High-performance cement expansive agent and production method thereof

A high-performance concrete and production method technology, applied in the field of concrete expansion agent, can solve problems such as cracking and deterioration, achieve reasonable particle gradation, reduce early shrinkage, and have good anti-crack and anti-seepage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

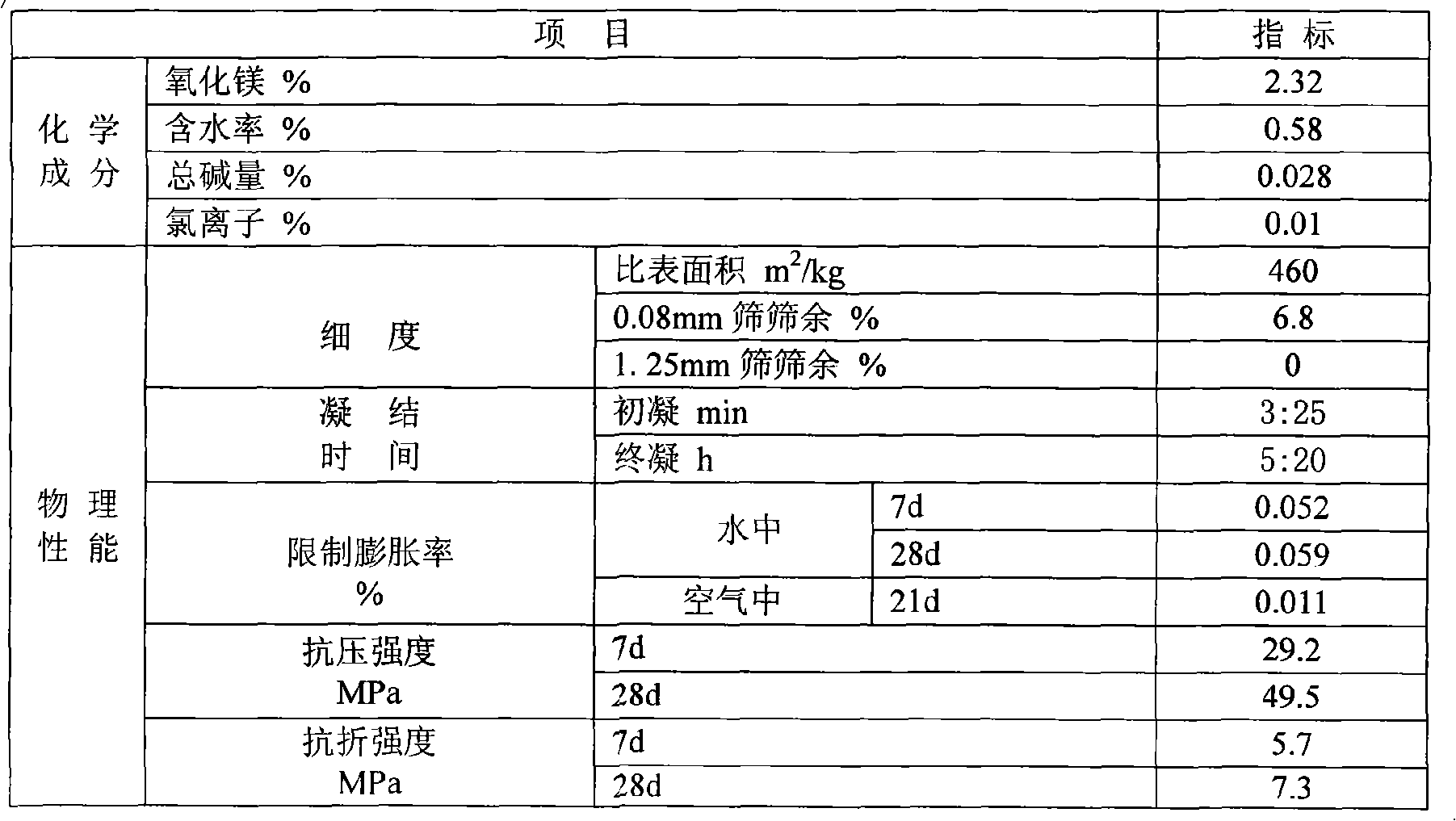

[0035] Embodiment: the prescription of high-performance concrete expansive agent and its production

[0036] The formula is as follows:

[0037] raw material name

Content (weight%)

t / h

40

10.40

Desulfurization gypsum

25

6.50

23

5.98

Alum mud

9

2.34

polyglycol ether

3

0.78

total

100

26.00

[0038] Put the blocky calcium aluminate clinker into the vertical mill to dry and grind to 1g0-220m 2 / Kg, enter the special warehouse, and then anhydrite, desulfurized gypsum, calcium aluminate clinker, and alum mud are electronically weighed according to the formula and weighed 25.22t / h, then enter the ball mill, and grind until the specific surface area is 400-500m 2 / Kg, at the same time, the polyethanol ether is atomized at 0.78t / h by special spray equipment and sprayed into the ball mill.

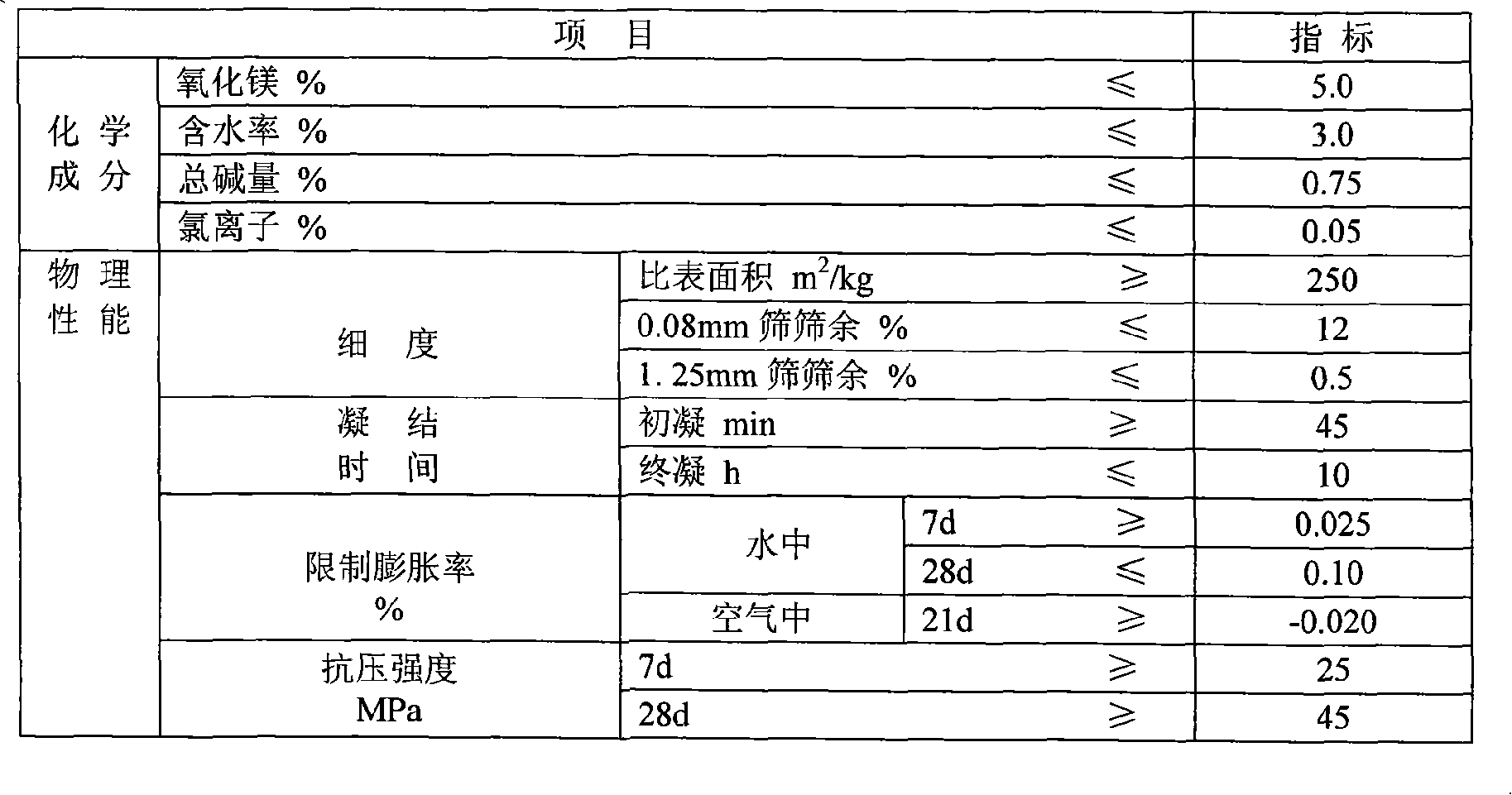

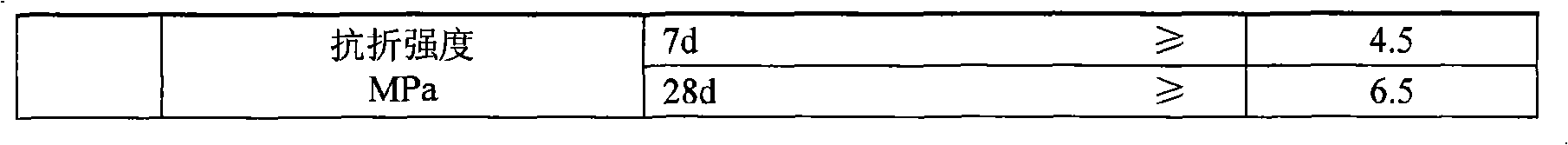

[0039] Product perfor...

example 1

[0064] Example 1: Application of high-performance concrete expansion agent in basement C35 and C40 impermeable concrete in the building of Weike Central Business District in Cixi City.

[0065] Concrete Design Requirements:

[0066] (1) The design concrete grade of the bottom plate is C35, the impermeability grade is P10, and the limited expansion rate of the concrete is 14d≥0.015% in water.

[0067] (2) The design concrete grade of the side wall is C40, the impermeability grade is P10, and the limited expansion rate of the concrete is 14d ≥ 0.020% in water.

[0068] See the table for specific data

[0069] Table 9 Floor and side wall concrete mix ratio

[0070]

[0071]

[0072] Table 10 concrete performance index

[0073]

[0074] The above data all meet the design requirements.

example 2

[0075] Example 2: The application of high-performance concrete expansion agent in the basement floor, side wall and post-pouring belt of Shangcheng by Linhai Lake.

[0076] Concrete Design Requirements:

[0077] (1) The design concrete grade of the bottom plate is C35, and the limited expansion rate of the concrete in water for 14 days is ≥0.015%.

[0078] (2) The design concrete grade of the side wall is C40, and the limited expansion rate of the concrete after 14 days in water is ≥0.020%.

[0079] (3) The design concrete grade of the post-pouring belt is C40, and the limited expansion rate of the concrete in water for 14 days is ≥0.025%.

[0080] Table 11 Concrete mix ratio for floors, side walls, and post-cast strips

[0081]

[0082] Table 12 concrete performance index

[0083]

[0084] The above data all meet the design requirements.

[0085] The invention realizes reasonable grading of particles by making full use of the difference in grindability of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com