Anti-shrinkage concrete and preparation process thereof

A technology for concrete and anti-shrinkage, applied in the field of concrete preparation, can solve problems such as corrosion resistance and other problems, concrete cracking, etc., and achieve the effects of reducing shrinkage rate, improving strength, and improving graft reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

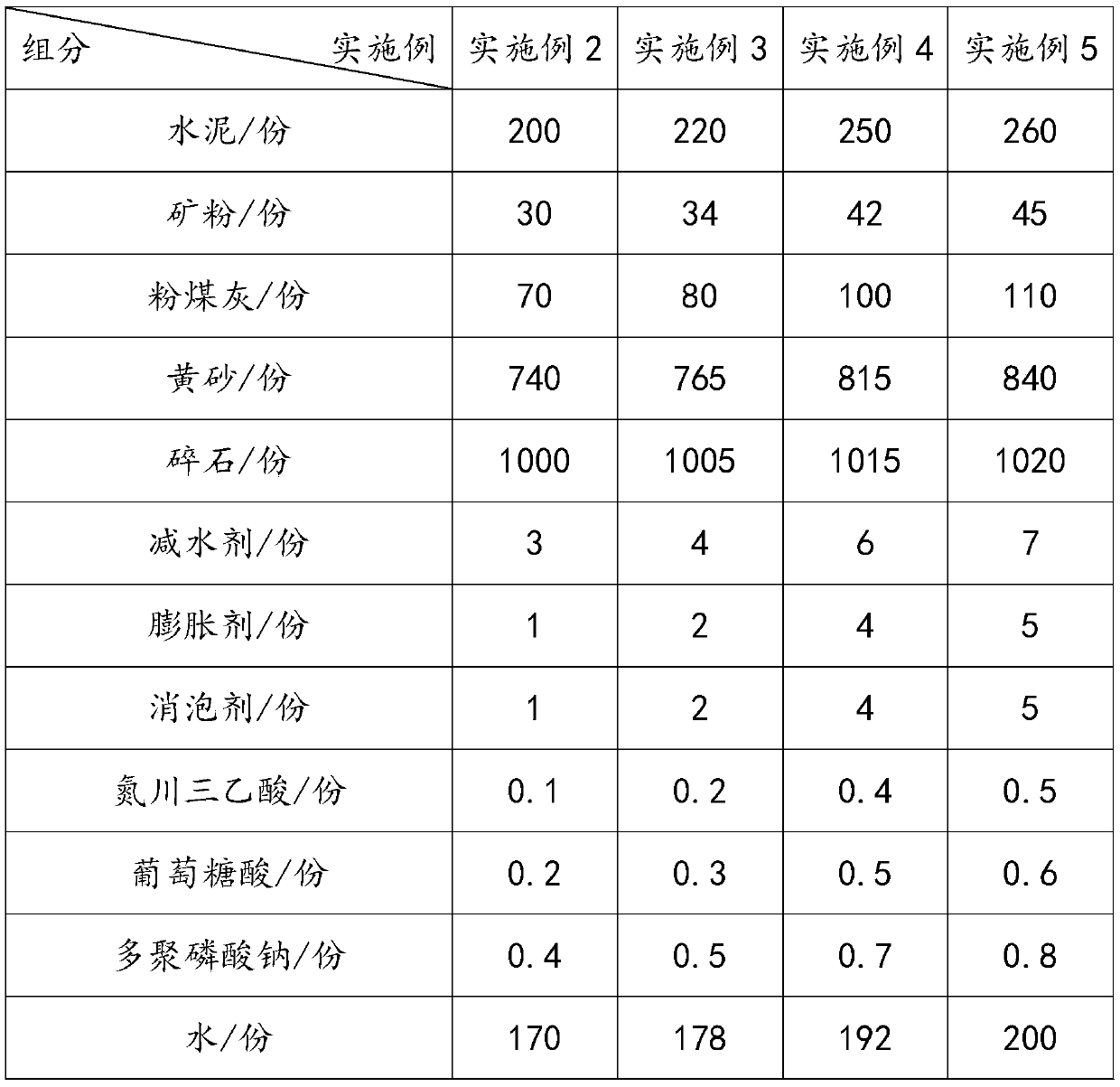

Examples

preparation example Construction

[0082] The present invention discloses a method for preparing anti-shrinkage concrete, comprising the following preparation steps:

[0083] 1) Prepare water reducer in proportion:

[0084] A. Prepare the first auxiliary agent in proportion;

[0085] a. After mixing 3% maleic anhydride and 28.6% water, A mixture is prepared;

[0086] b. After mixing 18% of the sepiolite fiber and the A mixture, the B mixture is prepared;

[0087] c. After mixing 4% SPDPC and 22% dimethyl sulfoxide, add it to the B mixture to prepare the C mixture;

[0088] d. Add 12% of PSPHD, 12% of low-density polyethylene and 0.4% of titanate coupling agent to C mixture to prepare the first auxiliary agent; the titanate coupling agent is from Nanjing Nengde Chemical Co., Ltd. The titanate coupling agent sold by the company is TCA-AA75;

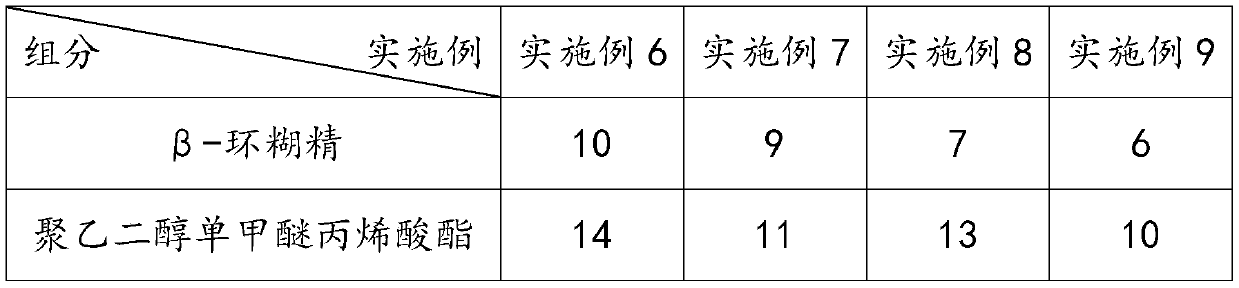

[0089]B. After mixing 8% of β-cyclodextrin, 12% of polyethylene glycol monomethyl ether acrylate, 8% of sodium methacrylate sulfonate, 3% of butanediol and 38.2% of wate...

Embodiment 1

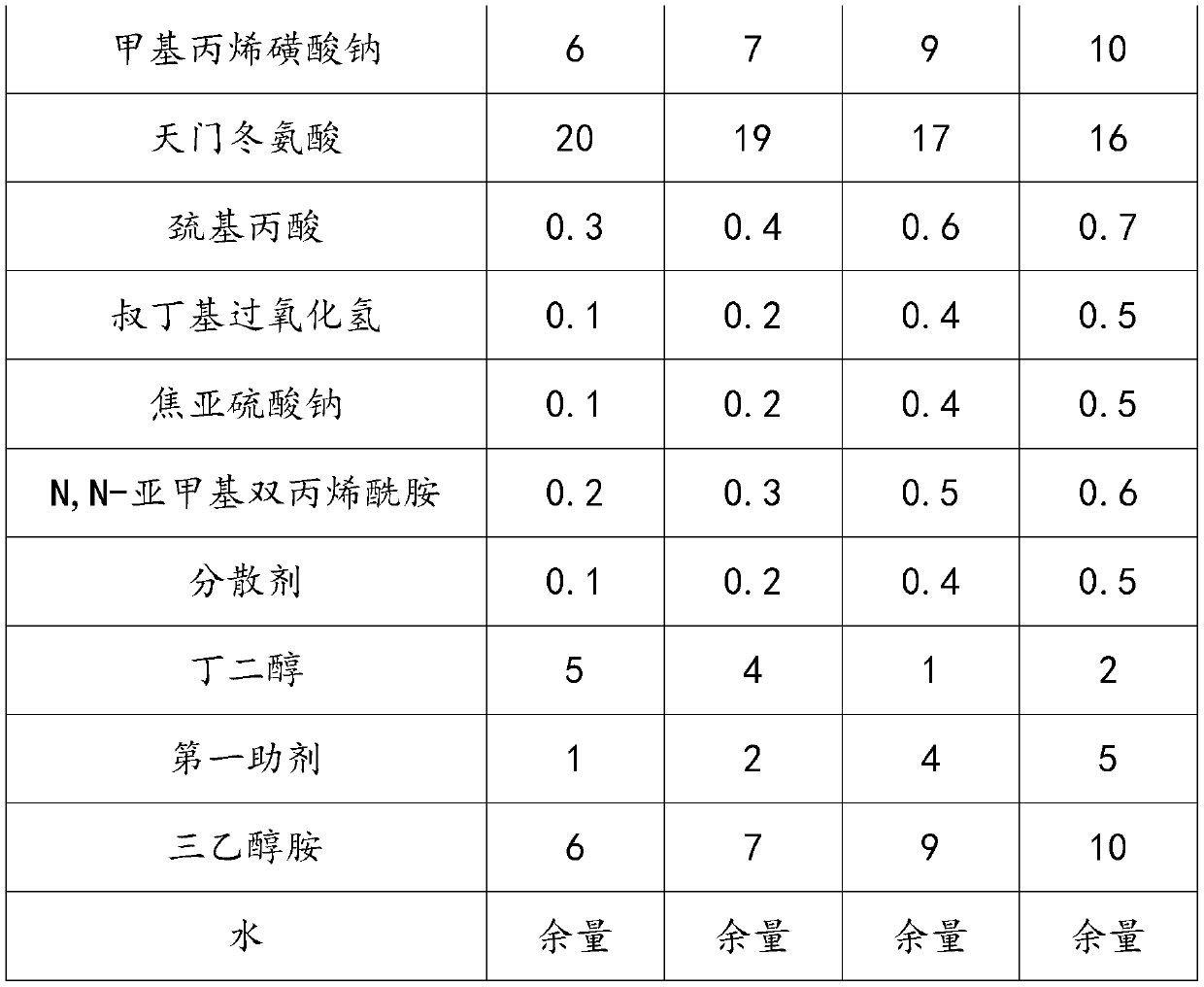

[0108] The difference between Examples 10-13 and Example 1 is that the first auxiliary agent includes the following raw materials in weight percent:

[0109]

[0110] The difference between Embodiment 14-17 and Embodiment 1 is that the expansion agent includes the following raw materials in weight percentage:

[0111]

[0112] The difference between Embodiment 18-21 and Embodiment 1 is that the second auxiliary agent includes the following raw materials in weight percentage:

[0113]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com