Patents

Literature

104results about How to "Increase the number of branches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

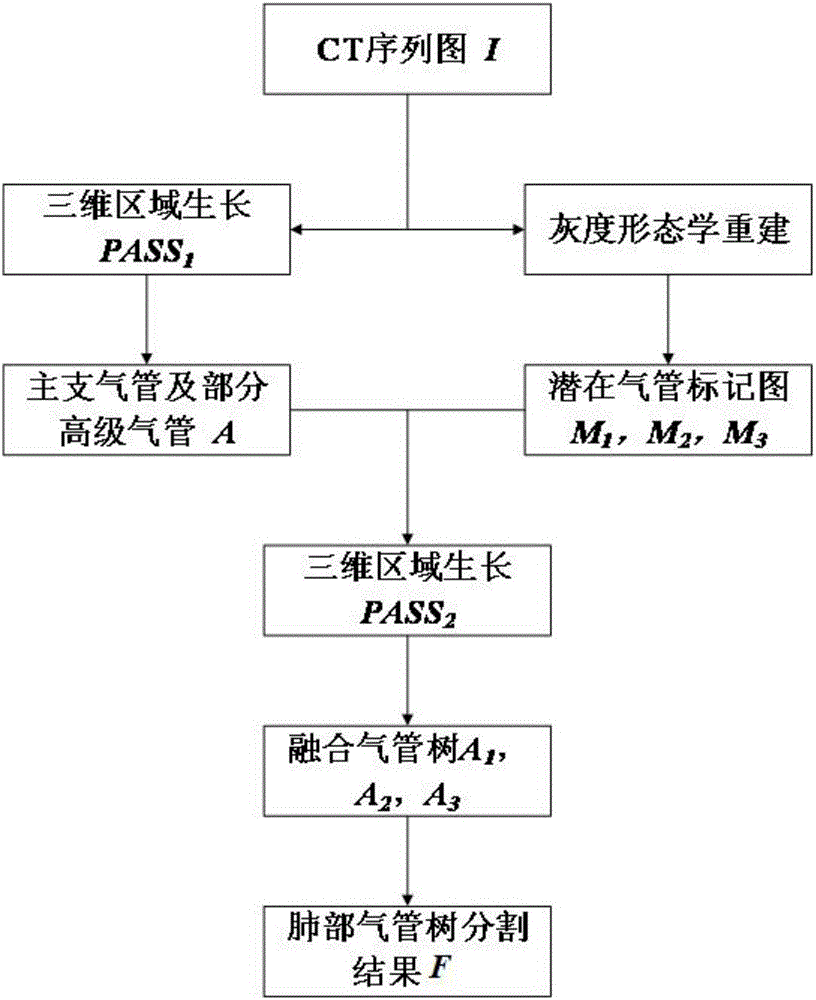

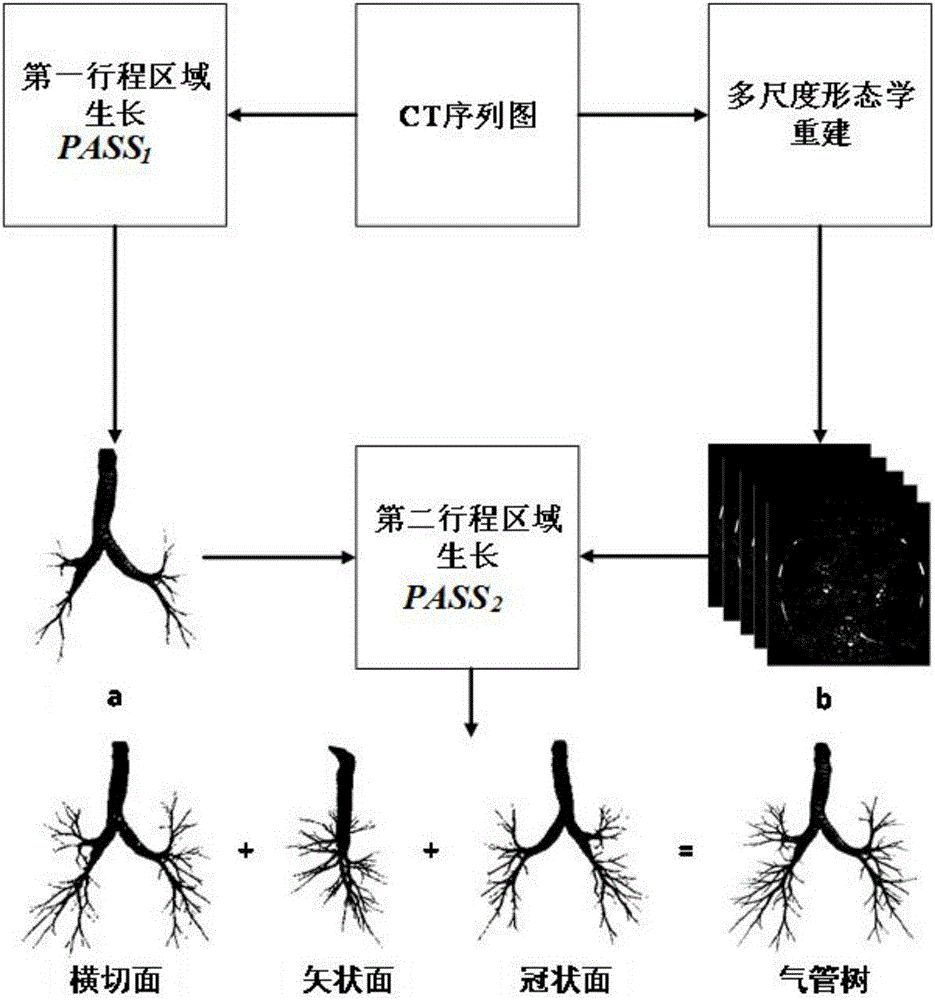

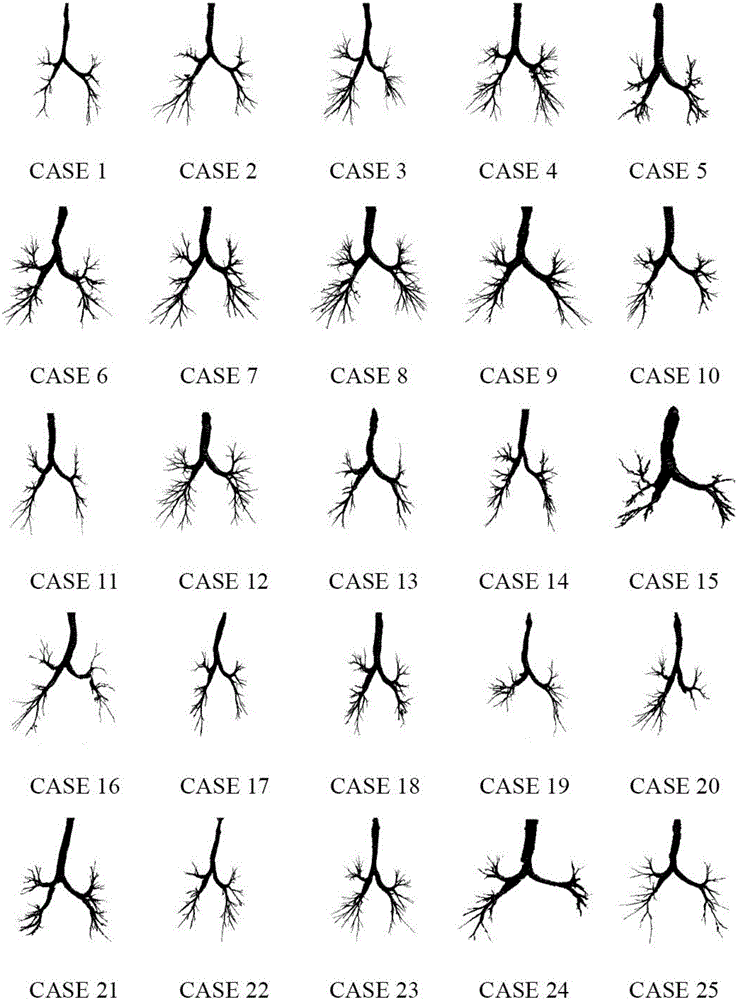

Two-pass region growing and morphological reconstruction combination-based lung airway tree segmentation method

ActiveCN106097305AIncrease the number of branchesReduce the ratioImage enhancementImage analysisMorphological operatorsCoronal plane

The invention aims to provide a two-pass three-dimensional region growing and morphology combination-based lung airway tree segmentation algorithm for solving the problem to realize effective segmentation of a lung airway tree. The two-pass region growing and morphological reconstruction combination-based lung airway tree segmentation method provided by the invention comprises the following steps of automatically obtaining a seed point P1 of three-dimensional region growing from a serial section image; performing first-pass region growing by taking P1 as the seed point to obtain a lung main airway tree; setting a multi-scale morphological operator, and obtaining corresponding airway marking graphs in three anatomic positions of a cross section, a coronal plane and a sagittal plane by utilizing gray-scale morphological reconstruction operation; performing second-pass region growing by taking the lung main airway tree as a basis and the airway marking graphs in the three anatomic positions as limitation conditions to obtain corresponding segmented airway trees; and fusing the segmented airway trees to obtain a final lung airway tree segmentation result F.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

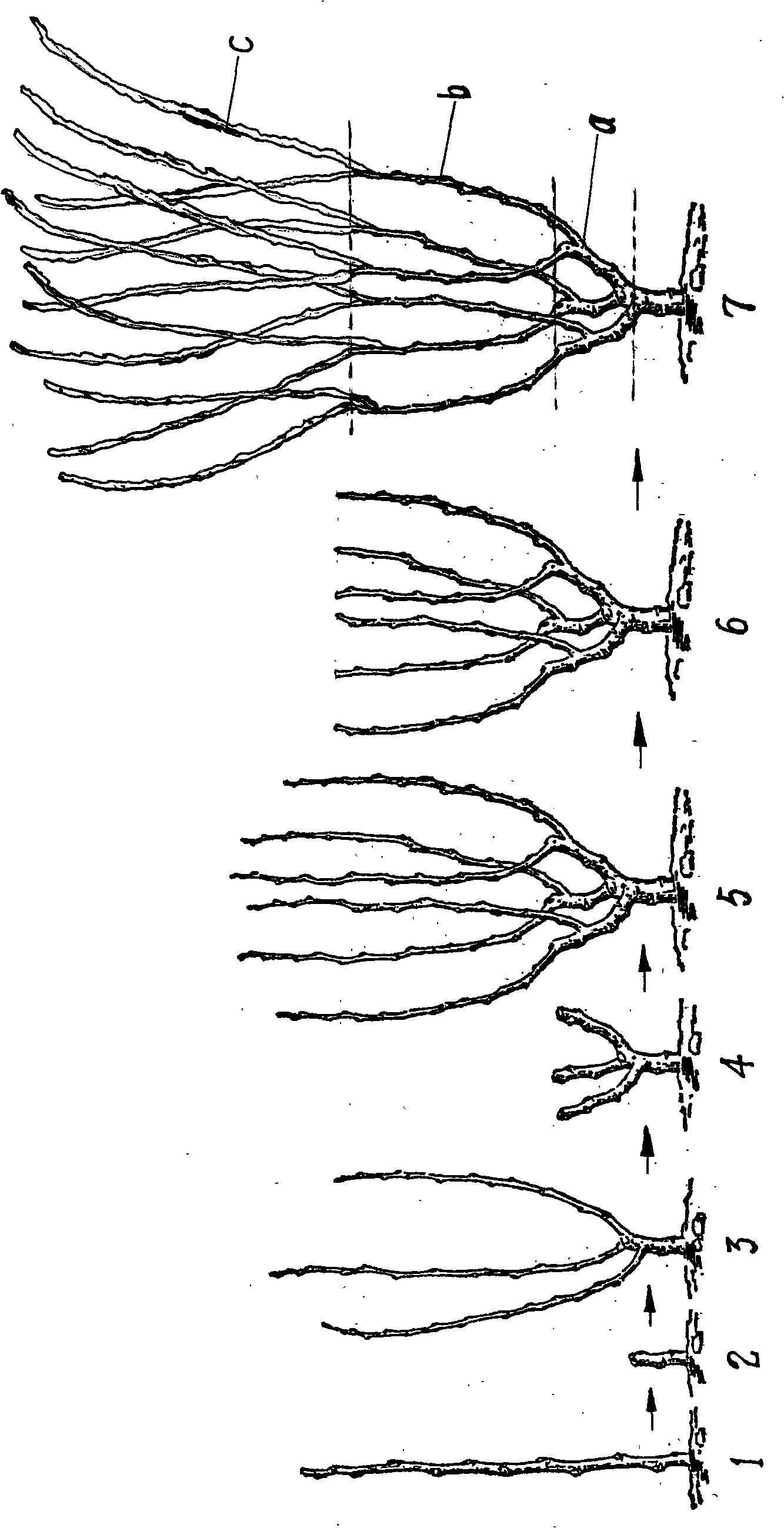

Breeding method of apple dwarf self-rooting multi-branch nursery stock

InactiveCN102577900AGood rooting rateOvercoming rooting rateCultivating equipmentsHorticultureRootstockObserved Survival

The invention discloses a breeding method of an apple dwarf self-rooting multi-branch nursery stock. The breeding method comprises the following steps: firstly selecting apple dwarf rootstock varieties G41, M9, Pajam1 and T337 as maternal stocks, establishing an apple dwarf rootstock breeding seedbed, and using saw dust to cover newly grown branches of the apple dwarf rootstocks on the seedbed from the beginning of June to the beginning of July, so as to breed the apple dwarf rootstocks with good root systems; planting the apple dwarf rootstocks in a density of 5000-6000 plants per mu in a nursery garden in spring, establishing the nursery garden for producing finished nursery stocks; and grafting apple variety in autumn in the same year to obtain the apple dwarf self-rooting multi-branch nursery stocks in the next year. With the adoption of the cultivation method provided by the invention, the disadvantages of poor quality of nursery stocks produced by the existing stock breeding method, thin and weak nursery stocks, and low survival rate of the nursery stocks in the established nursery garden are overcome.

Owner:NORTHWEST A & F UNIV

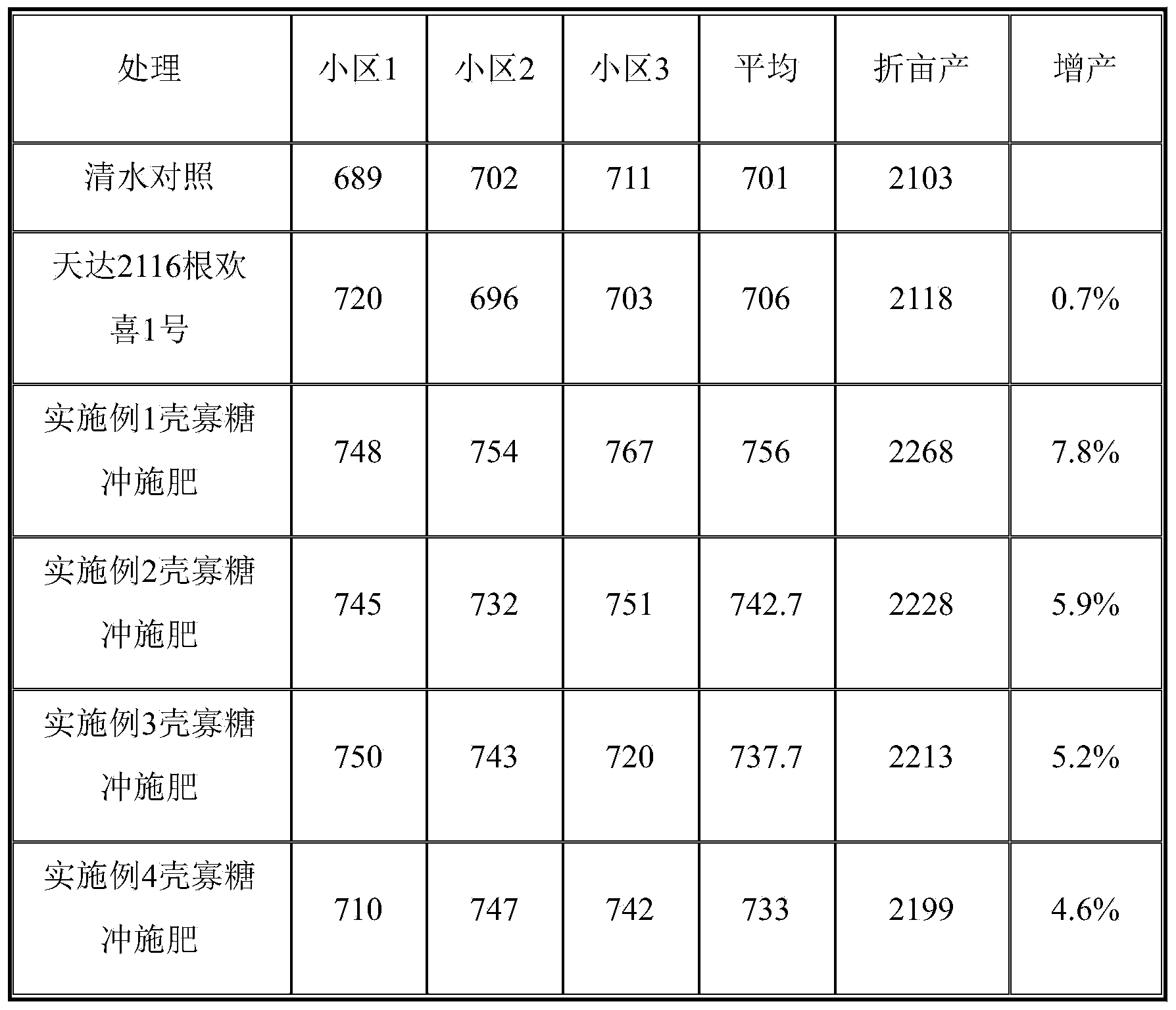

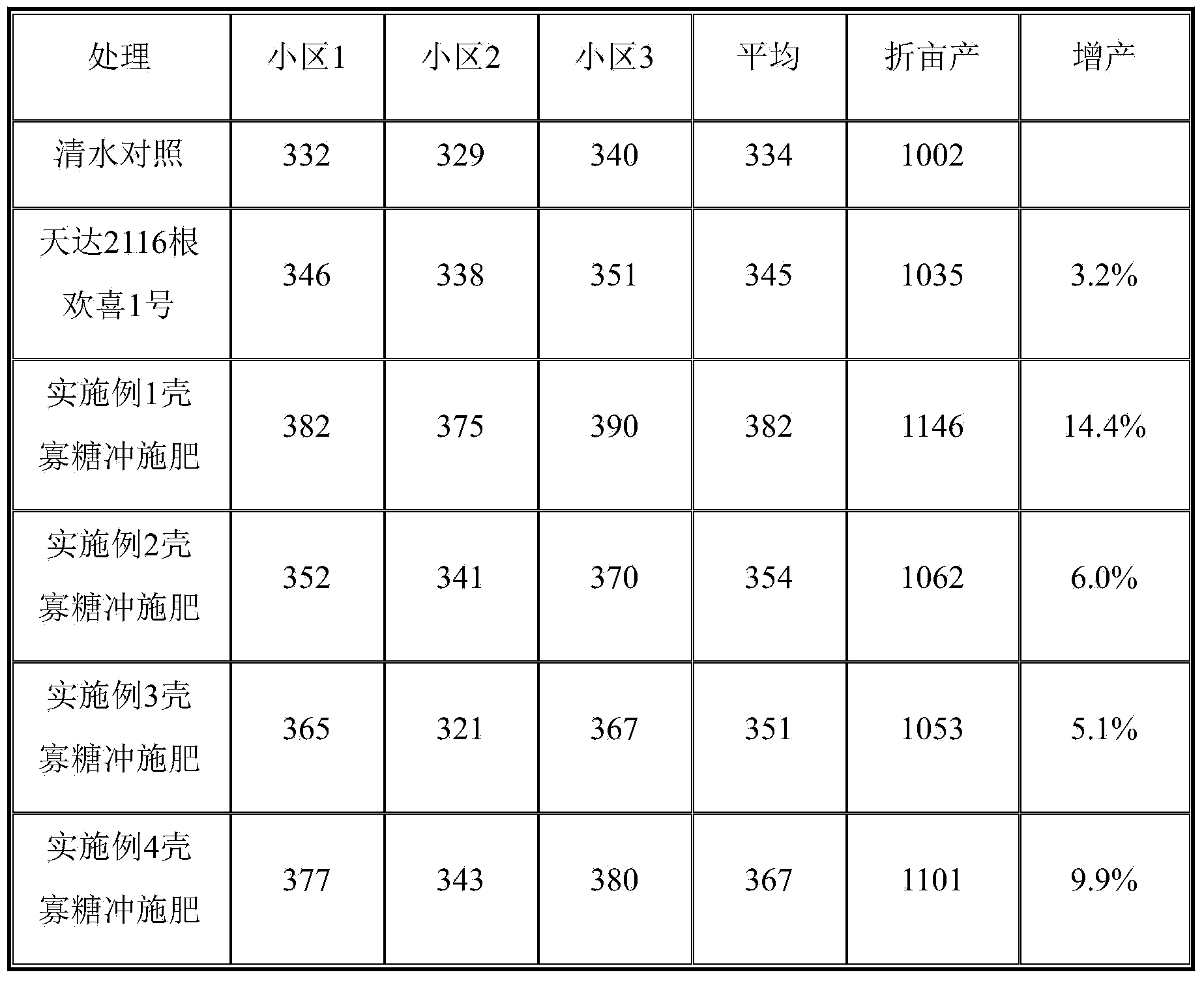

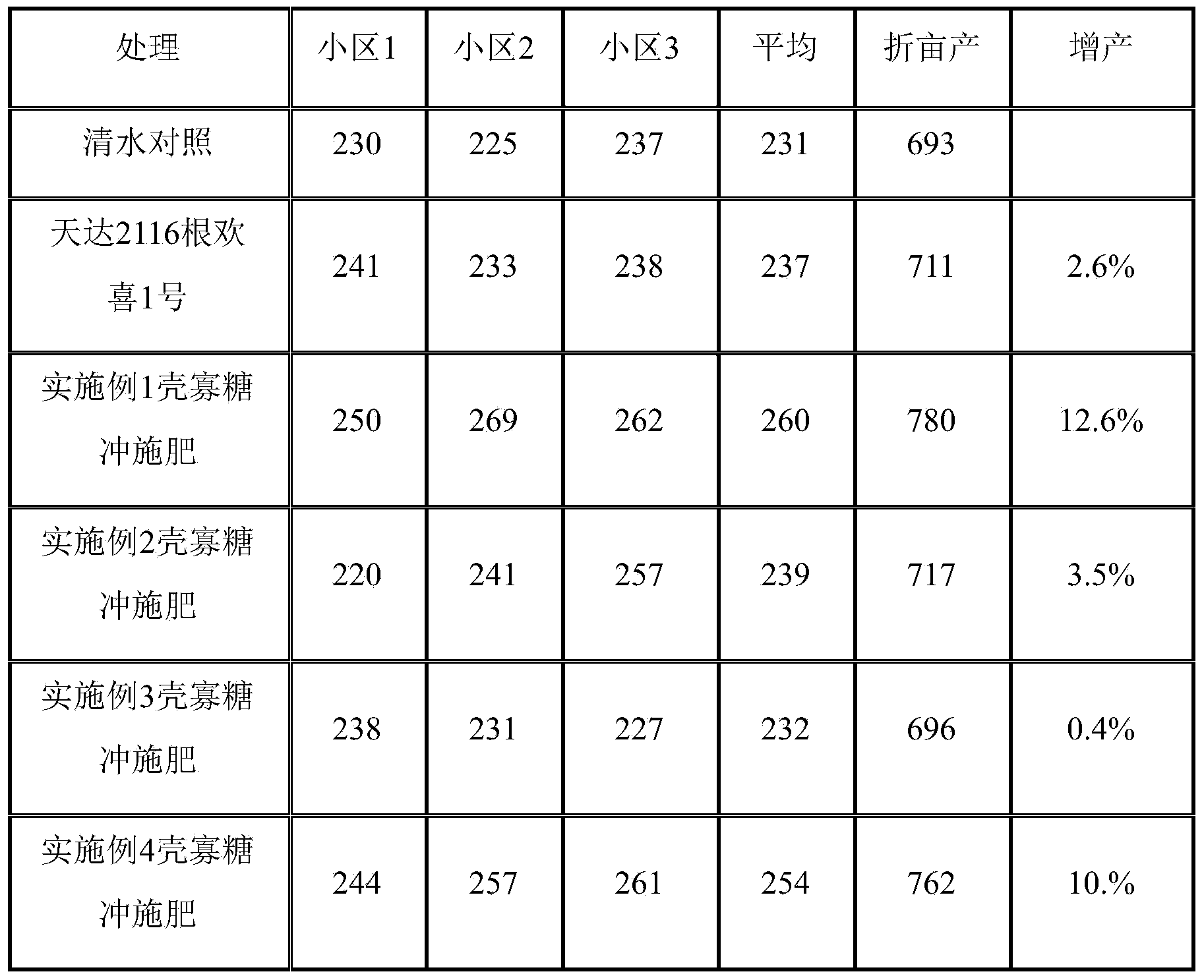

Water flush fertilizer containing chitosan oligosaccharide

ActiveCN104262015APromote germinationPromote generationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassium nitrateBrassinolide

The invention relates to the field of agriculture, in particular to a water flush fertilizer containing chitosan oligosaccharide. The water flush fertilizer consists of the following components in percentage by weight: 20-35% of amino acid raw powder, 10-20% of calcium nitrate dehydrate, 5-15% of monopotassium phosphate, 0.1-0.5% of chitosan oligosaccharide, 3-8% of iron vitriol, 1-5% of zinc sulfate heptahydrate, 1-5% of boric acid, 15-30% of potassium nitrate, 3-8% of urea and 0.01-0.05% of brassinolide. According to the water flush fertilizer provided by the invention, chitosan oligosaccharide is innovatively added into the water flush fertilizer, so that nutrition can be provided to plants continuously, the action time is long, different essential growth periods of the plants can be promoted, the environment is not affected, effective protecting films can be formed on the surfaces of the plants, and the anti-disease property and the resistance of the plants are improved.

Owner:QINGDAO BZ OLIGO BIOTECH

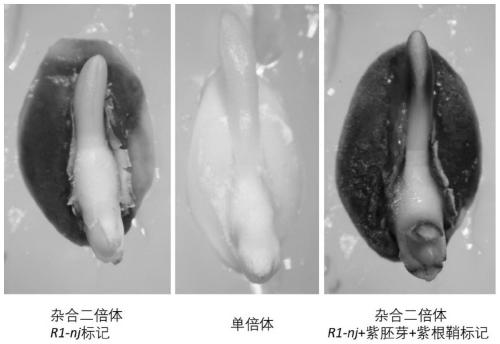

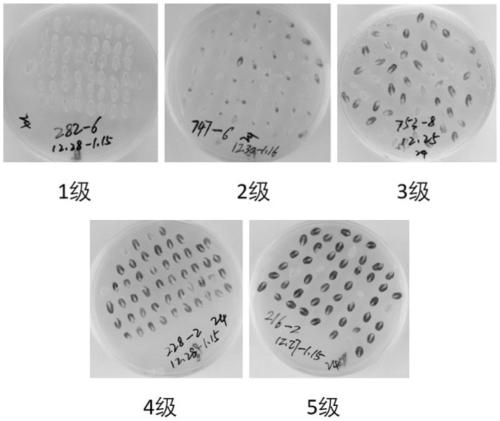

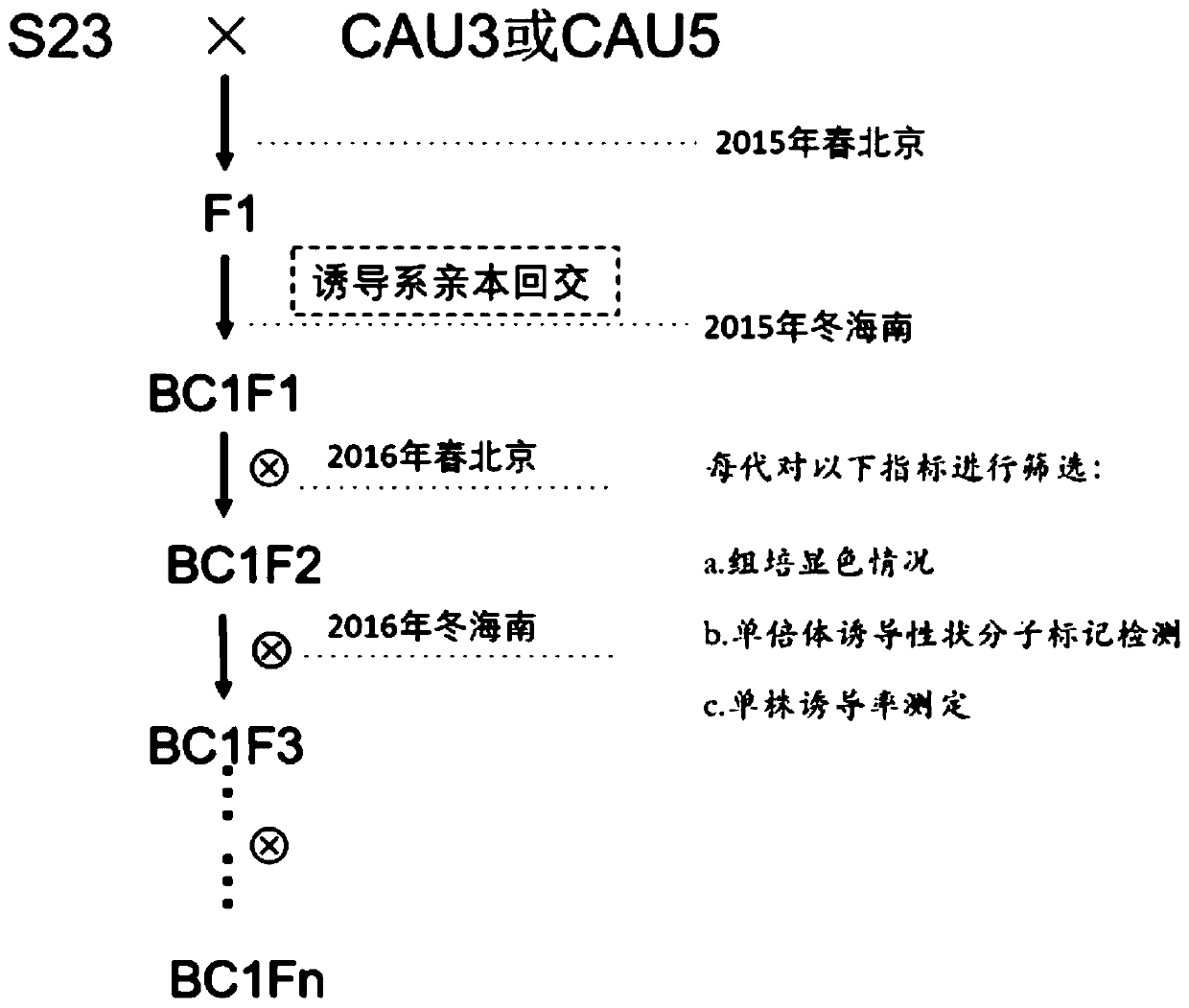

Breeding method of induction line for efficiently identifying corn haploid young embryo

ActiveCN111165350AIncrease fruit countImprove accuracyMicrobiological testing/measurementPlant genotype modificationSingle plantBiotechnology

The invention discloses a breeding method of an induction line for efficiently identifying a corn haploid young embryo. The method comprises the following steps of hybridizing a corn haploid inductionline with a corn inbred line S23 to obtain a hybrid F<1> generation; backcrossing the hybrid F<1> generation and the corn haploid induction line to obtain a backcross posterity BC<1>F<1>; selecting asingle plant of the corn from the backcross posterity BC<1>F<1> to continuously self-cross to obtain the induction line for efficiently identifying the corn haploid young embryo, wherein the single plant of the corn is high in color developing degree of the young embryo after being hybridized with corn hybrids, high in haploid induction rate and high single-ear haploid number after being hybridized with the corn hybrids and is homozygous for both Zmpla1 gene and Zmdmp gene; and the haploid inductivity, the single-ear haploid number, the plant height, the ear position, the tassel branch number, the single-ear fructification number and the haploid young embryo identification accuracy of the induction line for efficiently identifying the corn haploid young embryo are all higher than those ofthe corn haploid induction line. The breeding method of the induction line for efficiently identifying the corn haploid young embryo has important application value.

Owner:CHINA AGRI UNIV

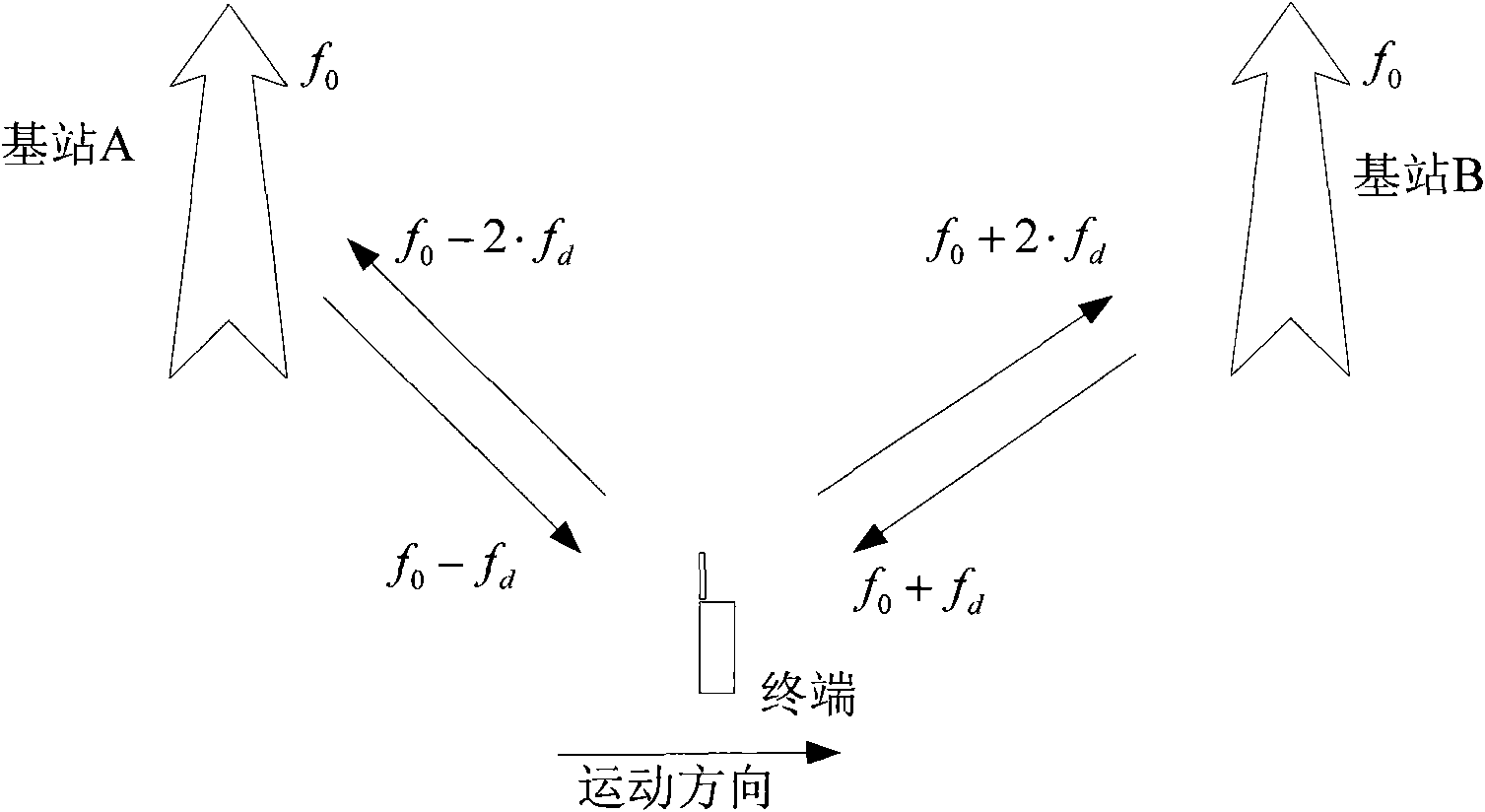

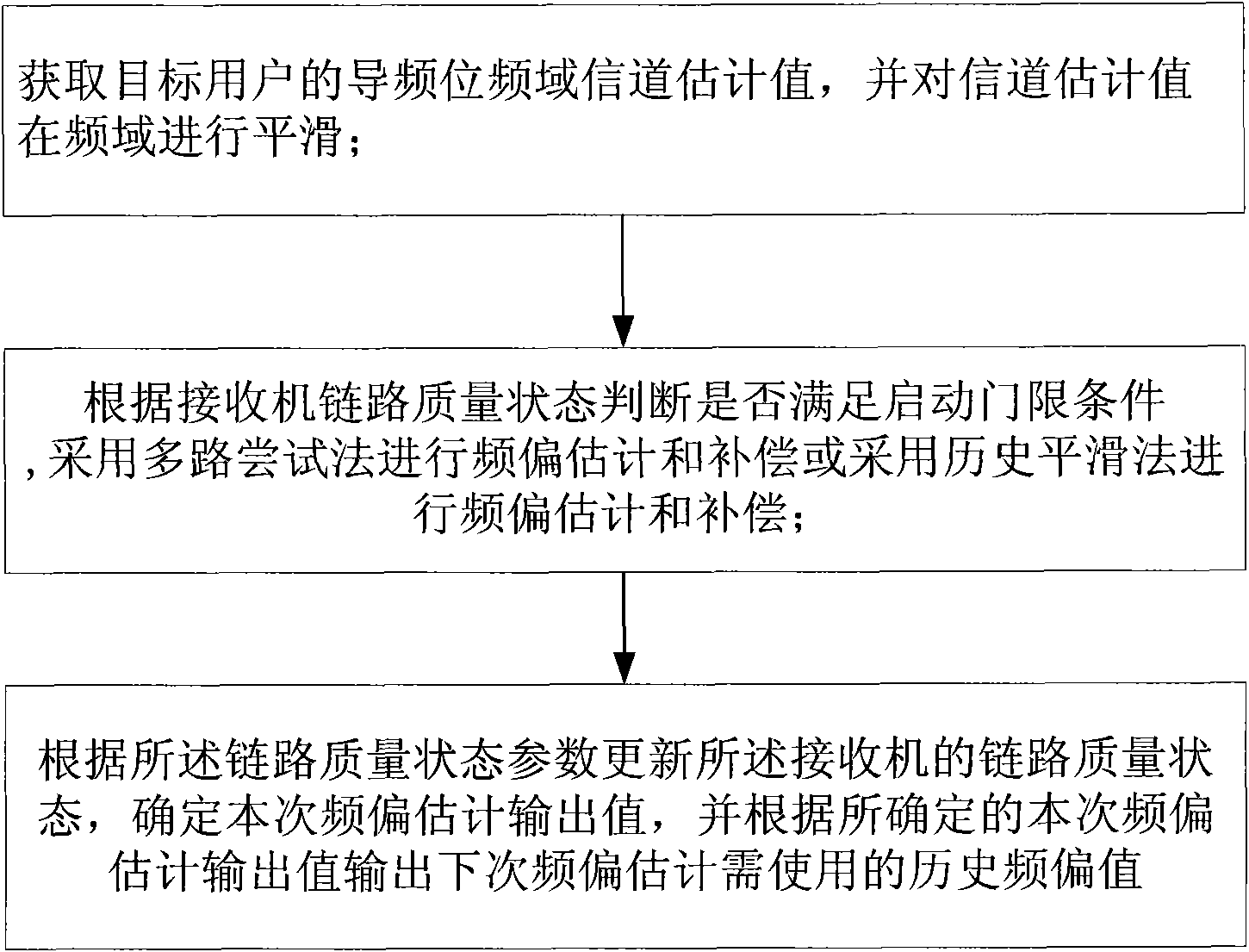

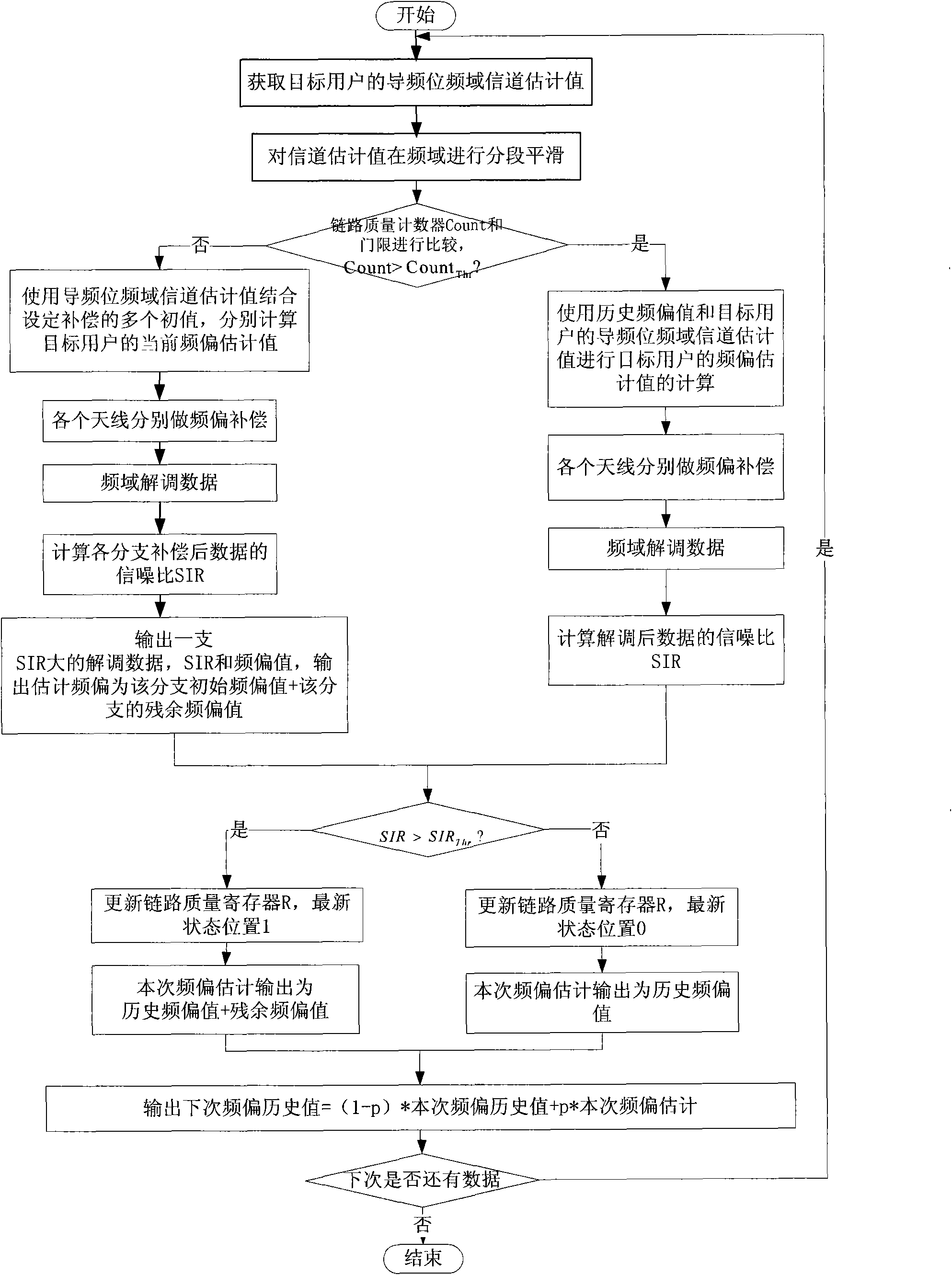

Method and device for estimating and correcting frequency offset of orthogonal frequency division multiplexing system

ActiveCN101938444AEffective estimateReduce distractionsChannel estimationMulti-frequency code systemsState parameterMass parameter

Owner:ZTE CORP

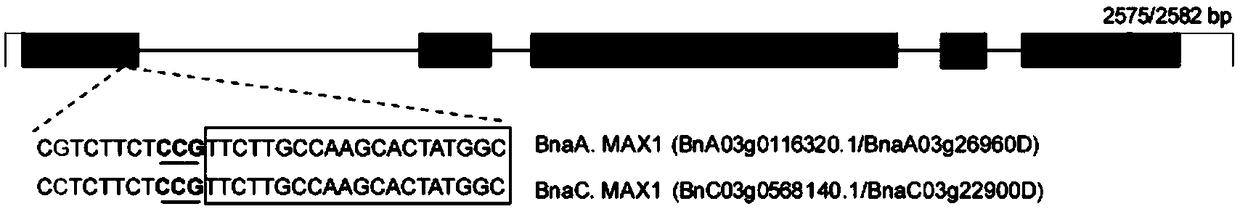

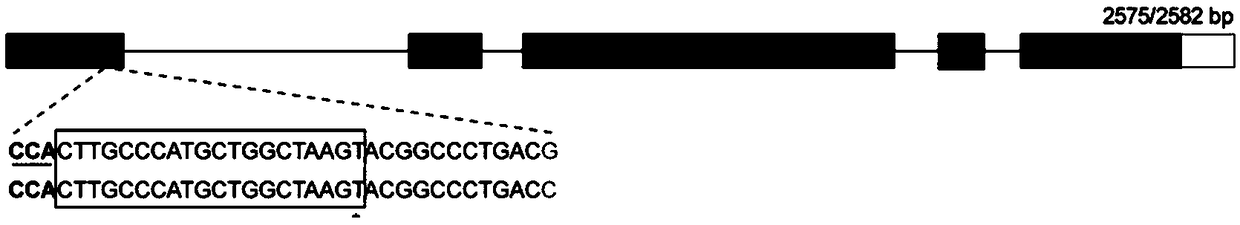

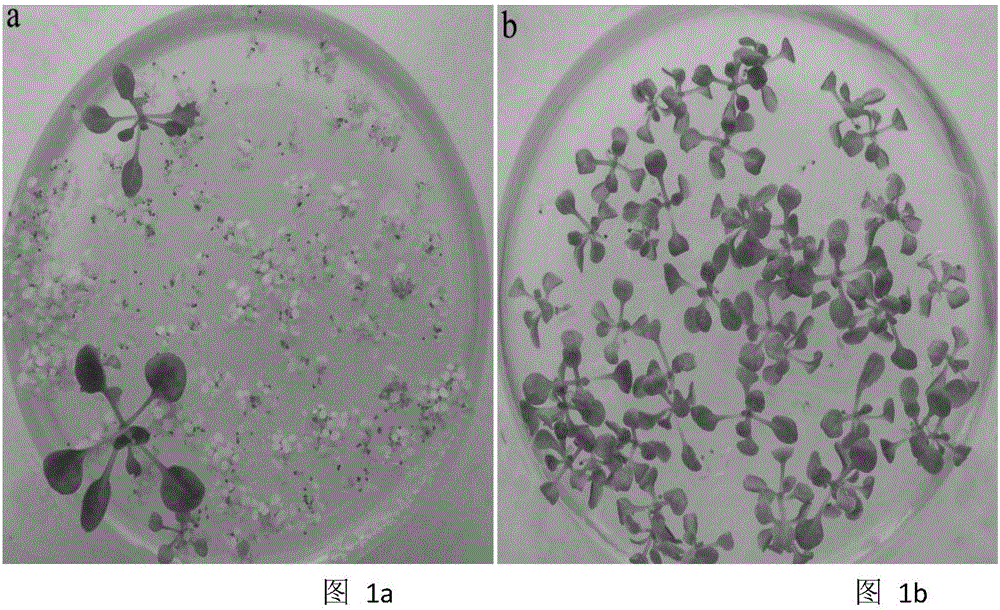

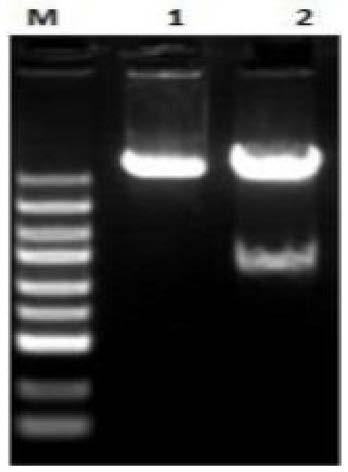

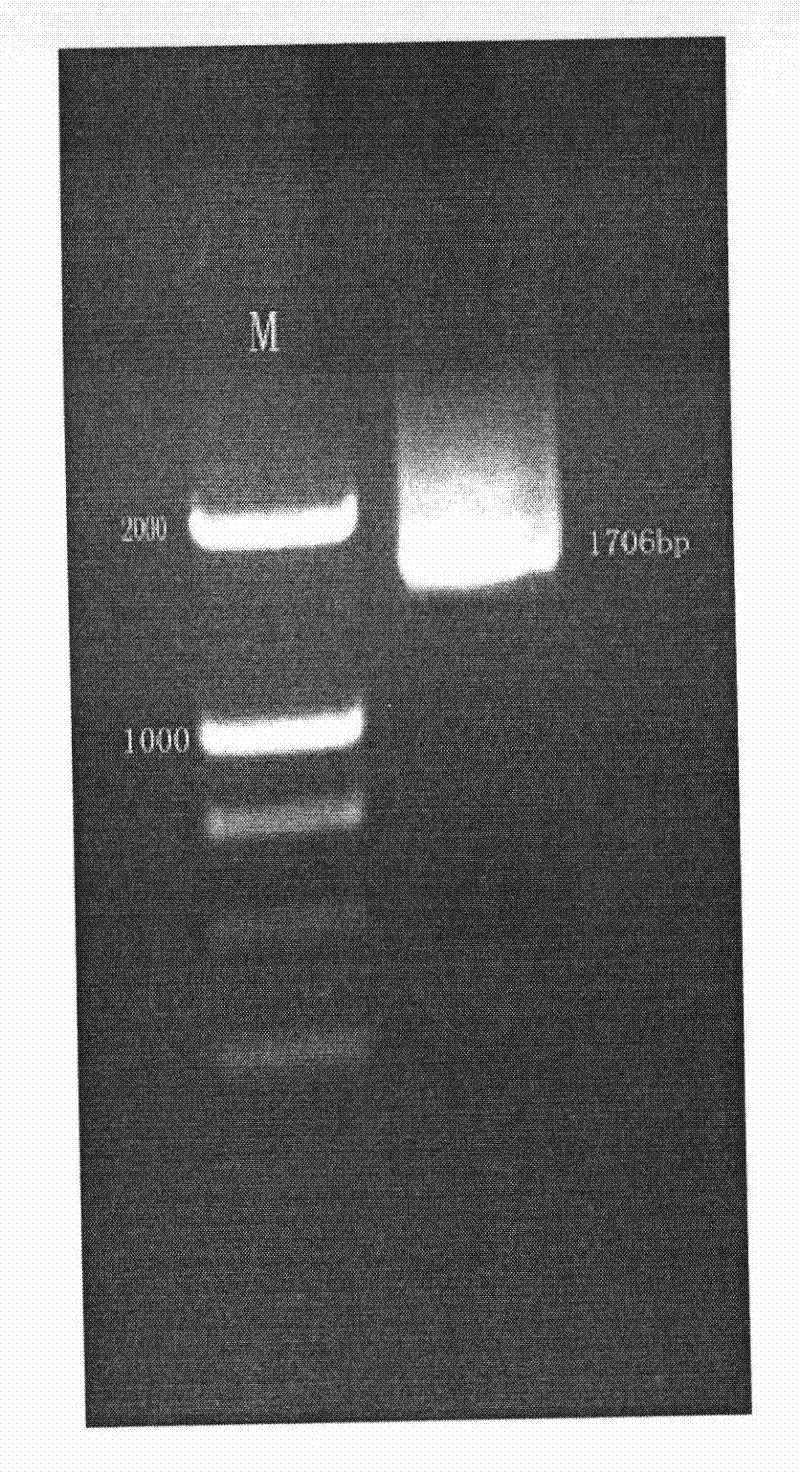

Method and application of knocking out BnMAX1 gene in Brassica napus by CRISPR-Cas9 system

ActiveCN109266646ASimplify build stepsSpeed up the research processPlant peptidesVector-based foreign material introductionBrassicaHypocotyl

The invention discloses a method and application of knocking out a BnMAX1 gene in Brassica napus by a CRISPR-Cas9 system, two sgRNAs of specifically targeting Brassica napus BnMAX1 gene are designed and synthesized into oligo dimer, are connected with Cas9 vector, and introduced into hypocotyl callus of Brassica napus by Agrobacterium tumefaciens-mediated transformation to regerated into shoots. Cas9 nuclease was guided by sgRNA to cleave target sequence. Each sgRNA could pass through CRISPR-Cas9 system mediates the cleavage of BnMAX1 gene in A and C genomes, and achieves the goal of gene knockout. Phenotypic identification showed that homozygous mutant lines increased the number of branches and pods per plant, decreased plant height and increased yield.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

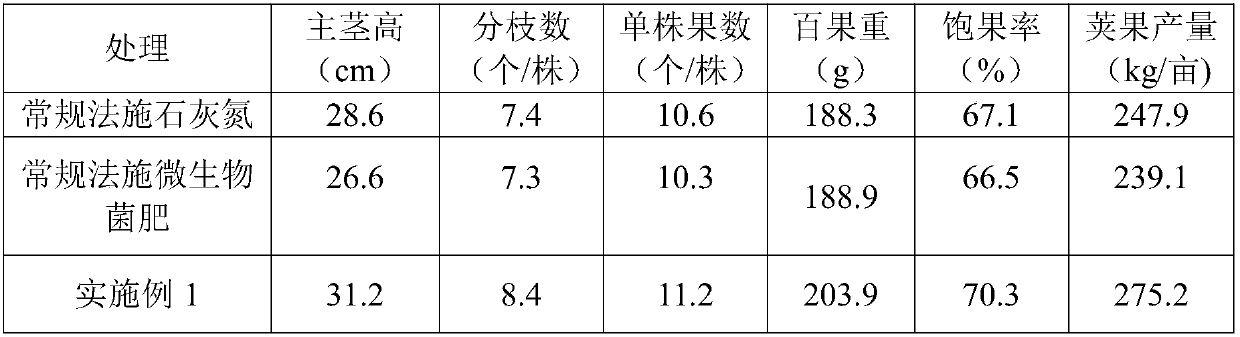

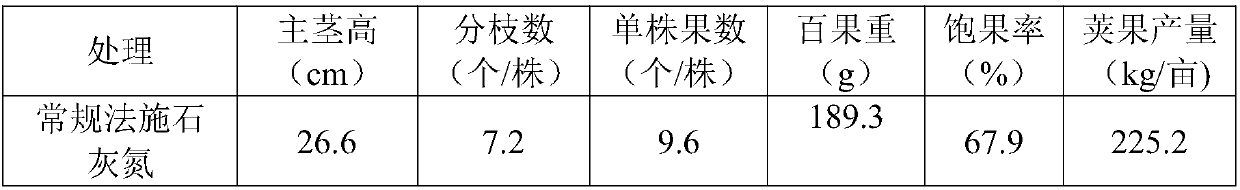

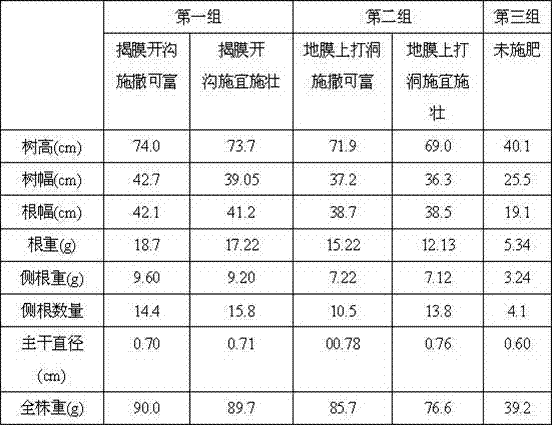

High-yield peanut cultivation method for relieving successive cropping obstacle

InactiveCN107836314AStay enoughImprove disinfection effectClimate change adaptationFabaceae cultivationToxic gasNitrogen

The invention discloses a high-yield peanut cultivation method for relieving successive cropping obstacle. The high-yield peanut cultivation method for relieving successive cropping obstacle comprisesthe following steps: (1) soil preparation: laying lime nitrogen and dazomet, and ploughing; (2) ridging and film mulching: laying trickle irrigation tubes while film mulching; (3) trickle irrigation:controlling water to permeate into the soil with the depth being 20 cm or above; (4) seeding hole forming: forming seeding holes in films to release toxic gas; (5) seeding: carrying out trickle irrigation through the trickle irrigation tubes in time after seeding, and during trickle irrigation, dropwise adding liquid peanut nitragin along with water; and (6) trickle irrigation and bacterial supplementing: carrying out trickle irrigation in a peanut four-leaf stage, and dropwise adding a compound microbial additive along with water for supplementing beneficial bacteria. The soil sterilizing effect is improved, the beneficial bacteria are supplemented, irrigation can be implemented as required, successive cropping obstacle can be relieved effectively, and growth and development of peanuts are promoted. The heights of stems of the peanuts are increased by 8.4%-25.6%, the branching number is increased by 4.1%-19.4%, the number of fruits of a single plant is increased by 3.1%-17.7%, the weight of one hundred peanuts is increased by 6.0%-11.9%, the full fruit rate is increased by 3.6%-7.3%, and the yield of legume is increased by 8.1%-28.9%.

Owner:SHANDONG PEANUT RES INST

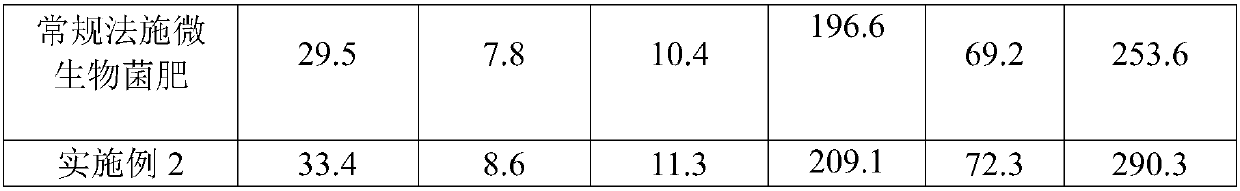

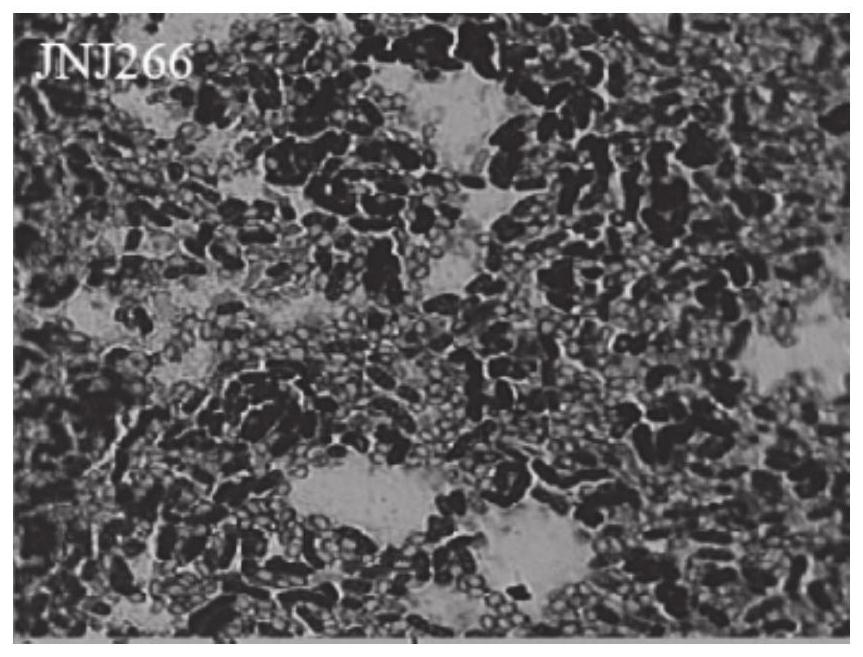

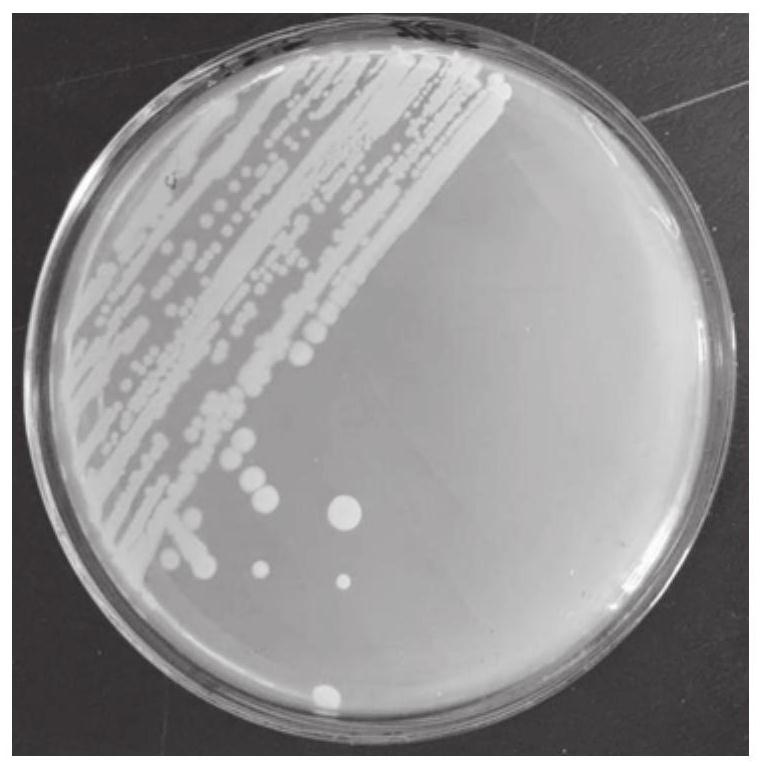

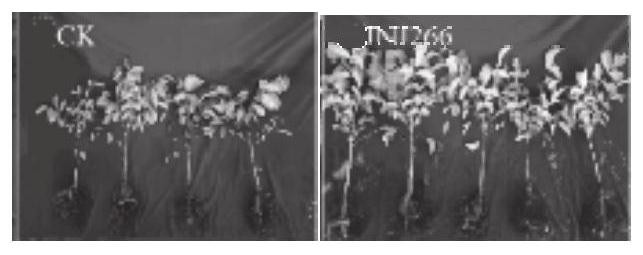

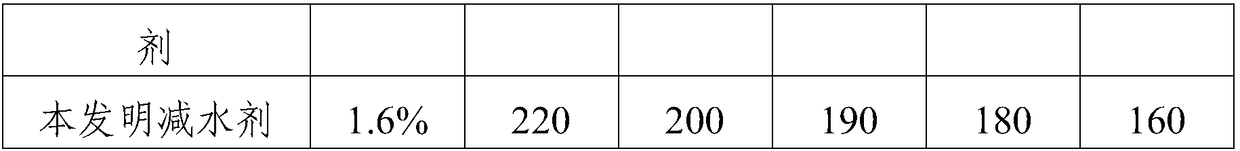

Bacillus aryabhattai and application thereof

ActiveCN112410244AImprove nutritional statusPromote growthBacteriaMicroorganism based processesBacillus aryabhattaiChlorophyllin

The invention provides a bacillus aryabhattai JNJ266 strain and an application thereof, and belongs to the technical field of microorganisms. The strain is preserved in China General Microbiological Culture Collection Center on August 5, 2020, and the biological preservation number of the strain is CGMCC No. 20483. The strain has the functions of dissolving phosphorus and potassium, producing protease, IAA, siderophore and the like, under the potting condition, root irrigation treatment is carried out on the bacillus asterii fermentation liquor after walnut seedlings are fixed, after the JNJ266 fermentation liquor is applied, the diameter, the plant height, the branch number, the wet weight and the dry weight of the walnut are increased, and the chlorophyll content, the walnut leaf enzymeactivity and the walnut soil enzyme activity are also improved; and under the drought condition, the diameter, the plant height, the branch number, the wet weight and the dry weight of the walnuts treated with JNJ266 fermentation broth increased, and the chlorophyll content, the walnut leaves enzyme activity and the walnut soil enzyme activity are also increased. The bacillus aryabhattai screenedhas good walnut growth-promoting and drought-resisting effects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

Method of braiding, planting and cultivating multiple plants of photinia fraseri into stereoscopic landscape shape

InactiveCN102144476AEnhance resilienceHigh breeding success rateHorticulture methodsStress resistanceGrowth plant

The invention relates to a method of braiding, planting and cultivating multiple plants of photinia fraseri into a stereoscopic landscape shape, belonging to a tree cultivation technique. The invention aims to solve the problems that the cultivation quality is influenced slightly while the cultivation success rate is severely reduced by giving up halfway and keeping all the previous effects wasted due to broken or dead plants subjected to the planting severe factors as the traditional method adopts the single-seedling planting, the production cost is high as the cultivation period is as long as 3-5 years, the optimum time to market is missed so as to cause low market price and reduced economic benefits. The method is characterized in that at least two seedlings with the height of over 30cm are braided into a bundle for planting and cultivating, and the seedlings are cultivated, pruned and braided into a bundle again for 12 months to form the stereoscopic landscape shape finished seedling according to the design requirement. After implementation, compared with the prior art, the method has the advantages that the stress resistance of the stereoscopic landscape shape is enhanced, therefore, the cultivation success rate can reach up to over 99%, the plant growth is doubled, and the cultivation time is greatly shortened to 1-2 years.

Owner:ZHENJIANG SHENGHONG LANDSCAPE PLANT

Incubation method of open-centralized shape mulberry

The invention relates to a high-yield culture method for an open-center type mulberry. The method comprises the following steps: fixing a stem for a cultured nursery stock in a first spring; carrying out the summer cutting for the twigs growing on a first stem; after the summer cutting, carrying out the autumn cutting for the twigs growing on the first stem so as to form a second stem; breeding silkworms through the twigs cut from the top of the second stem; and carrying out the cycle. Through the summer cutting for the twigs on the first stem in the second year, the method prolongs the spring growing period of the mulberry and brings about an additional silkworm spring rearing season. Through the autumn cutting for the twigs after the summer cutting in the same year, the culture period is reduced from three years to two years. A plurality of twigs are forked from the top of the second stem, so that the method increases the number of the twigs and improves the yield. The method changes a traditional mode of picking mulberry leaves and adopts mulberry twig harvest to replace the leaf collection, thereby improving the mulberry leaf yield and reducing the workload of mulberry leaf collection. The method has the advantages of saving time and labor, reducing cost and increasing benefits, along with short culture period, high leaf yield and good silkworm breeding effects; therefore, the method deserves generalization.

Owner:王承元

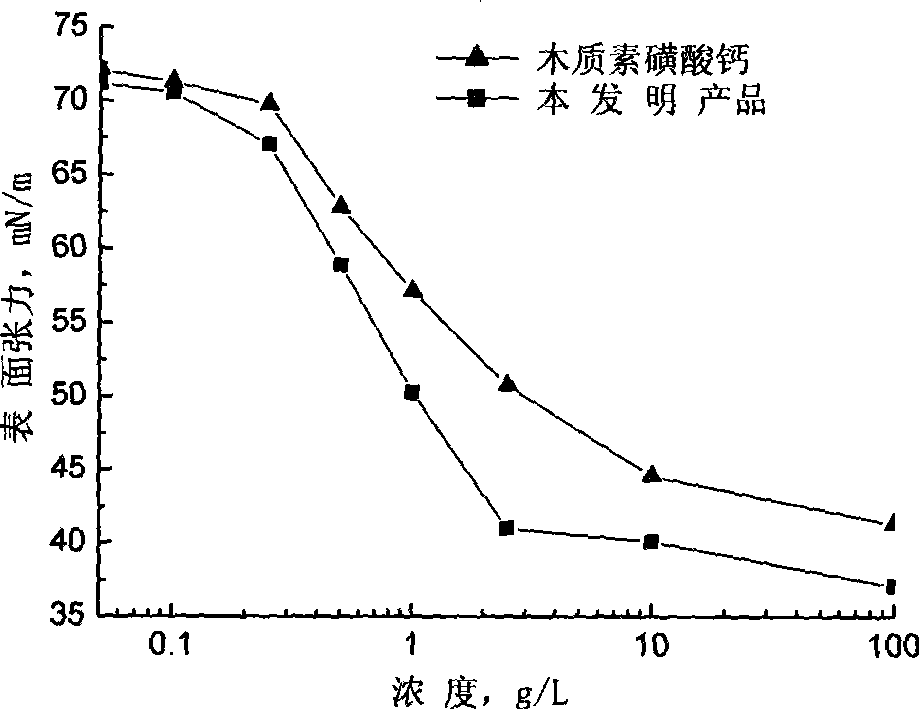

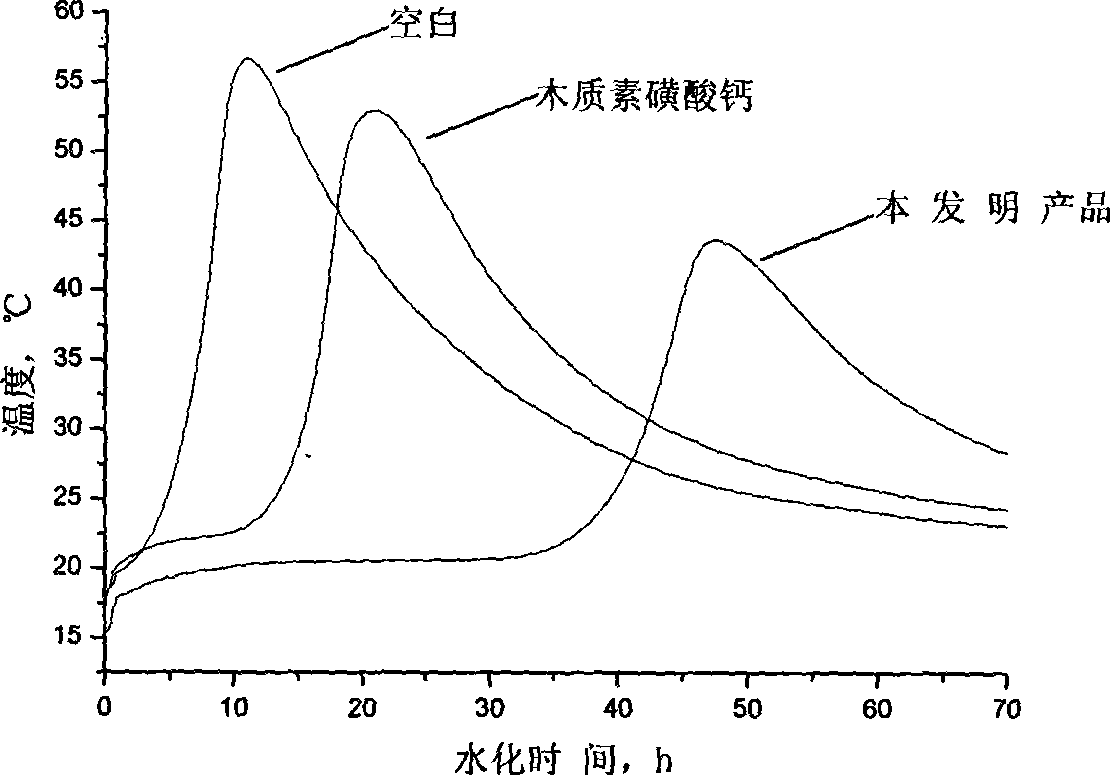

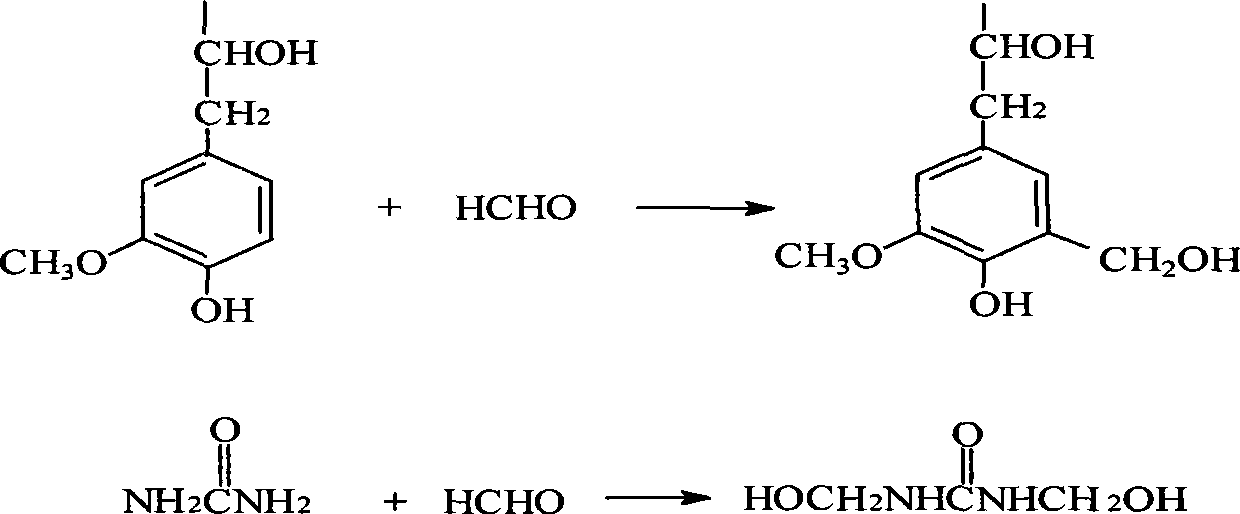

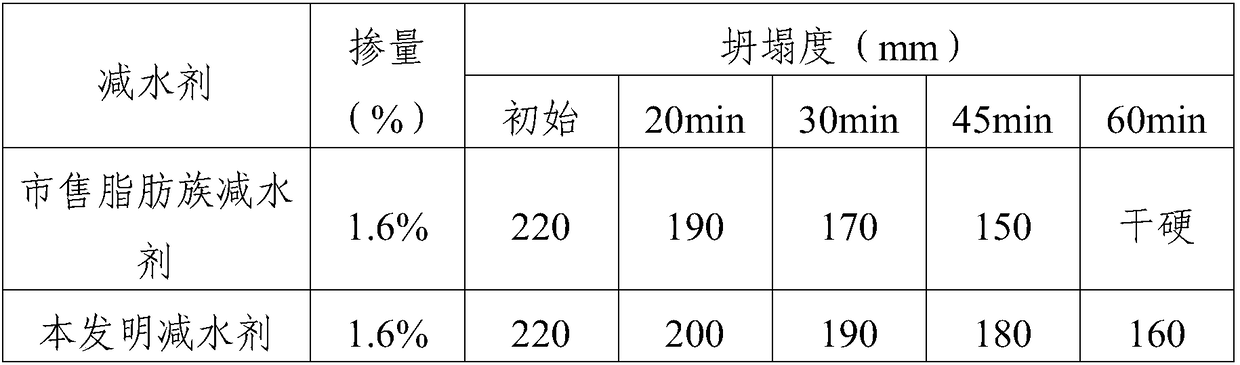

Dry powder mortar additive suitable for novel wall material and preparation method thereof

The invention discloses an environment friendly dry mortar admixture applicable to novel wall materials, and a preparation method thereof. The method comprises the steps: (1) lignosulphonate is added with water and mixed uniformly, the system pH value is adjusted to be 8.0 to 11.0, urea and formaldehyde are added, and the mixture reacts for 1 to 2 hours at the temperature of 80 to 100 DEG C; (2) the system pH value is adjusted to be 4.0 to 6.0, and the mixture reacts for 2 to 3 hours at the temperature of 80 to 100 DEG C; and (3) an oxidant is added, the mixture reacts for 1 to 2 hours at the temperature of 70 to 90 DEG C and is cooled to obtain the liquid product of the mortar admixture, and the powder product of the mortar admixture can be obtained after spray drying. The mortar admixture has simple preparation process and low production cost, is environment-friendly as the papermaking and pulping by-product, lignosulphonate, is taken as raw material, has high water reduction rate, appropriate retardation and air-entraining performance, and can cause the mortar to have good cohesiveness, anti-cracking and impermeability.

Owner:SOUTH CHINA UNIV OF TECH

Fully film-mulched corn and soybean interplanting method

InactiveCN105794437AEasy to shapeImprove featuresHorticultureSoil-working methodsEconomic benefitsCrop cultivation

The invention relates to the technical field of crop cultivation, and specifically relates to a fully film-mulched corn and soybean interplanting method. On a basis of corn cultivation with a full film-mulching method, according to the light requirements of corn and soybean, natural conditions such as land and lighting are reasonably utilized, such that crop yield is improved, land utilization rate is improved, and economic benefit is improved.

Owner:王亚军

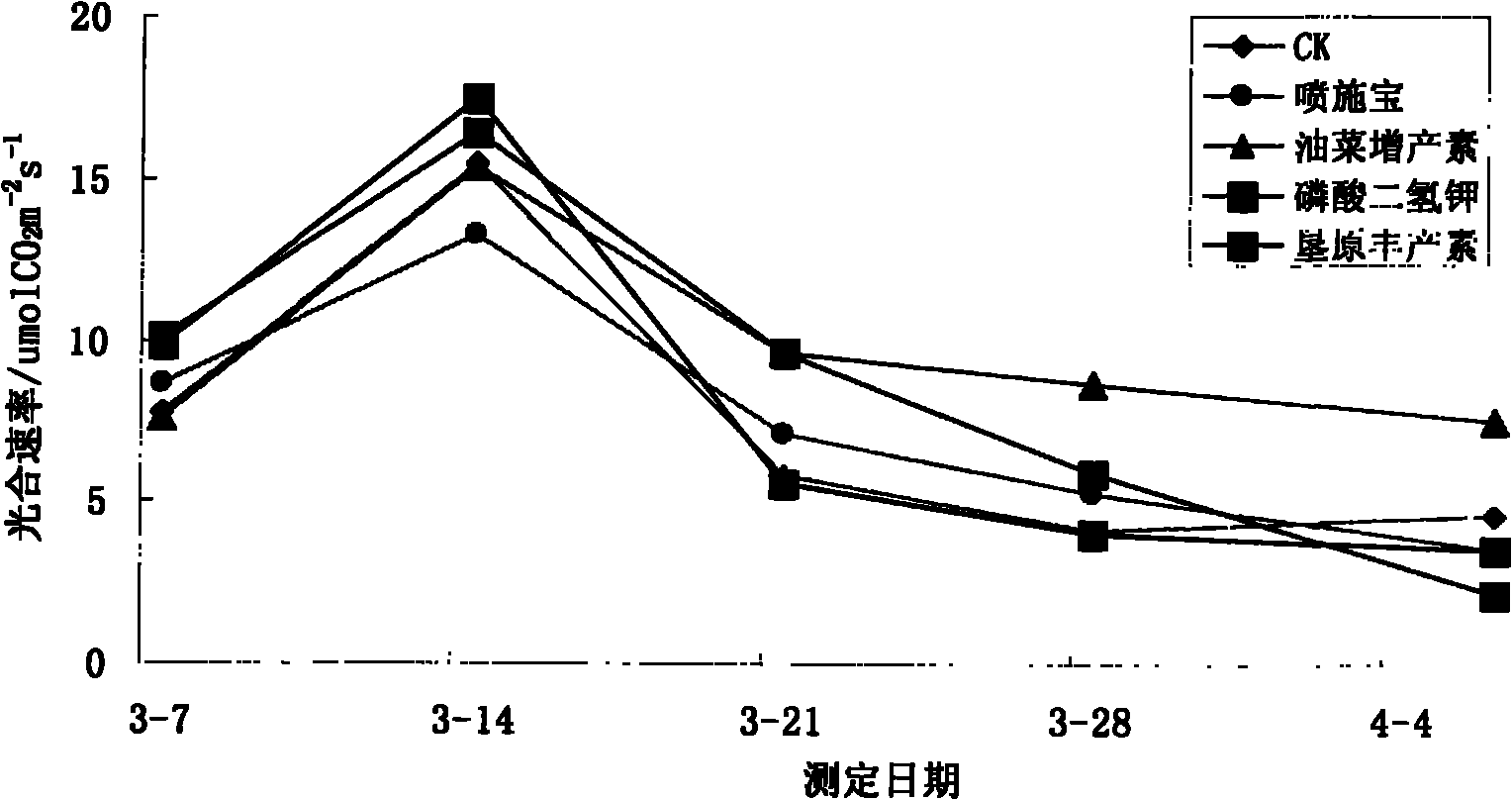

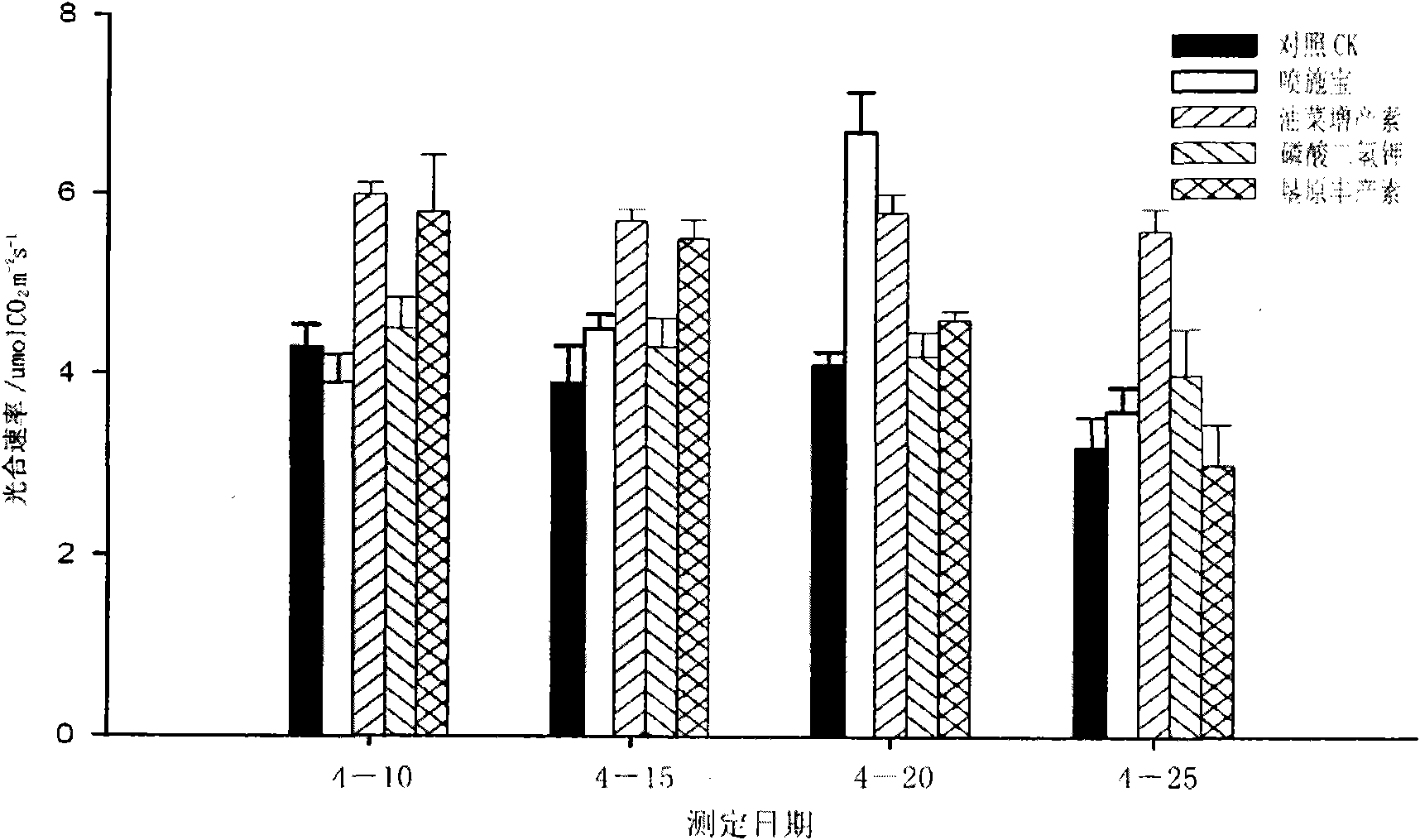

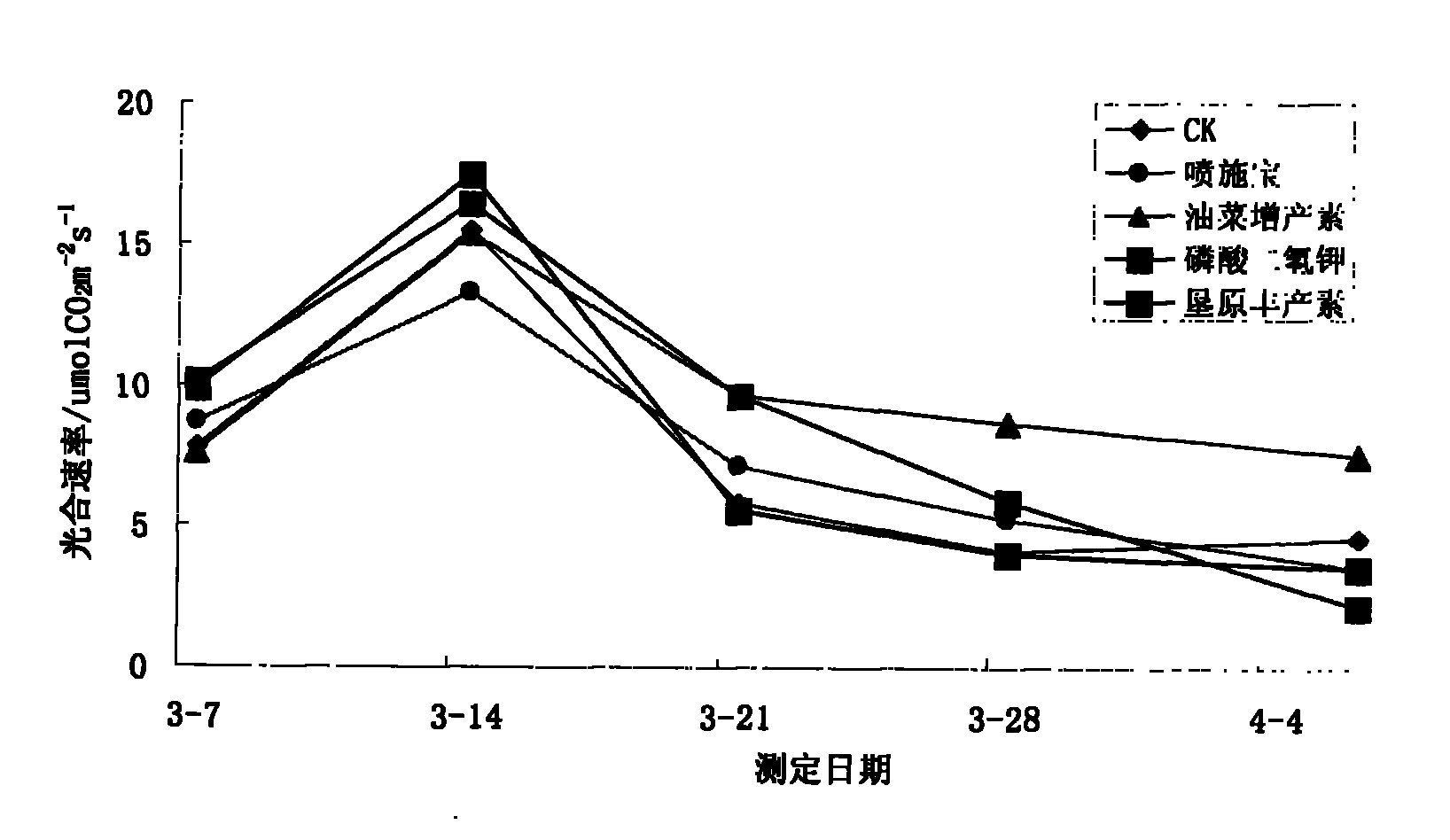

Yield increasing element for rape

InactiveCN101785466AIncrease the number of branchesIncrease productionBiocidePlant growth regulators6-BenzylaminopurineChemistry

The invention relates to a yield increasing element for rape. Components of the yield increasing element are as follows (the mass percent of each component is shown in brackets): sodium dodecyl (3.0 to 5.0%), boric acid (0.1 to 0.2%), potassium nitrate (30 to 40%), monoammonium phosphate (30 to 40%), TCIPN (20 to 30%), 6-benzylaminopurine (6-BA) (0.1 to 1%) and 6-furfuryladenine (6-KT) (0.1 to 1%), wherein the mass ratio between the 6-benzylaminopurine and the 6-furfuryladenine is 1:2, and the mass ratio between the potassium nitrate and the monoammonium phosphate is 1:1. The yield increasingelement for the rape increases the carbon level of a rape plant at the growing stage and adjusts as well as controls the transferring as well as absorbing of the rape plant, so as to promote flower bud differentiation of the rape, thereby achieving the effects of increasing the yield, preventing diseases and resisting lodging.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Method for improving wild cabbage seed production yield

InactiveCN104885736AIncrease the number of branchesIncrease the number of bloomsCultivating equipmentsPlant cultivationHorticultureSavoy cabbage

The invention discloses a method for improving wild cabbage seed production yield. At the initial heading stage (around December 10) of wild cabbage, a head is integrally cut, about 10 outer leaves are reserved, a plant sprout 5-10 buds about two weeks after the head is cut, 3-4 buds are reserved, redundant buds are cut off, remaining 3-4 buds can slowly grow up, bolting and flowering are realized at the beginning of spring in a coming year, and the wild cabbage is timely harvested when 2 / 3 of wild cabbage seed pods turn yellow and seeds turn yellowish-brown. By the method, the branching number and the flowering number of the wild cabbage can be increased, and the wild cabbage seed production yield can be effectively improved.

Owner:镇江鑫源达园艺科技有限公司

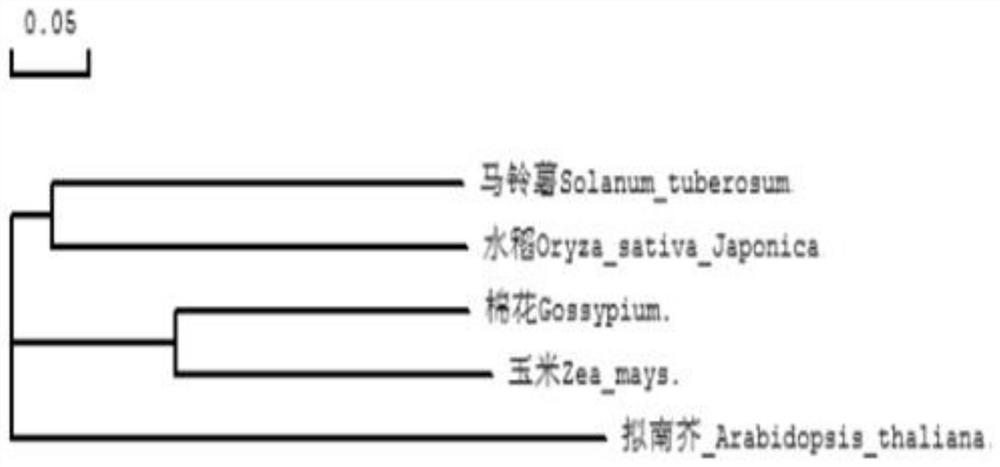

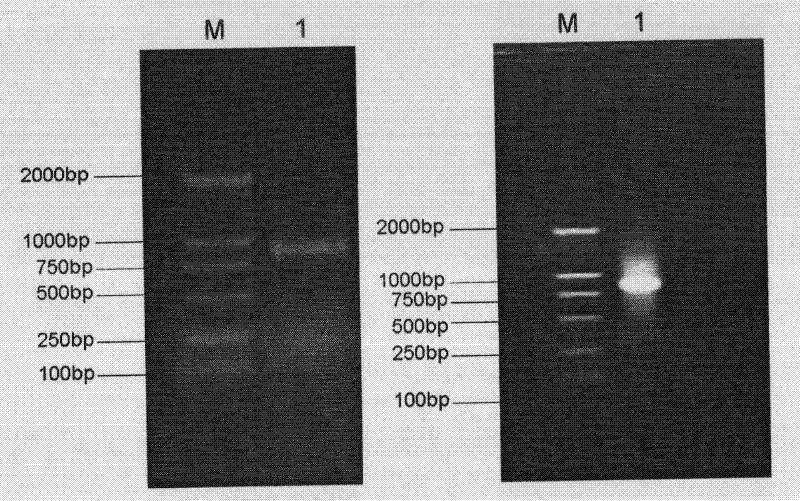

Dahurian larch LkANT gene, protein and applications

ActiveCN106047887AIncrease the number of branchesIncrease productionPlant peptidesFermentationProtein proteinGenetic engineering

A dahurian larch LkANT gene, a protein and applications are disclosed. The cDNA sequence of the gene is shown as SEQ ID NO:1. The protein encoded by the gene is characterized in that the amino acid sequence of the protein is shown as SEQ ID NO:2, and is characterized by applications of the protein in culture of multi-branch transgenic plants. By utilization of the modern molecular biological technique, the gene critical to regulation and control of branches and seed development for dahurian larch is cloned, separated and subjected to functional analysis. The acquisition of the critical gene of this type has important theoretical value, provides important candidate genes for increasing grain yields by utilizing genetic engineering means, and has an important application prospect in the field of crop genetic improvement and the like.

Owner:TIANJIN AGRICULTURE COLLEGE

Potato KNOX transcription factor StKNOX1 gene, encoded protein and application thereof

ActiveCN111607599AIncrease productionImprove qualityPlant peptidesFermentationTransgeneNucleotide sequenc

The invention provides a potato KNOX transcription factor StKNOX1 gene, an encoded protein and an application of the potato KNOX transcription factor StKNOX1 gene in potato planting or potato breeding, and belongs to the technical field of gene engineering. The nucleotide sequence of the potato KNOX transcription factor StKNOX1 gene provided by the invention is as shown in SEQ ID No. 1. The StKNOX1 gene is transferred into a potato plant and is obtained by analyzing the physiological properties of the potato with the transferred StKNOX1 gene, the expression quantity of the StKNOX1 gene in a transgenic positive strain is remarkably higher than that of a control group, and the plant height, the single-plant tuberization number and the single-plant yield of the three positive strains are remarkably higher than those of the control group; meanwhile, the transgenic lines show the characters of increasing the branch number, increasing the length-width ratio of tubers, changing the shapes ofthe tubers and the like. Therefore, the invention provides the application of the StKNOX1 gene in potato planting or potato breeding.

Owner:宁夏农林科学院农业生物技术研究中心

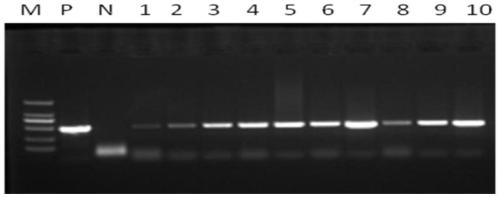

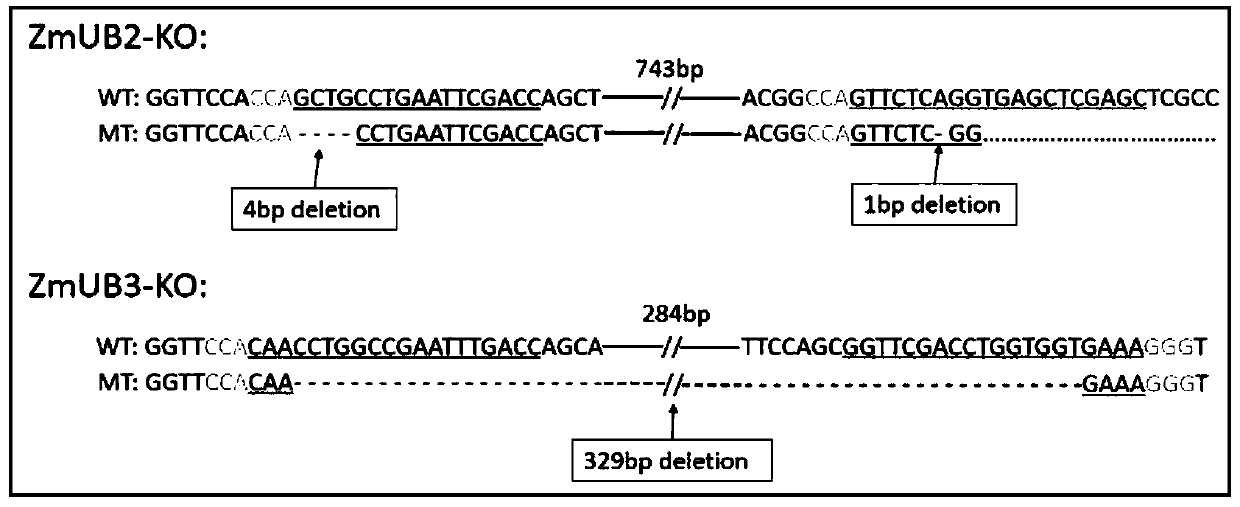

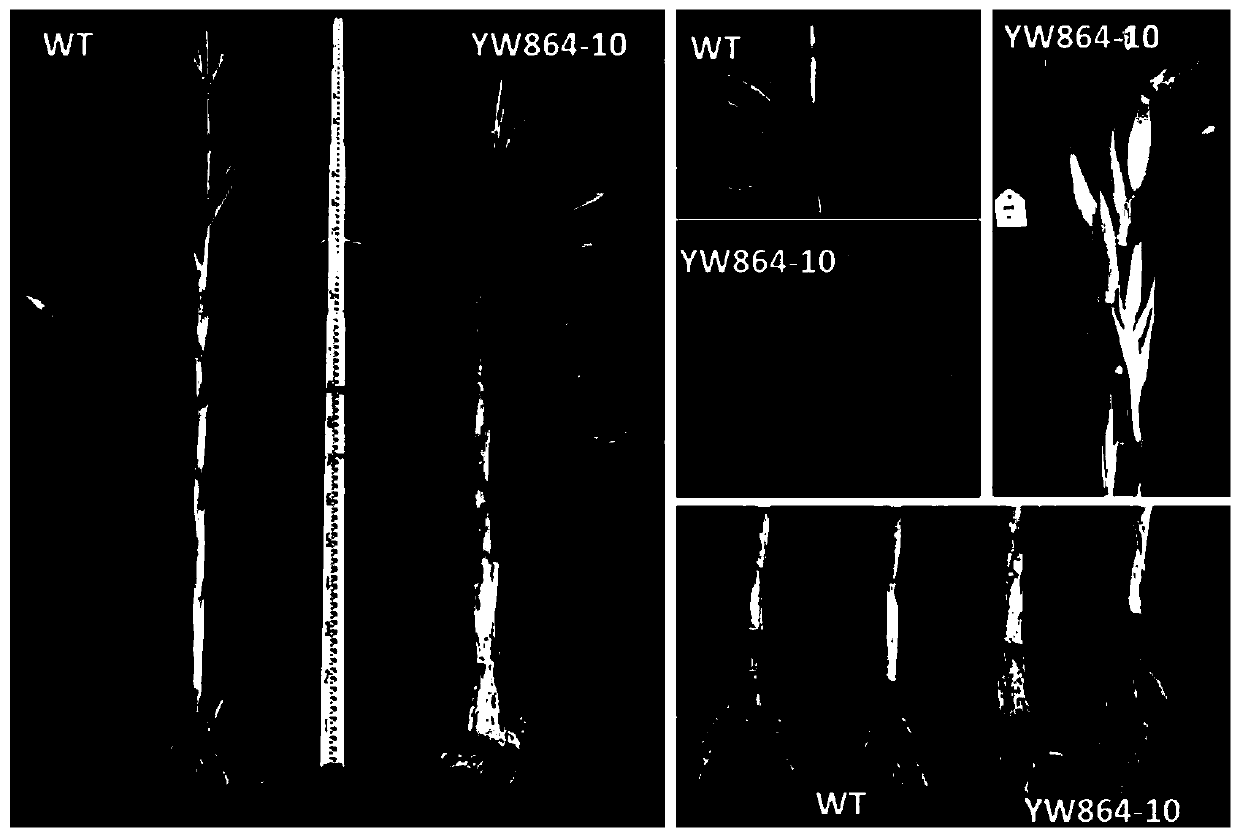

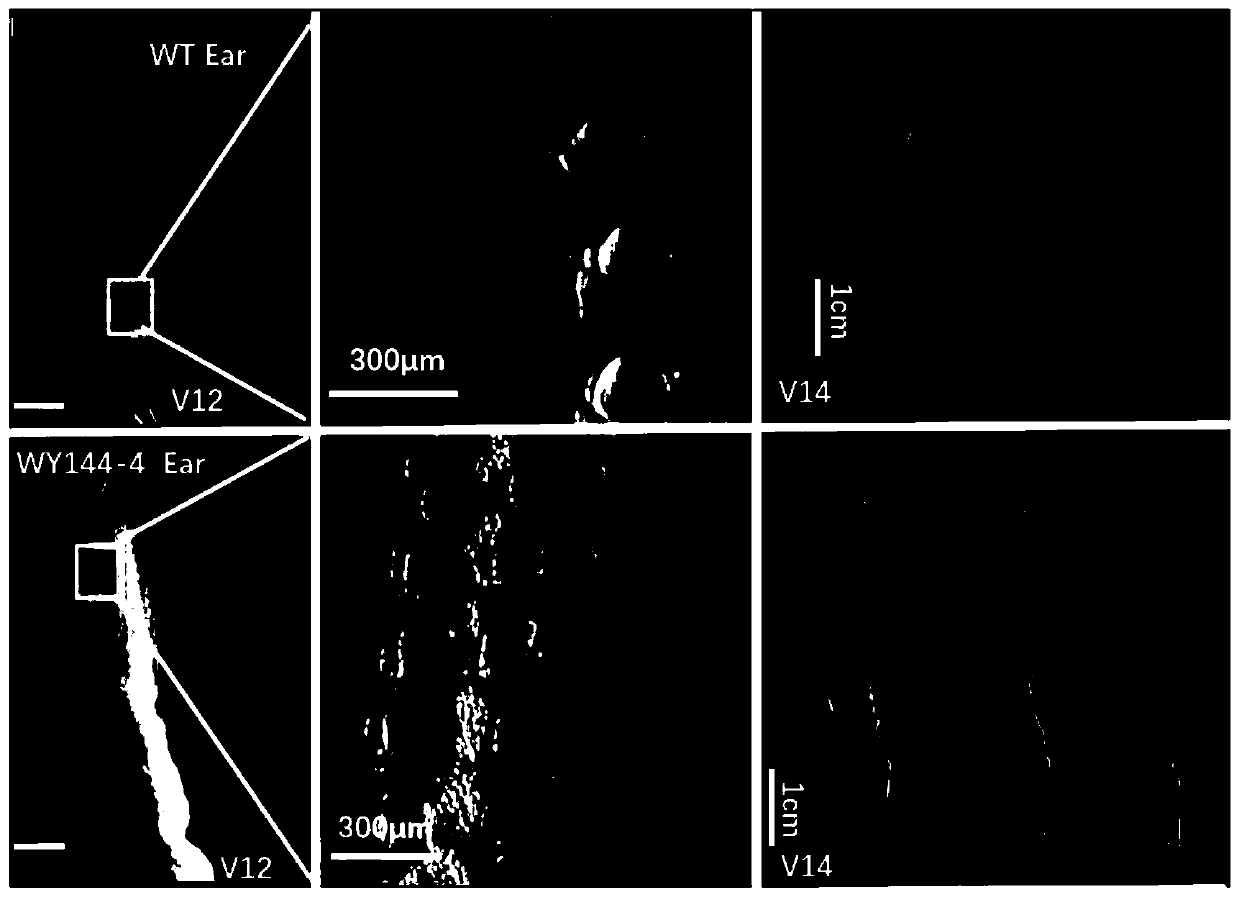

Application of UB2/UB3 gene in regulation and control of corn multi-spike development

ActiveCN110577964ADecreased number of tassel branchesReduce the number of branchesPlant peptidesFermentationBiotechnologyDouble mutation

The invention discloses application of a UB2 / UB3 gene in regulation and control of corn multi-spike development, and particularly relates to application of UB2 and UB3 gene double mutation in regulation and control of corn multi-spike development. According to the invention, gene editing is carried out on two targets UB2 and UB3 in corn by using a CRISPR / Cas9 transgenic technology, so that the target site of the UB2 gene has deletion of a basic group to cause frameshift mutation and deletion of large fragments of the UB3 gene. Results show that the tassel branch number of UB2 and UB3 double mutant plants is reduced, the increase of the spike number of the UB2 and UB3 double mutants is observed for the first time, new female spikes grow on spike stalks of main spikes, the multi-spike property is shown, auxiliary meristem at the lower part is also derepressed to be developed into female spikes, and phenotypes with increased aerial roots are accompanied; and it shows that after the UB2 gene and the UB3 gene are knocked out, a corn mutant plant can show a multi-spike phenotype. The invention provides a theoretical basis for genetic improvement of the corn multi-spike property has a large application prospect.

Owner:SOUTH CHINA AGRI UNIV

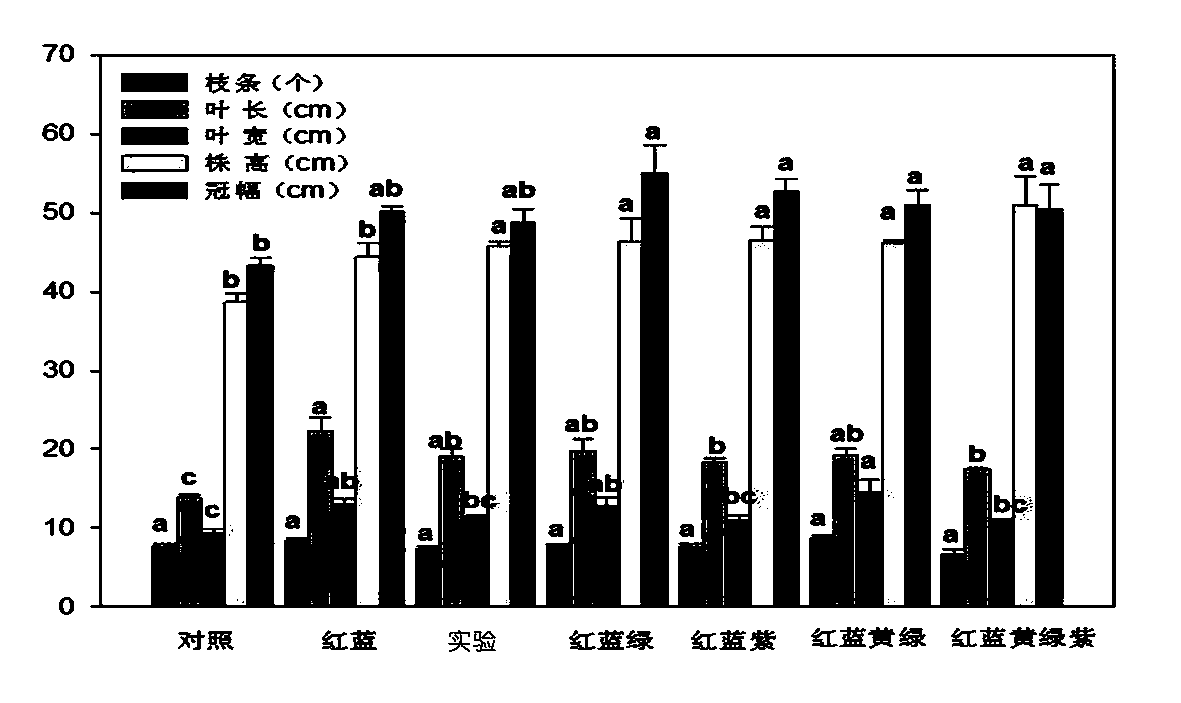

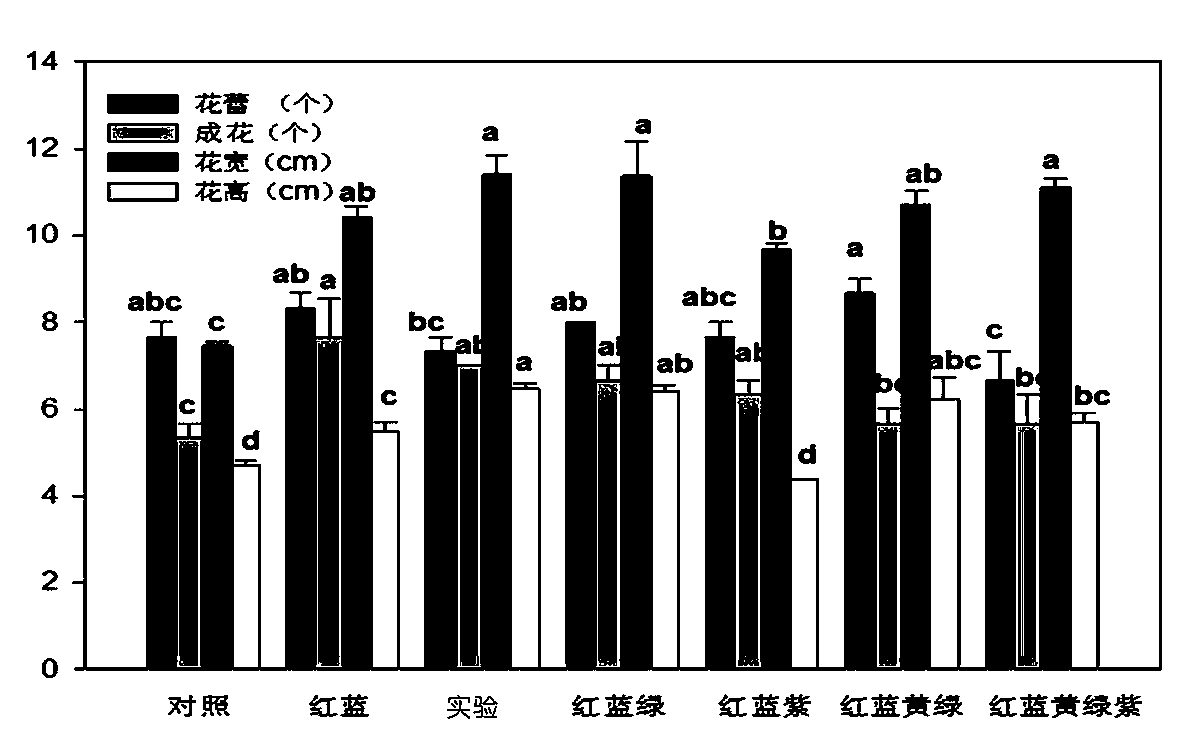

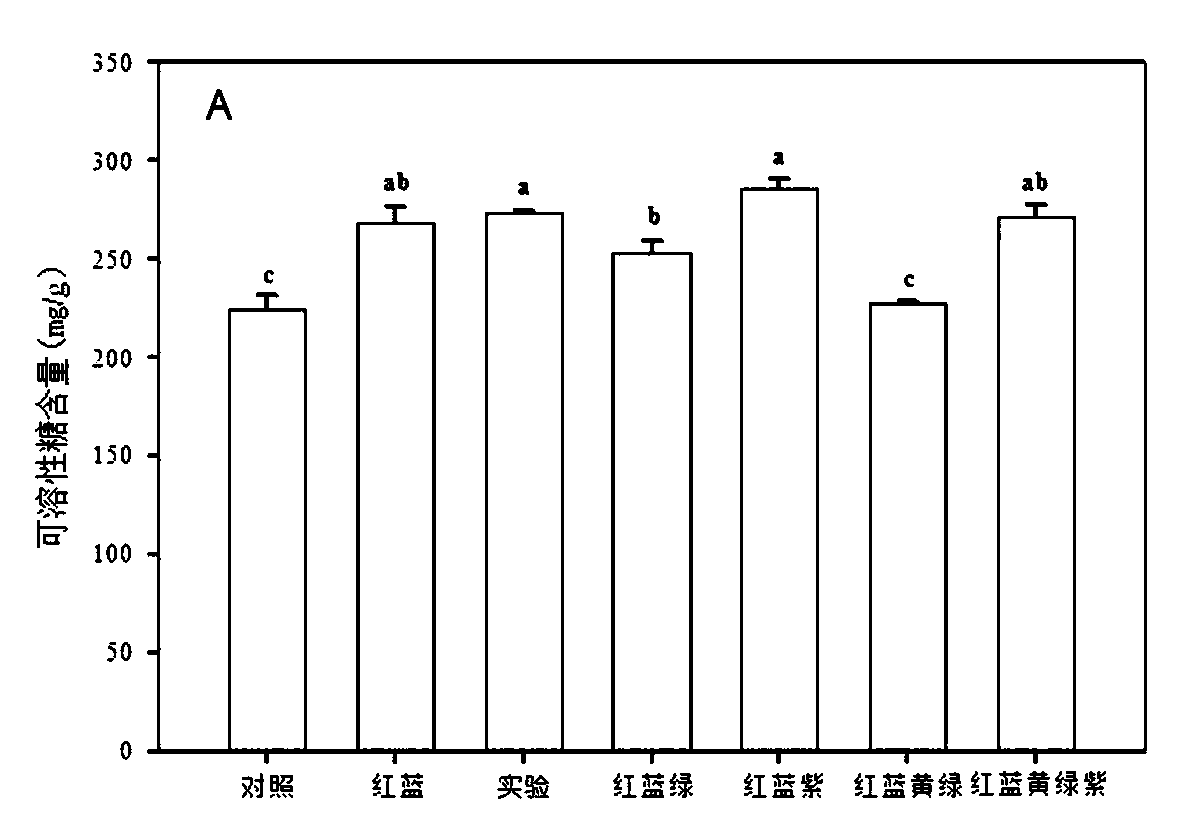

Supplementing lighting method for improving cultivating quality of peonies for Lunar New Year

ActiveCN103814762AAdequate nutritionProlong flowering periodSaving energy measuresHorticulture methodsMaterials sciencePhotochemistry

Disclosed is a supplementing lighting method for improving cultivating quality of peonies for the Lunar New Year. The supplementing lighting method includes that different light rays are adopted in different growing stages of the peonies for supplementing lighting; for the germination stage, composite light with lighting intensity of 150-180Lux and formed by blue light and yellow light according to a proportion of 3-1:2-1 is adopted; for the squaring stage, composite light with lighting intensity of 160-210Lux and formed by red light and blue light according to a proportion of 3-1:2-1 is adopted; for the small wind bell stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for the big wind bell stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for the garden-peach color transparency stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for a week before the flowering stage, composite light of red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1 is adopted; for a week after flowering, composite light of red light and blue light according to a proportion of 3-1:2-1 is adopted. By the supplementary lighting method, influences are generated on biological characteristics of peony plants, and nutritional growing and flowering quality of the peonies for the Lunar New Year is improved remarkably.

Owner:HENAN UNIV OF SCI & TECH

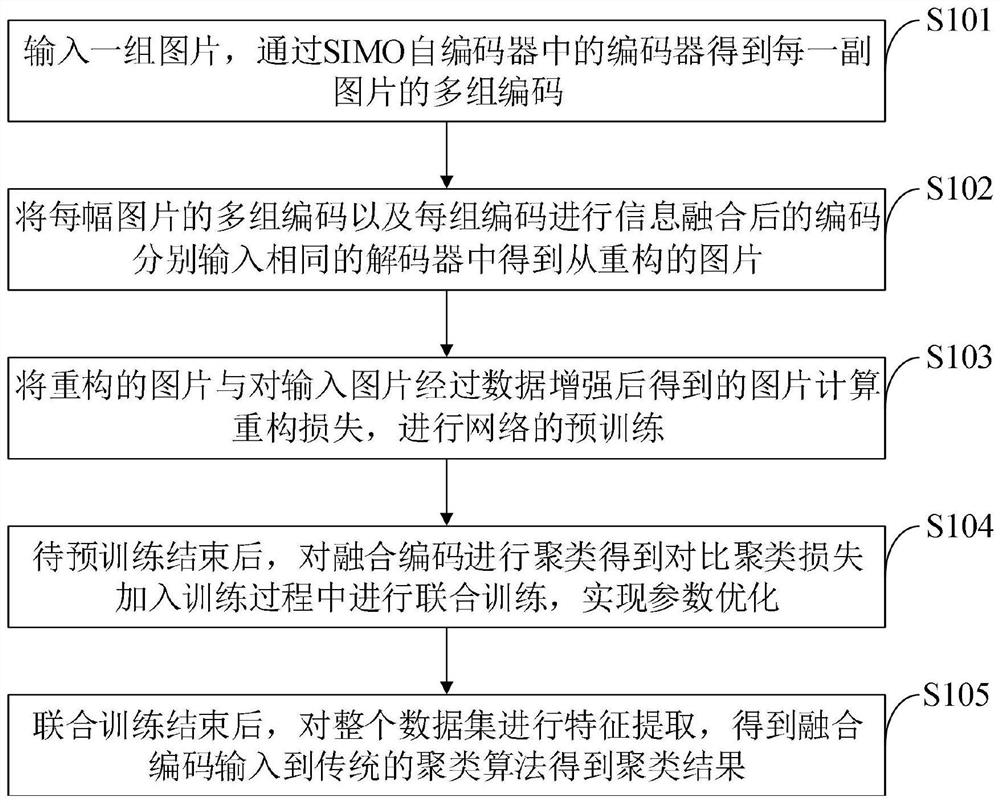

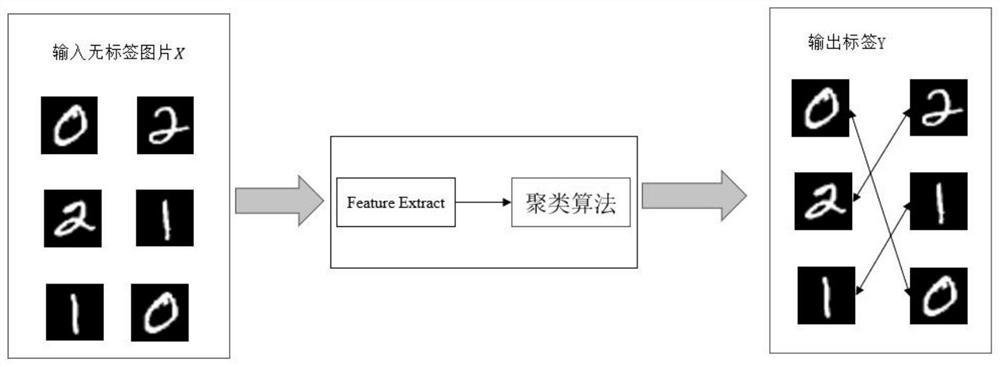

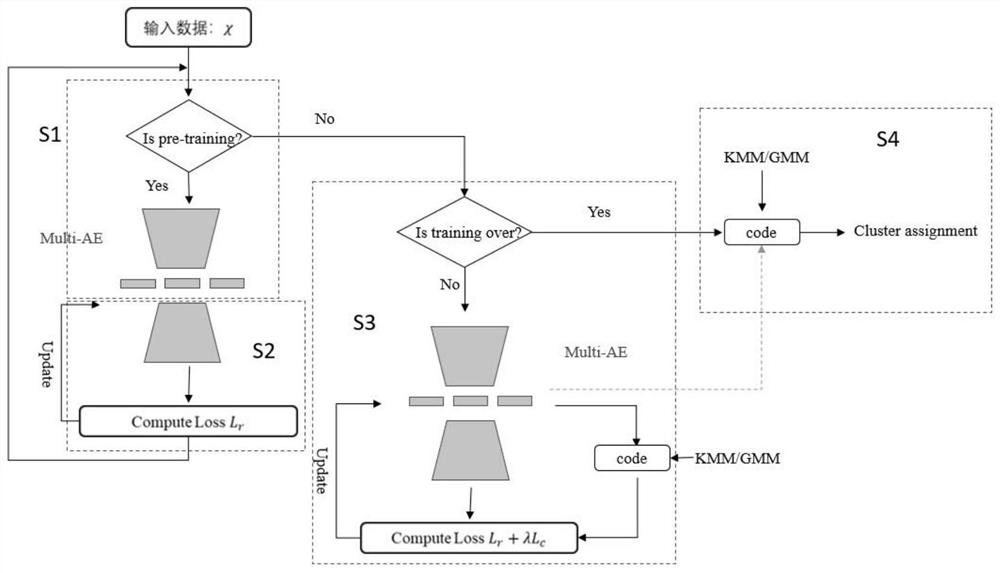

Depth image clustering method, system and device, medium and terminal

PendingCN113971735AIncrease richnessPhysically significantCharacter and pattern recognitionCluster resultImage identification

The invention belongs to the technical field of unsupervised image recognition, and discloses a depth image clustering method, system and device, a medium and a terminal.The depth image clustering method comprises the steps that a set of pictures is input, and multiple sets of codes of each picture are obtained through an encoder in an SIMO self-encoder; the multiple groups of codes of each picture and the codes obtained after information fusion is carried out on the codes are input into the same decoder to obtain reconstructed pictures; the reconstruction loss of the reconstructed picture and the picture obtained after data enhancement of the input picture is calculated, and pre-training of the network is carried out; after the pre-training is finished, the fusion codes are clustered to obtain comparison clustering loss, the comparison clustering loss is added into the training process for joint training, and parameter optimization is achieved; and after the joint training is finished, feature extraction on the whole data set is performed to obtain a fusion code, and the fusion code is input into a traditional clustering algorithm to obtain a clustering result. According to the method, semantic information of multiple angles of a single image can be extracted at the same time, and the richness of the information is improved.

Owner:XIDIAN UNIV

Soybean photoreceptor GmPLP1 and coding gene and application thereof

InactiveCN102453084AIncrease the number of branchesEarly floweringFungiBacteriaBiotechnologyPlant traits

The invention discloses a soybean photoreceptor GmPLP1 and a coding gene and application thereof. The protein provided by the invention is named as GmPLP1 and is a protein as described in the following (1) or (2): (1) protein with an amino acid sequence as shown in the sequence 2 in a sequence table; and (2) protein which is derived from (1) by substituting and / or deleting and / or adding one or more amino acid residues of the amino acid sequence of the sequence 2, and is associated with plant traits. The plant traits comprise at least one of the following (1)-(10): (1) branch number; (2) time of flowering; (3) plant height; (4) blade area; (5) distance between nodes; (6) root length; (7) photosynthetic rate; (8) stress tolerance; (9) stem diameter; and (10) node number. The photoreceptor gene GmPLP1 disclosed by the invention can be used for changing the plant morphology, increasing the plant branches and changing the time of flowering and ripening of the plant, and has great importance for plant breeding and research on the function and action mechanism of the photoreceptor gene.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

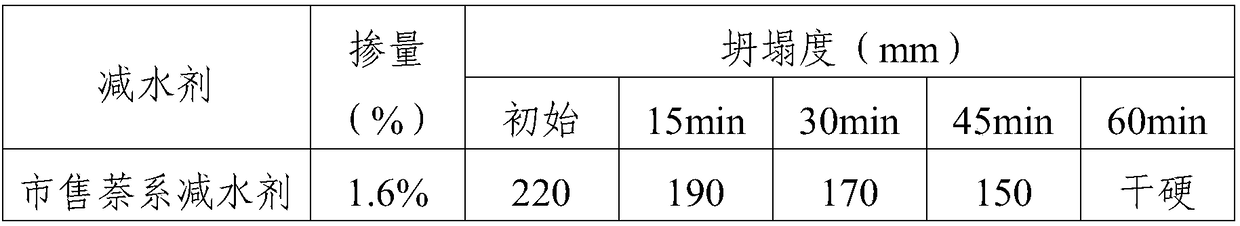

Modified naphthalene water reducer containing waste residue generated in phenol production process

InactiveCN108484852AAvoid pollutionIncrease the number of branchesEnvironmental resistanceThermal insulation

The invention provides a modified naphthalene water reducer containing waste residue generated in a phenol production process, and relates to the technical field of building materials. The water reducer comprises the following components in parts by weight: 200 to 350 parts of industrial naphthalene, 220 to 400 parts of industrial concentrated sulfuric acid, 50 to 100 parts of the waste residue generated in the phenol production process, 150 to 200 parts of formaldehyde, 400 to 600 parts of liquid caustic soda, and 5 to 50 parts of water. A preparation method comprises the following steps: (1), weighing the raw materials; (2), feeding the industrial naphthalene into a four-mouth flash, heating the industrial naphthalene to 150 DEG C to be molten, rising the temperature, dropwise adding theconcentrated sulfuric acid while stirring and controlling the dropwise adding speed, performing thermal insulation reaction for 3 to 5h after dropwise adding is accomplished, and detecting the acid degree value of a material; (3), lowering the temperature to 120 DEG C, replenishing water according to the acid degree value, performing hydrolysis for 30min, adding the waste residue generated in thephenol production process after hydrolysis is accomplished, stirring for 30min, dropwise adding the formaldehyde at 100 to 115 DEG C while controlling the dropwise adding speed, performing thermal insulation reaction after dropwise adding is accomplished, and slowing adding the liquid caustic soda to regulate PH after thermal insulation is accomplished. The water reducer not only solves the problem of environment protection, but also creates an economic benefit.

Owner:萧县沃德化工科技有限公司 +1

Cultivation method for bringing tea trees into production in advance

InactiveCN107094580APromote rootingAvoid infectionFertilising methodsCultivating equipmentsHydrogenPlastic mulch

The invention discloses a cultivation method for bringing tea trees into production in advance. The cultivation method includes steps of (1), clearing lands, applying fertilizers, carrying out watering and covering the lands with black mulching films; (2), dipping the roots of tea seedlings in root liquid for 10-15 s before the tea seedlings are transplanted; (3), transplanting the tea seedlings, to be more specific, digging holes in the mulching films and planting the tea seedlings in double-row and double-plant modes; (4), carrying out watering and soil covering, to be more specific, sufficiently watering the tea seedlings with root colonizing water, then carrying out soil covering and sealing on broken openings of the mulching films but necessarily exposing soil in the ranges of 10-12 cm around the root stock of the tea seedlings; (5), applying fertilizers, to be more specific, perforating the mulching films to apply the fertilizers, or furrowing the centers of small tea rows to apply the fertilizers and applying the compound fertilizers with the pH (potential of hydrogen) values of 6-7; (6), secondarily pruning the tea seedlings and carrying out secondary topping on the tea seedlings. The root liquid comprises 800-1000 times dilution of rooting agents, 1200-1500 times dilution of bactericides and 0.4-0.6 kg / L of clay. The cultivation method has the advantages that the survival rate of the tea seedlings can be increased, and the tea trees can be brought into production in advance by a year; more than a half of weeding cost can be reduced, the quality of the tea trees can be enhanced, the yield of the tea trees can be increased, and economic value of the tea trees can be increased.

Owner:SICHUAN AGRI UNIV

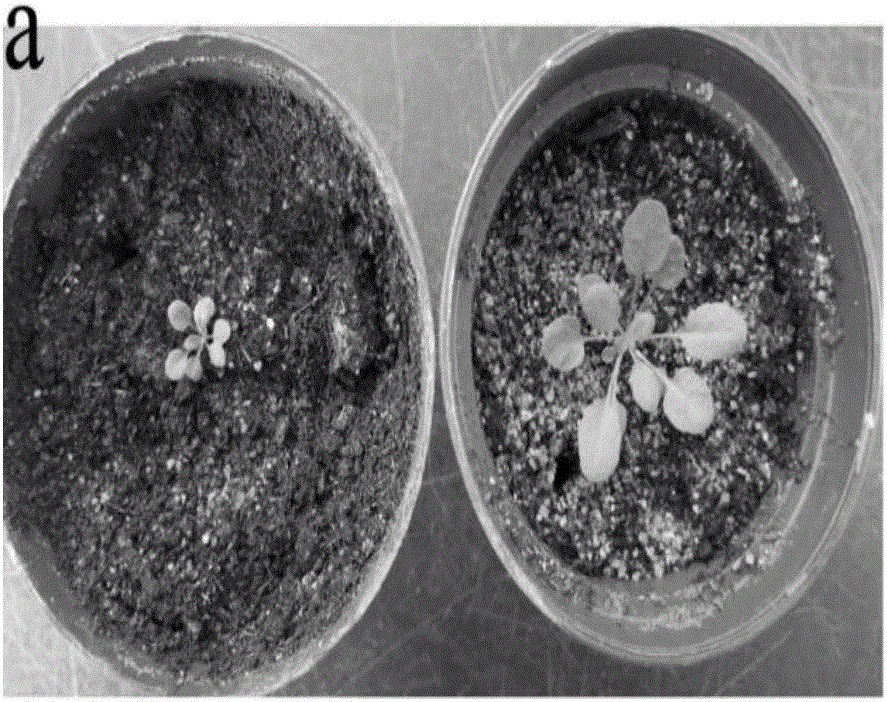

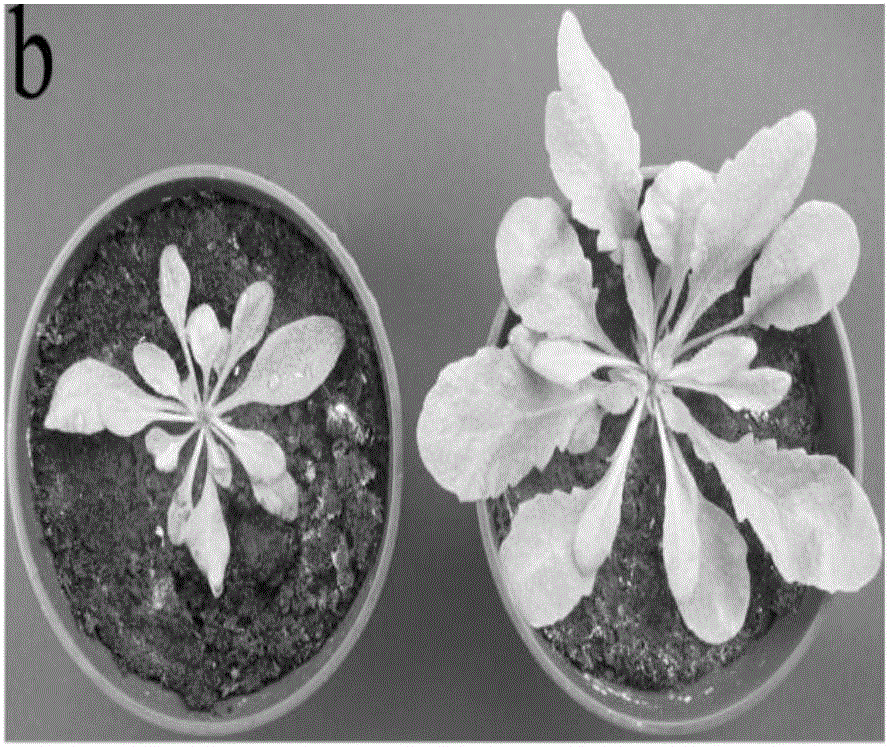

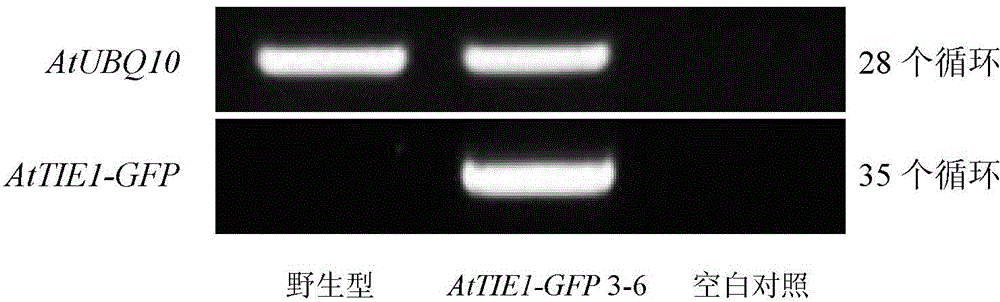

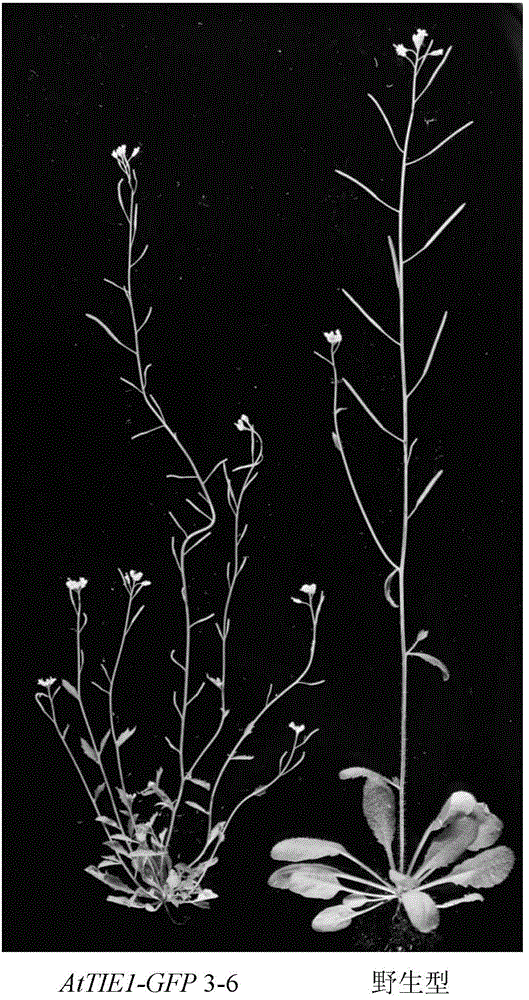

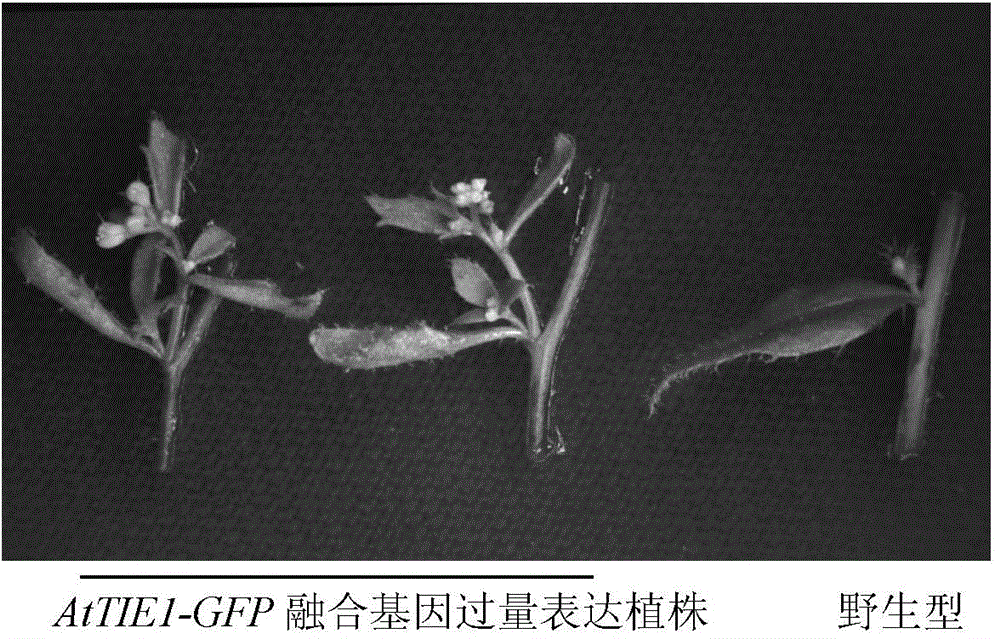

Arabidopis thaliana gene AtTIE 1 controlling plant branching and applications thereof

InactiveCN104862319AIncrease the number of branchesPlant peptidesFermentationMolecular breedingArabidopsis thaliana

The invention discloses an Arabidopis thaliana gene AtTIE 1 controlling plant branching and applications thereof. The AtTIE 1 gene codes a plant regulation and control factor or derivative proteins with the same functions with an amino acid sequences shown in SEQ ID No:1 in a sequence table. The gene is expressed in Arabidopis thaliana and branching number of Arabidopis thaliana plants can be increased. The AtTIE 1 gene has important application values in optimization of plant morphogenesis, and ideotype plants with practical production and application values are expected to be cultivated through molecular breeding by utilization of the gene.

Owner:PEKING UNIV

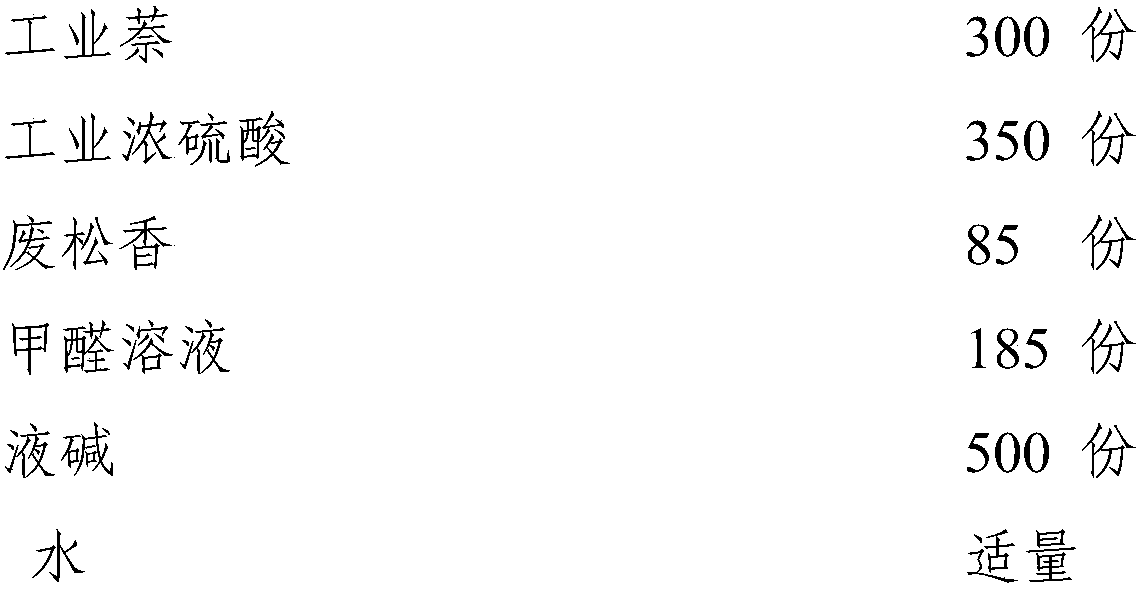

Waste colophony used for modifying naphthalene water reducer during binding agent production

InactiveCN108503254AAvoid pollutionIncrease the number of branchesWater reducerToxic industrial waste

The invention discloses a method for using waste colophony to modify a naphthalene water reducer during binding agent production. The modified naphthalene water reducer is prepared from, by weight, 200-350 parts of crude naphthalene, 220-400 parts of industrial concentrated sulfuric acid, 50-100 parts of waste colophony, 150-200 parts of formaldehyde solution, 400-600 parts of liquid caustic sodaand moderate water. The water reducer obtained by adopting the technical scheme can effectively prevent cement from collapsing, the preparation technology is green and environmentally friendly, and the industrial waste materials can be effectively recycled.

Owner:萧县沃德化工科技有限公司 +1

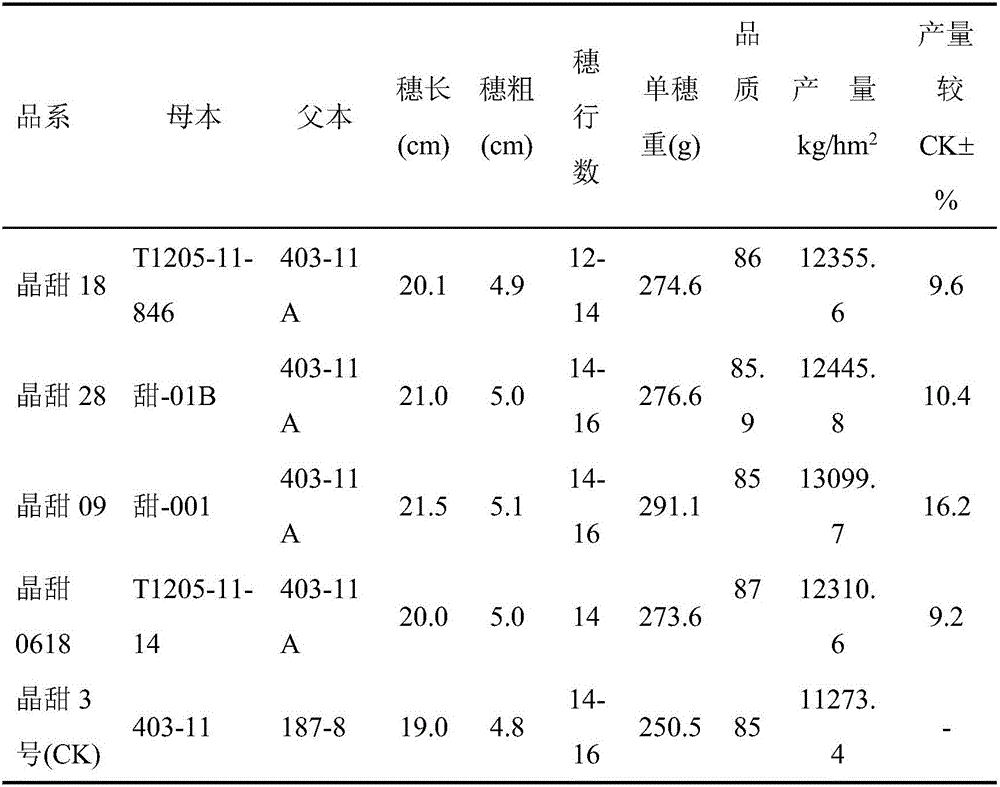

Breeding method of excellent super sweet corn inbreeding line

InactiveCN105961186AImprove stress resistanceImprove qualityPlant genotype modificationAgricultural scienceTemperature resistance

The invention discloses a breeding method of an excellent super sweet corn inbreeding line, and belongs to the technical field of agriculture new variety breeding. The breeding method is characterized in that a subtropical variety resource which is good in stress resistance, wide in applicability and good in quality is selected to carry out hybridization and backcross improvement with inbreeding super sweet corn, and strict selection is carried out on width, resistance, quality and the like of grains; excellent genetic genes sourcing from different source resources are gathered together, and richer sweet corn gene resources are provided for breeding. A super sweet corn inbreeding line 403-11A bred through the invention is semi compact in plant type, moderate in ear position, more tolerant in close planting and strong in heat resisting ability and cold resisting ability; higher general combining ability and specific combining ability effects are obtained, a prepared hybrid variety is high in yield, good in high temperature resistance and low temperature resistance, strong in rain resistance and wide in applicability, and a high-yield and stable-yield variety can be easily bred; the grains are relatively outstanding in quality, appearance properties, seed yield and the like, and the super sweet corn inbreeding line is good in comprehensive properties.

Owner:NANJING INST OF VEGETABLE SCI

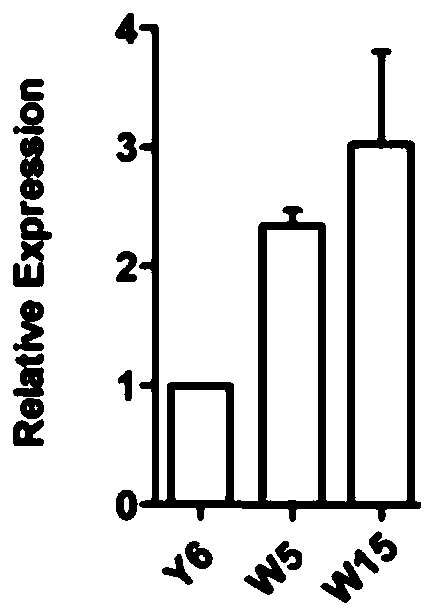

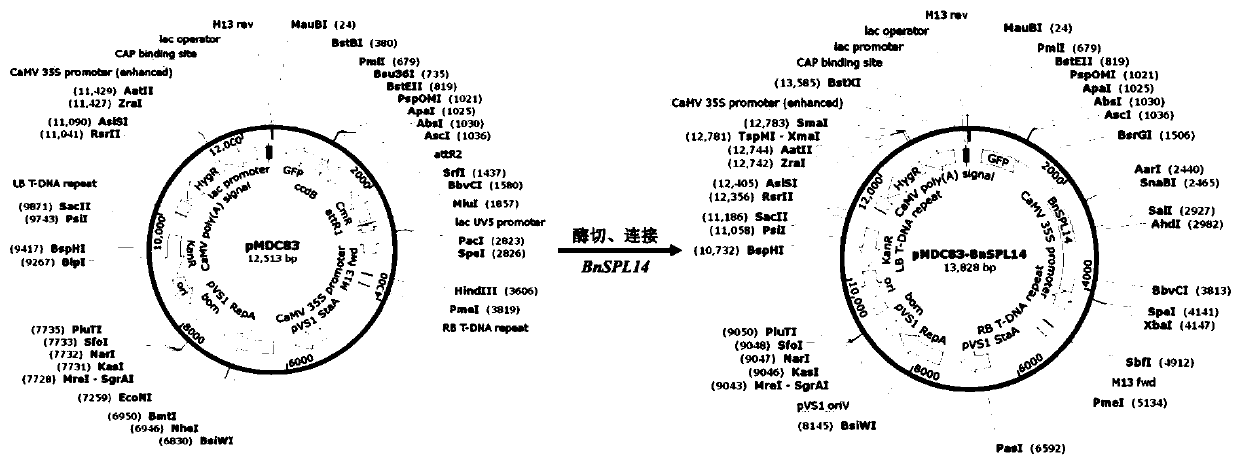

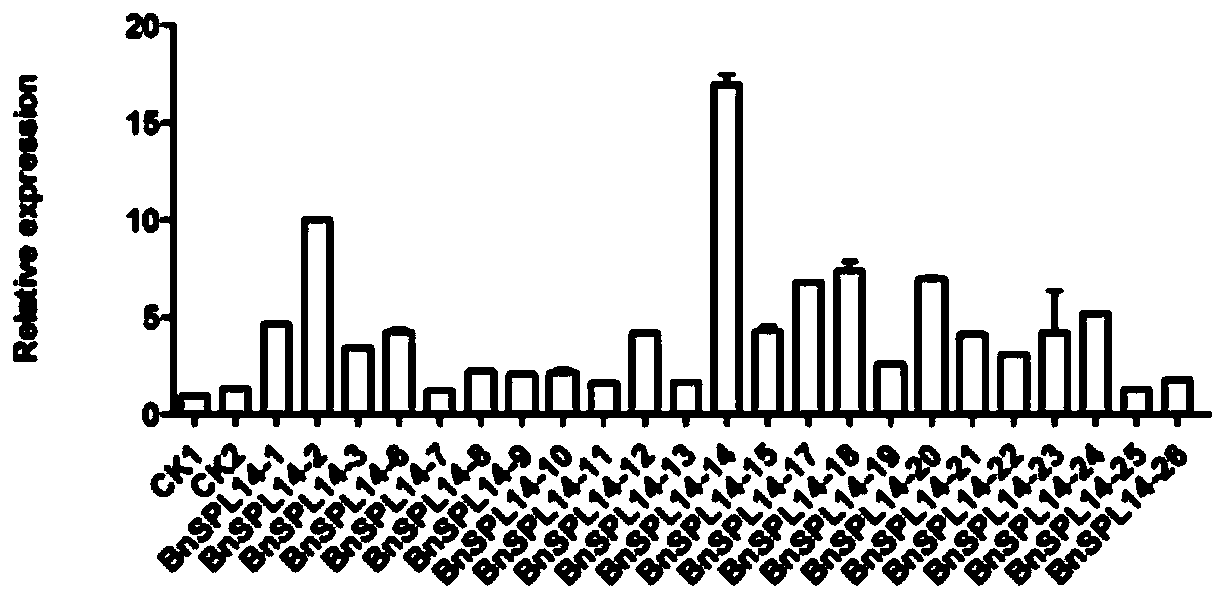

BnSPL14 gene and protein, and application thereof in controlling strain types of Brassica napus L.

ActiveCN110204600AIncrease productionIncrease the number of branchesPlant peptidesFermentationBrassicaNucleotide

The invention relates to a BnSPL14 gene and protein, and an application thereof in controlling strain types of Brassica napus L. A DNA fragment including the BnSPL14 gene is separated and applied, andthe fragment gives a function which can increase the number of branches to the Brassica napus L.; and the nucleotide sequence including BnSPL14 gene coding regions is shown as a sequence table SEQ IDNO : 1, the length of the sequence is 3,099 bp, the nucleotide sequence of the protein which coded by the gene is shown as SEQ ID NO : 2, and the number of amino acids is 1,032. The BnSPL14 gene canbe separated from the Brassica napus L.; the biological function of the gene on improving the strain types of the Brassica napus L. can be identified; and therefore, the gene has very important meanings for cultivating new high-yield Brassica napus L. species.

Owner:YANGZHOU UNIV

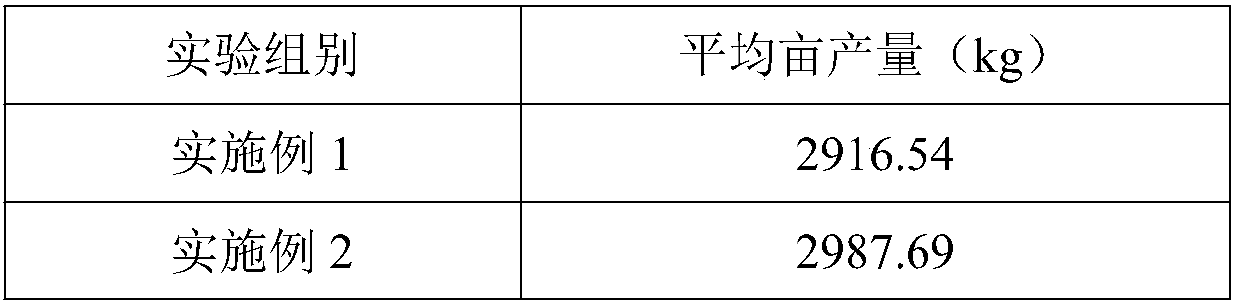

Preparation technology for dedicated high-efficiency ecological biological organic fertilizer for sweet potatoes

InactiveCN107721629AIncrease the average yield per muWith increased productionExcrement fertilisersBioloigcal waste fertilisersSaccharumSucrose

The invention discloses a preparation technology for dedicated high-efficiency ecological biological organic fertilizer for sweet potatoes and belongs to the technical field of fertilizer preparation.The dedicated high-efficiency ecological biological organic fertilizer for the sweet potatoes is prepared from the following raw materials of traditional Chinese medicine residues, chicken manure, grass carbon, sugar cane bagasse, poplar biochar, potassium fulvic acid, kaolin, urea, mannitol, sodium molybdate, compound bacteria, polyoxyethylene, brassinolide and chitosan oligosaccharide. The dedicated high-efficiency ecological biological organic fertilizer for the sweet potatoes is prepared by the steps of fermenting, concentrating, smashing, granulating and the like. After the fertilizer disclosed by the invention is used, a disease and pest rate of the sweet potatoes can be reduced, and an average acre yield of the sweet potatoes is improved.

Owner:东兴市红家宝电子商务有限公司

Foliar fertilizer for improving yield and quality of sarcandra glabra, lonicerae flos and fortune euonymus

InactiveCN104718860AHigh transplant survival rateIncrease plant heightFertilising methodsFertilizer mixturesGrowth plantEuonymus

The invention discloses a foliar fertilizer including a plant growth regulator and two plant growth essential nutrient elements, and the foliar fertilizer for improving the transplant survival percent and yield and quality of sarcandra glabra, lonicerae flos and fortune euonymus in drought conditions can be used for planting regulation of Chinese herbal medicine sarcandra glabra, lonicerae flos and fortune euonymus. The invention discloses the preparation of the foliar fertilizer for improving the transplant survival percent and yield and quality of sarcandra glabra, lonicerae flos and fortune euonymus in drought conditions, and an application method and time of the foliar fertilizer after adjusting and control hardening-seedling and field planting; and before transplant of three Chinese herbal medicine young seedlings and cutting seedlings, the foliar fertilizer is applied by foliage spray. The application results show that the foliar fertilizer can improve the transplant survival percent of the Chinese herbal medicine sarcandra glabra, lonicerae flos and fortune euonymus in drought conditions, can increase the plant height, branch number and per-plant weight of the Chinese herbal medicine sarcandra glabra, lonicerae flos and fortune euonymus in drought conditions and normal water conditions, can improve the quality of the Chinese herbal medicine ssarcandra glabra, lonicerae flos and fortune euonymus, and can increase effective medicinal ingredients.

Owner:GUANGXI UNIV

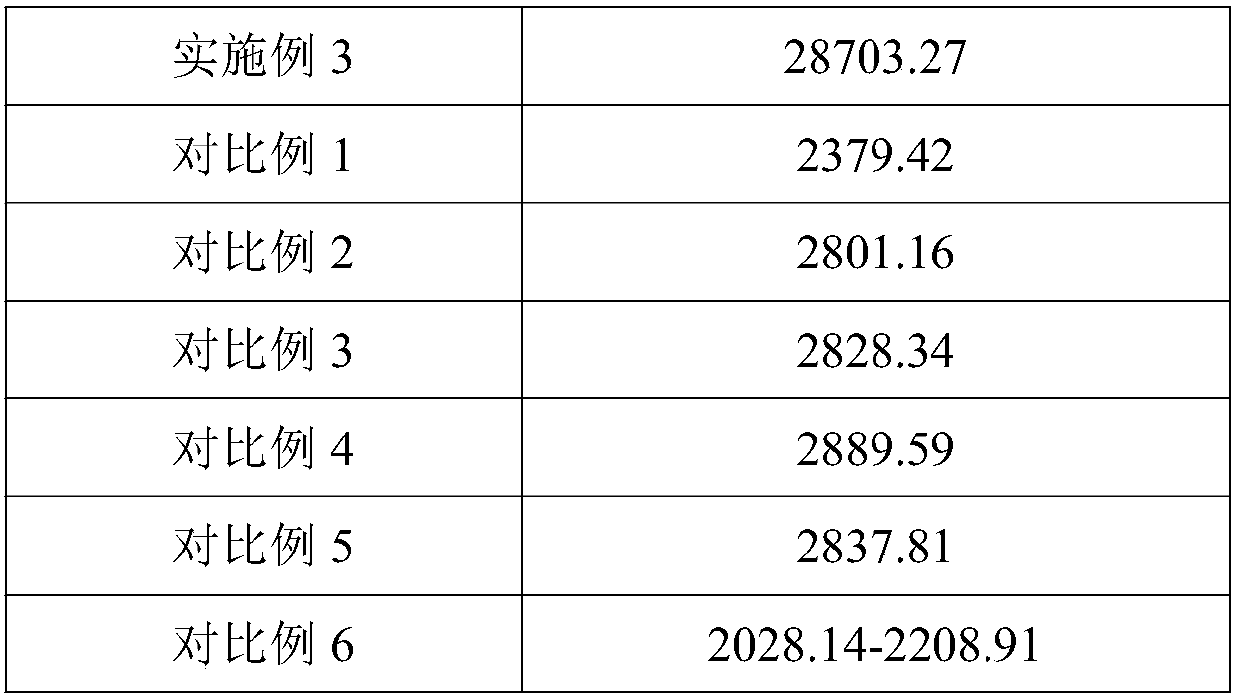

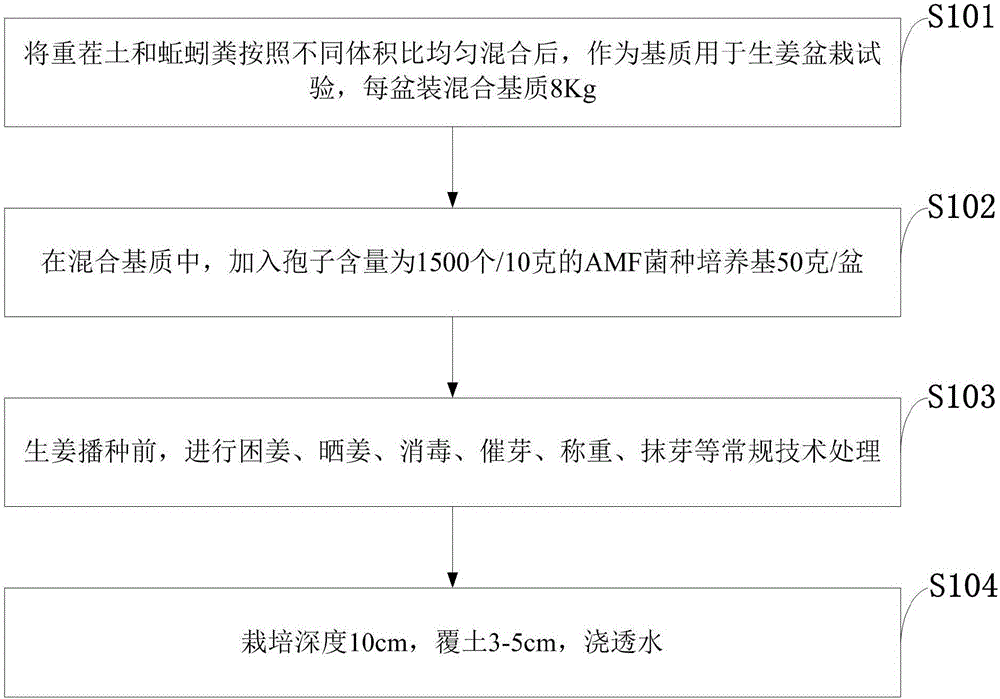

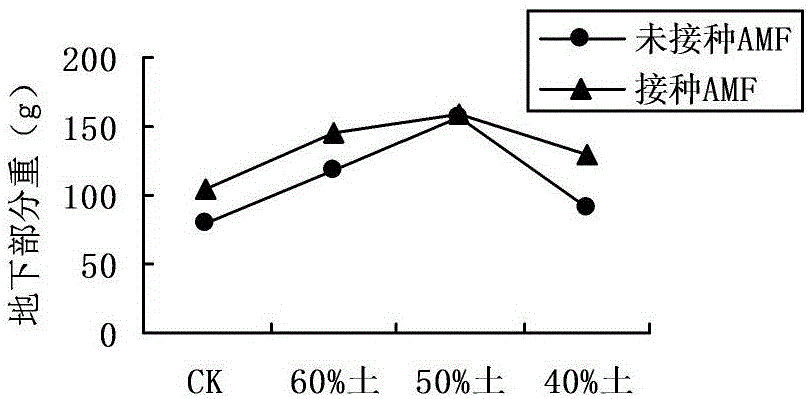

Planting method of continuous cropping gingers based on earthworm dung and AMF,

InactiveCN107173009APromote activationPromote biodegradationExcrement fertilisersCultivating equipmentsDiseaseContinuous cropping

The invention belongs to the technical field of continuous cropping ginger cultivation, and discloses a planting method of continuous cropping gingers based on earthworm dung and AMF. The continuous cropping gingers are taken as objects, and the effects of different proportions of earthworm dung + AMF on the number of branches, plant height, stem diameter, part of fresh weight on the ground, yield, disease index and control effect of the continuous cropping gingers are studied. The results showed that earthworm dung and AMF have a great influence on the number of the branches of the continuous cropping gingers, and the branch germination of the gingers at early stage is promoted by adding earthworm dung to the continuous cropping soil. According to the planting method of continuous cropping gingers, by starting from the aspects of ginger biological and soil microbial quantity and the like, the local characteristic crop gingers taken as the mediums and the earthworm dung used as the foundation are combined with inoculated GM inoculum (one of the AMF) to study the effects of compound substrate of the earthworm dung + AMF on ginger continuous cropping obstacles, so as to provide a theoretical basis for the development of the local ginger industry, the resource utilization of the earthworm dung and the production of the novel biological organic fertilizers.

Owner:阜阳职业技术学院

Modified aliphatic water reducer containing waste residues in phenol production process

The invention provides a modified aliphatic water reducer containing waste residues in the phenol production process and relates to the field of building materials. The modified aliphatic water reducer is prepared from the following components in parts by weight: 300-500 parts of water, 110-180 parts of sodium nitrite, 230-280 parts of formaldehyde, 50-80 parts of the waste residues in the phenolproduction process and 85-105 parts of acetone. A synthetic method comprises the following steps of (1) weighing the raw materials in parts by weight; (2) adding water into a four-mouth flask, addingthe sodium nitrite while stirring, feeding the waste residues in the phenol production process after uniform stirring and mixing, performing continuous reaction for 30 minutes, weighing the acetone ina constant-pressure funnel after reaction is finished, controlling a dropwise adding speed of the acetone, finishing dropwise adding for 20-30 minutes, performing stirring for continuous reaction for30 minutes after dropwise adding is finished, starting to dropwise adding the formaldehyde, controlling a dropwise adding speed of the formaldehyde, finishing dropwise adding for 2-3 hours, performing heating to 95 DEG C after dropwise adding is finished, performing continuous insulation reaction for 3-4 hours, and descending the temperature after insulation is finished. The modified aliphatic water reducer provided by the invention solves the environmental protection problem and also creates the economic benefit.

Owner:萧县沃德化工科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com