Anti-cracking plastering mortar

A technology for plastering mortar and mortar additives, applied in the field of anti-cracking plastering mortar, which can solve problems such as poor construction performance, poor water retention, poor construction performance, and easy cracking, so as to improve anti-cracking and anti-seepage performance, improve fracture toughness, and facilitate construction sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

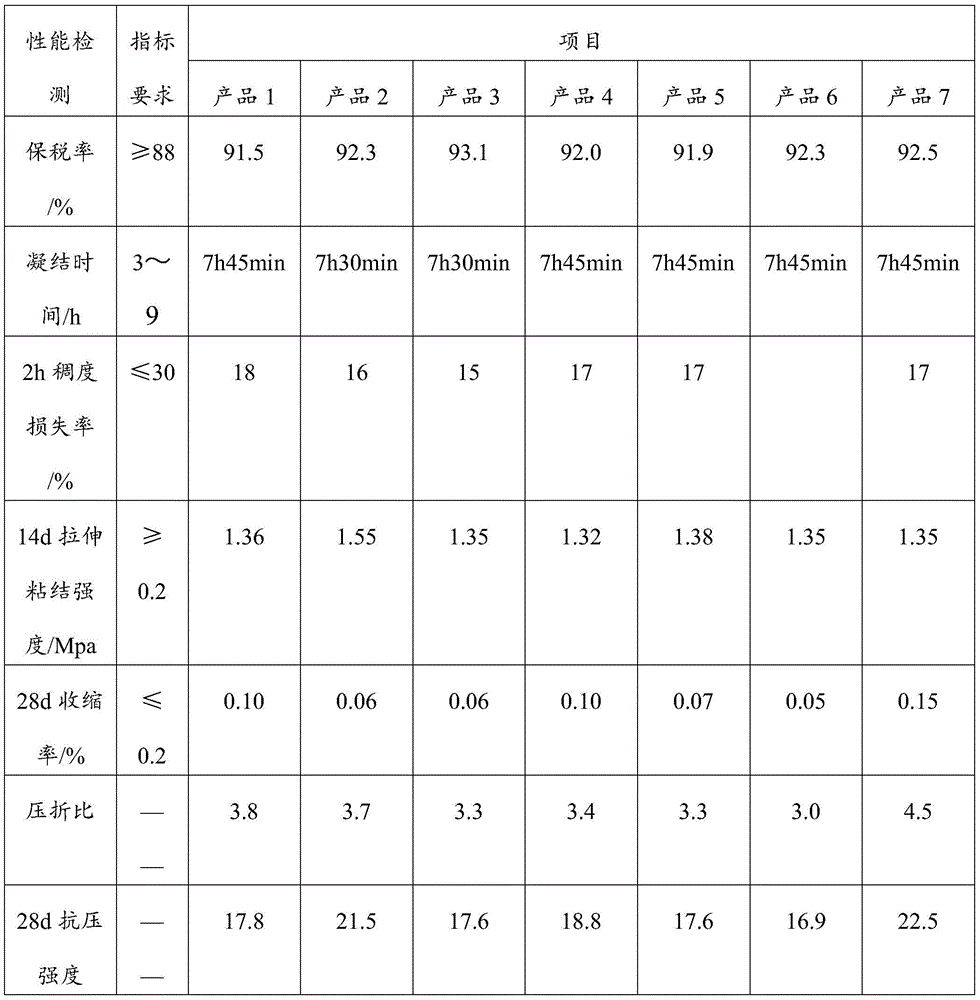

Embodiment 1

[0015] 202kg of ordinary Portland cement, 798kg of engineering sand, 1kg of polypropylene fiber and 0.5kg of ordinary mortar additive were uniformly mixed to obtain product 1.

Embodiment 2

[0017] 218kg of ordinary Portland cement, 782kg of engineering sand, 1.5kg of polypropylene fiber, and 0.5kg of ordinary mortar additive were uniformly mixed to obtain product 2.

Embodiment 3

[0019] 210kg of ordinary Portland cement, 790kg of engineering sand, 1.2kg of polypropylene fiber, and 0.6kg of ordinary mortar additives were uniformly mixed to obtain product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com