Patents

Literature

144results about How to "High carboxyl content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

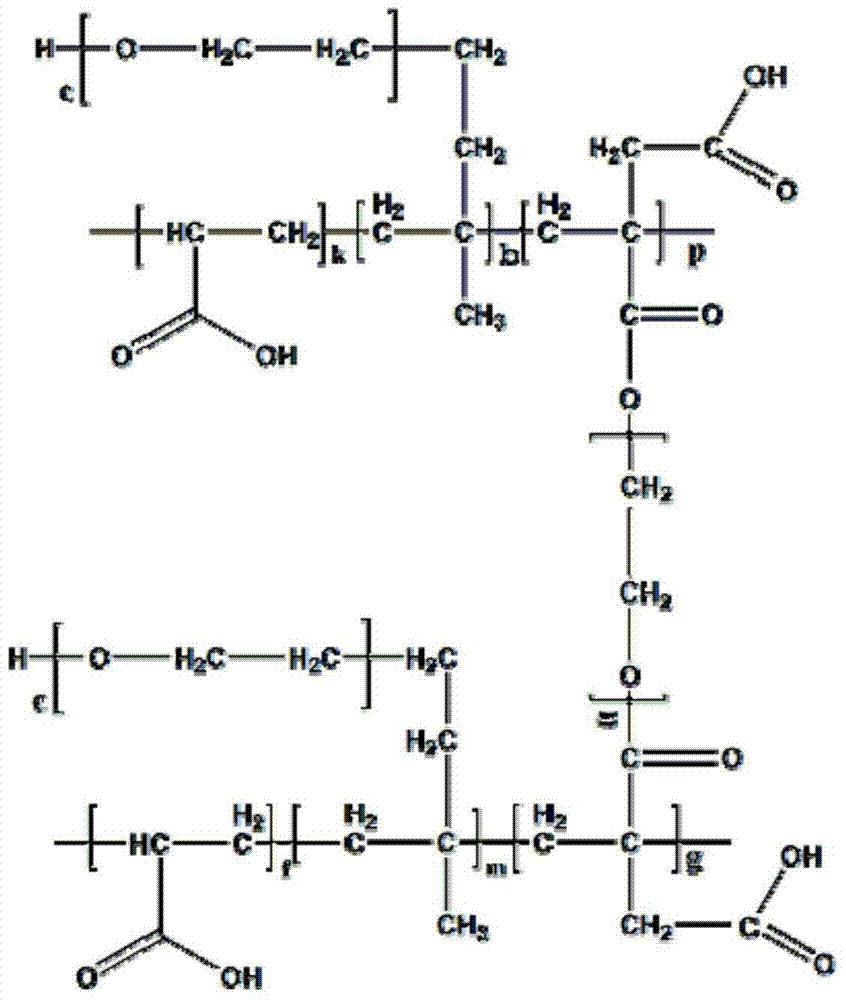

Method for preparing acrylic aqueous dispersion with hydroxyl through two-step polymerization

The invention provides a method for preparing acrylic aqueous dispersions with hydroxyl through two-step polymerization and the method comprises the synthesis of hydroxy acrylic resin, the removal ofsolvent, the neutralization and salt-formation and the deionized water dispersion, wherein the synthesis of hydroxy acrylic resin adopts two-step feeding synthesis method instead of one-step feeding method in prior art, the composition of the first added monomer mixture is different from that of the second added monomer mixture and preferentially, the weight percent of the second added hydrophilicmonomer is higher than that of the first added monomer when feeding tends to end up. The aqueous dispersions obtained by the technical solution of the invention reduces the dosage of monomer with hydroxyl so as to increase the water resistance of coating which is formed by combining aqueous dispersions and curing agent, reduce the grain size of dispersions, lower the viscosity and increase the stability obviously.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

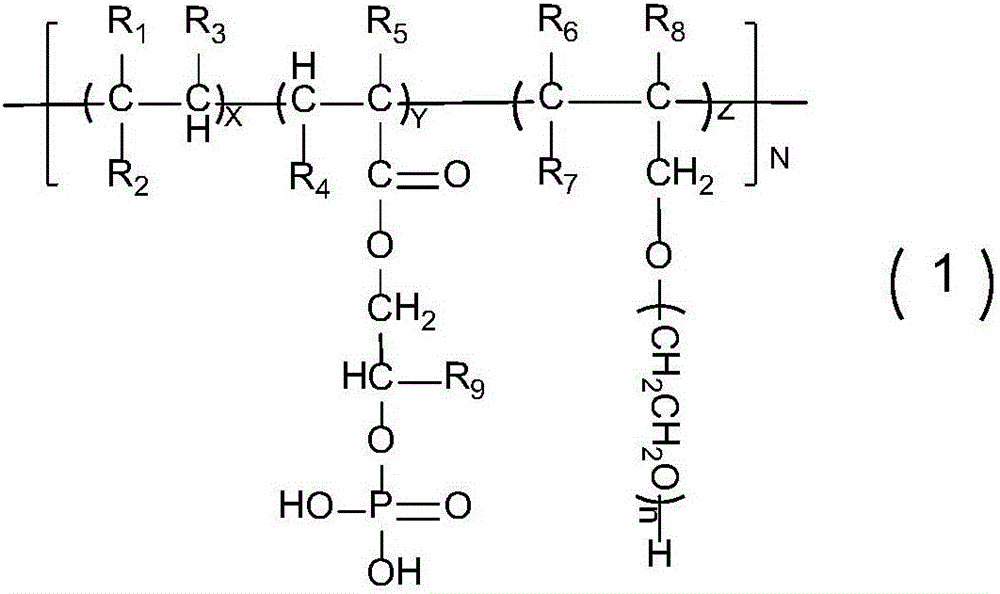

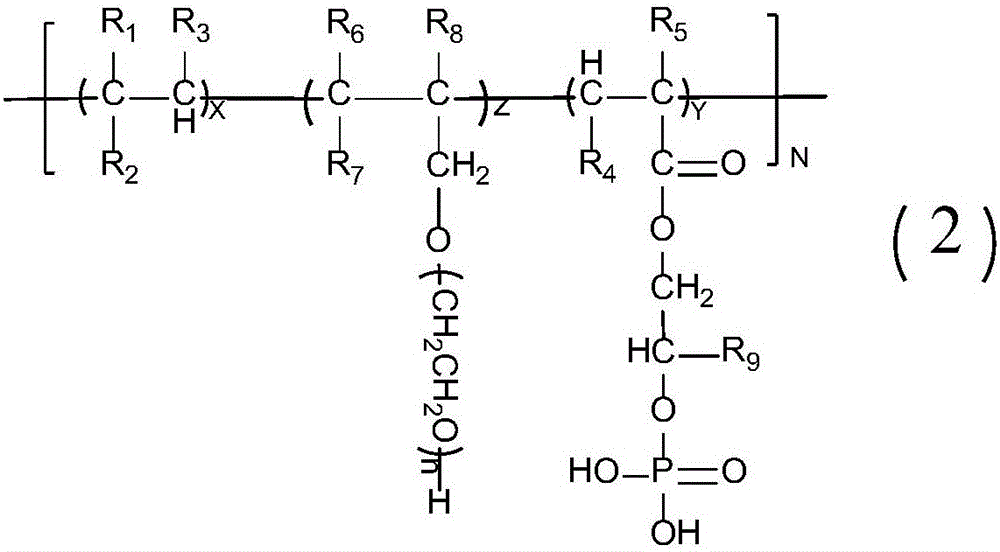

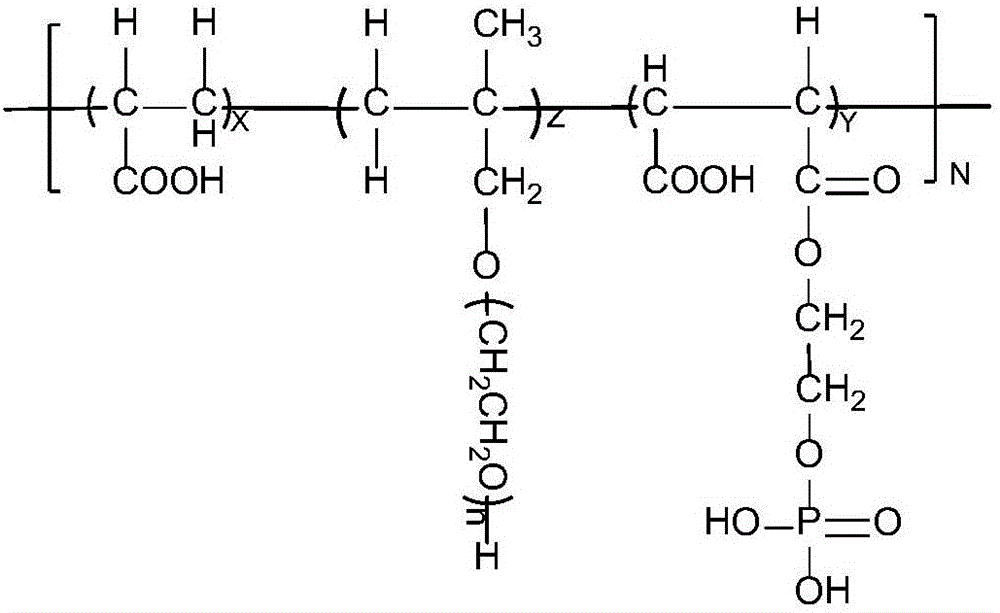

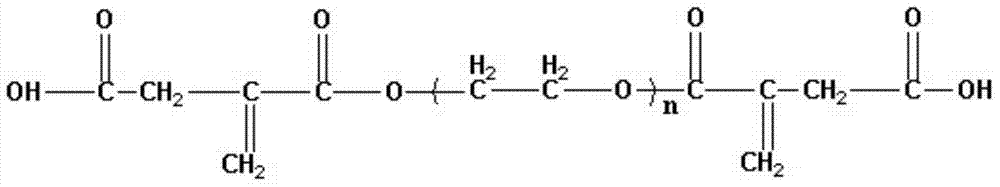

Phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent and preparation method thereof

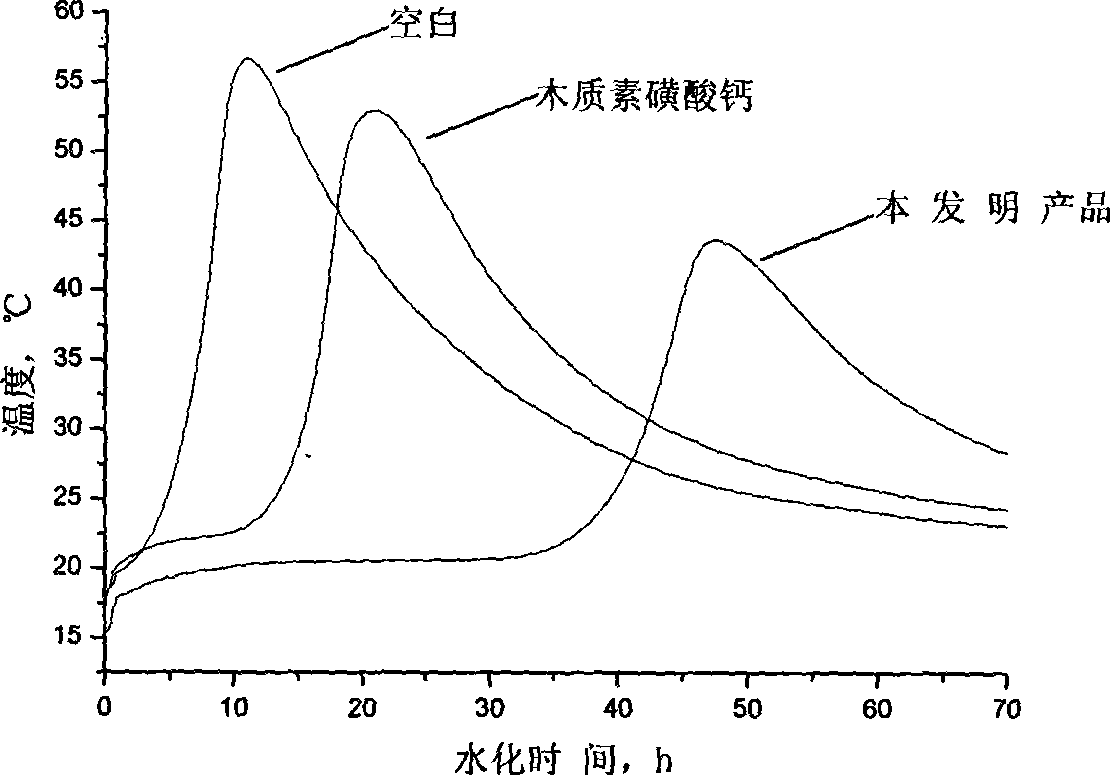

InactiveCN105837761AHigh carboxyl contentSlow down the hydration processOrganic compound preparationCarboxylic acid esters preparationAcid derivativeChain transfer

The invention relates to a structural formula and a preparation method of a phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The method includes: performing esterification reaction of alcohol and a mixture of one or more of unsaturated acids and unsaturated acid anhydrides, performing phosphorylation of a phosphatizing agent and prepared unsaturated acid ester, subjecting prepared phosphate and isobutene or TPEG, a chain transfer agent and a mixture of one or more of unsaturated acids and unsaturated acid derivatives to free radical polymerization reaction at the normal temperature, and after reaction is finished, adding an alkali solution to regulate a pH to be 7-9 to obtain the phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The water reducing agent has the advantages of excellent performances, low admixing quantity, high water reducing rate, excellent slump loss resistance, high cement adaptability, insensitivity to mud content of concrete materials and the like.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

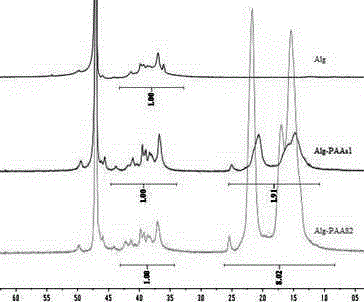

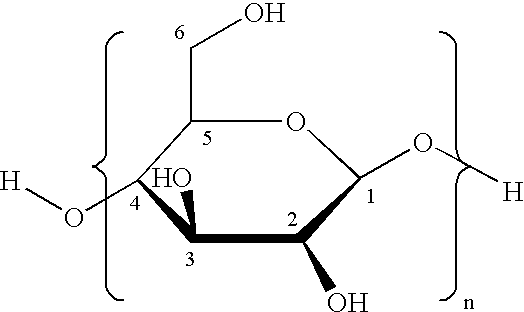

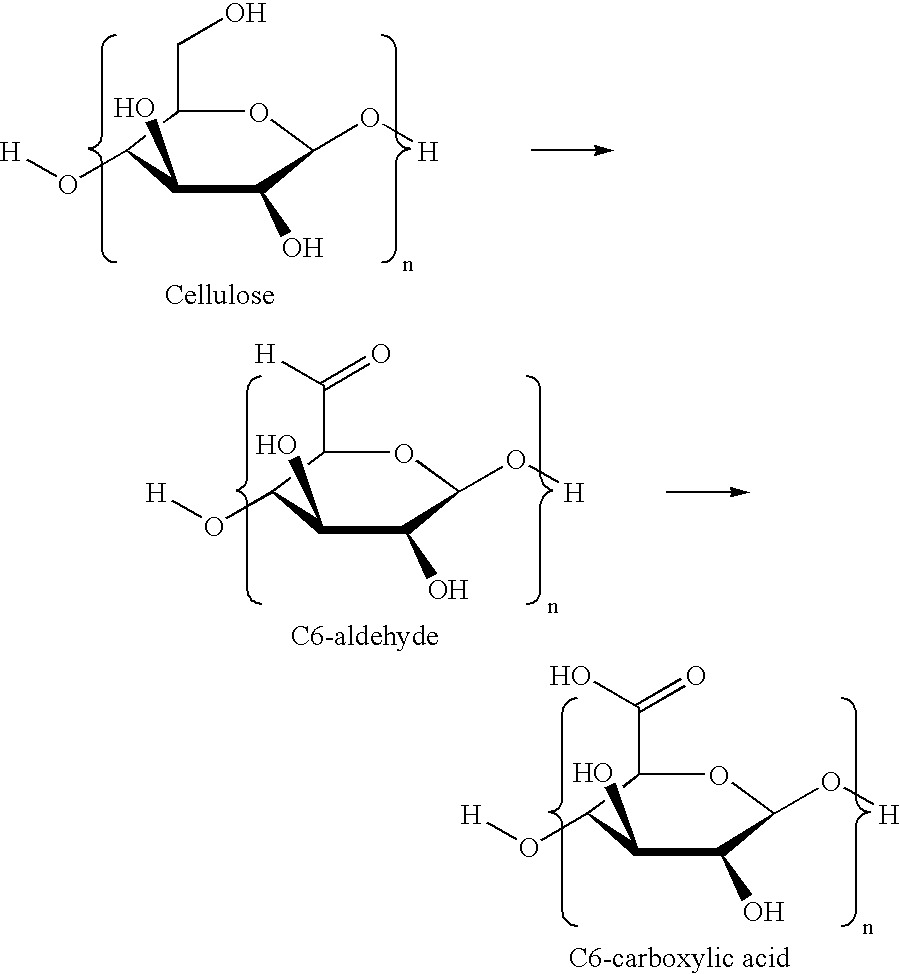

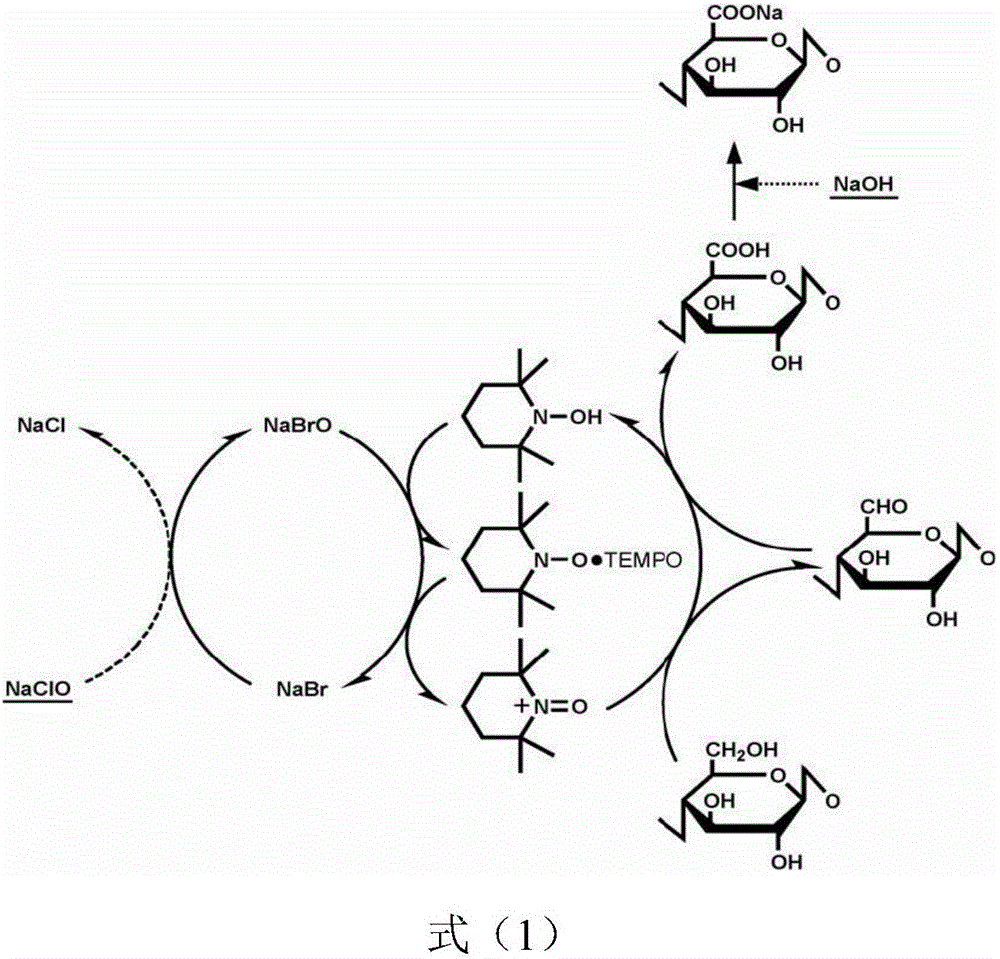

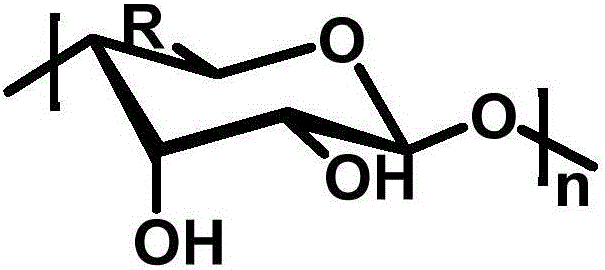

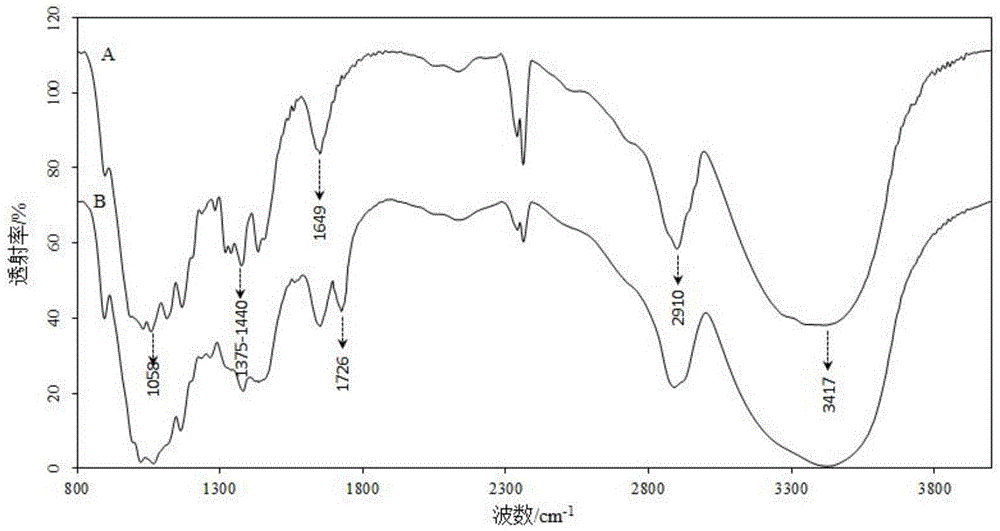

Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

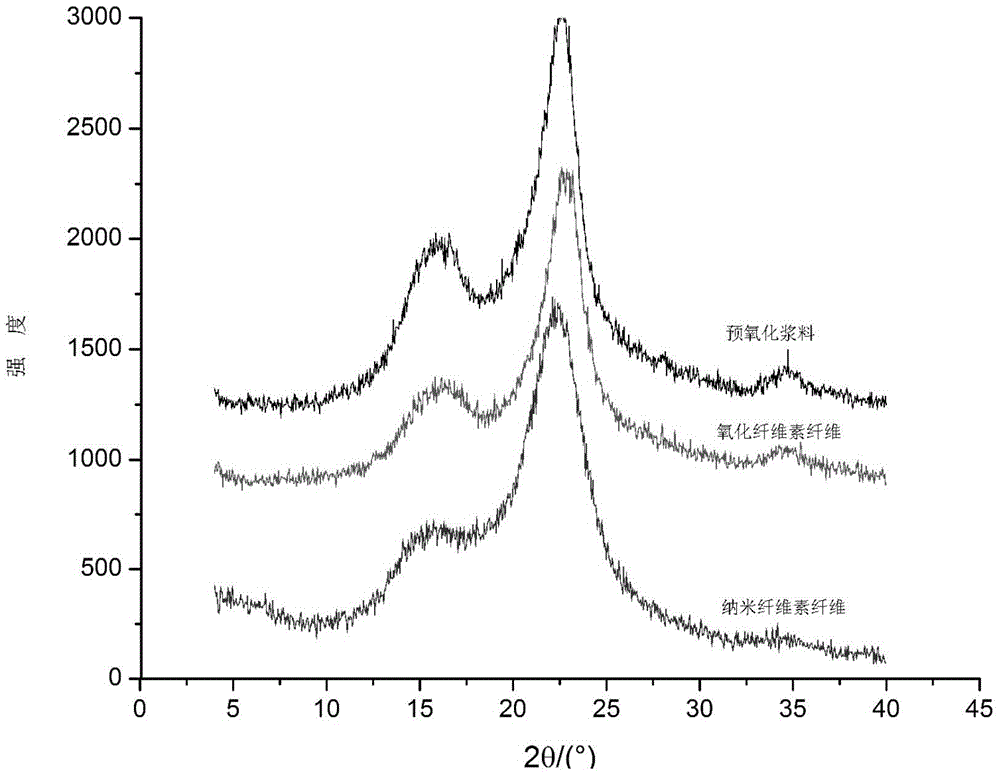

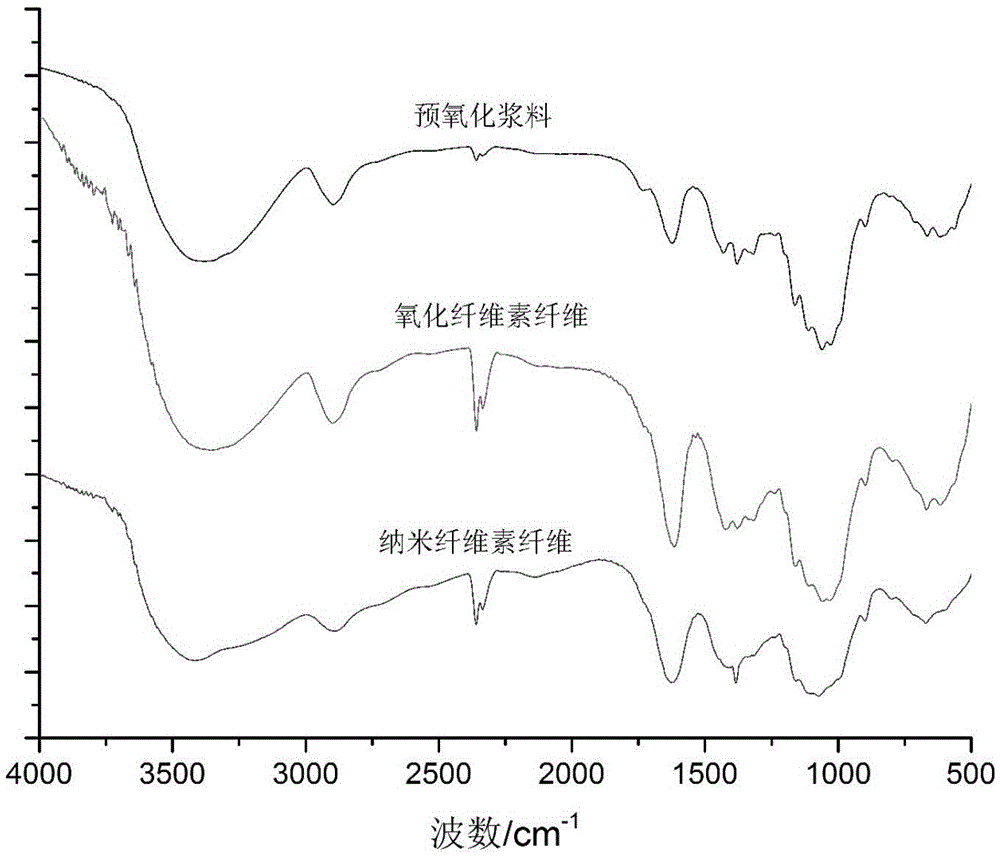

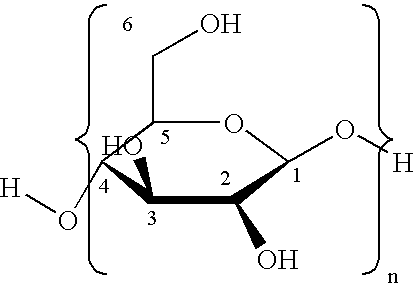

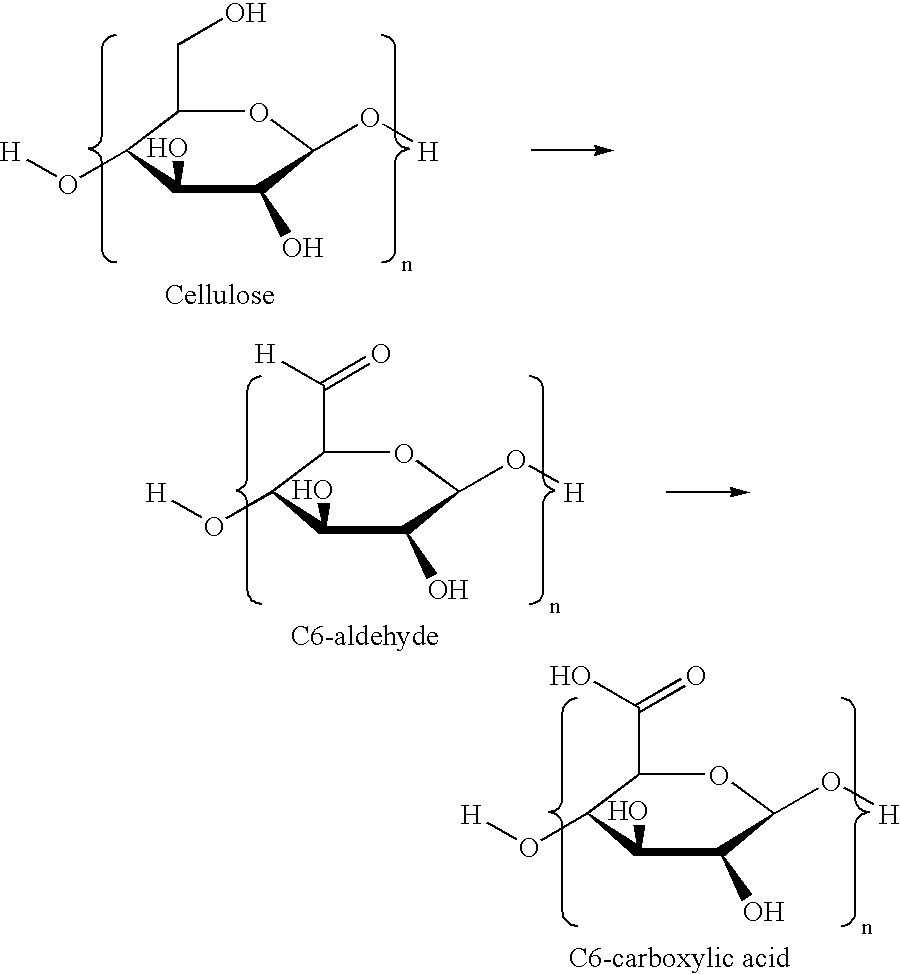

InactiveCN105463606AIncrease the total carboxyl contentGuaranteed crystallinityOther chemical processesArtificial filaments from cellulose derivativesPolymer scienceFreeze-drying

The invention belongs to the technical field of biomass nanometer materials and discloses a nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof. A preparation method comprises the steps of preheating fiber slurry for 0.5-1.5h with sodium periodate at the temperature of 50-60 DEG C; adding a sodium chlorite solution and acetum into the slurry to be reacted for 1-3h at the temperature of 30-50 DEG C, adding TEMPO, NaClO2 and NaClO, and performing microwave heating to the temperature of 55-65 DEG C to enable the mixture to be reacted for 1-3h; performing ultrasonic dispersion and freeze drying to obtain the nano-crystalline cellulose fiber high in carboxyl group content. According to the nano-crystalline cellulose fiber, hydroxyl at the positions of C2 and C3 of cellulose is oxidized into a formyl group which is oxidized into carboxyl by sodium chlorite, hydroxyl at the position of C6 is selectively oxidized into carboxyl through a TEMPO neutral oxidation system, and accordingly the total carboxyl group content of the fiber is greatly increased, and obtained products can be used for advanced treatment of waste water at the middle section of paper making.

Owner:SOUTH CHINA UNIV OF TECH

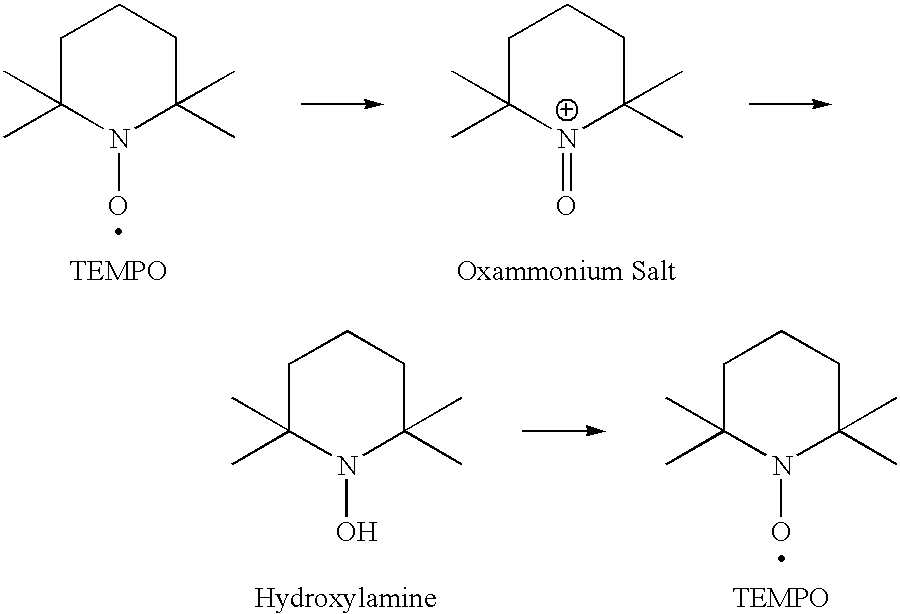

Hypochlorite free method for preparation of stable carboxylated carbohydrate products

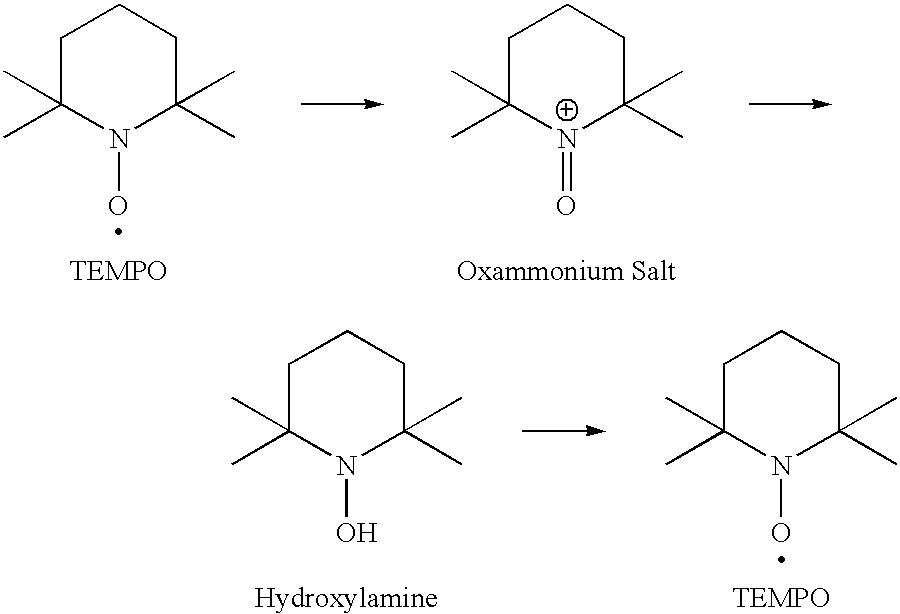

InactiveUS6919447B2Low costEnvironmental lossPulp properties modificationSugar derivativesHydroxylamineHypochlorite

Owner:INT PAPER CANADA PULP HLDG ULC

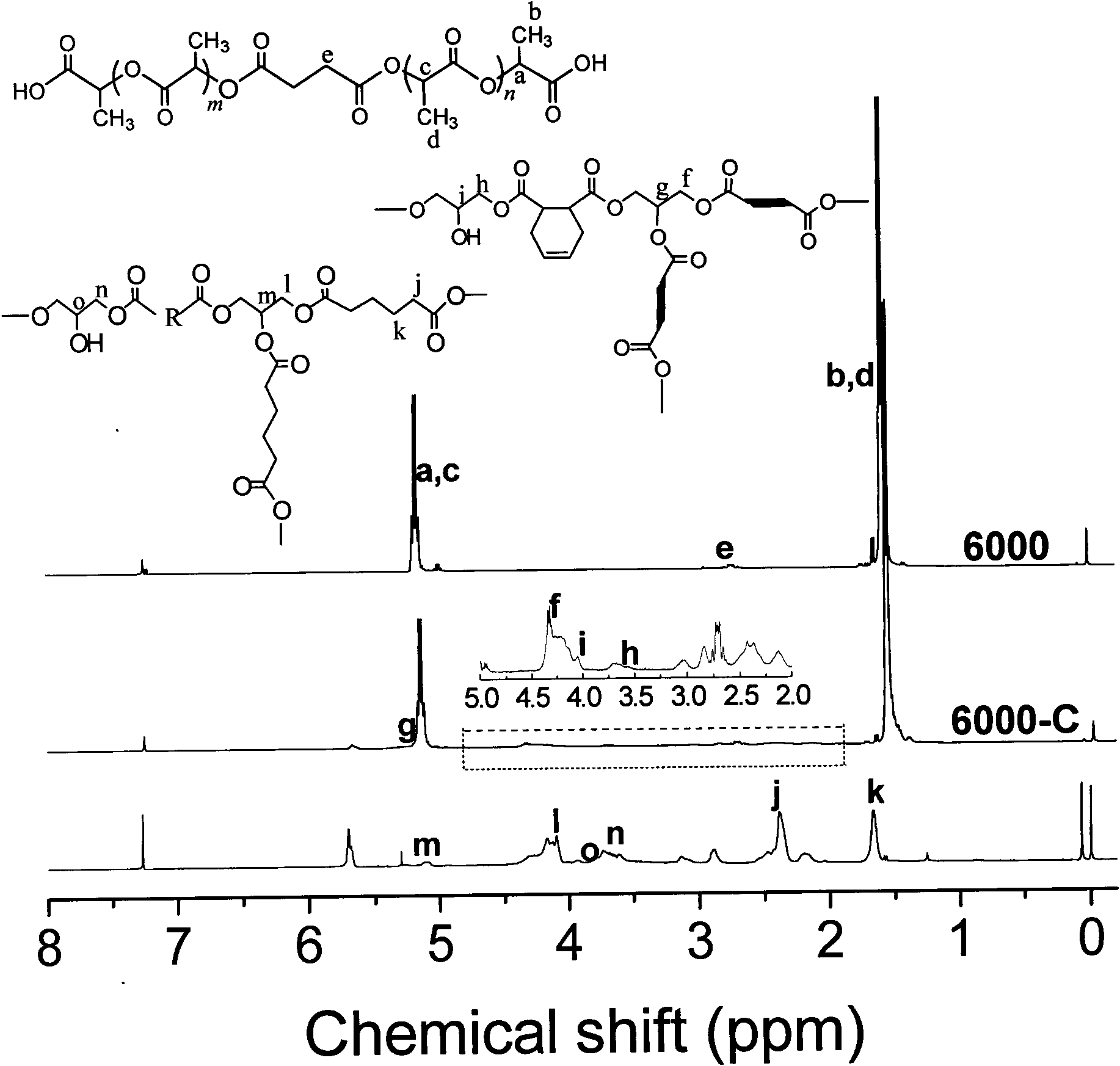

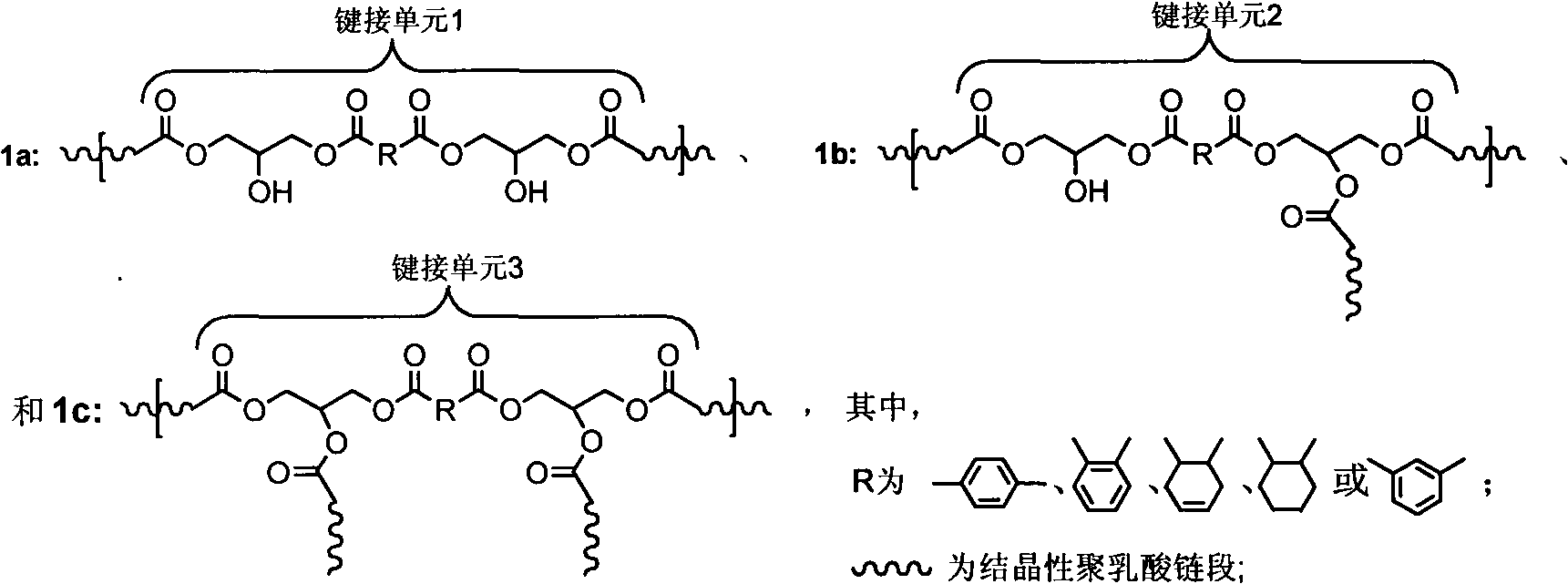

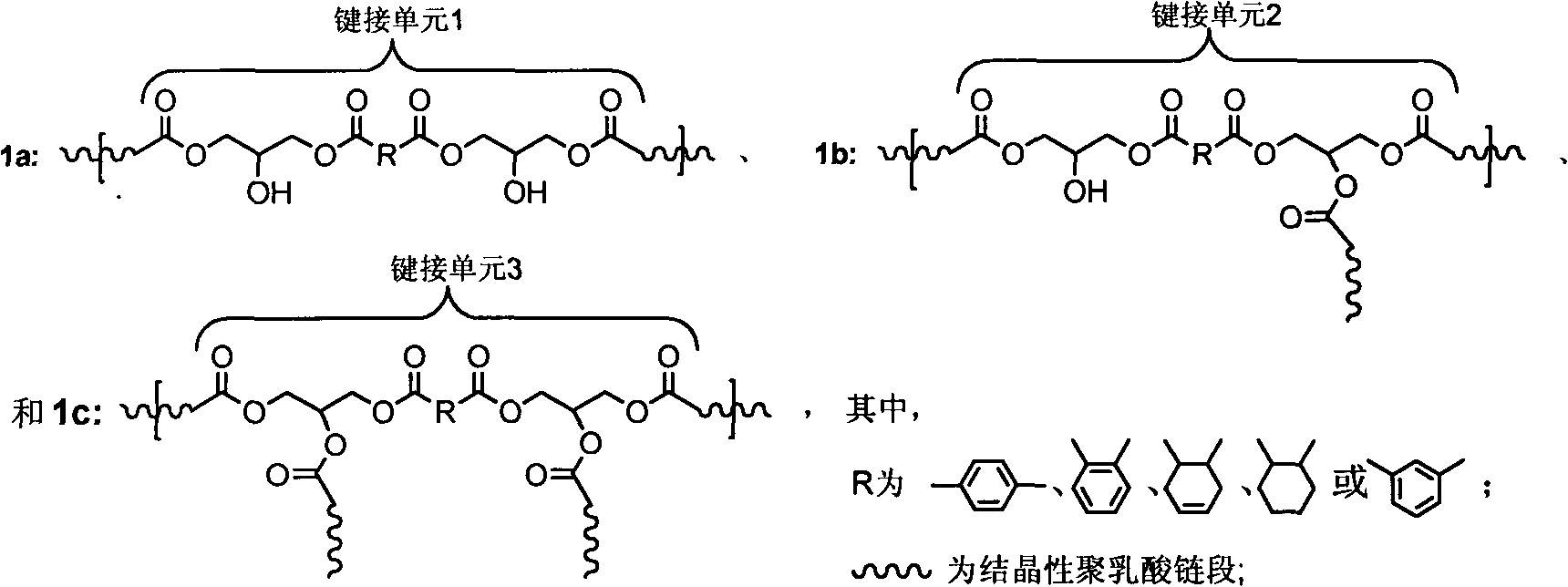

High-molecular weight long-chain branched crystalline polylactic acid material and preparation method thereof

The invention discloses a high-molecular weight long-chain branched crystalline polylactic acid material and a preparation method thereof. The preparation method comprises the following steps of: 1) adding 0.1 to 1 percent of protonic acid catalyst into aqueous solution of lactic acid or mixed solution of the aqueous solution of the lactic acid and silicon dioxide nano particle silica sol containing 0.1 to 10 weight percent of lactic acid, and dehydrating to obtain a product I; 2) adding 0.4 to 2 molar percent of dibasic acid or anhydride into the product I, and reacting to obtain a product II; 3) adding 0.1 to 1 weight percent of lewis acid catalyst into the product II, performing melt polycondensation, and adding 0.1 to 5 weight percent of crystallization accelerator to obtain terminal carboxyl group crystalline polylactic acid prepolymers; and 4) reacting diglycidyl ester and the terminal carboxyl group crystalline polylactic acid prepolymers in a molar ratio of 0.8:1-1.2:1 to obtain the high-molecular weight long-chain branched crystalline polylactic acid material. The preparation method has the advantages of simplicity, short reaction time, high efficiency, low cost and environmental friendliness and capability of contributing to realizing commercialization.

Owner:ZHEJIANG UNIV

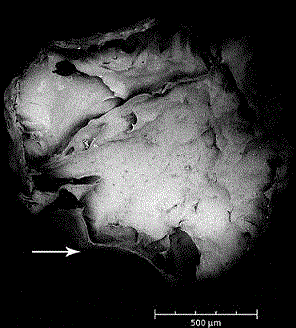

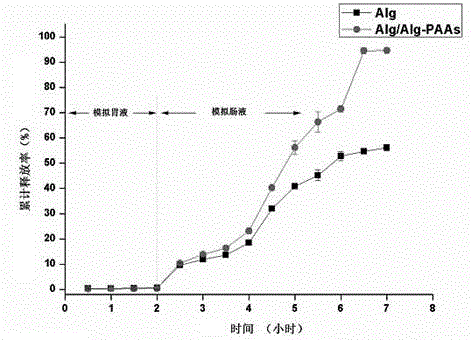

Sodium polyacrylate-grafted and sodium alginate-embedded probiotic microcapsule and preparation method thereof

InactiveCN104644612AHigh carboxyl contentImprove buffering effectDigestive systemUnknown materialsFood additiveBiology

The invention discloses a sodium polyacrylate-grafted and sodium alginate-embedded probiotic microcapsule, which is prepared by carrying out ionic crosslinking and embedding on probiotic with a complex of sodium polyacrylate-grafted sodium alginate and sodium alginate as an inner layer wall material, and coating chitosan on an outer layer. The embedded probiotic is one or more than two of lactobacillus, galactococcus or bifidobacterium; and the sodium polyacrylate is a state-approved food additive, and is safe and nontoxic in embedding. The buffer action on gastric acid caused by the inner layer wall material is increased through a grafting method; reduction of viable count in a gastric juice environment is reduced; meanwhile, the mechanical strength of the microcapsule is enhanced by cross-linking property of the capsule and calcium ions; the viscosity of a wall material solution is lower than that of an existing high polymer material; the preparation difficulty of the microcapsule is reduced; the prepared microcapsule has the functions of resisting gastric juice and accelerating intestinal release; the effective living bacteria count of intestinal tracts can be improved when the microcapsule is applied to embedding the probiotic; and the in-vivo probiotic function is enhanced.

Owner:TIANJIN UNIV OF SCI & TECH

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

Method for preparation of stabilized carboxylated cellulose

InactiveUS20030051834A1Low costEnvironmental lossNon-fibrous pulp additionSpecial paperAmmonium compoundsHydroxylamine

The invention is directed to a method of making a heat and light stable carboxylated cellulose fiber whose fiber strength and degree of polymerization is not significantly sacrificed. The method involves the use of a catalytic amount of a hindered cyclic oxammonium salt as a primary oxidant and a peracid and halide salt as a secondary oxidant in an aqueous environment. The oxammonium compounds may be formed in situ from their corresponding amine, hydroxylamine, and nitroxyl compounds. The oxidized cellulose is then stabilized against D.P. loss and color reversion by further treatment with an oxidant such as sodium chlorite, a chlorine dioxide / hydrogen peroxide mixture, or a peracid under acidic conditions. Alternatively it may be treated with a reducing agent such as sodium borohydride. The method results in a high percentage of carboxyl groups located at the fiber surface. The product is especially useful as a papermaking fiber where it contributes strength and has a higher attraction for cationic additives. The product is also useful as an additive to recycled fiber to increase strength. The method can be used to improve properties of either virgin or recycled fiber. It does not require high alpha-cellulose fiber but is suitable for regular market pulps.

Owner:WEYERHAEUSER CO

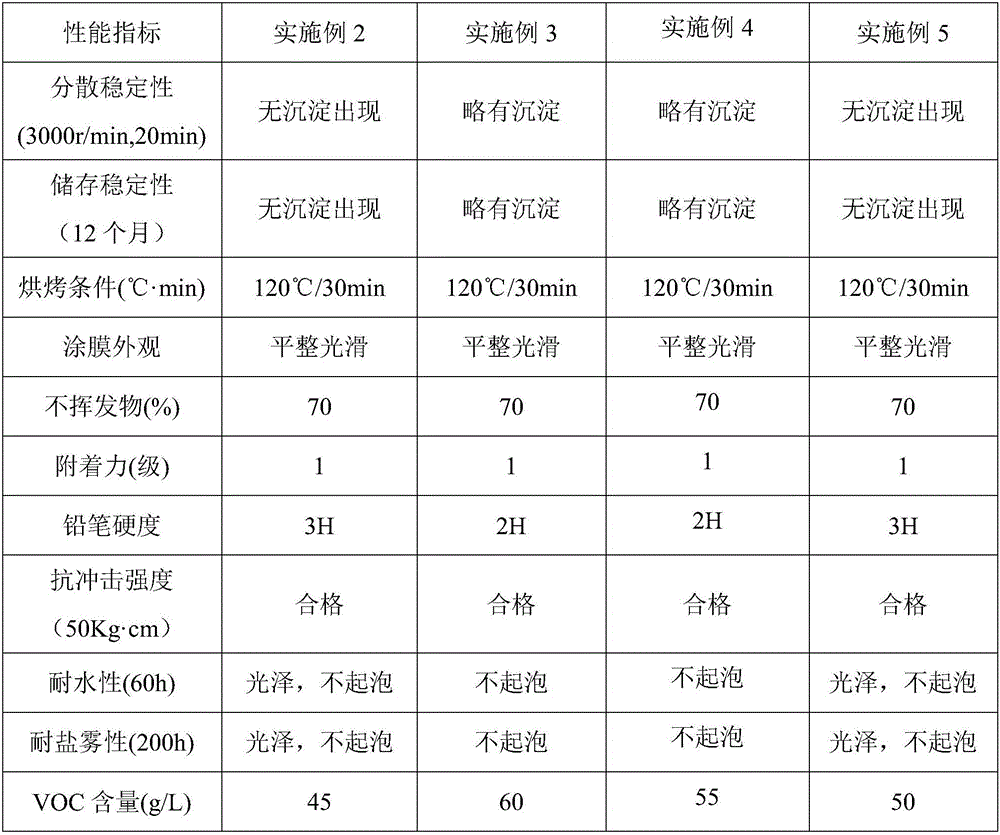

Preparation method and application of aqueous acrylic modified epoxy ester resin

The invention discloses a preparation method of aqueous acrylic modified epoxy ester resin, and an application of the prepared epoxy ester resin in the preparation of a coating. Epoxy resin is modified with acrylic acid through a double esterification technology, and the primary esterification reaction blocks one epoxy group of epoxy resin to prevent a cyclization gel reaction caused by the simultaneous opening reaction of two epoxy groups in the later acrylic modification process; and the second esterification reaction in the double esterification technology is the reaction of a pre-polymerized acrylic polymer and pre-esterified epoxy resin, so the carboxyl content after a grafting reaction is greatly increased, thereby the waterborne degree of the above product is improved.

Owner:山东齐鲁漆业有限公司

Method of preparing polyester with low content of acetaldehyde

The invention discloses a making method of low-acetaldehyde polyester, which is characterized by the following: adopting pure terephthalic acid (PTA) and ethylene glycol (EG) as raw material; adding built additive in the fusing polyetherifying segment, polycondensation segment and solid polymerizing course; selecting built additive from (1) heat stabilizer with phosphor, (2) anti-oxidant, (3) low-molecular weight amino compound, amide compound and polyhydroxy compound.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

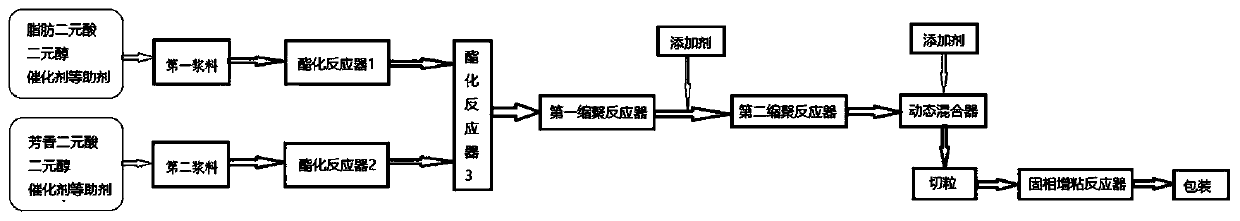

Biodegradable fat-aromatic copolyester with low carboxyl content and continuous preparation method thereof

The embodiment of the invention provides a biodegradable fat-aromatic copolyester with low carboxyl content and a continuous preparation method thereof, and relates to the technical field of high polymer material synthesis. The continuous preparation method mainly comprises the following steps: continuously preparing a fatty acid ester and an aromatic acid ester, continuously feeding into an esterification reactor, uniformly mixing, carrying out esterification reaction to obtain an ester with the esterification rate of more than or equal to 95%, continuously feeding into a first polycondensation reactor, removing small molecules under a low-vacuum condition to obtain a low-molecular-weight polymer, continuously feeding into a second polycondensation reactor, removing small molecules undera high-vacuum condition to obtain a medium-molecular-weight polymer, continuously feeding the mixture and an auxiliary agent into a dynamic mixer, uniformly mixing, granulating, and carrying out solid-phase tackifying to obtain the biodegradable fat-aromatic copolyester. The method is simple in process and high in automation degree, the obtained product is uniform in quality, free of batch difference, large in molecular weight, high in intrinsic viscosity and low in carboxyl content, and the ageing resistance of the product can be greatly improved.

Owner:戴清文

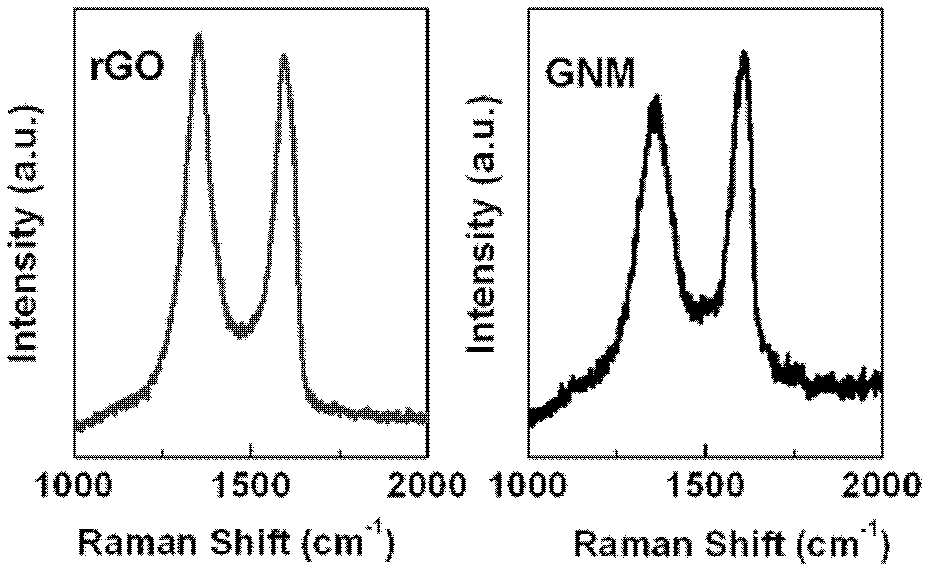

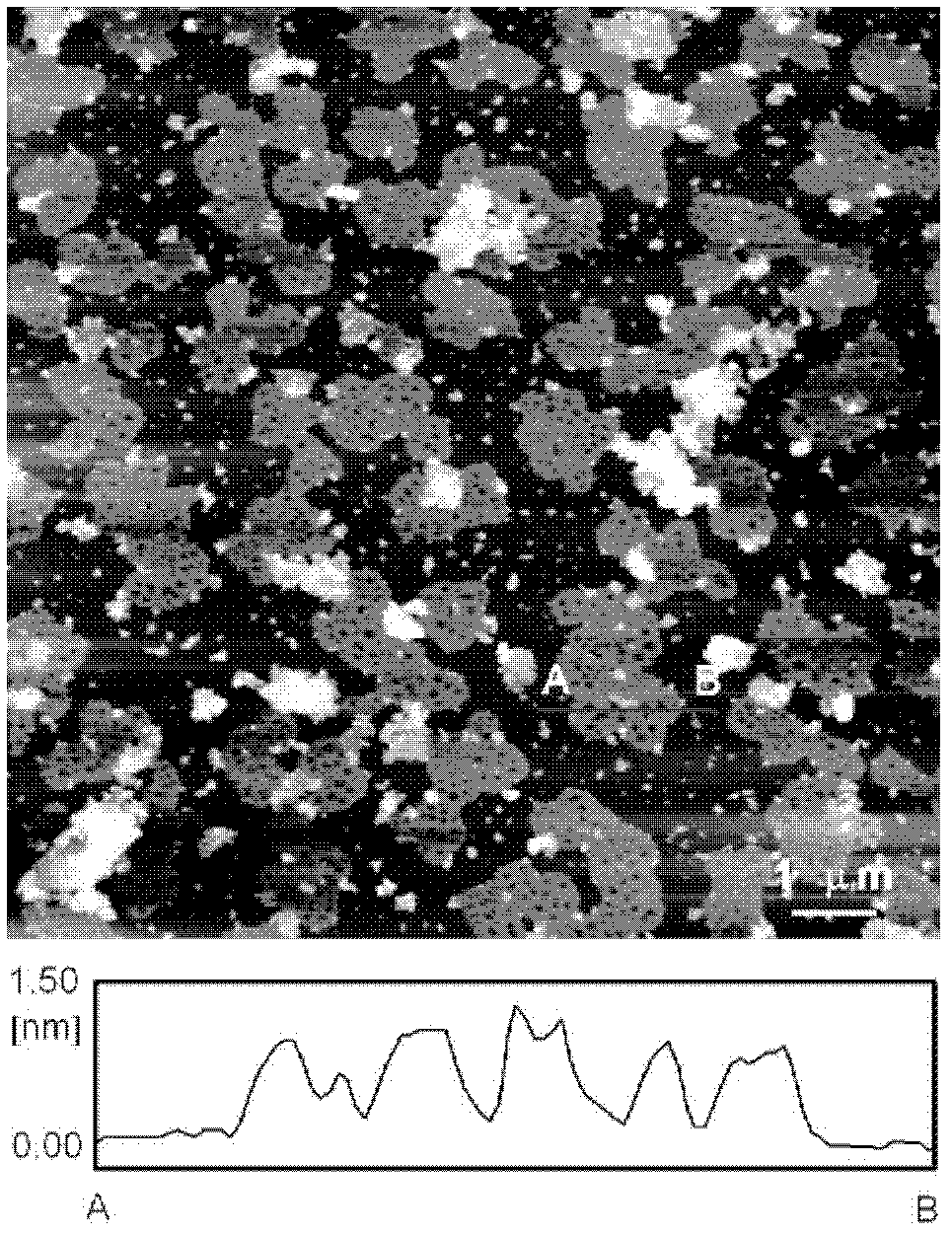

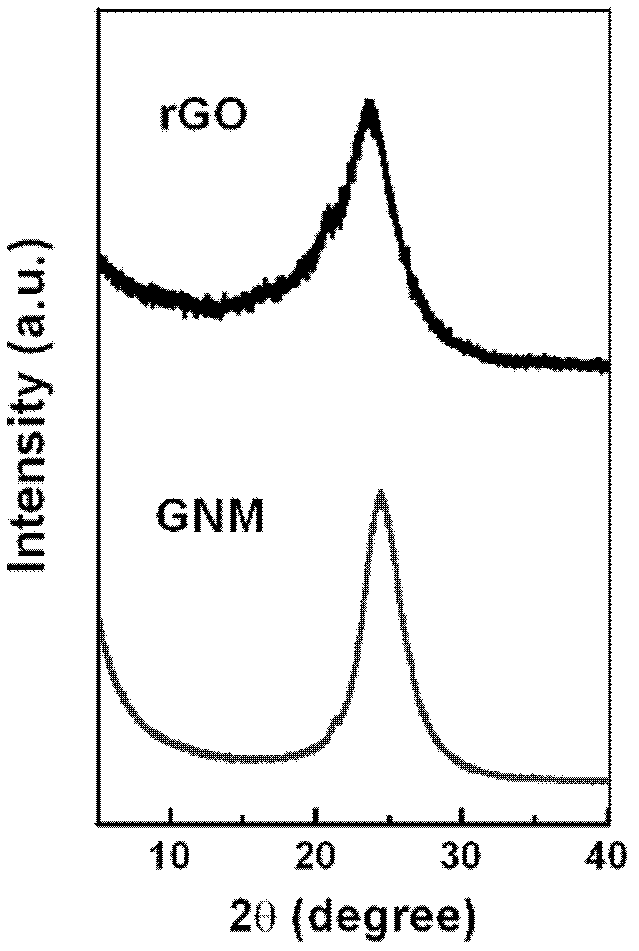

Nanopore grapheme, its preparation method and application

The invention discloses nanopore grapheme, its preparation method and application. In the graphene, the aperture of the nanopore is 20-100nm, the interlamellar spacing is 3.60-3.75 angstroms, the carboxyl content is 7-10%, and the electrical conductivity is 185-435S / cm. The preparation method comprises the steps of: dispersing chemically converted graphene in a nitric acid water solution to undergo a reflux reaction, after the reaction, conducting washing to neutrality, and performing drying, thus obtaining the graphene. Being convenient and practicable, the method can be used for mass production. The obtained material can be widely used for preparation of graphene nanocomposite materials, transparent conducting electrodes, and energy storage devices (such as super capacitors, lithium ion batteries, and solar batteries, etc.).

Owner:TSINGHUA UNIV

Continuous casting crystallizer covering slag for ASP medium-carbon steel and a preparation method thereof

The invention discloses continuous casting crystallizer covering slag for ASP medium-carbon steel and a preparation method thereof. The covering slag comprises the following raw materials in percentage by weight: 0-6% of glass powder, 10-30% of premelting materials, 10-30% of wollastonite, 10.5-15.5% of fluorite, 4-8% of white alkali, 4-8% of carbon black, 4.5-8.5% of graphite, 0-5% of sodium fluoride, 5-8% of manganese carbonate, 4-9% of magnesia, 8-12% of bauxite, 0.5-3% of cryolite, 1-3% of adhesive, and 0.3-1% of water reducing agent. The covering slag optimizes the ratio, guarantees a certain melting speed while guaranteeing the insulation effect, has a certain liquid slag layer thickness, is uniformly consumed, guarantees smooth actuation of a continuous casting process, and produces an excellent casting blank.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

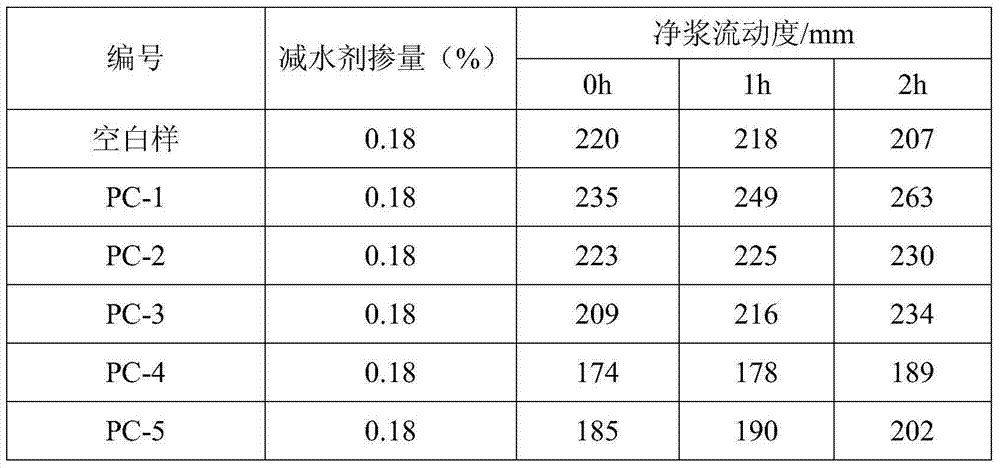

Polyether crosslinked concrete water reducer, and preparation method and application thereof

The invention belongs to the field of concrete additives, and discloses a polyether crosslinked concrete water reducer, and a preparation method and an application thereof. The preparation method comprises the following steps: adding an aqueous solution of an initiator and methallyl alcohol polyoxyethylene ether into a reactor; heating the reactor to 50-100DEG C, simultaneously adding a monomer mixed solution and a reducing agent-chain transferring agent mixed solution in a dropwise manner for 2-5h and [(2-5)-(0.5-1.5)]h respectively, and carrying out a constant temperature reaction for 1-5h after the dropwise addition of the reducing agent-chain transferring agent mixed solution is finished; and cooling a product in the reactor to room temperature after the ending of the constant temperature reaction, and adjusting the pH value to 6-8 by using an NaOH solution to obtain the polyether crosslinked concrete water reducer. The polyether crosslinked concrete water reducer prepared by using polyethylene glycol diitaconic acid monoester as a crosslinking agent has the advantages of low admixture amount, good dispersibility, high water reducing rate, high compressive strength and good slump keeping performance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Preparation method of antibacterial polypropylene fiber non-woven fabric for wiping paper

InactiveCN109023942AHigh carboxyl contentChange wettabilityBiochemical fibre treatmentFibre typesSodium phosphatesCarbon nanotube

The invention discloses a preparation method of an antibacterial polypropylene fiber non-woven fabric for a wiping paper. The preparation method comprises: dispersing graphene oxide in dimethylacetamide, adding mercapto-succinic acid and anhydrous triethylamine into the solution for a reaction, carrying out aftertreatment to obtain a material A, dispersing the material A in dimethylacetamide, adding curcumin and p-toluenesulfonic acid into the solution for a reaction, carrying out aftertreatment to obtain modified graphene oxide, uniformly mixing sodium dodecylbenzenesulfonate, sodium lauryl sulfate, sodium phosphate, modified graphene oxide, carbon nanotubes, nano-silver, aloe extract and water to obtain an immersion liquid, immersing a polypropylene fiber non-woven fabric in the immersion liquid, carrying out drying to obtain the immersed non-woven fabric, adding 5, 5-dimethyl hydantoin into the aqueous sodium hydroxide solution, adding methanol and allyl bromide into the solution for a reaction to obtain a hydantoin derivative, uniformly mixing acrylic resin, hydroxyethyl acrylate, octadecyl acrylate, hydantoin derivative, a light initiator and ethyl acetate, immersing the immersed non-woven fabric into the mixed solution, and carrying out drying, curing, chlorination, washing and drying.

Owner:HEFEI JIENUO MEDICAL PROD CO LTD

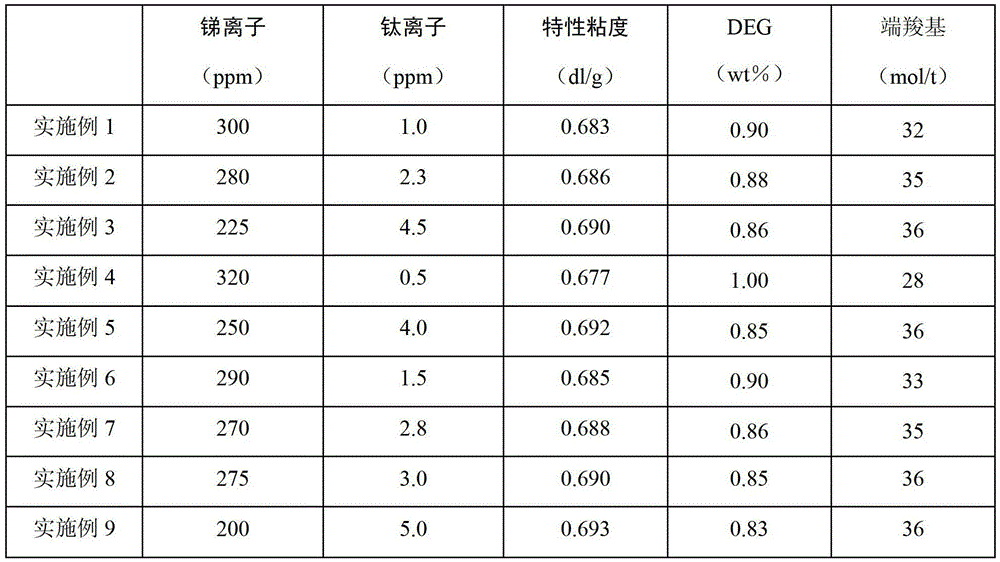

Preparation method of polyester for making high modulus and low shrinkage type industrial yarns

A preparation method of polyester for making high modulus and low shrinkage type industrial yarns comprises the following steps: carrying out an esterification reaction on terephthalic acid and ethylene glycol at 250-290DEG C to generate an intermediate ethylene glycol terephthalate until the esterification rate is at least 92%, and removing generated water in the reaction process; and carrying out a condensation polymerization reaction on the intermediate ethylene glycol terephthalate under a negative pressure in the presence of an antimony and titanium mixed catalyst system comprising a liquid titanium catalyst and ethylene glycol antimony at 270-300 DEG C for 2-3h. The polyester prepared in the invention has the characteristics of high viscosity, low diglycol content, high carboxyl end group content, high purity and good spinnability, and the production rate and the performances of the high modulus and low shrinkage type industrial yarns made by using polyester are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method of oxidized cellulose

The invention discloses a synthetic method of oxidized cellulose. According to the method, firstly, cellulose materials are pretreated through an NaOH or LiOH solution by combining an ultrasonic technology; then, an NaClO4 and K2FeO4 oxidation system is used for further oxidizing the materials through regulating the pH values in the mixed material via NaAc; the oxidation temperature is 30 to 42 DEG C; the oxidization time is 1 to 3h; finally, an oxidized product is cleaned and dried. The method has the advantages that the cellulose oxidization time can be greatly shortened; in addition, the obtained oxidized cellulose has high-content carboxyl; the content of the carboxyl can reach 21.6 percent to 35.8 percent; the oxidized cellulose belongs to a medical material with better application prospects.

Owner:JIANGSU LANWAN BIOTECH

A plasmonic-photochemical method for grafting carboxyl groups on the surface of cell culture

InactiveCN102276866AAvoid environmental and human hazardsSimplify removal stepsTissue/virus culture apparatusChemistryPhotoinitiator

The invention discloses a plasma-photochemical method for grafting carboxyl on a cell culture surface. The method comprises the following steps of: preprocessing the cell culture surface in a plasma reaction chamber, and exposing in air or oxygen for 25 minutes to 24 hours; dissolving a monomer in water to form solution A; spreading the solution A to culture surface obtained by the step (2) uniformly to form a liquid surface layer; irradiating the culture surface on which the liquid surface layer is spread by ultraviolet (UV); and taking the culture surface out of the solution A, and cleaningby the water to obtain the cell culture surface on which the carboxyl is grafted. By the plasma-photochemical method, the carboxyl content of the cell culture surface is improved effectively without using an organic solvent and a light initiator; the damage of the organic solvent and the light initiator to the environment and human bodies in the production process and the potential impact of subsequent stem cell culture are avoided successfully; a step of removing residues is simplified, the production period is shortened, and the cost is saved.

Owner:BEAVERNANO TECH

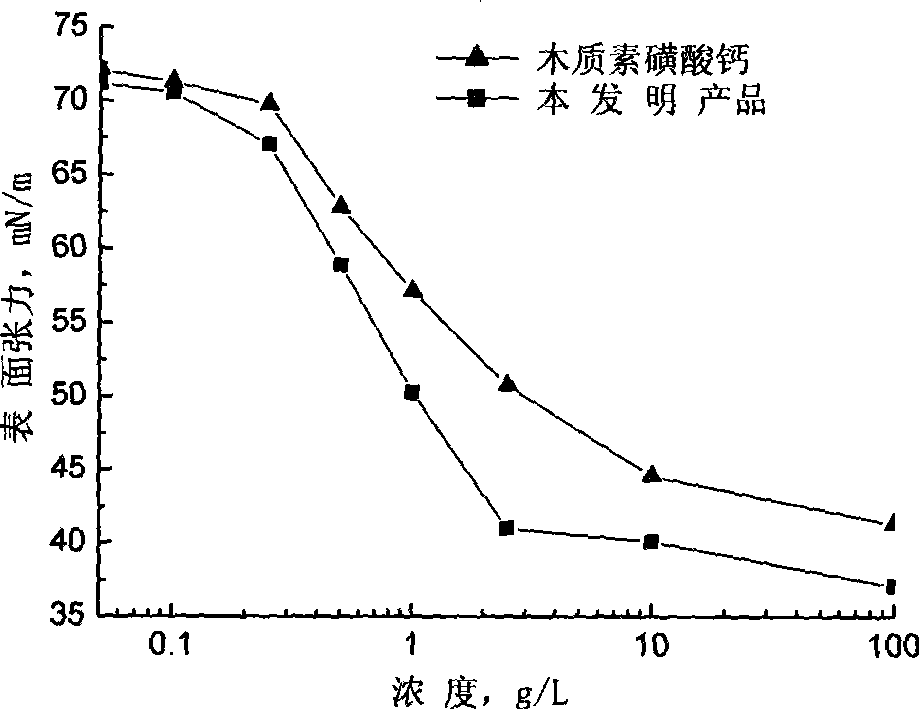

Dry powder mortar additive suitable for novel wall material and preparation method thereof

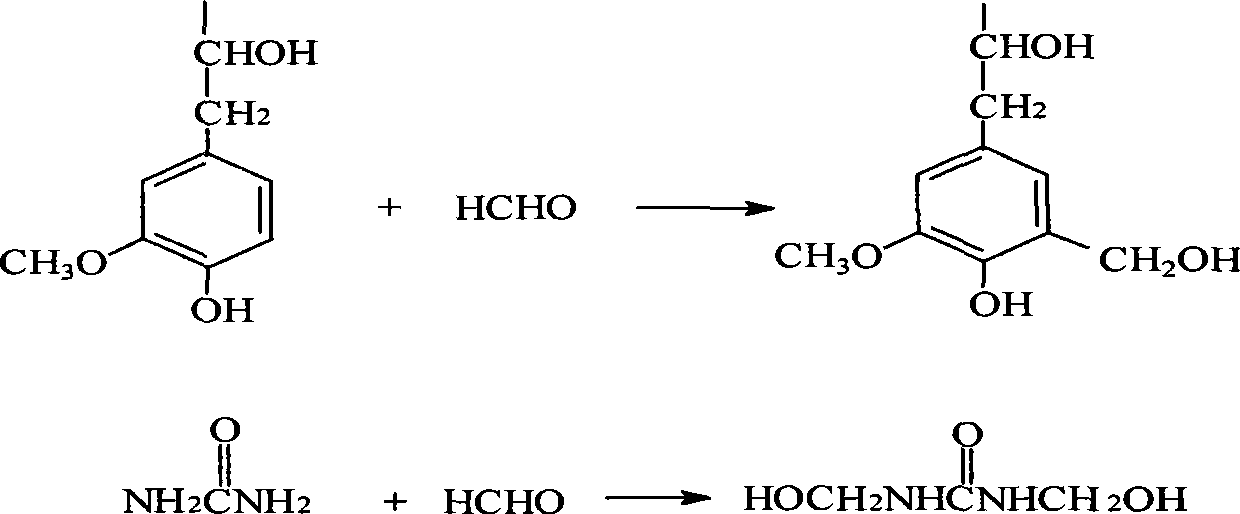

The invention discloses an environment friendly dry mortar admixture applicable to novel wall materials, and a preparation method thereof. The method comprises the steps: (1) lignosulphonate is added with water and mixed uniformly, the system pH value is adjusted to be 8.0 to 11.0, urea and formaldehyde are added, and the mixture reacts for 1 to 2 hours at the temperature of 80 to 100 DEG C; (2) the system pH value is adjusted to be 4.0 to 6.0, and the mixture reacts for 2 to 3 hours at the temperature of 80 to 100 DEG C; and (3) an oxidant is added, the mixture reacts for 1 to 2 hours at the temperature of 70 to 90 DEG C and is cooled to obtain the liquid product of the mortar admixture, and the powder product of the mortar admixture can be obtained after spray drying. The mortar admixture has simple preparation process and low production cost, is environment-friendly as the papermaking and pulping by-product, lignosulphonate, is taken as raw material, has high water reduction rate, appropriate retardation and air-entraining performance, and can cause the mortar to have good cohesiveness, anti-cracking and impermeability.

Owner:SOUTH CHINA UNIV OF TECH

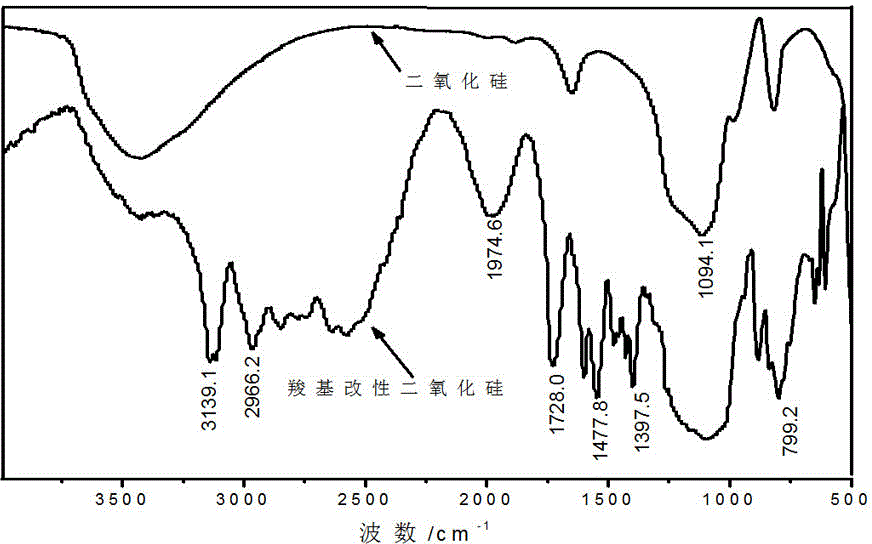

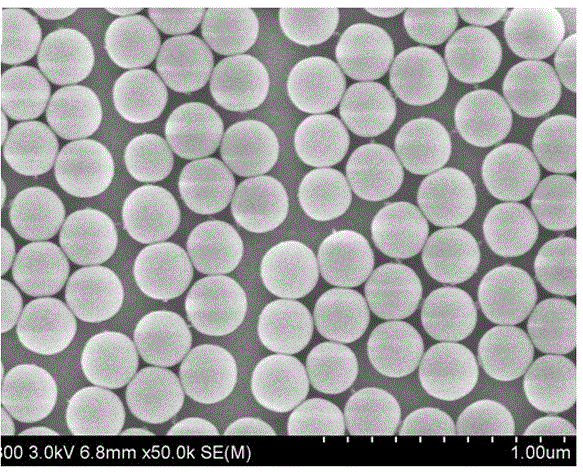

Polycarboxyl silicon dioxide nanoparticles and preparation method thereof

ActiveCN104629494ASimple preparation processMild reaction conditionsPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsAcyl groupCarboxylic acid

The invention discloses polycarboxyl silicon dioxide nanoparticles and a preparation method thereof. The preparation method comprises the following steps: by using hydroxy silicon dioxide nanoparticles as the initial raw material, treating with an aminosilane coupling agent to introduce reactive amino or amine group, and reacting with N,N-carbonyldiimidazole-activated butane tetrabasic carboxylic acid under very mild conditions to introduce 3,4,5-tricarboxylvaleryl group onto the surface of the hydroxy silicon dioxide nanoparticles, thereby obtaining the surface-polycarboxylated modified silicon dioxide nanoparticles. By using the butane tetrabasic carboxylic acid to perform carboxylation modification on the hydroxy silicon dioxide nanospheres, the polycarboxyl silicon dioxide nanoparticles have the advantages of high carboxyl content and controllable carboxyl content; and since the reaction conditions for the N,N-carbonyldiimidazole-activated butane tetrabasic carboxylic acid and amino group are very mild, the reaction is easy to perform and is complete. The method disclosed by the invention has the advantages of simple preparation technique and accessible raw materials, and is easy for industrial production and popularization.

Owner:JIANGSU HUAJIA SILK

Preparation method of high-strength and high-toughness polyamide/polyester alloy

The invention discloses a preparation method of a high-strength and high-toughness polyamide / polyester alloy. The preparation method comprises the following steps of: processing PET (polyethylene Terephthalate) through sodium benzoate to obtain a high terminal carboxyl group PET; processing polyamide through polyolefin grafted maleic anhydride to obtain carboxyl-terminated polyamide; reacting a bifunctional epoxide with the terminal carboxyl group PET and the carboxyl-terminated polyamide to obtain a copolymer of the PET and the polyamide; and carrying out capacity increasing and chain extension on the PET and the polyamide, thus obtaining the high-strength and high-toughness polyamide / polyester alloy. According to the preparation method of the high-strength and high-toughness polyamide / polyester alloy, the polyolefin grafted maleic anhydride is adopted, an anhydride group and the terminal amino group are reacted and grafted at a molten state, and the resulting product which is the terminal carboxyl group has high output, and the toughness of the product is greatly improved due to an introduced graft; the bifunctional epoxide is adopted, thus the copolymer material gains high toughness of modified polyamide, and also gains the mechanical strength which is increased along with the raise of molecular weight; and the preparation method has the advantages that the adopted raw components are wide in resource and low in price, and the industrialization is easily realized accordingly.

Owner:HEFEI UNIV OF TECH

Synthesis method of high-carboxylation-degree oxidized cellulose

The invention discloses a synthesis method of high-carboxylation-degree oxidized cellulose, comprising the steps of combining pre-treatment and multistep oxidization to fully oxidize a cellulosic material, namely, first sealing, mixing and ball-milling the cellulosic material and dry ice and exposing a sample to air to realize the pre-treatment process after finishing ball-milling, then adopting NaNO3 and H2SO4 for carrying out primary oxidization on the material, and carrying out secondary oxidization by adopting KCLO4 as an oxidizing agent, wherein a reaction is performed at the temperature of 30 to 40 DEG C and the reaction time is 30 to 60 min; finally, further oxidizing the material subjected to the secondary oxidization by adopting KCLO, wherein the oxidization temperature is 50 to 60 DEG C and the time is 50 to 65 min. An oxidized cellulose product obtained through the synthesis method is relatively high in content of carboxyl, the content of the carboxyl can reach up to 35.6 percent to 48.7 percent, and the product has good application prospect in the technical field of biological medicine materials.

Owner:JIANGSU LANWAN BIOTECH

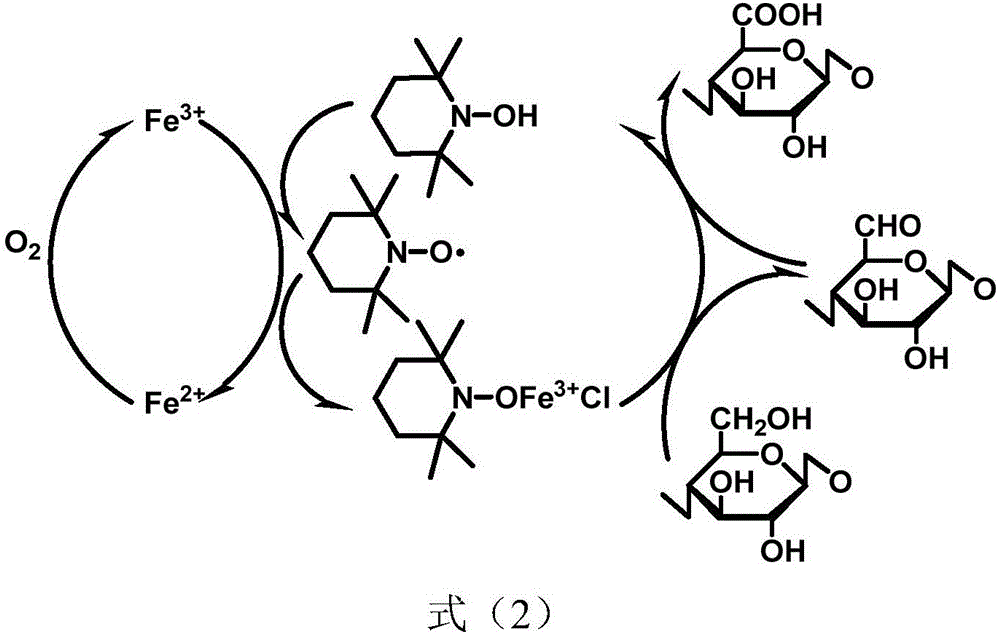

Method for preparing C6-site selective carboxylation cellulose by using air as oxidizing agent

The invention provides a method for preparing C6-site selective carboxylation cellulose by using air as an oxidizing agent. The oxidization method is characterized in that a TEMPO derivative and metallic nitrate are utilized as a co-catalyst, potassium chloride is utilized as a promoter, and the air is utilized as a main oxidizing agent to achieve selective oxidation of cellulose primary hydroxyl group. Compared with a traditional cellulose selective oxidization method, the method has the advantages of being economical, environment-friendly, small in equipment corrosion, safe to operate, low in cellulose degradation degree, complete in carboxylation, free of aldehyde group, and the like.

Owner:WANHUA CHEM GRP CO LTD

Method for grafting anhydride onto cellulosic material in ionic liquid to prepare carboxyl cellulose

InactiveCN105461815AHigh yieldThe preparation method is simple and environmentally friendlyGraft reactionEvaporation

The invention discloses a method for grafting anhydride onto a cellulosic material in ionic liquid to prepare carboxyl cellulose. The method includes the following steps that an ionic-liquid cellulosic solution and an ionic-liquid anhydride solution are respectively prepared; the anhydride solution and the cellulosic solution are mixed to be subjected to a constant-temperature reaction, and the carboxyl cellulose is prepared. According to the method, the ionic liquid serves as an activating agent and a solvent; as a cellulose anhydride-grafted method is adopted, the reaction condition is moderate and easy to control, and the reaction is environmentally friendly and free of pollution; the ionic liquid solvent can be recycled through rotary evaporation and drying, and the recycling rate is as high as 98%. According to the reaction system, the grafting reaction only needs to be carried out for 1-2 h, the content of carboxyl in the carboxyl cellulose can be 14%-20%, and the content of the carboxyl in the carboxyl cellulose is greatly increased in a short time.

Owner:JIANGSU UNIV OF SCI & TECH

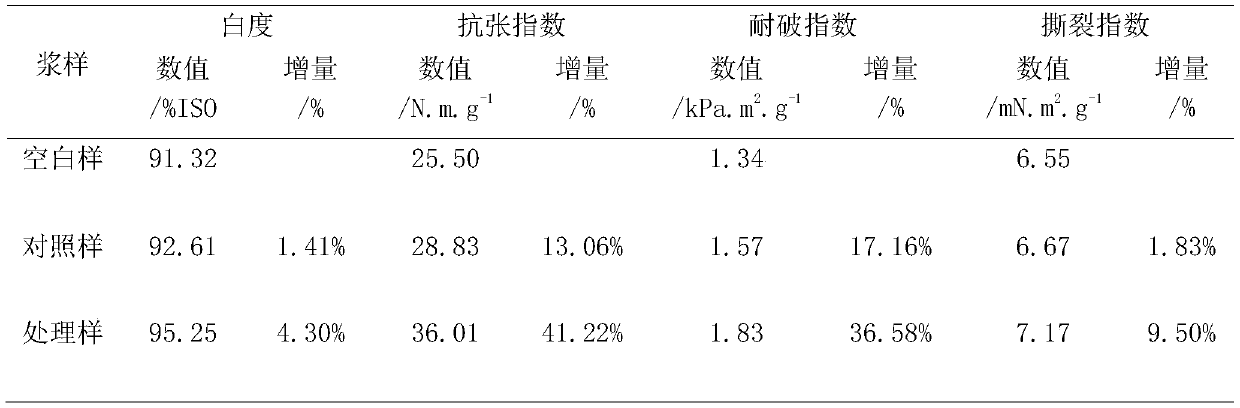

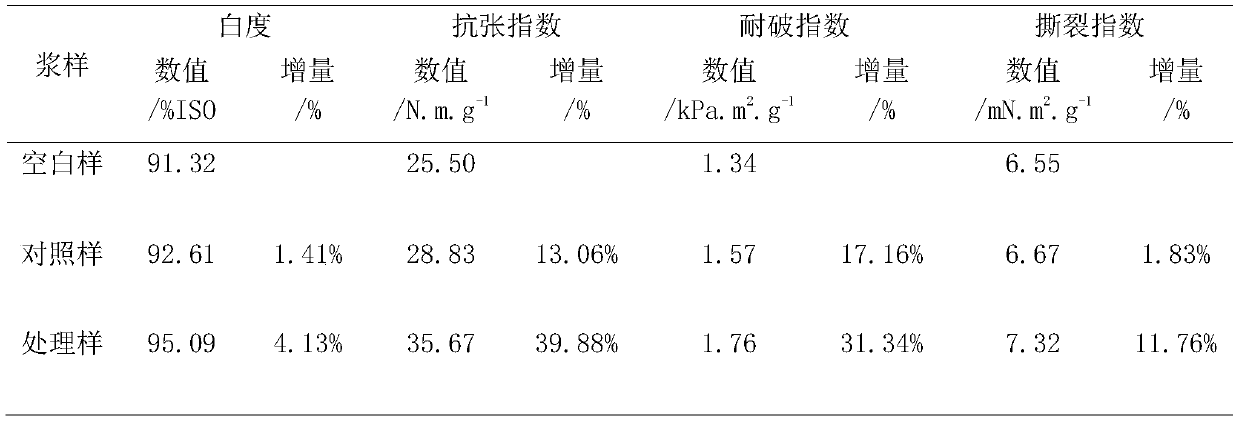

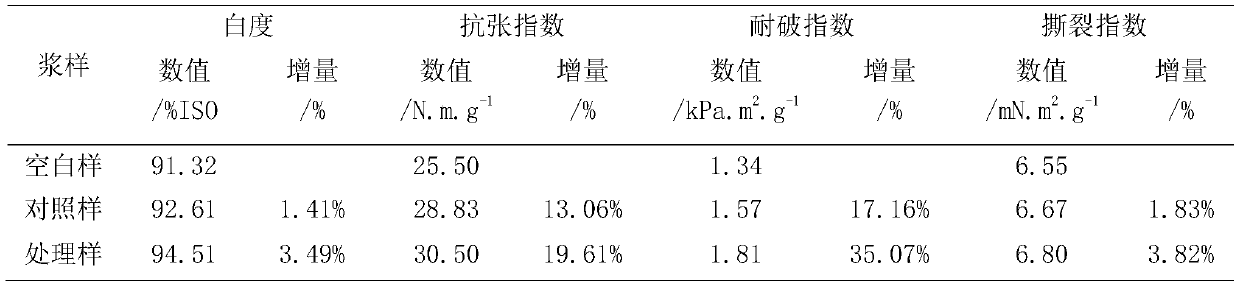

Method for improving the fiber strength of waste paper with low lignin content by using cellulase/amino acid modification and paper prepared by the method

InactiveCN110184848AImprove bindingImprove physical performanceMicroorganism/enzyme additionPaper/cardboardPapermakingSlurry

The invention discloses a method for improving the fiber strength of waste paper with low lignin content by using cellulase / amino acid modification and the paper prepared by the method. The method comprises the following steps: pulping waste paper to obtain pulp, adding cellulase and amino acid into the pulp, adjusting the pH value to 5-8 and reacting at 40-60 DEG C for 40-70 min; after the reaction is completed, washing the filtrate with water until colorless, and then pulping and performing papermaking. As that cellulase is used for treating the fiber, the fiber becomes soft and plastic, andthen pulping can significantly improve the fine fiber of the fiber, increase the binding force between the fiber, the amino group in the amino acid is combined with the hydroxyl group on the cellulose by the hydrogen bonding force, the amino acid is grafted onto the cellulose chain, so that the carboxyl group content in the slurry is increased, and the swelling ability of the fiber is increased.Compared with the unmodified fiber, the physical properties of the paper produced by cellulase / amino acid treatment are greatly improved, and the method was simple, green, pollution-free and easy forindustrial production.

Owner:SOUTH CHINA UNIV OF TECH

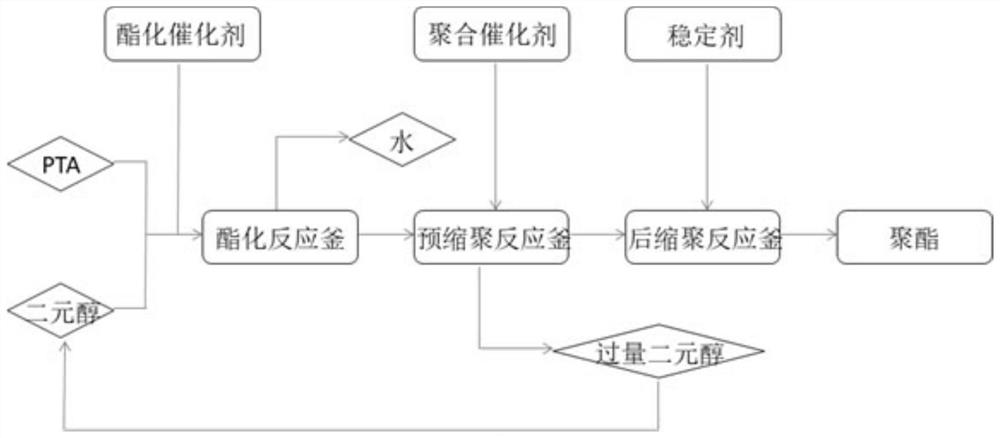

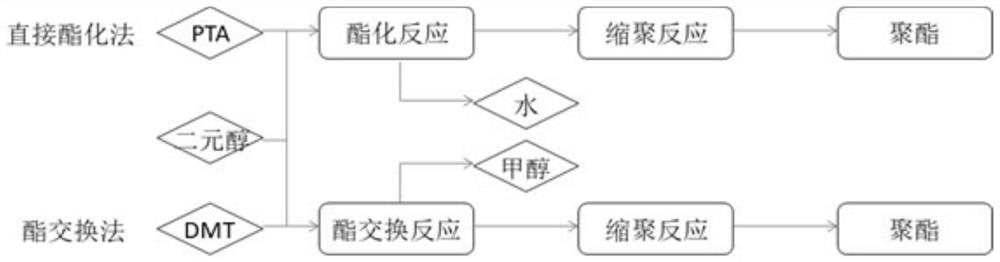

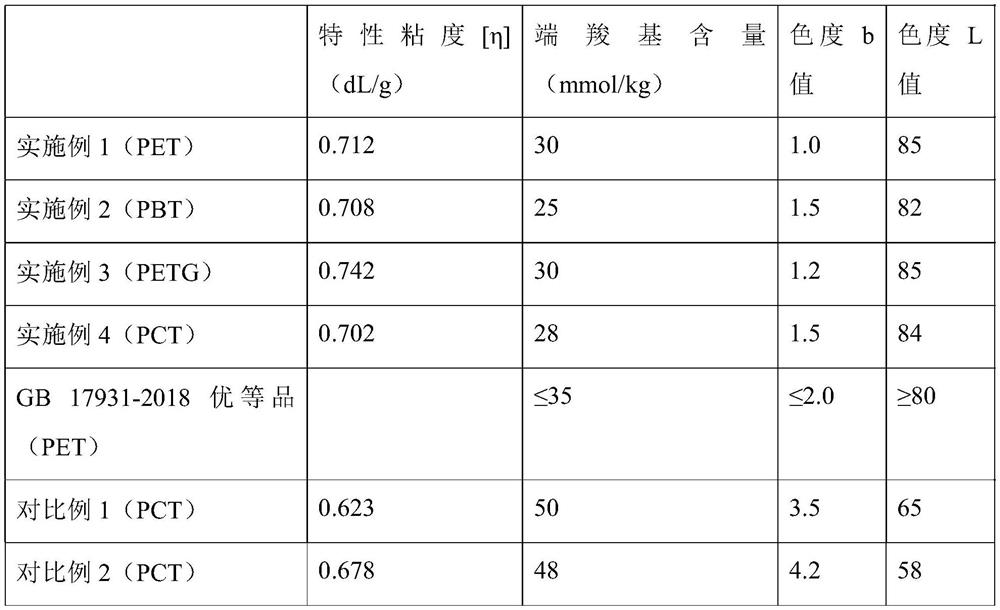

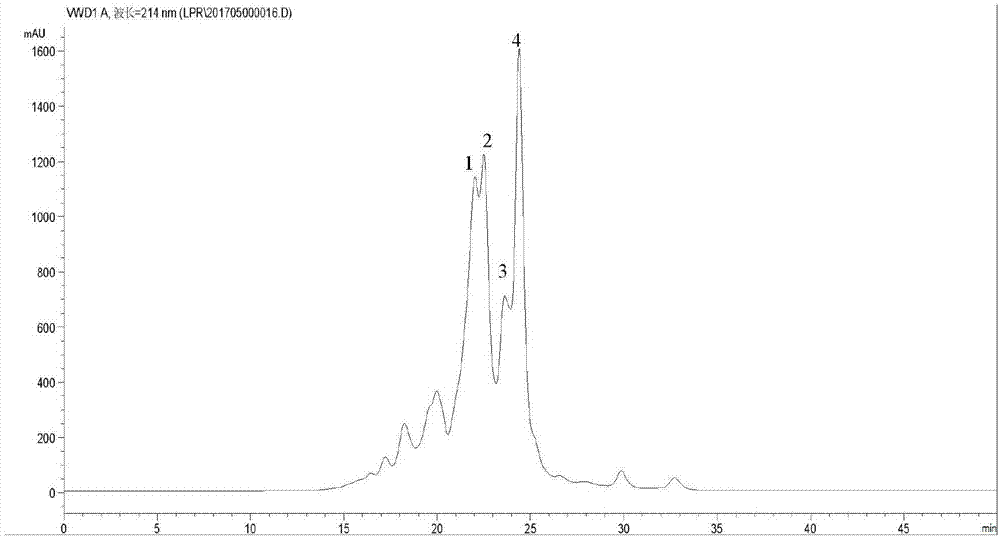

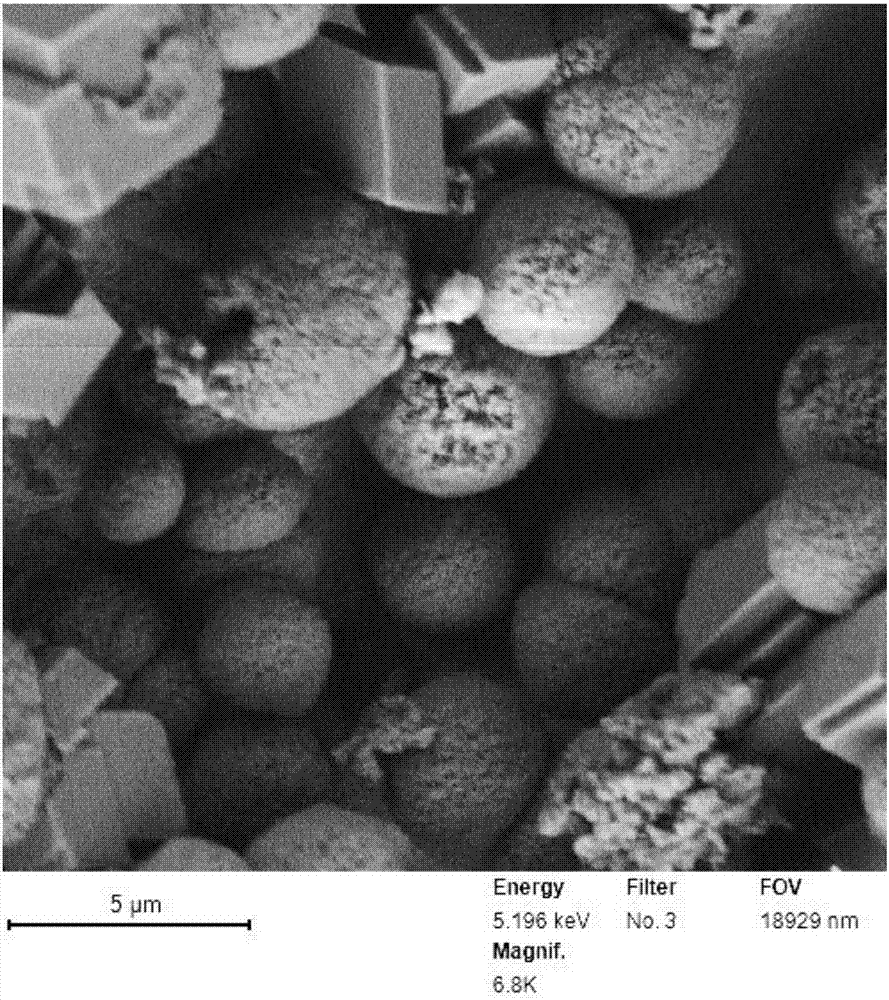

Efficient synthetic method of terephthalic polyester

The invention provides an efficient synthetic method of terephthalic polyester, the method comprises the following steps: taking terephthalic acid and various dihydric alcohols as raw materials, sequentially carrying out esterification, pre-polycondensation and post-polycondensation to obtain high-quality polyester, wherein the catalyst is a composite catalyst consisting of an esterification catalyst, a polymerization catalyst and a stabilizer, and is added in sections; and post-polycondensation adopts a continuous production process, so that material back-mixing is avoided, side reactions are effectively reduced, the reaction efficiency and the reaction stability are improved, and indexes such as viscosity, terminal carboxyl group content and chromaticity of the product are also obviously improved.

Owner:CHINA TIANCHEN ENG

Natural slow-release multi-effect medical sponge and preparation method thereof

InactiveCN104784738AHigh carboxyl contentGood water solubilityAbsorbent padsBandagesPtru catalystFreeze-drying

The invention relates to natural slow-release multi-effect medical sponge and a preparation method thereof. The preparation method comprises the following steps: firstly, by taking hydrogen peroxide as an oxidant and copper sulfate as a catalyst, partially oxidizing straight-chain starch; adding a medicine to be slow-released into a water solution of the oxidized straight-chain starch in a mass ratio of 1:(2-100), and stirring at the room temperature so as to react to obtain a clathrate compound solution; dissolving collagen by using an acetum solution so as to obtain a collagen solution, subsequently mixing the clathrate compound solution with the collagen solution, and performing freeze-drying, thereby obtaining the natural slow-release multi-effect medical sponge. Collagen is used as the basis material of the medical sponge and has better hydrophily, biocompatibility and biocompatibility. The natural slow-release multi-effect medical sponge provided by the invention has various bioactivities, has the characteristics of slow-release and temperature control release, and has good application prospect in the medicinal industry.

Owner:SICHUAN UNIV

Starch adhesive for packaging cartons

InactiveCN107286866AImprove stabilityHigh carboxyl contentNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveCarton

The invention discloses a starch adhesive for packaging cartons and relates to the technical field of packaging. A preparation method comprises the steps as follows: (1) starch slurry preparation; (2) activation treatment; (3) filler addition: nano titania coated nano silica composite powder with the mass accounting for 2.4%-2.6% that of starch is added to starch slurry, the obtained material is stirred at the rotating speed of 2,500 r / min for 1 h, and starch mixed slurry is obtained; (4) a crosslinking reaction; (5) stabilization treatment. The prepared starch adhesive is uniform, stable and not prone to layering.

Owner:HEFEI LONGFA PACKING CO LTD

Preparation method of spherical calcium carbonate

InactiveCN107445191ASimple processSave raw materialsCalcium/strontium/barium carbonatesHydrolysateFreeze-drying

The invention discloses a preparation method of spherical calcium carbonate. The invention uses waste silk as a raw material to extract silk fibroin, then enzymatically decomposes the silk fibroin into a silk fibroin hydrolyzate, and prepares a freeze-dried powder by rotary steaming and freeze-drying. The powder is a crystal form control agent. Add the freeze-dried powder into the calcium hydroxide solution, stir and react at a constant temperature of 25-35°C for 1 hour, and then pass the mixed gas of CO2 and N2 into the calcium hydroxide solution evenly to react to the pH of the solution. Reduce to 7.5-7.0, then stir at a speed lower than 200rpm for 30min, then separate the solid product and wash it with deionized water and absolute ethanol. After washing, dry it in a vacuum oven not higher than 60°C for 3h, and finally prepare Spherical calcium carbonate is obtained. The invention has the characteristics of low cost, mild preparation conditions, simple production equipment, strong operability and easy industrial production. The spherical calcium carbonate prepared by the invention has uniform particle size and good dispersibility.

Owner:广西碳酸钙产业化工程院有限公司 +1

Method for preparing multiple products including hemicellulose, carboxylated cellulose nanocrystals, fibrils and citrate from fibers by using citric acid

ActiveCN111087491AMeet the requirements for protected coexistenceExtensive sources of raw materialsMaterial nanotechnologyCarboxylic acid salt preparationFiberHemicellulose

The invention discloses a method for preparing multiple products including hemicellulose, carboxylated cellulose nanocrystals, fibrils and citrate multicomponent products from fibers by using citric acid. The method comprises the following steps: with fibers as a base material, preparing hemicellulose through citric acid hydrolysis and alcohol precipitation, preparing citrate through crystallization, preparing cellulose nanocrystals through ultrasonic treatment and centrifugation, and preparing cellulose nanofibrils from solid fibers through homogenization. The method is friendly to environment, free of toxicity, low in risk, high in fiber component utilization rate, diversified in high-value products and high in yield. The prepared cellulose nanocrystals and cellulose nanofibrils have dispersion stability, excellent specific surface area and high carboxyl content, and lay a foundation for nanocellulose modification. Finally, prepared nanocellulose has no residual toxic and harmful substances, and has wide application prospects in the aspect of functional materials taking cellulose as a substrate, especially in the aspects related to health, such as biomedical materials, food, health care products, skin care cosmetics and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com