Dry powder mortar additive suitable for novel wall material and preparation method thereof

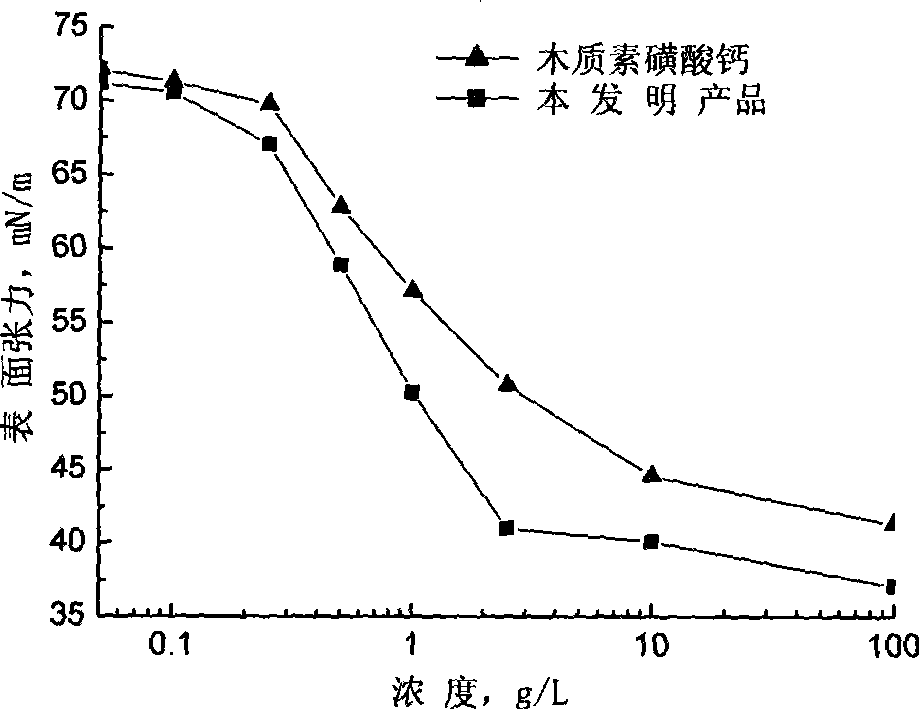

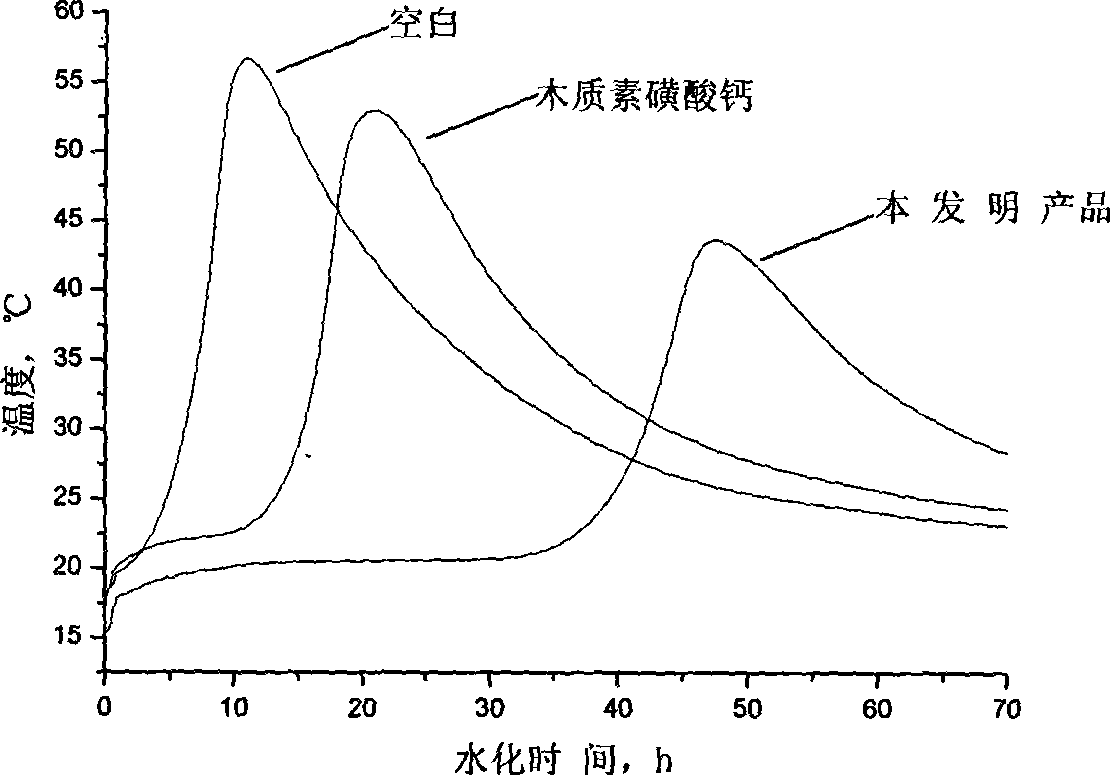

A technology for wall material and dry powder mortar, which is applied in the field of mortar admixture and its preparation, environment-friendly and high-efficiency dry powder mortar admixture and its preparation field, can solve the problems of less utilization of lignosulfonate, complicated production process, etc., and achieves high performance The effect of excellent price ratio, good water solubility and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

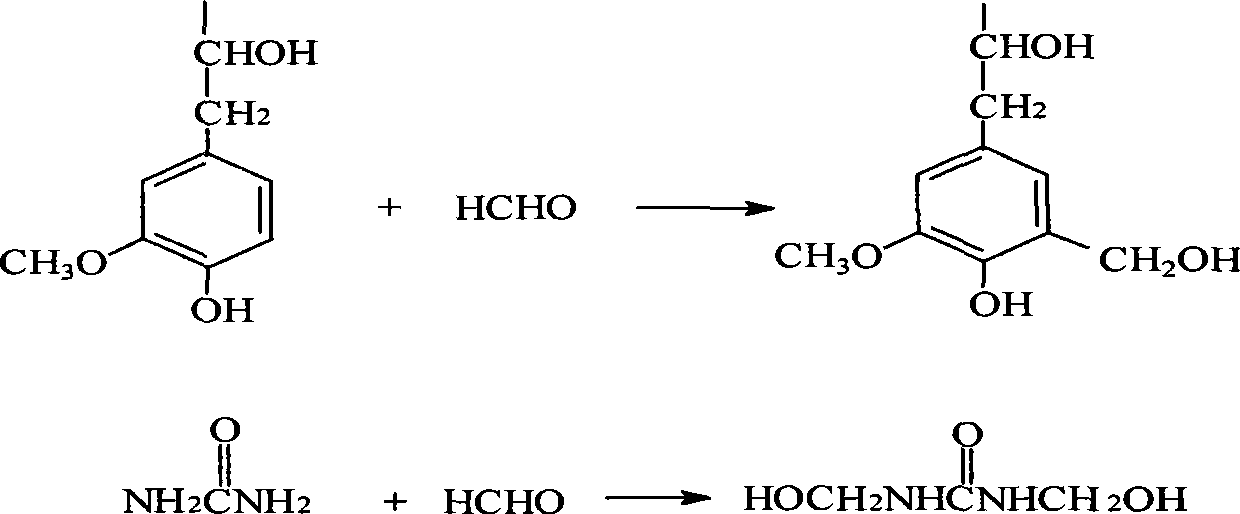

[0033] Take 1000g of magnesium lignosulfonate, add water to make a solution with a concentration of 40%, add NaOH solution to adjust the pH value of the system to 8.0, add 100g of urea, 150g of formaldehyde, heat to a certain operating temperature while stirring, and the operating temperature is controlled at 95 °C, react for 1 hour; add H 2 SO 4 Adjust the pH value of the system to 6.0, adjust the reaction temperature, and react at 90°C for 2 hours; add 50g of potassium permanganate, and react at 90°C for 2 hours. After cooling, the liquid product of the mortar admixture of the present invention can be obtained and sprayed Drying can obtain the powdery product of the present invention.

Embodiment 2

[0035] Take 1000g of sodium lignosulfonate, add water to make a solution with a concentration of 50%, add NaOH solution to adjust the pH value of the system to 11.0, add 50g of urea and 100g of formaldehyde, heat to a certain operating temperature while stirring, and control the operating temperature at 85 °C, react for 1 hour; add H 2 SO 4 Adjust the pH value of the system to 5.0, adjust the reaction temperature, and react at 80°C for 3 hours; add 80g of calcium perchlorate, adjust the reaction temperature, and react at 70°C for 1 hour, and the liquid of the mortar admixture of the present invention can be obtained after cooling The product can be spray-dried to obtain the powdered product of the present invention.

Embodiment 3

[0037] Take 1000g of calcium lignosulfonate, add water to make a solution with a concentration of 30%, add NaOH solution to adjust the pH value of the system to 9.0, add 150g of urea and 200g of formaldehyde, heat to a certain operating temperature while stirring, and control the operating temperature at 80°C , reacted for 2 hours; added H 2 SO 4Adjust the pH value of the system to 4.0, adjust the reaction temperature, and react at a temperature of 100°C for 2 hours; add 100g of potassium dichromate, heat up to 85°C and react for 1.5 hours, and the liquid product of the mortar admixture of the present invention can be obtained after cooling , spray drying can obtain the powder product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com