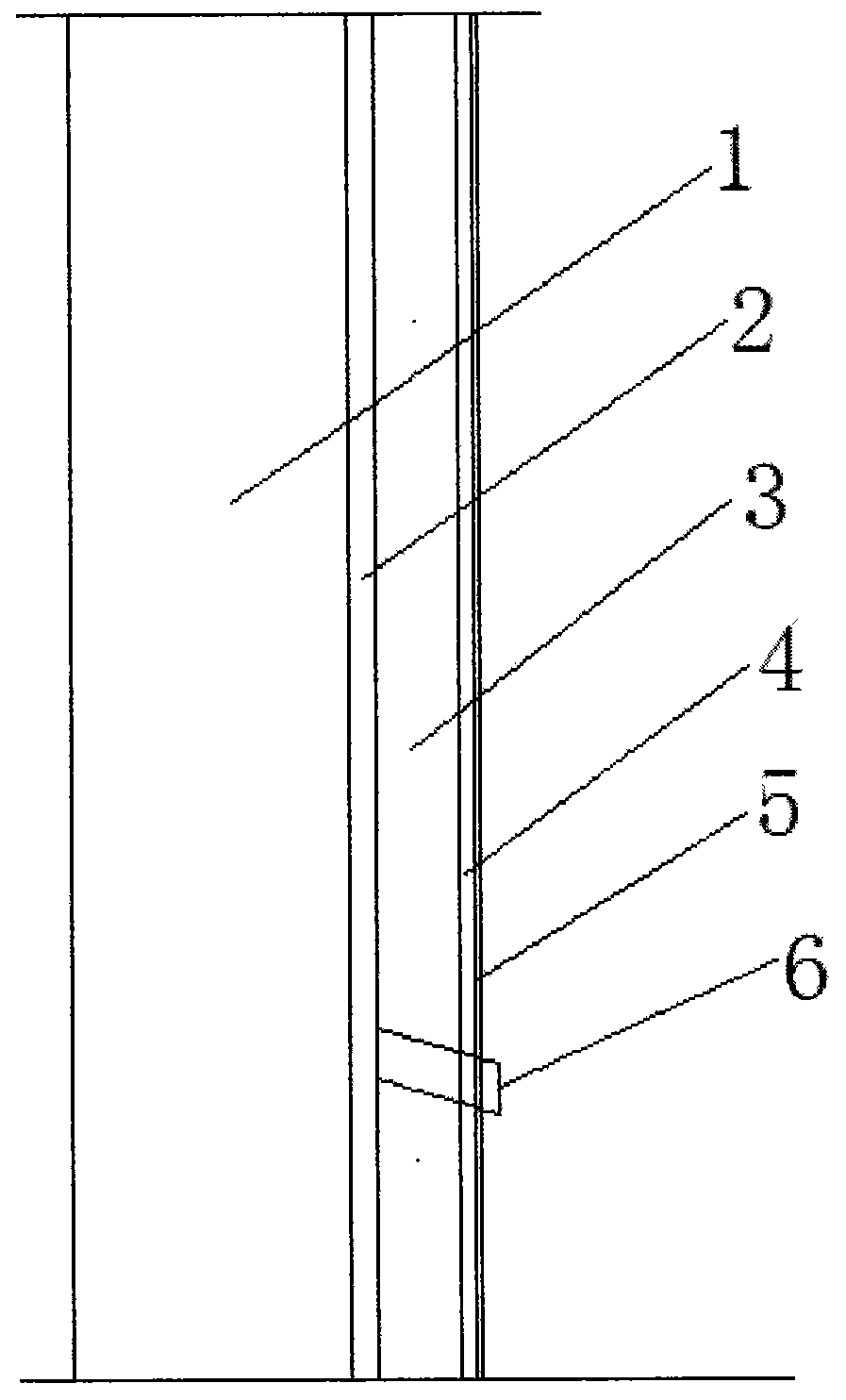

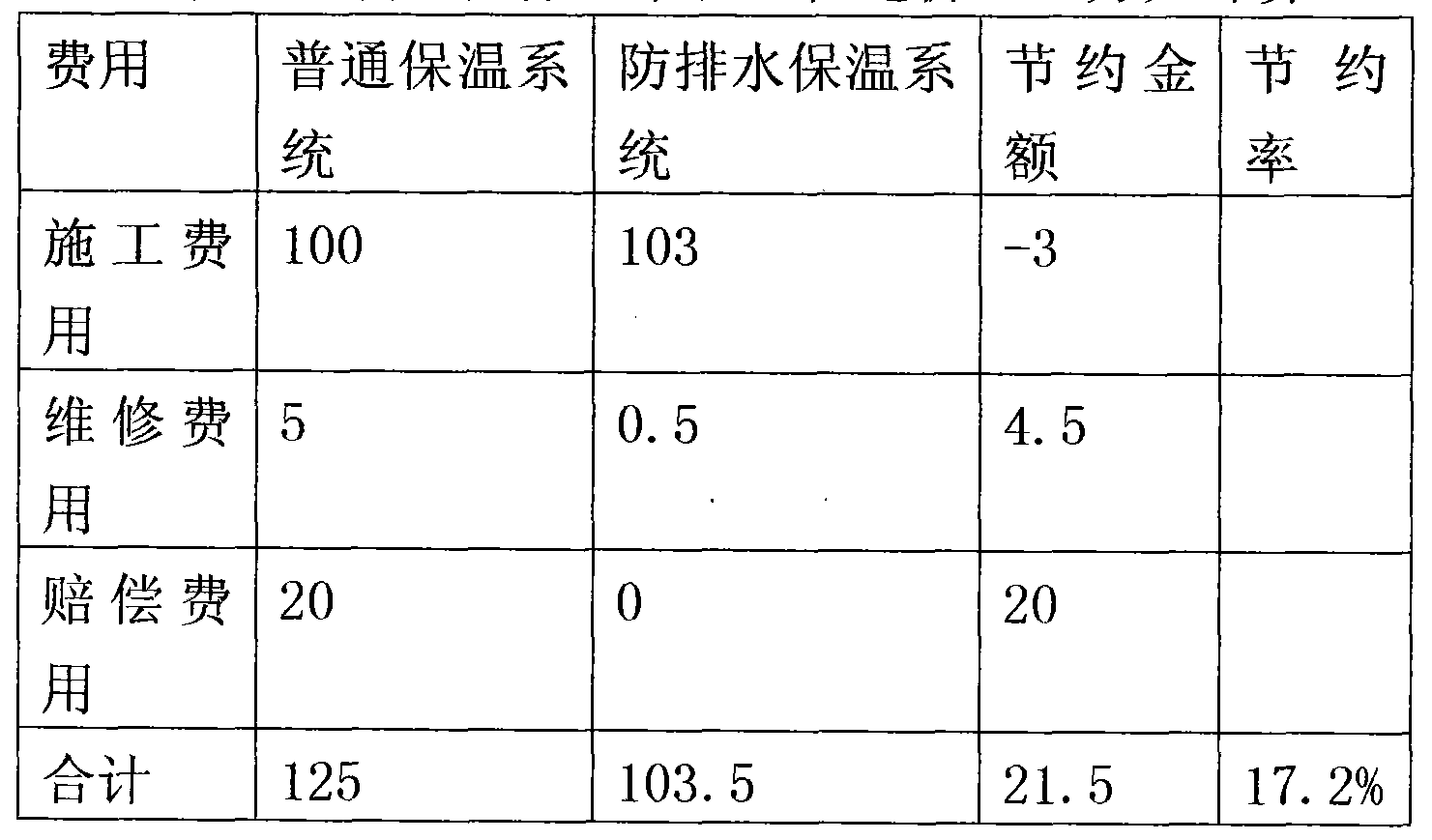

Building exterior wall external thermal insulation system waterproof and drainage construction method

InactiveCN104179263AImprove anti-crack and anti-seepage performanceEliminate potential safety hazardsHeat proofingBuilding insulationsSocial benefitsCrack resistance

Owner:ZHONGQI JIAOJIAN GRP

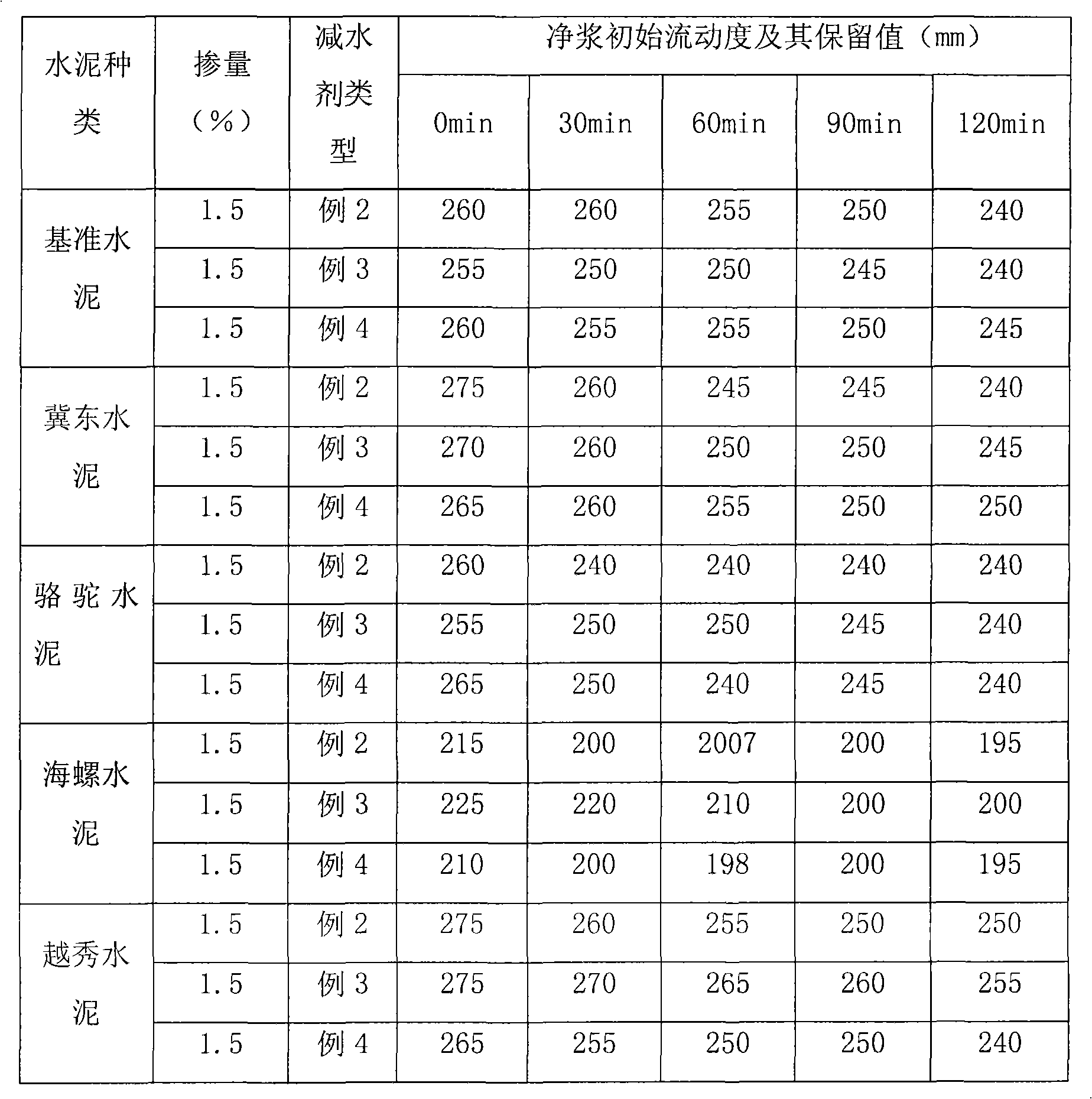

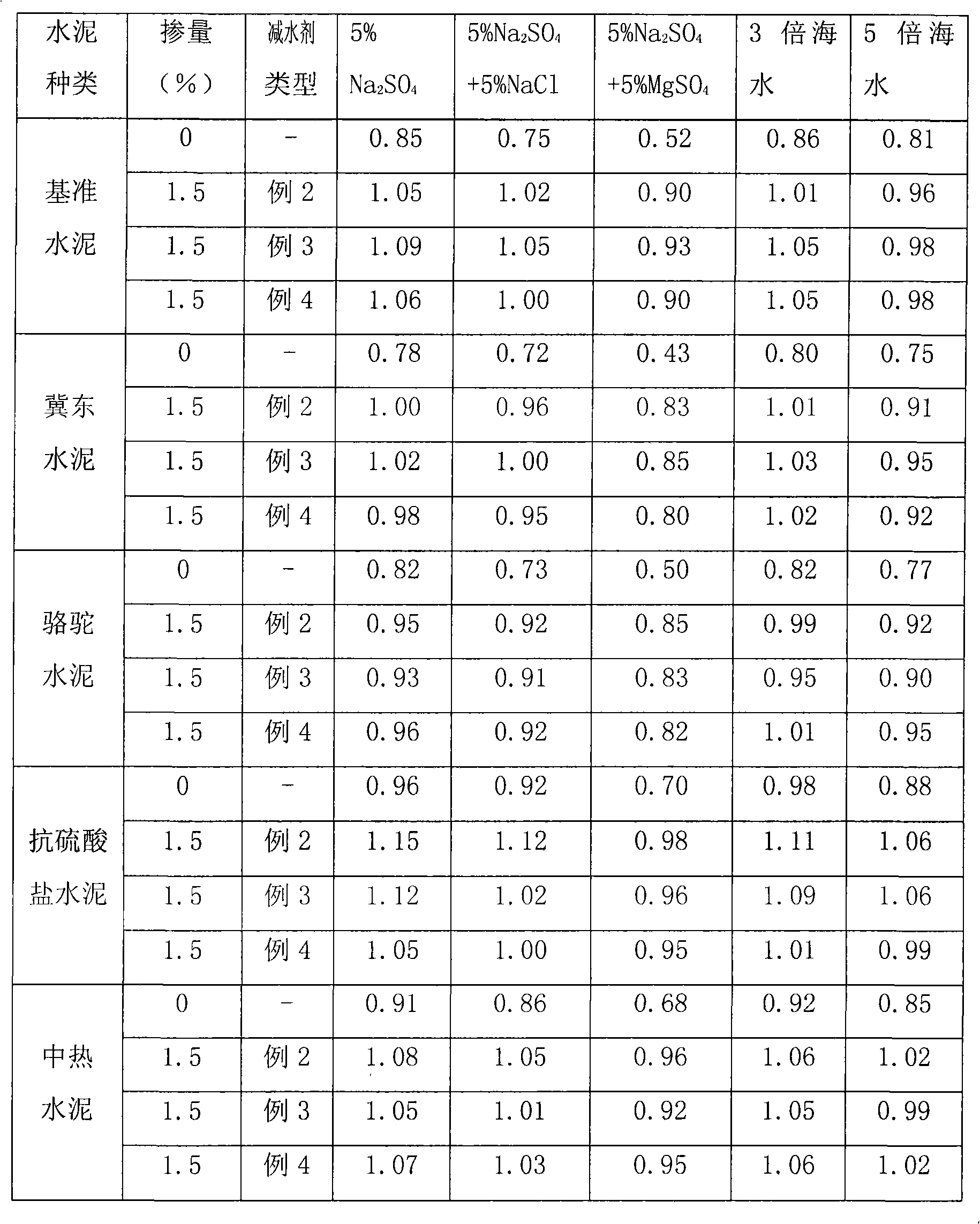

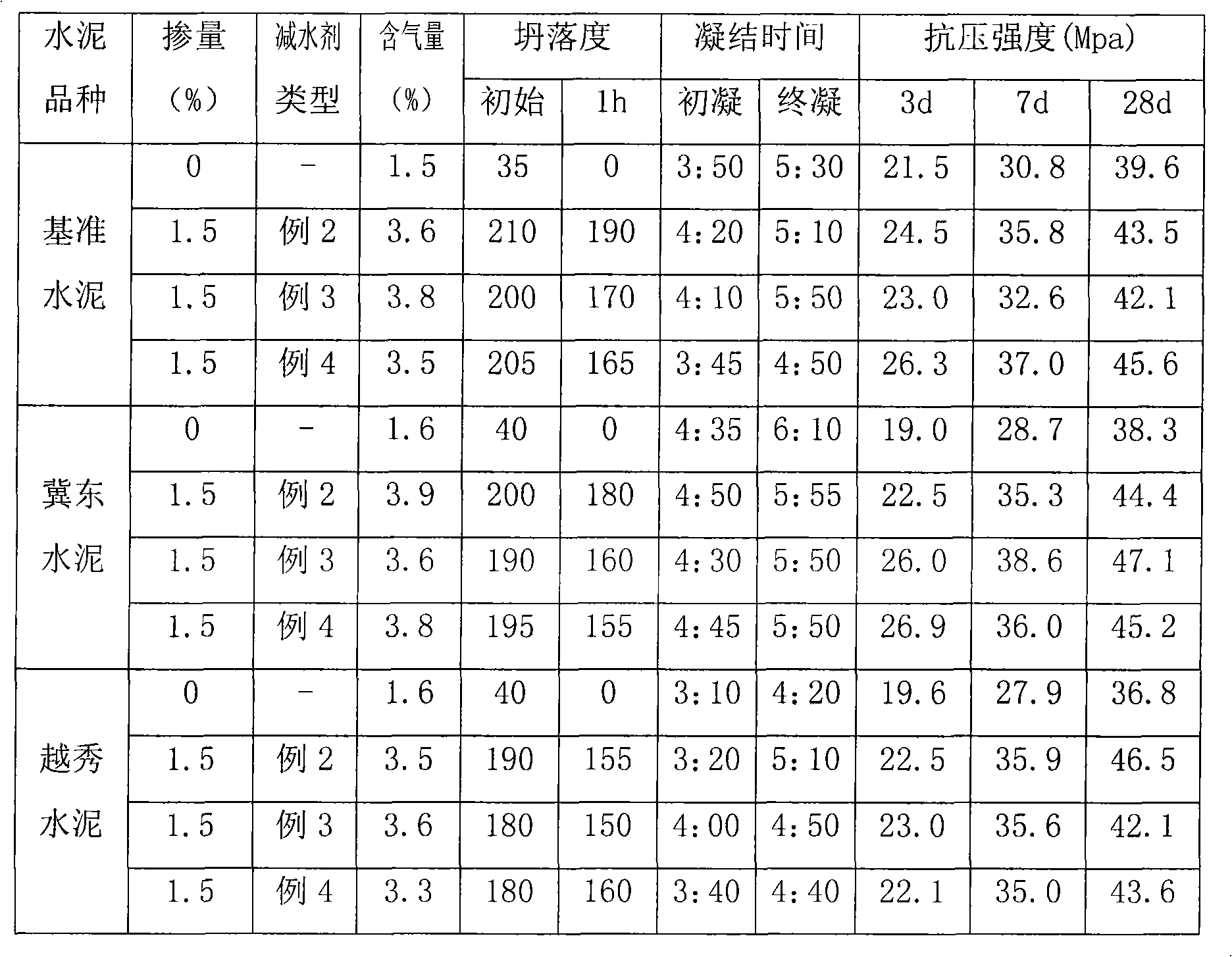

Polycarboxylic acid water reducing agent and preparation method thereof

InactiveCN101767952AImprove anti-crack and anti-seepage performanceExtended service lifeAluminium saltsCorrosion

The invention relates to a polycarboxylic acid water reducing agent and a preparation method thereof, belonging to the technical field of concrete water reducing agent. The polycarboxylic acid water reducing agent comprises the following components in percentage by weight: 30-50 of polycarboxylic acid, 15-30 of sodium nitrite as a corrosion resisting agent, 0.1-2.0 of sodium dodecyl benzene sulfonate as an air-entraining agent, 5-15 of sodium stearate as a waterproofing agent, 0.1-0.5 of polyether glycol as a defoaming agent and 15-40 of aluminum sulfate as a volume stabilizer. The preparation method comprises the following steps: adding the polycarboxylic acid into a reaction kettle, controlling the temperature at 45-80 DEG C, and while stirring, adding the sodium nitrite as the corrosion resisting agent, the sodium dodecyl benzene sulfonate as the air-entraining agent, the sodium stearate as the waterproofing agent, the polyether glycol as the defoaming agent and the aluminum sulfate as the volume stabilizer to carry out a synthetic reaction, and isothermally reacting for 1.5-2.5 hours to obtain the polycarboxylic acid water reducing agent. The water reducing agent of the invention has high water reducing rate, high concrete durability, good compatibility, good adaptivity and long service life, and the process of the invention has the advantages of simple flow, short reaction time, convenient industrial production, safety, cleanness and the like.

Owner:天津市飞龙砼外加剂有限公司

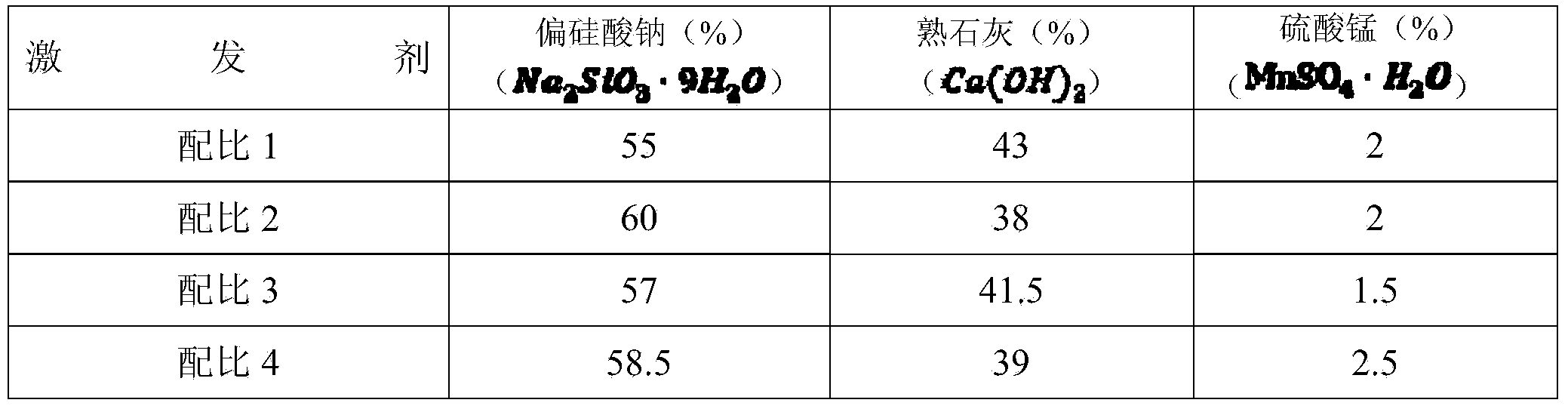

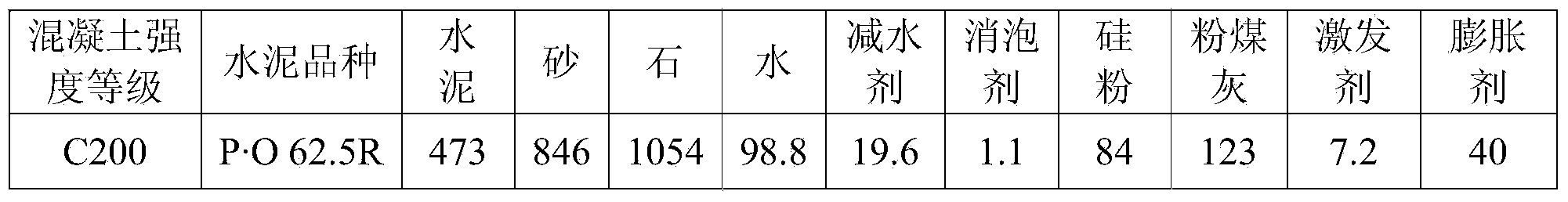

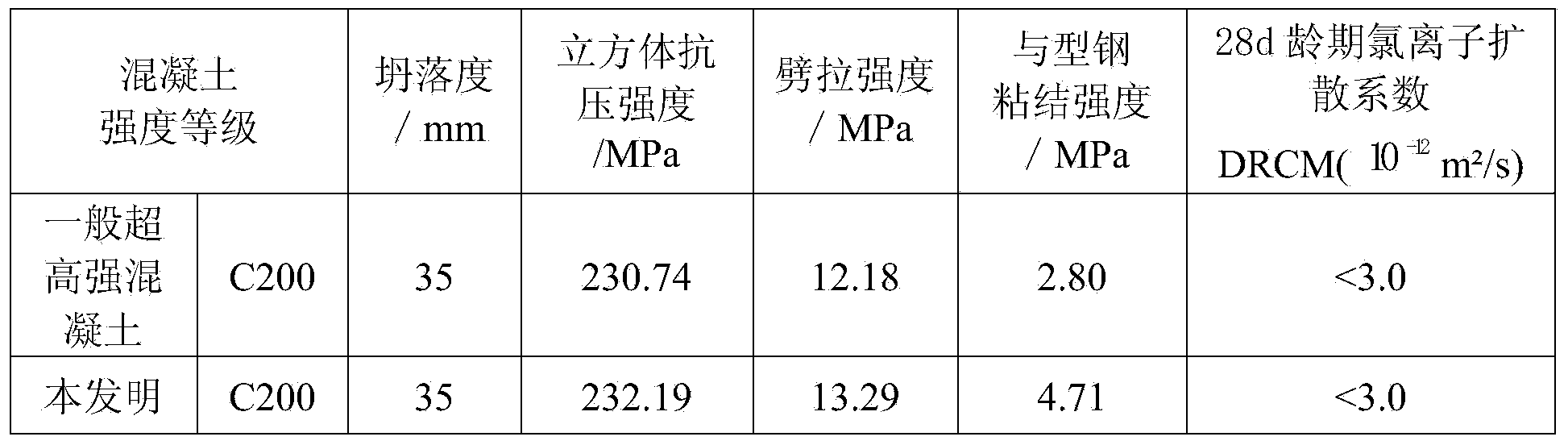

C200 strength-grade concrete for formed steel concrete composite structure

InactiveCN103553460AIncreased durabilityHigh Strength and DurabilitySolid waste managementNatural stateSuperplasticizer

The invention discloses a C200 strength-grade concrete for a formed steel concrete composite structure, which is composed of 473 parts of cement, 846 parts of fine aggregate, 1054 parts of coarse aggregate, 98.8 parts of water, 19.6 parts of concrete superplasticizer, 1.1 parts of defoaming agent, 84 parts of silicon powder, 123 parts of expanding agent, 7.2 parts of activator and 40 parts of expanding agent. The preparation method comprises the following steps: blending the concrete superplasticizer and activator into weighed water to obtain a mixture, sequentially adding the fine aggregate and 1 / 3 of the mixture into a stirrer according to parts by weight, and stirring; adding the coarse aggregate and 1 / 3 of the mixture, and stirring; adding the cement, expanding agent, silicon powder and fly ash, and stirring; and adding the defoaming agent and the rest of mixture, stirring and discharging. The concrete can obviously improve the bonding property between the formed steel and the concrete in a natural state, effectively displays the respective mechanical properties and the synergic working performance of the steel and concrete, greatly enhances the loading capacity, service performance and durability of the structural member, and has high volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

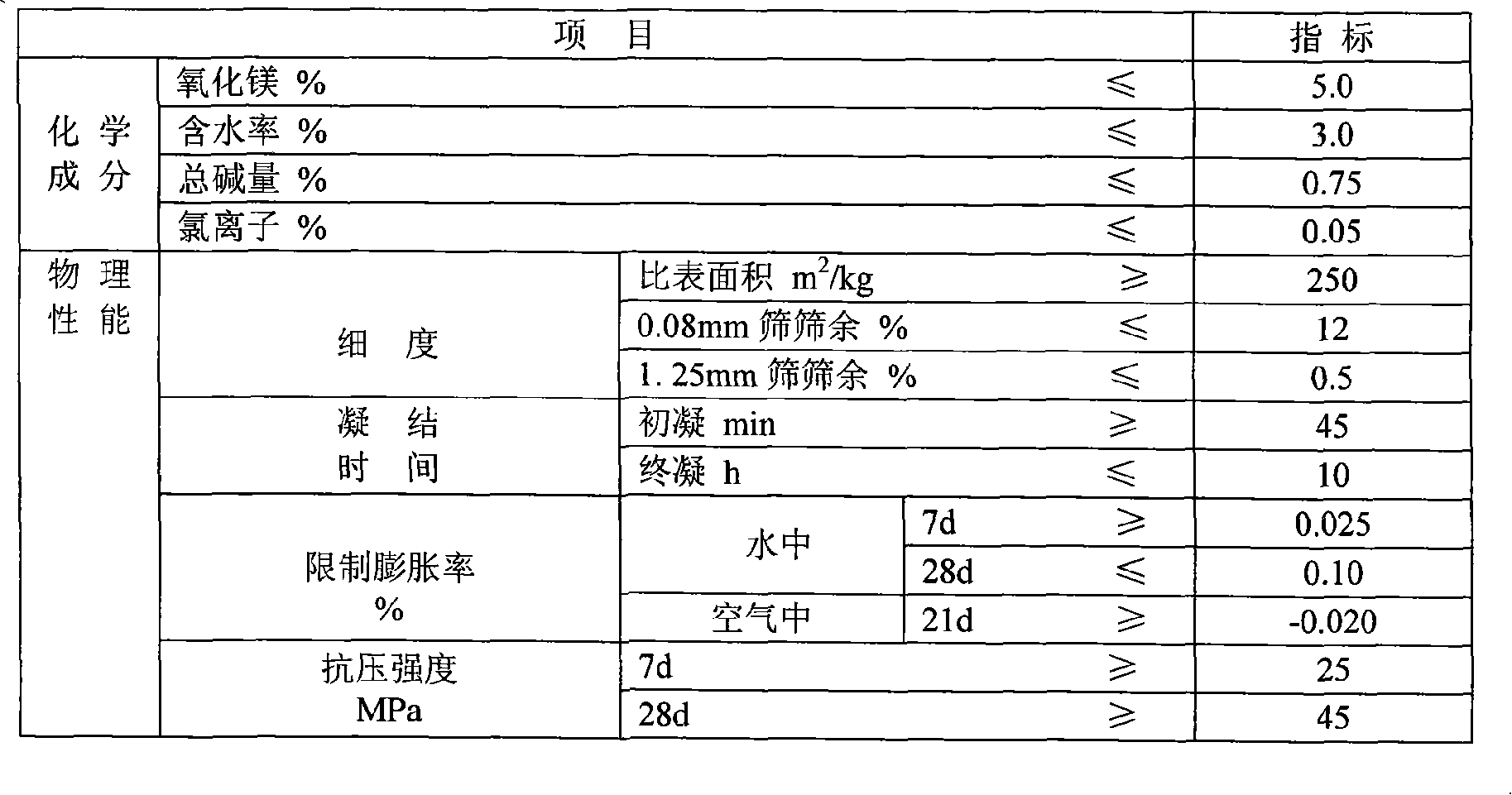

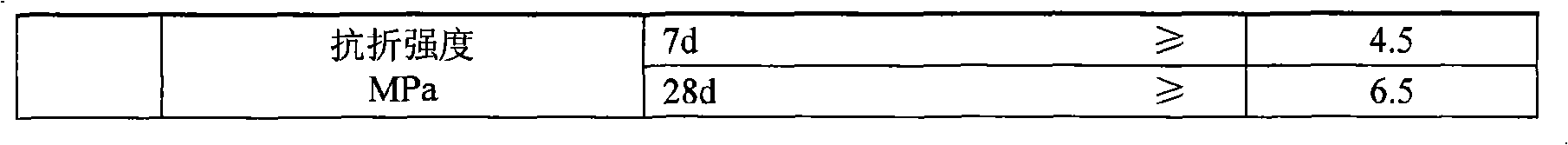

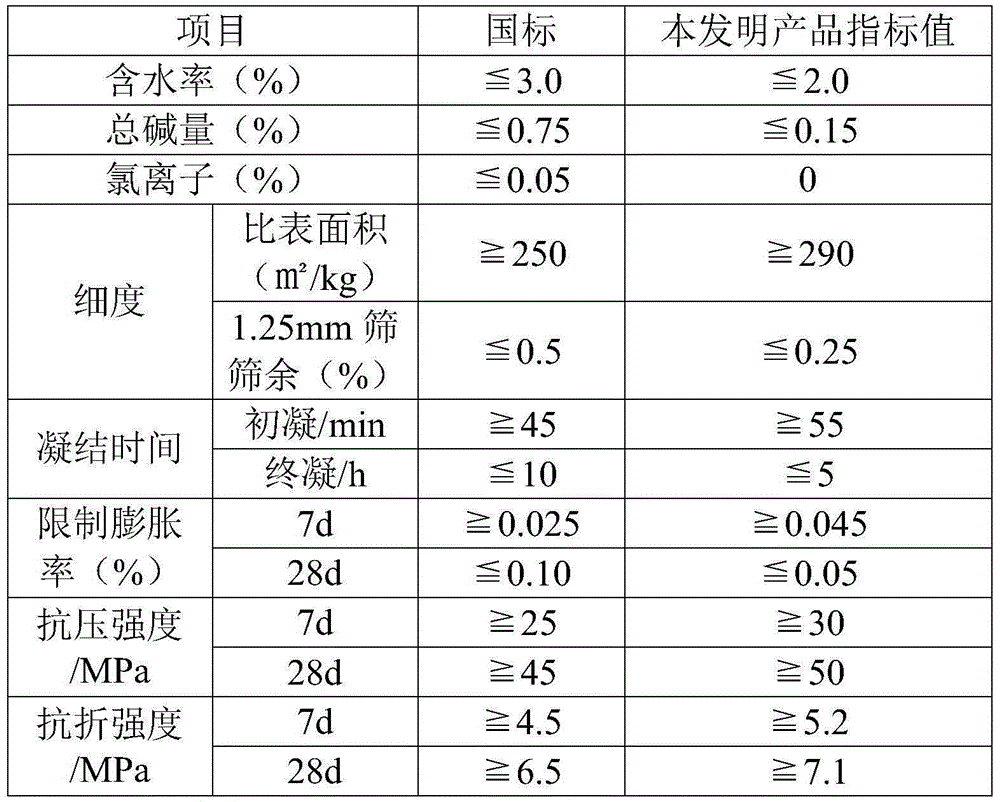

High-performance cement expansive agent and production method thereof

The invention relates to a high-performance cement expansive agent and a production method thereof. Aluminate expansive chamotte calcined at high temperature in a rotary kiln, other aluminum chamotte, anhydrite, desulfurized gypsum and polyalcohol ether (a reducing component) are mixed together according to a certain proportion to form the high-performance cement expansive agent. The production method comprises the following steps: firstly adding the blocky aluminate expansive chamotte into a vertical mill so as to pulverize the chamotte to a certain specific surface area; then adding the anhydrite, the desulfurized gypsum and the other aluminum chamotte together into a ball mill so as to pulverize the mixture to a certain specific surface area; and during the pulverizing in the ball mill, spraying the reducing component into the ball mill after atomizing the reducing component through a special device so as to evenly mix the components and obtain the finished product. Through the full use of the difference between the grinding performances of different mineral materials, the method compounds the recipe and carries out the process parameter control so as to realize the reasonable gradation of the particles. The high-performance cement expansive agent can reduce or avoid the problems that: a concrete structure produces harmful cracks due to early contraction, dry shrinkage and cold shrinkage, thereby bringing about structural leakage. The high-performance cement expansive agent can be used for continuous production, and has high compensation and contracting performance and convenient use.

Owner:浙江合力海科新材料股份有限公司

Preparation of heat-insulating energy-saving mortar containing phase-change material

ActiveCN101302089APrevent seepageLong-term heat preservation and energy saving effectMicro bubblePolymer science

The invention relates to a method for preparing insulated energy-saving mortar containing phase-change materials, comprising the following steps that: (1) at a temperature of between 30 and 130 DEG C and the vacuum degree is between 0.03 and 0.09, 80 to 500 kg of ceramsite and 0.8 to 2.5 kg of polypropylene hollow fibers are immersed in a phase-change material solution and treated for 5 to 120 minutes, so that the phase-change material solution permeates into holes of the ceramsite and cavities of the polypropylene hollow fibers; (2)the obtained ceramsite and polypropylene hollow fibers, together with 100 to 300 kg of cement and 50 to 200 kg of vitrified micro bubbles, are mixed for 3 to 5 minutes in the condition that the cement water factor is controlled between 0.4 and 0.6. The method is easy and convenient to implement and has low requirement on equipment; and the obtained mortar has good insulated energy-saving effect and can be widely applied in the aspect of heat-insulation of walls in the building field.

Owner:DONGHUA UNIV

Assembly type heat preservation plate

InactiveCN109208771AExcellent sound insulationKeep the temperature constantHeat proofingSound proofingRebarGypsum

The invention discloses an assembly type heat preservation plate, and aims to solve the problem that the heat preservation performance of an existing heat preservation plate needs to be improved. Theassembly type heat preservation plate comprises a base plate, a supporting layer and a heat preservation layer. The base plate, the supporting layer, and the heat preservation layer are sequentially and fixedly connected into a whole from bottom to top. The preparation process of the supporting layer comprises the following steps: (1) a plurality of rectangular small frames are formed among reinforced steel bars by taking steel bars as keels and constructing a supporting framework on the base plate; (2) a sound absorption felt is filled in the rectangular small frames, and a supporting layer is formed. According to the invention, the ardealite is used as a raw material to prepare the base plate. Meanwhile, the supporting layer and the heat preservation layer are structurally improved, so that the prepared heat preservation plate has excellent performances such as light weight, high strength, water resistance, moisture resistance, stretching resistance and the like. On the basis of thestructural improvement of the heat preservation plate, the heat preservation plate disclosed by the invention is light in weight, high in strength, small in heat conduction coefficient, good in fireproof and waterproof effects and the like. Meanwhile, the ardealite is used as the raw material, so that the resource utilization of the ardealite is realized.

Owner:西南科技大学城市学院

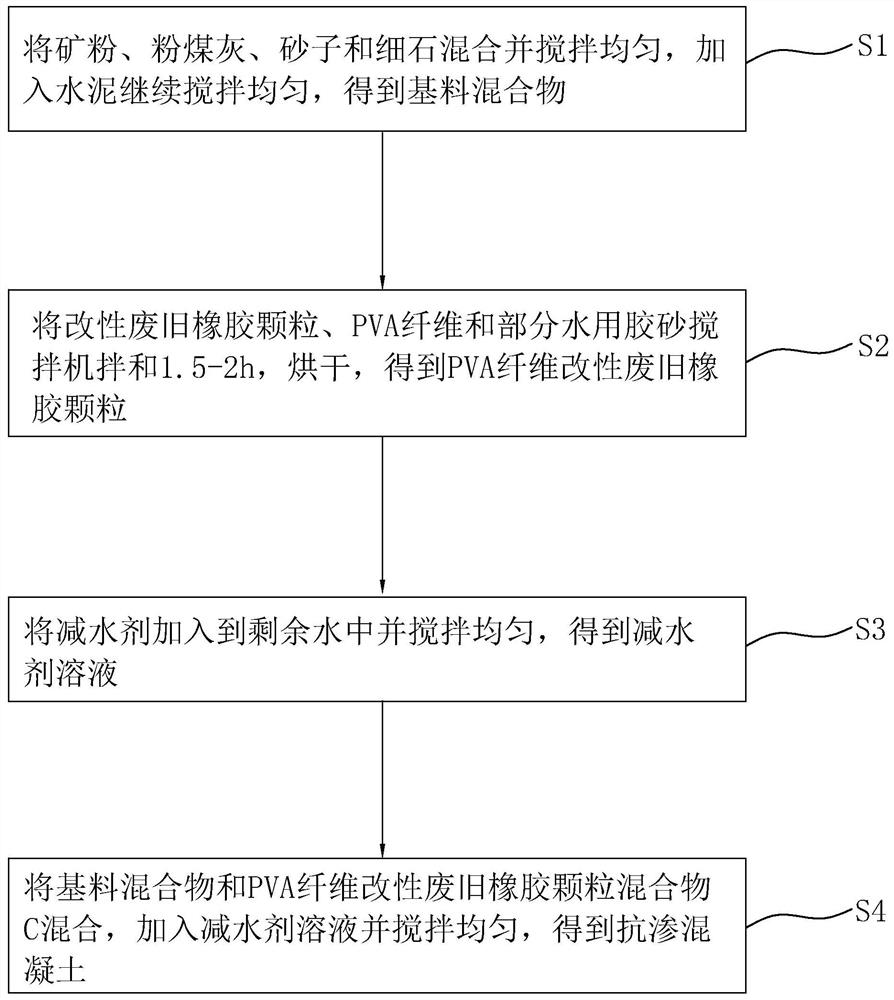

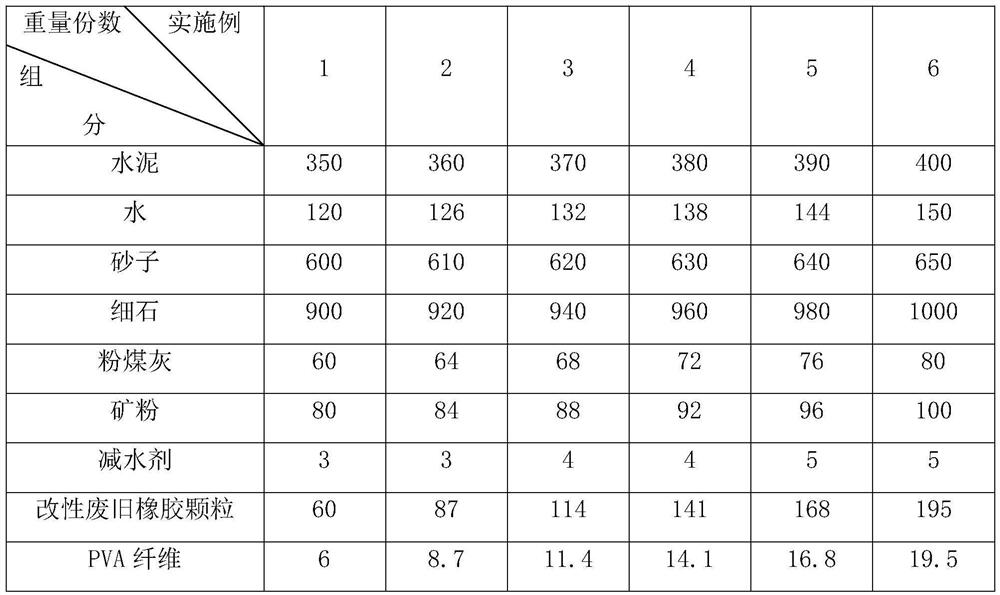

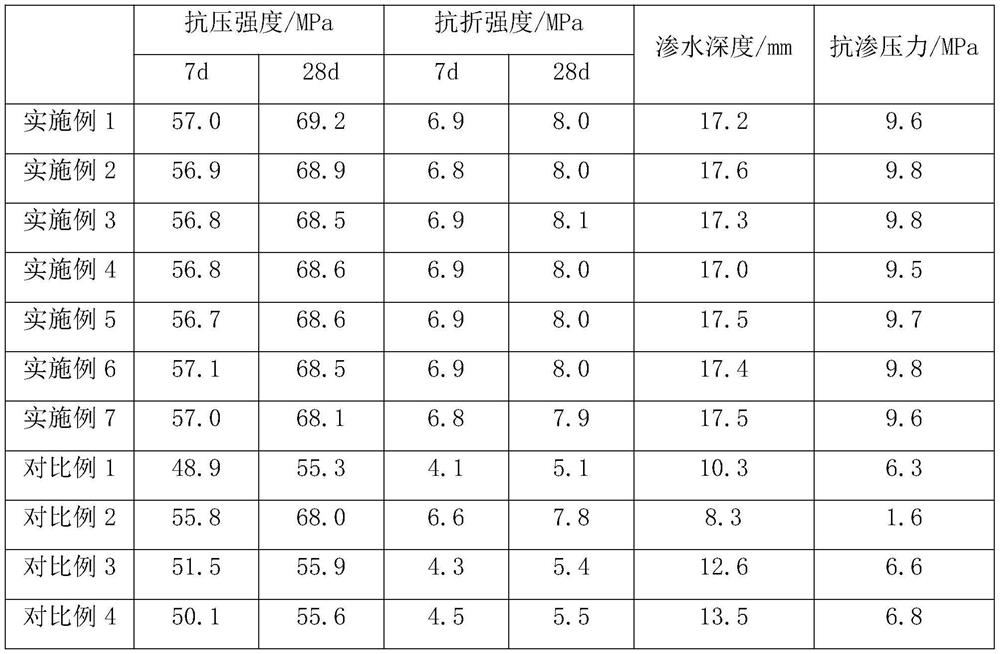

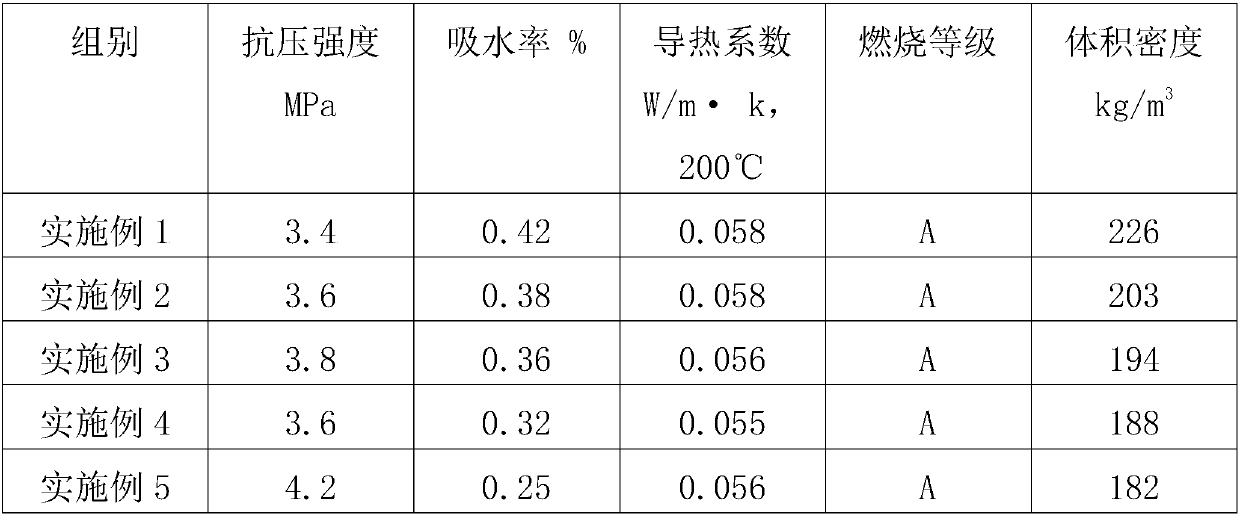

Impermeable concrete and preparation method thereof

InactiveCN111704403AImprove adhesionImprove stress resistanceSolid waste managementFiberWaste rubber

The invention discloses impermeable concrete and a preparation method thereof, and relates to the technical field of concrete. According to the technical key points, the impermeable concrete comprisesthe following components in parts by weight: 350 to 400 parts of cement, 120 to 150 parts of water, 600 to 650 parts of sand, 900 to 1000 parts of fine stone, 60 to 80 parts of fly ash, 80 to 100 parts of mineral powder, 3 to 5 parts of a water reducing agent, 60 to 195 parts of modified waste rubber granules, and 9 to 30 parts of PVA fiber; the preparation method of the modified waste rubber granules comprises the following steps: adding the waste rubber granules into a 1 mol / L NaOH solution according to a weight ratio of 1:4, soaking the rubber granules for 2-3 h, cleaning the waste rubbergranules with water until the pH value is equal to 8, drying the rubber granules, soaking the rubber granules in absolute ethyl alcohol with a silane coupling agent for 2-3 h, cleaning the rubber granules, and drying the rubber granules to obtain the modified waste rubber granules. The waste rubber granules doped into the impermeable concrete account for 30% of the fine aggregate to the maximum extent, and the impermeable concrete has the advantages that the waste rubber granules are fully utilized and the mechanical property of the concrete is high.

Owner:昊丰赢(上海)新材料科技有限公司

Foamed ceramic heat preservation board

InactiveCN109608167AImprove performanceHigh porosityCeramic materials productionCeramicwareEpoxyFiber

The invention relates to the technical field of new building materials, in particular to a foamed ceramic heat preservation board, which is composed of the following raw materials in parts by weight:20-40 parts of coal gangue, 10-20 parts of iron tailings, 10-30 parts of fly ash, 5-15 parts of dolomite, 4-10 parts of silicon carbide, 3-9 parts of far infrared ceramic powder, 4-10 parts of calcined talc, 8-12 parts of perlite, 3-9 parts of calcium carbonate, 10-20 parts of epoxy resin powder, 2-4 parts of crack resistant fiber, 1-3 parts of brucite nanofibers, 7-15 parts of modified diatomaceous earth, and 2-4 parts of graphene. The invention takes solid wastes such as coal gangue, iron tailings, fly ash and the like as main raw materials, provides an effective solution for resource reuse,and makes the foamed ceramic heat preservation board have high mechanical strength. Pearlite enveloped with calcium carbonate and epoxy resin powder can increase the overall strength and aging resistance of the heat preservation board, reduce water absorption and improve impermeability. The heat preservation board has the effects of crack resistance, impermeability, heat preservation, flame retardancy, abrasion resistance and compression resistance through the mutual assistance of the raw materials.

Owner:LIUZHOU LIUJING TECH CO LTD

High anti-crack liquid expanding agent doped epoxy asphalt concrete and preparation method thereof

ActiveCN107285674AReduce the effect of volume shrinkageImprove anti-crack and anti-seepage performanceEpoxyCrosslinked polymers

The invention discloses a high anti-crack liquid expanding agent doped epoxy asphalt concrete, which comprises the following raw materials in parts by weight: 100 to 200 parts of cement, 35 to 75 parts of epoxy asphalt, 10 to 25 parts of liquid expanding agent, 240 to 480 parts of aggregate, and 150 to 300 parts of water. Epoxy asphalt is subjected to toughening modification to improve the toughness of epoxy asphalt crosslinked polymer; the thermosetting property of epoxy asphalt is weakened; silica powder is used to fill the gaps in epoxy asphalt crosslinked polymer so as to reduce the influence of low temperature on the concrete volume shrinkage; at the same time, a liquid expanding agent is added to enhance the concrete volume expanding so as to reduce concrete volume shrinkage; the anti-crack and anti-permeability performance of concrete is strengthened, compared with the powdery expanding agents, the liquid expanding agent can be more accurately measured and more evenly mixed, the dust pollution caused by powdery expanding agents is avoided at the same time, and the liquid expanding agent is environmentally friendly.

Owner:江苏众科新材料科技发展有限公司

Heat-insulation type concrete for civil construction and preparation method thereof

The invention discloses heat-insulation type concrete for civil construction and belongs to the technical field of concrete. The heat-insulation type concrete is prepared from the following raw materials in parts by weight: 90 to 100 parts of cement, 20 to 25 parts of fly ash, 40 to 50 parts of fine sand, 10 to 20 parts of ceramsite, 5 to 8 parts of cast stone powder, 6 to 9 parts of zeolite powder, 60 to 70 parts of water, 1 to 2 parts of fiber, 0.5 to 1 part of a waterproof agent, 1 to 3 parts of a de-foaming agent, 0.2 to 0.8 part of a suspension agent and 0.1 to 0.2 part of an activating agent. The invention further discloses a preparation method of the heat-insulation type concrete for the civil construction. The heat-insulation type concrete for the civil construction is simple to prepare and has relatively excellent waterproof, fireproof and heat-insulation capabilities.

Owner:山东励仙电力工程有限公司

High-performance concrete expansive agent

The invention relates to the technical field of concrete admixture, in particular to a high-performance concrete expansive agent. The high-performance concrete expansive agent is prepared from, by weight, 30-40 parts of calcium sulphoaluminate, 8-16 parts of sepiolite, 4-11 parts of teflon powder, 3-9 parts of pentaerythrite, 1-4 parts of benzenediol and 5-10 parts of glass fiber powder. Shrinkage compensating of the high-performance concrete expansive agent has long effectiveness, the high-performance concrete expansive agent can be adapted to strength development of concrete, has excellent high-cracking-resistance impermeability, avoids that because cracking-resistance impermeability of concrete is insufficient, accumulated water permeability is generated, and the concrete can not be used and has high performance, and all the properties of the concrete expansive agent are improved and include the capacity of cracking resistance and impermeability, concrete compression strength and concrete breaking strength.

Owner:黄万忠

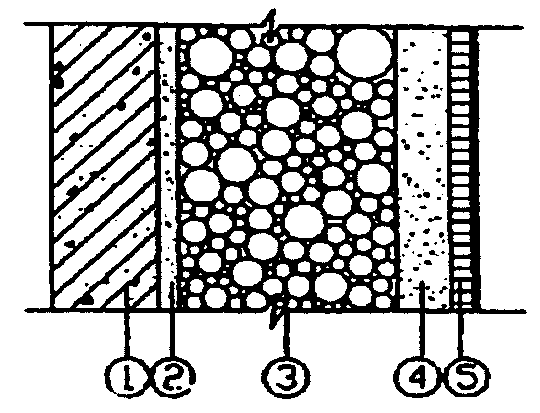

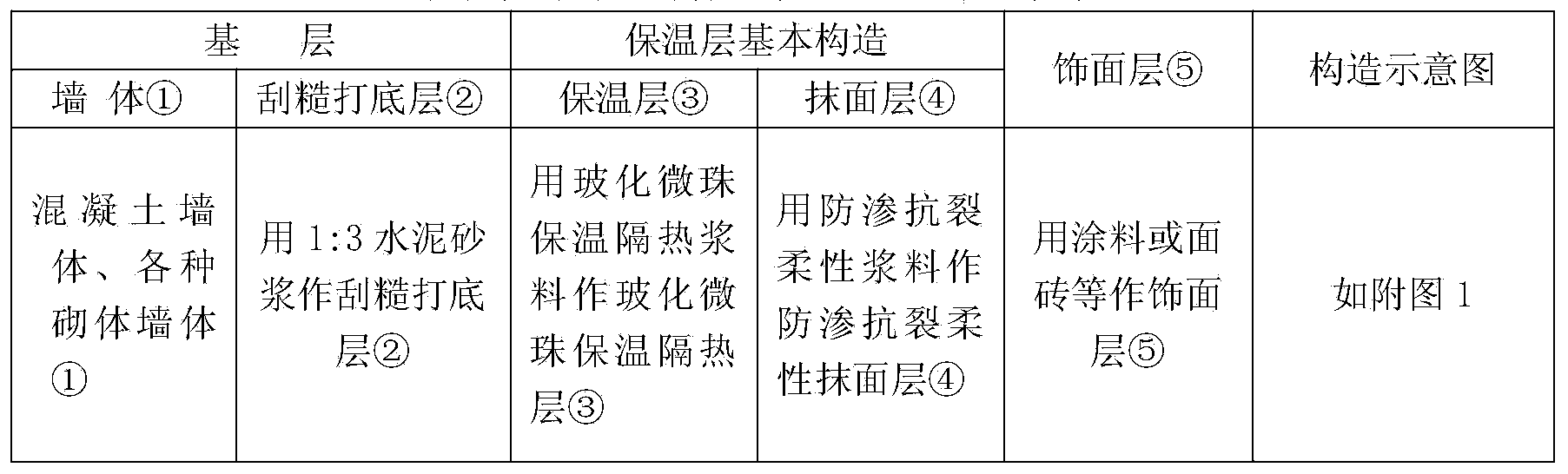

GHB (Glazed Hollow Bead) heat preservation and heat insulation building wall body and construction technology

InactiveCN103850362AImprove thermal insulationImprove anti-crack and anti-seepage performanceWallsClimate change adaptationInsulation layerBuilding energy

The invention discloses to a GHB (Glazed Hollow Bead) heat preservation and heat insulation building wall body and construction technology, and relates to the field of building energy conservation. The GHB heat preservation and heat insulation building wall body and construction technology comprises the GHB heat preservation and heat insulation building wall body and a construction technology of the GHB heat preservation and heat insulation building wall body, wherein the GHB heat preservation and heat insulation building wall body is formed by sequentially manufacturing a coarse scraping base layer, a GHB heat preservation and heat insulation layer, a seepage-proofing and anti-crack flexible plastering layer and a decorating layer on a building wall body by adopting a GHB heat preservation and heat insulation material; the GHB heat preservation and heat insulation layer is formed by GHB heat preservation and heat insulation slurry which is prepared by GHB heat preservation and heat insulation dry powder, and the seepage-proofing and anti-crack flexible plastering layer is formed by seepage-proofing and anti-crack flexible slurry which is prepared by seepage-proofing and anti-crack flexible mortar and a reinforcing net. The GHB heat preservation and heat insulation building wall body disclosed by the invention has the advantages that the heat conduction coefficient is low, the heat preservation and heat insulation effect is good, the seepage-proofing and anti-crack performance is good, safety and fire prevention can be obtained, the strength is high, environmental protection is realized, and good energy saving and consumption reducing effects of a building structure is realized; the GHB heat preservation and heat insulation building wall body and construction technology can be widely promoted and applied in the field of heat preservation and heat insulation, energy saving and consumption reducing, and safety and fire prevention of a building.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Crack-resistant anti-seepage concrete and preparation method thereof

The invention relates to crack-resistant anti-seepage concrete and a preparation method thereof, and mainly solves the problem that the concrete is easy to crack and leak. The crack-resistant anti-seepage concrete comprises 280 to 290 parts of cement, 105 to 115 parts of fly ash, 790 to 800 parts of sand, 1050 to 1060 parts of crushed stone, 1 to 10 parts of a water reducing agent, 2 to 7 parts ofwhite sugar, 20 to 30 parts of a fiber expansion agent, 20 to 30 parts of a crack-resistant anti-seepage agent, 3 to 10 parts of a water repellent, 95 to 105 parts of coal gangue, 73 to 83 parts of metal silicon powder, 40 to 50 parts of iron powder, 65 to 75 parts of copper ore tailings, 10-20 parts of a reactant and 148 to 158 parts of water. The fly ash, the sand, the crushed stone and the copper mine tailings are selected as main raw materials, the production cost of the raw materials is reduced, the anti-wear and anti-erosion ability of the concrete is reduced, the durability of the concrete is improved, and the compactness of the concrete is improved. The crack-resistant anti-seepage concrete has better frost resistance and seepage resistance, and the unique crack-resistant anti-seepage agent is added to the concrete to greatly improve the crack resistance and seepage resistance of the concrete.

Owner:WENZHOU INNOVATION NEW MATERIAL CO LTD

Composite cracking and seepage resistant agent and production process thereof

InactiveCN101993216AImprove anti-crack and anti-seepage performanceSURFACTANT BLENDMaterials science

The invention relates to a composite admixture applied to concrete and a production process thereof. The composite admixture is compounded by polypropylene fiber, expansion agent, waterproof agent, surfactant, water reducing agent and auxiliary material which serve as main components. The composite admixture can remarkably improve the cracking and seepage resisting effects of the concrete.

Owner:宝应县克列达新型建材研发中心

Preparation method of polymer-modified cement mortar for reparation

InactiveCN106495606AEnhanced resistance to peelingImprove anti-crack and anti-seepage performanceMethacrylatePolymer modified

The invention relates to a preparation method of polymer-modified cement mortar for reparation, and belongs to the technical field of preparation of mortar for reparation. The method includes subjecting lauryl sodium sulfate and fatty alcohol polyoxyethylene ether and the like to heating reaction prior to mixing with butyl acrylate, epoxypropyl methacrylate and the like, dropwise adding ammonium persulfate solution, filtering and discharging after complete reaction to prepare acrylate polymer emulsion, preparing acrylate polymer emulsion and vinyl chloride ethylene copolymer emulsion into mixed emulsion according to proportion, meanwhile preparing ordinary Portland cement, quartz sand, rubber powder, polypropylene fiber and the like into mixed powder, and uniformly stirring mixed powder, mixed emulsion and deionized water prior to discharging to obtain the polymer-modified cement mortar for reparation. By compounding of acrylate polymer emulsion and vinyl chloride ethylene copolymer emulsion, durability and cohesiveness of mixed emulsion are improved, and mechanical property of mortar is improved by addition of polypropylene fibers, rubber powder and the like.

Owner:常州市鼎升环保科技有限公司

Compound-doped mineral admixture for reinforced concrete structure of oceanographic engineering

The invention relates to the field of concrete additives for oceanographic engineering, and aims at providing a compound-doped mineral admixture for a reinforced concrete structure of the oceanographic engineering. The compound-doped mineral admixture comprises the following components in percentage by mass: 20 to 35% of coal ash, 5 to 10% of zeolite, 20 to 40% of slag, 5 to 15% of silica fume, 5 to 15% of corrosion inhibitor, 2 to 5% of dispersing agent, 0 to 10% of shrinkage reducing agent, and 0 to 16% of antimitotic agent. According to the compound-doped mineral admixture, multi-component design is adopted, the functions of all the components are combined and coordinated, and thus the crack resistance and rust resistance of the structure are optimized, and the wear resistance of the oceanographic engineering can be improved; and a plurality of functional components are compounded into the admixture, so that the functional components can be uniformly dispersed in the concrete, and the effects of stably resisting crack and resisting rust can be realized. The compound-doped mineral admixture can reduce the concrete agitating conditions and reduce the usage cost of an enterprise, and is convenient for massive popularization and application.

Owner:浙江合力海科新材料股份有限公司

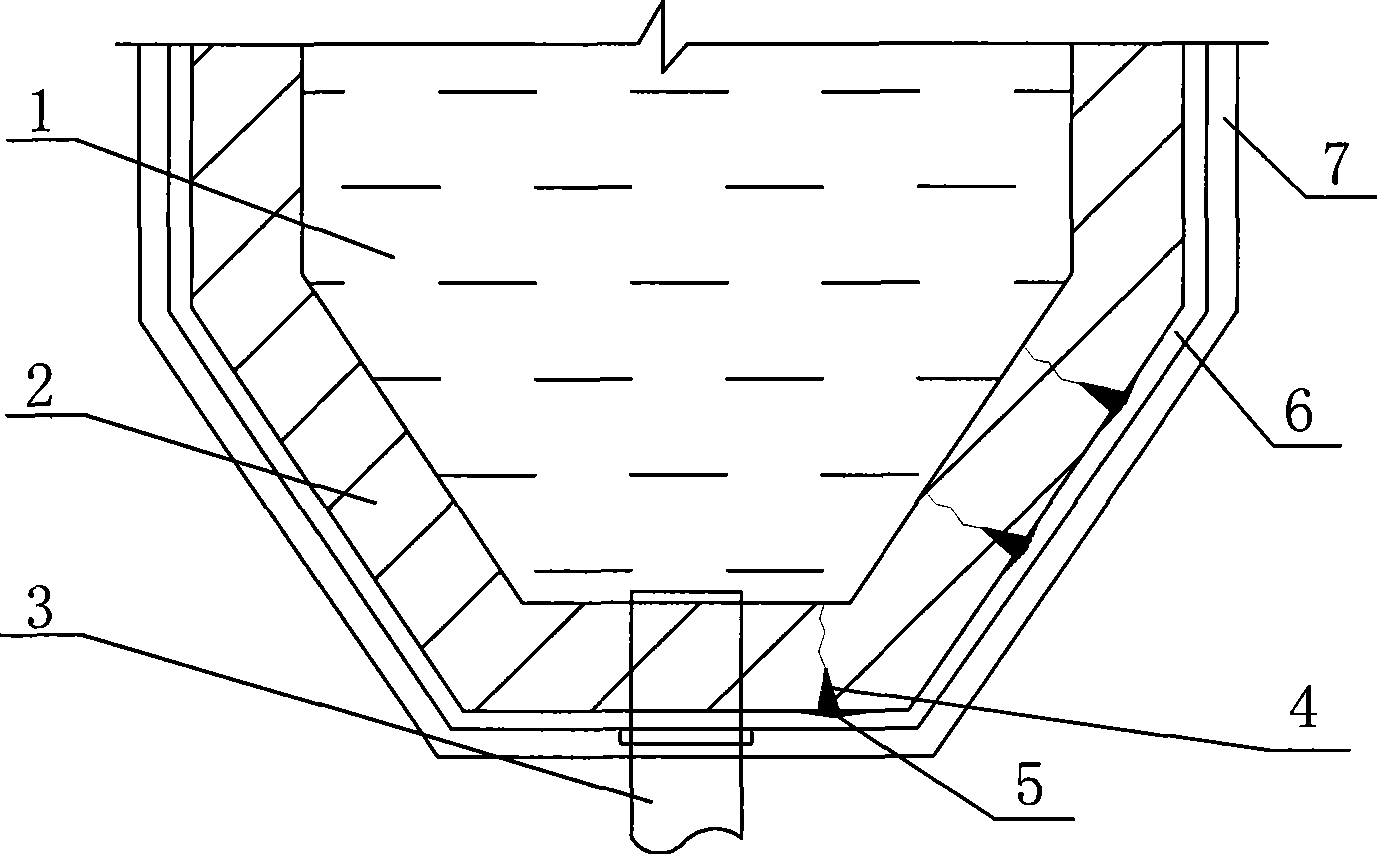

Method for compensation and anti-permeation of temperature difference cracks of ground concrete high-temperature pool

InactiveCN101545320AControl appearsImprove anti-crack and anti-seepage performanceBuilding repairsGymnasiumSelf-healingPortland cement

The invention discloses a method for compensation and anti-permeation of temperature difference cracks of a ground concrete high-temperature pool. The method comprises the following steps of: reliably sealing the place having the crack permeation firstly, and then (1) preparing self-healing mortar and using the self-healing mortar to plaster the surface of the pool; and (2) preparing temperature difference compensation mortar and using the temperature difference compensation mortar to plaster the surface of the pool. The self-healing mortar comprises the following compositions by weight portion: 100 portions of ordinary Portland cement, 200 to 400 portions of medium coarse sand, 6 to 10 portions of D-type adjusting agent, 0.1 to 1 portion of water reducing agent, 1 to 3 portions of silicon ash and 30 to 40 portions of water. The temperature difference compensation mortar comprises the following compositions by weight portion: 100 portions of ordinary Portland cement, 200 to 400 portions of medium coarse sand, 2 to 4 portions of F type adjusting agent, 0.1 to 0.2 portion of air-entraining agent and 30 to 50 portions of water. The method reduces the pool wall temperature stress, effectively controls temperature difference cracks and reduces the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Concrete for lining segment and preparation method for concrete

The invention discloses concrete for a lining segment and a preparation method for the concrete, and belongs to the technical field of concrete products. The concrete is characterized in that the concrete for the lining segment is prepared from, by weight, 350-370 parts of cement, 1100-1200 parts of gravel, 700-720 parts of sand, 50-60 parts of coal ash, 4-6 parts of an anti-cracking agent, 5-6 parts of an additive and 120-130 parts of water; the anti-cracking agent is prepared by grinding calcium oxide expansion clinker, micro-silicon powder and redispersable emulsion powder, wherein the weight ratio of the calcium oxide expansion clinker to the micro-silicon powder to the redispersable emulsion powder is 6:3:1. By adopting the anti-cracking agent, the anti-cracking performance and anti-permeability performance of the concrete can be improved.

Owner:青岛光大集团大型构件有限公司

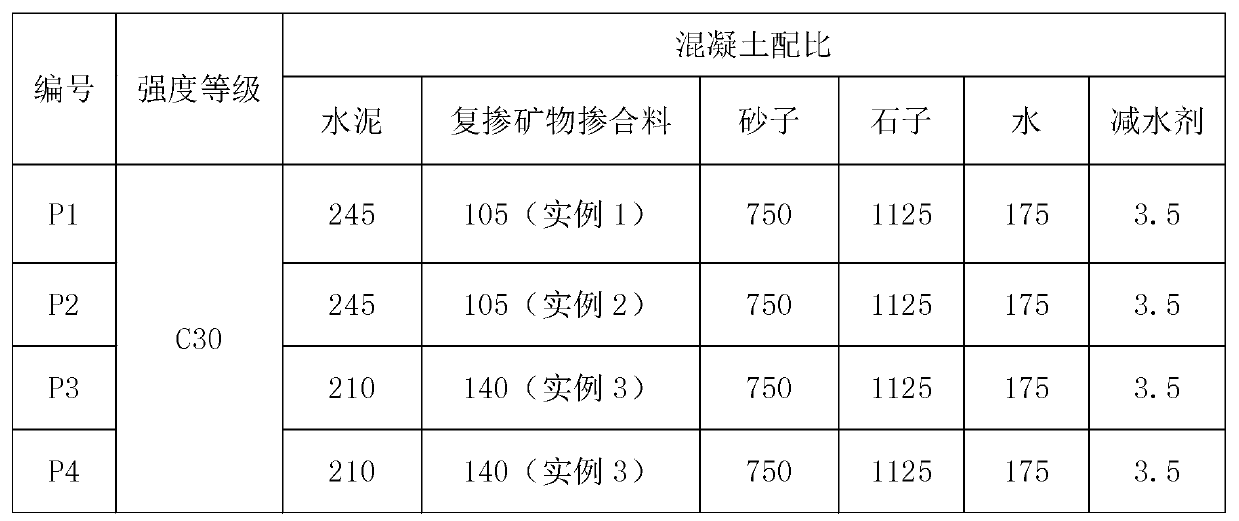

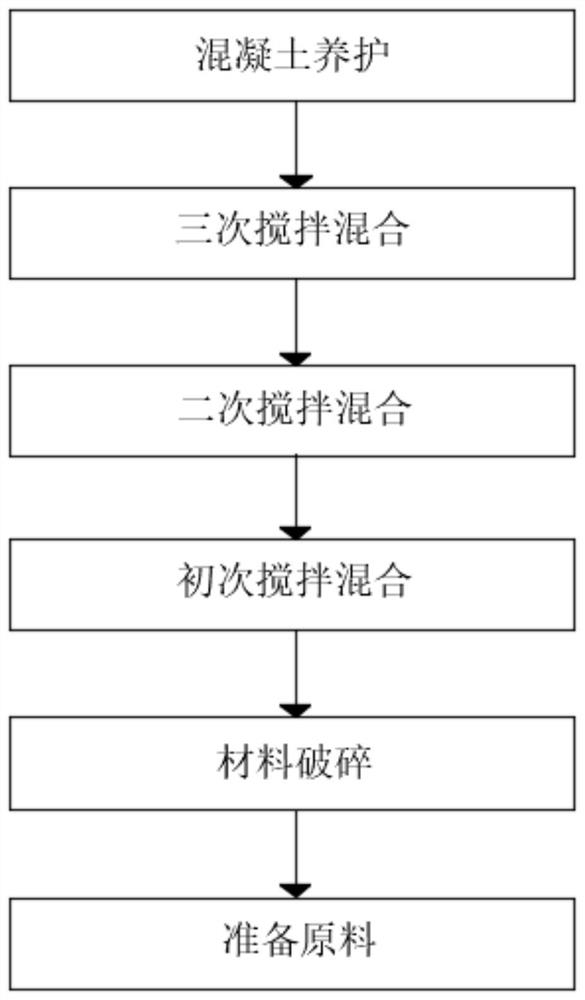

Concrete preparation process

InactiveCN112266212AImprove anti-crack and anti-seepage performanceImprove abrasion resistanceSolid waste managementFiberCrusher

The invention discloses a concrete preparation process. The concrete preparation process is characterized by specifically comprising the following steps of S1, preparing raw materials: taking the following raw materials in parts by mass: 400-550 parts of cement, 60-90 parts of fiber filler, 12-15 parts of retarder, 600-750 parts of sand, 30-45 parts of additive, 80-100 parts of silicon powder, 80-110 parts of fly ash, 50-80 parts of surfactant and 300-350 parts of water, S2, material crushing: fully mixing the cement, the fiber filler, the silicon powder and the fly ash in parts by weight, andthen putting the mixture into a crusher to be crushed to reach the use specification, and S3, primary stirring and mixing: selecting the crushed cement, fiber filler, silicon powder and fly ash and uniformly mixing with water and sand which are proportioned in parts by weight. The fiber filler can effectively control microcracks caused by factors such as plastic shrinkage, air shrinkage and temperature change of the concrete, and the anti-cracking and anti-seepage performance and the anti-impact and anti-abrasion performance of the concrete are improved.

Owner:梁光艳

Epoxy resin glue sand used for rapid repairing and microwave curing method thereof

The invention relates to a novel microwave radiation cured epoxy resin glue sand, especially relates to an epoxy resin glue sand composed of epoxy resin, a curing agent, a diluent, flyash, medium-coarse sand, and organic chopped fiber, and a microwave curing method of the epoxy resin glue sand. The epoxy resin glue sand comprises, by weight, 5 to 15wt% of epoxy resin, 2.5 to 7.5wt% of the curing agent, 0.3 to 3wt% of the diluents, 2 to 30wt% of flyash, 50 to 90wt% of medium-coarse sand, and 0.5 to 5wt% of organic chopped fiber. Early-stage operation time of the epoxy resin glue sand mixture is long; rapid curing molding can be realized under appropriate microwave radiation conditions, curing uniformity is excellent, mechanical properties are excellent, adhesive properties with common cement concrete interfaces are excellent, performance is stable, and the epoxy resin glue sand is an ideal rapid repairing material.

Owner:BEIHANG UNIV

Long-life lining type prestressed concrete cylinder pipe subjected to multilayer anti-corrosive treatment

ActiveCN102734568AImprove anti-crack and anti-seepage performanceAdd multiple barriersCorrosion preventionPipe protection against corrosion/incrustationFiberPre stress

The invention discloses a long-life lining type prestressed concrete cylinder pipe subjected to multilayer anti-corrosion treatment. The prestressed concrete cylinder pipe comprises a cylinder body part, a bellmouth steel ring and a spigot steel ring, wherein the bellmouth steel ring and the spigot steel ring are respectively arranged at two ends of the cylinder body part; the cylinder body part is provided with a steel cylinder inner wall concrete layer, a steel cylinder, a steel cylinder outer wall fiber anti-permeability and anti-cracking cement mortar protective layer and an outermost epoxy coal pitch anti-corrosive layer; the steel cylinder and the outer wall of the bellmouth steel ring are wound by prestressed steel wires; and anti-corrosive coatings are coated on the outer surface of the steel cylinder, the outer surface of the prestressed steel wires, the lower surface of the bellmouth steel ring and the upper surface of the spigot steel ring. The prestressed concrete cylinder pipe is simple in structure and anti-corrosive, and the service life of the prestressed concrete cylinder pipe can be effectively prolonged.

Owner:SHANDONG LONGQUAN PIPELINE ENG

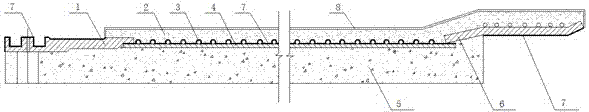

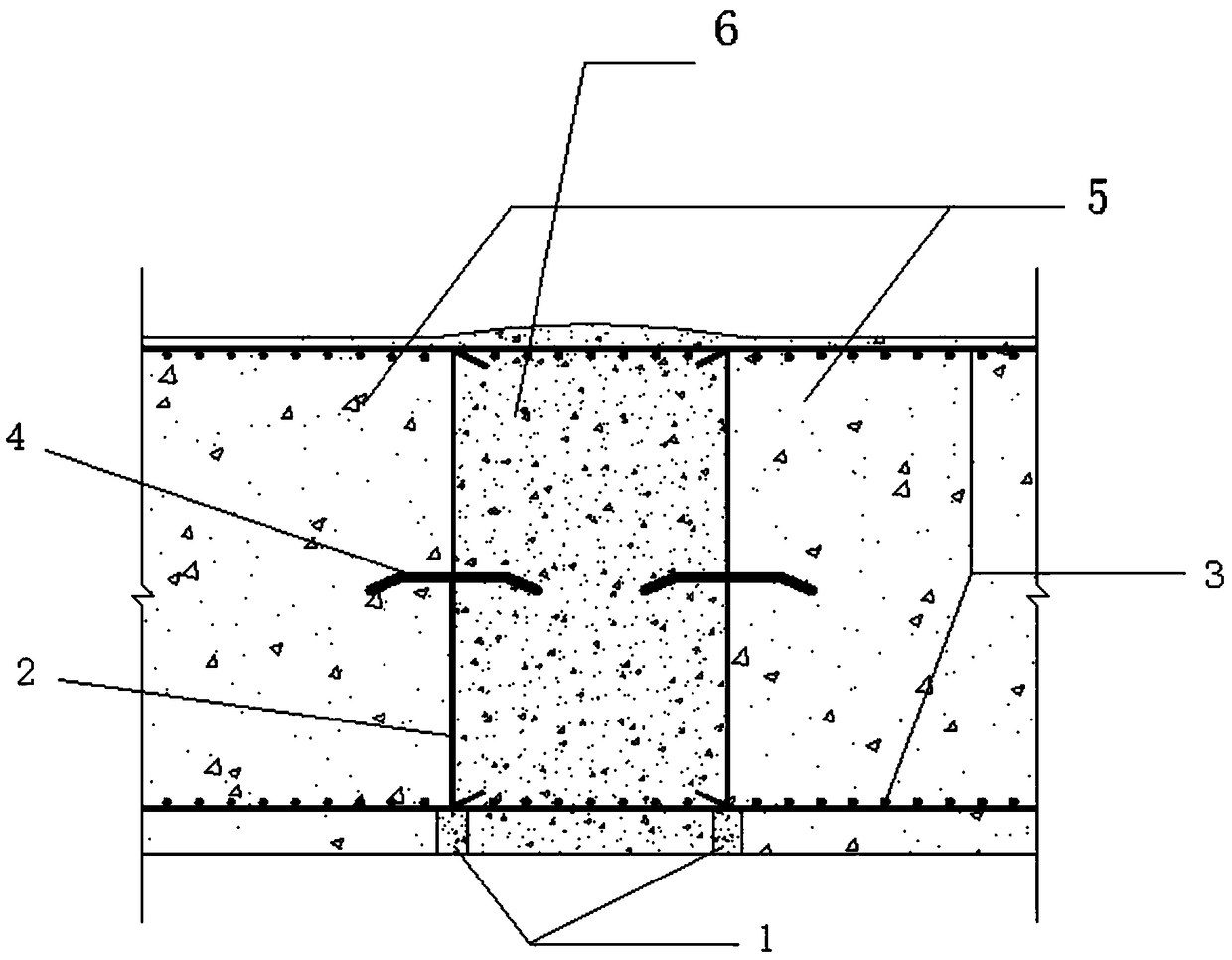

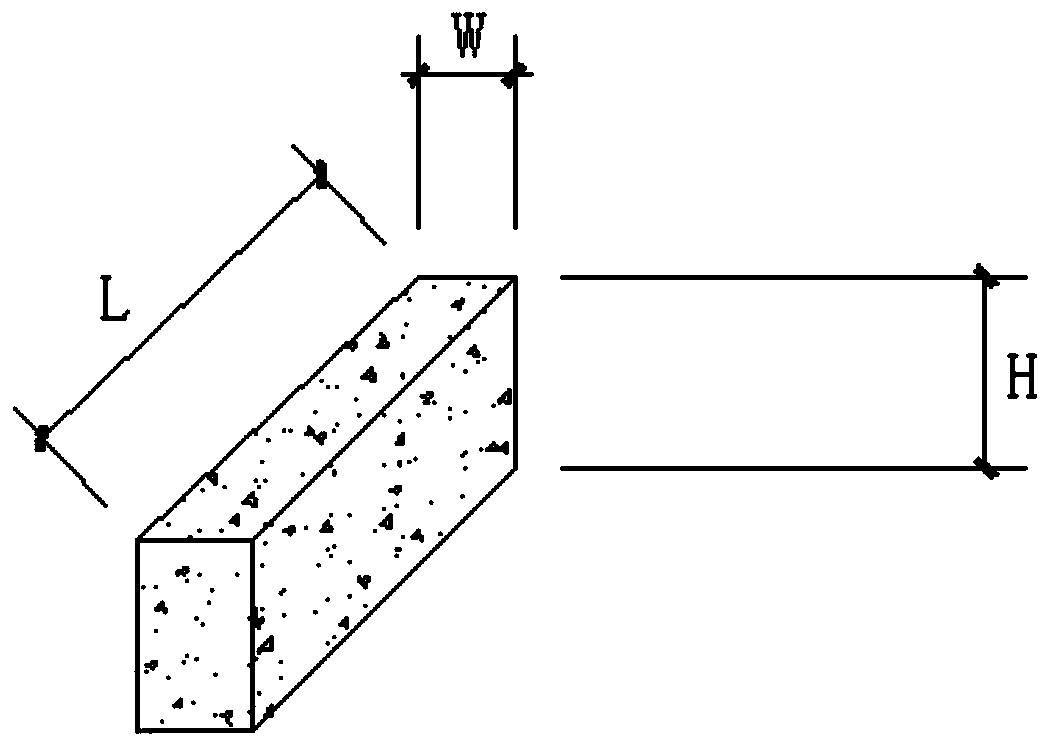

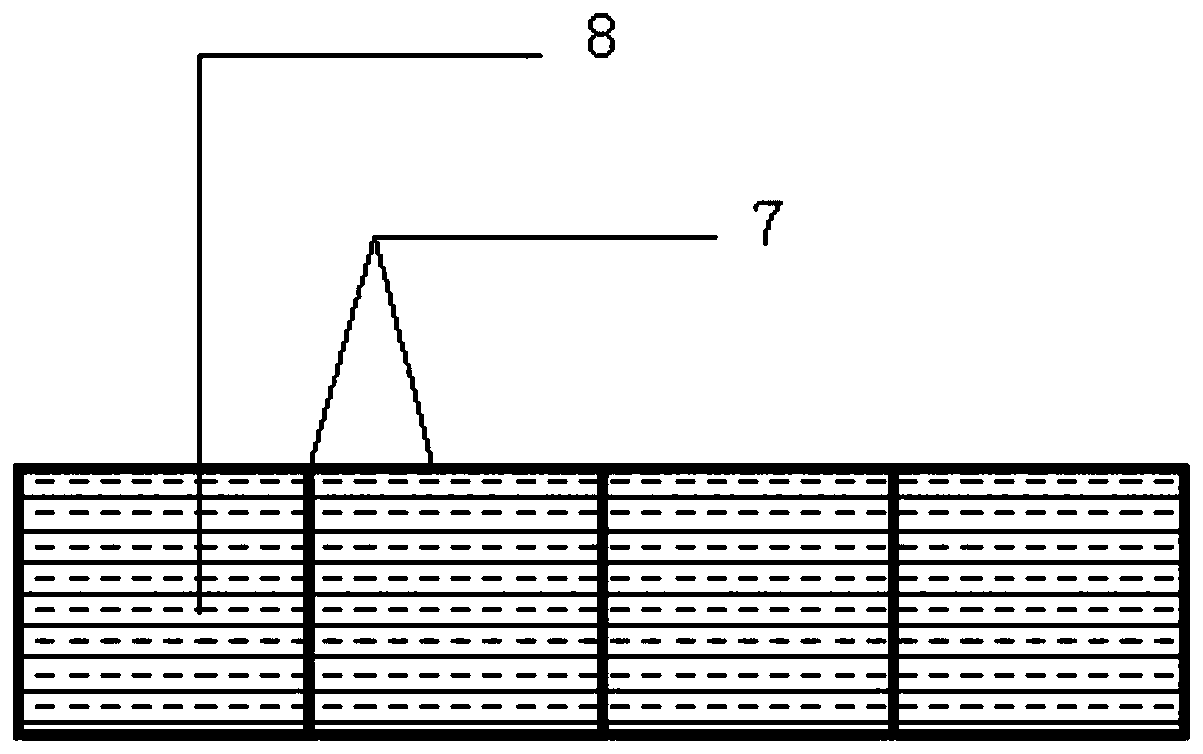

Anti-cracking waterproof construction method for post-poured strip

InactiveCN109057338AReduce gapGuarantee the construction qualityBuilding material handlingBuilding insulationsEconomic benefitsRebar

The invention discloses an anti-cracking waterproof construction method for a post-poured strip. The method comprises the following steps of pouring of fine-stone waterproof concrete strips; binding of plate bottom reinforcing steel bars; installation of a lower-layer dense-hole steel wire mesh frame; installation of water-stopping steel plates; installation of an upper-layer dense-hole steel wiremesh frame; binding of plate top reinforcing steel bars; formwork hanging; pouring of concrete at the two sides of the post-poured strip; die removing and maintenance; removal of dense-hole steel wire meshes; pouring of concrete in the post-poured strip. The construction method is reasonable in design and convenient to operate, the anti-cracking and waterproof effects of the post-poured strip after construction are good, the economic benefits are increased, and meanwhile the construction quality of the post-poured strip is effectively ensured.

Owner:CHINA MCC17 GRP

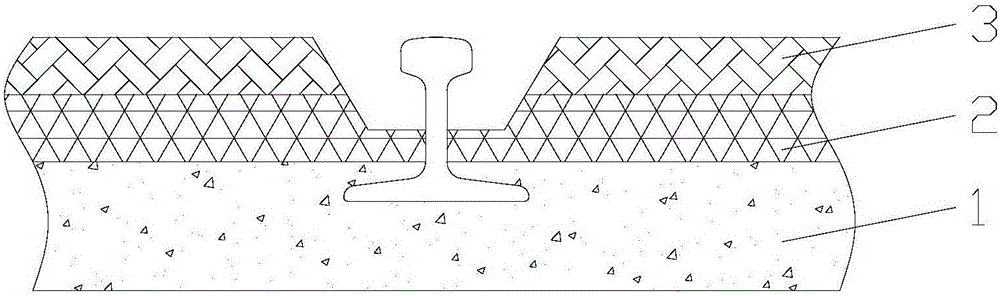

Tramcar basalt fiber composite road surface structure

InactiveCN106223158AExtended service lifeIncreased durabilityIn situ pavingsTemporary pavingsEnvironmental effectAsphalt mastic

Currently, a road surface structure in a tunnel is composed of conventional asphalt concrete and fracture-resistant concrete or steel fiber concrete. Primary causes of road surface damage comprise direct impact of repeated crushing of rubber wheels and external environmental effects, at best, cracks and tracks are generated, the riding comfort is affected, at worst, pits and grooves are generated, and the overall stability and safety of the road surface are threatened; and even traffic is delayed for a long time during later maintenance. To improve the fracture resistance and pressure resistance of the road surface, prolong the service life of the road surface and recover the road surface rapidly during later maintenance, the invention provides a tramcar basalt fiber composite road surface structure, and the tramcar basalt fiber composite road surface structure sequentially comprises a basalt fiber concrete base layer, a basalt fiber medium grain type asphalt concrete layer and a basalt fiber asphalt mastic gravel mixed aggregate layer from bottom to top.

Owner:中铁二院重庆勘察设计研究院有限责任公司 +1

Anti-cracking plastering mortar

InactiveCN105776993AImprove fracture toughnessImprove anti-crack and anti-seepage performancePortland cementMaterials science

The invention belongs to the technical field of building materials and construction, and particularly relates to anti-cracking plastering mortar.The anti-cracking plastering mortar is prepared from, by weight, 200-220 parts of ordinary Portland cement, 780-800 parts of engineering sand, 1-1.5 parts of polypropylene fibers and 0.5-0.6 part of ordinary mortar additive.The anti-cracking plastering mortar has a good application property and water-retaining property, and can be widely applied to building walls.Compared with traditional products or existing products, a three-dimensional disordered distribution net bearing function can be formed in concrete, and microcracks formed at the preliminary hardening stage of a cement product are blocked in the development process and can hardly further develop.Therefore, the breaking tenacity of the cement product can be improved, the anti-cracking and anti-seepage performance of the cement product is improved, and the anti-cracking plastering mortar is a novel ideal anti-cracking, anti-seepage, abrasion resisting and heat preserving material in the mortar and concrete work.

Owner:HUBEI HENGFU ENERGY SAVING TECH CO LTD

Construction technology for anti-crack and waterproof structure of post-cast strip

InactiveCN108411945APrevent inflowGuarantee the construction qualityArtificial islandsProtective foundationRebarWire mesh

The invention provides a construction technology for an anti-crack and waterproof structure of a post-cast strip. The construction technology comprises the following steps that fine stone waterproof concrete strips are poured; steel bars at a slab bottom are bound; a lower-layer dense hole steel wire frame is arranged; water stop steel plates are arranged; an upper-layer dense hole steel wire frame is arranged; steel bars at a slab top are bound; a mold is hoisted; concrete on the two sides of the post-cast strip is poured; mold stripping and maintenance are carried out; the dense hole steel wire frames are disassembled; and concrete in the post-cast strip is poured (the concrete in the post-cast strip can be poured only when the design requirement deadline is reached). The construction technology aims to solve the problem that sedimentation of the concrete in the post-cast strip is caused due to the facts that in a traditional technology, a gap is reserved between a steel wire mesh and a base layer, and the concrete always flows into the post-cast strip from the gap in the vibration process of the concrete.

Owner:CHINA MCC17 GRP

Liquid expansion agent for pumping concrete

The present invention relates to a liquid expansion agent for pumping concrete. The liquid expansion agent for pumping concrete comprises: an expansion component, a swelling component, a reduction component, a water retention component, a pumping component, and a functional component; The expansion component is made of anhydrous aluminum sulfate; the swelling component is made of polyvinyl alcohol, the reduction component is made of polyether, the water retention component is made of hydroxypropyl cellulose ether, the pumping component is made of a poly-carboxylic acid salt water reducer, and the functional component is made of sodium gluconate; and the contents of the components in percentage are: 0.10%-0.18% of anhydrous aluminum sulfate, 0.05%-0.10% of polyvinyl alcohol, 0.20%-0.60% of polyether, 0.08%-0.15% of hydroxypropyl cellulose ether, 0.40%-0.60% of poly-carboxylic acid salt water reducer, and 0.04%-0.07% of sodium gluconate. Adding the expansion agent into concrete can effectively increase volume expansion of the concrete and reduce volume shrinkage of the concrete, thereby improving crack resistance and impermeability of the concrete.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Anti-cracking and anti-seepage agent for concrete

ActiveCN104140217AExtend post-expansion timeGuaranteed post-shrinkage compensationSlagUltimate tensile strength

The invention is suitable for the field of building materials and provides an anti-cracking and anti-seepage agent for concrete. The anti-cracking and anti-seepage agent comprises the following components in parts by weight: 10-70 parts of flyash, 10-50 parts of fluorgypsum and 10-70 parts of phosphorus slag. The anti-cracking and anti-seepage agent for concrete can reduce hydration heat, compensate for concrete shrinkage, improve the concrete strength and prevent cracking, seepage and other phenomena of concrete, thus improving the stability and durability of concrete.

Owner:深圳崟坤科技有限公司

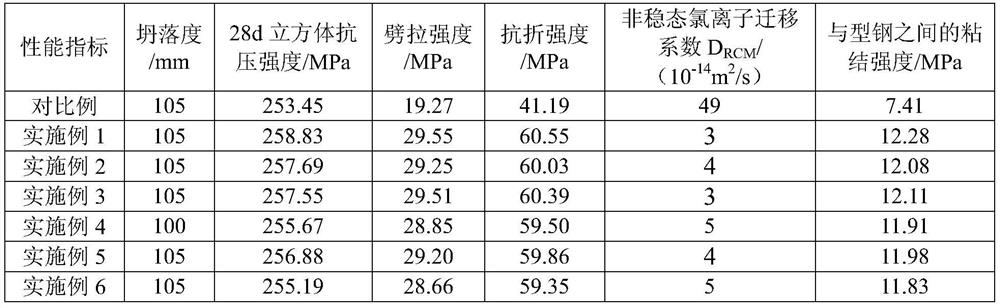

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

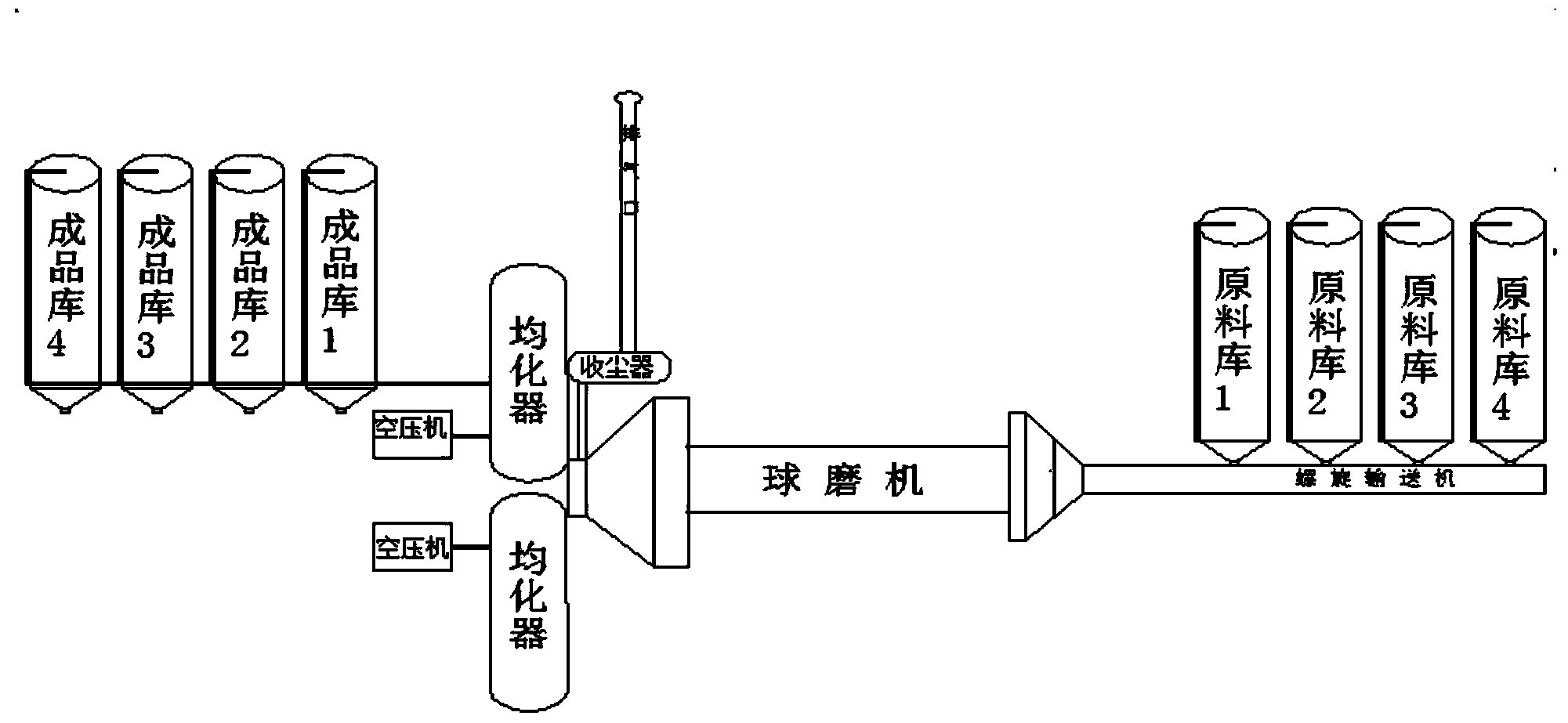

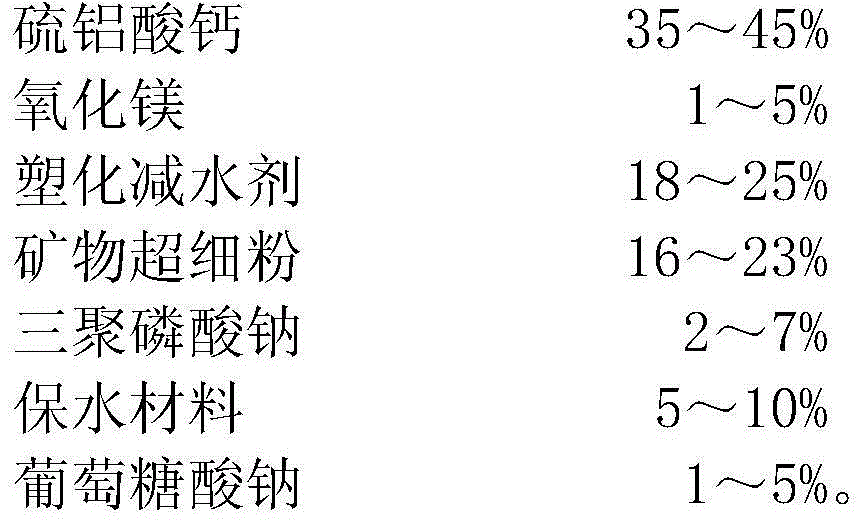

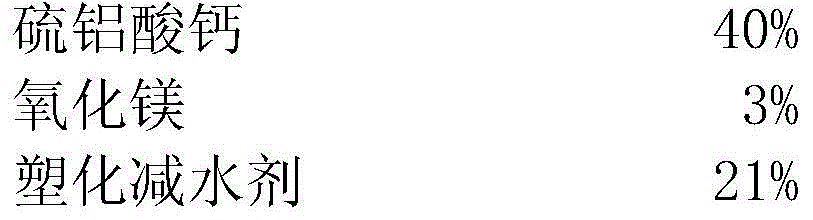

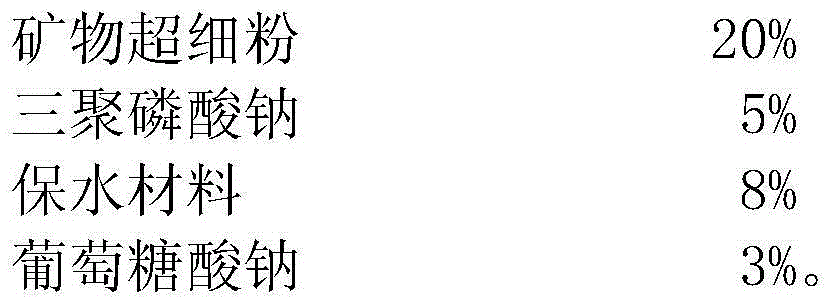

Concrete expansion agent

The invention relates to the technical field of concrete admixtures, and in particular relates to a concrete expansion agent. The concrete expansion agent is prepared from the following raw materials in percentage by weight: 35-45% of calcium sulphoaluminate, 1-5% of magnesium oxide, 18-25% of a plasticized water reducer, 16-23% of ultrafine mineral powder, 2-7% of sodium tripolyphosphate, 5-10% of a water holding material and 1-5% of sodium gluconate. The concrete expansion agent disclosed by the invention can be used for solving the problems of high expansion rate, insufficient shrinkage compensating effect and the like of an existing expansion agent; meanwhile, if being mixed in concrete, the concrete expansion agent disclosed by the invention can be used for improving the concrete strength in middle and later stages and properly prolonging the setting time of the concrete; and the concrete expansion agent is also excellent in high crack resistance and seepage control performance, good in adaptability, and suitable for concretes differing in strength grade.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com