Patents

Literature

42results about How to "Shorten the esterification time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

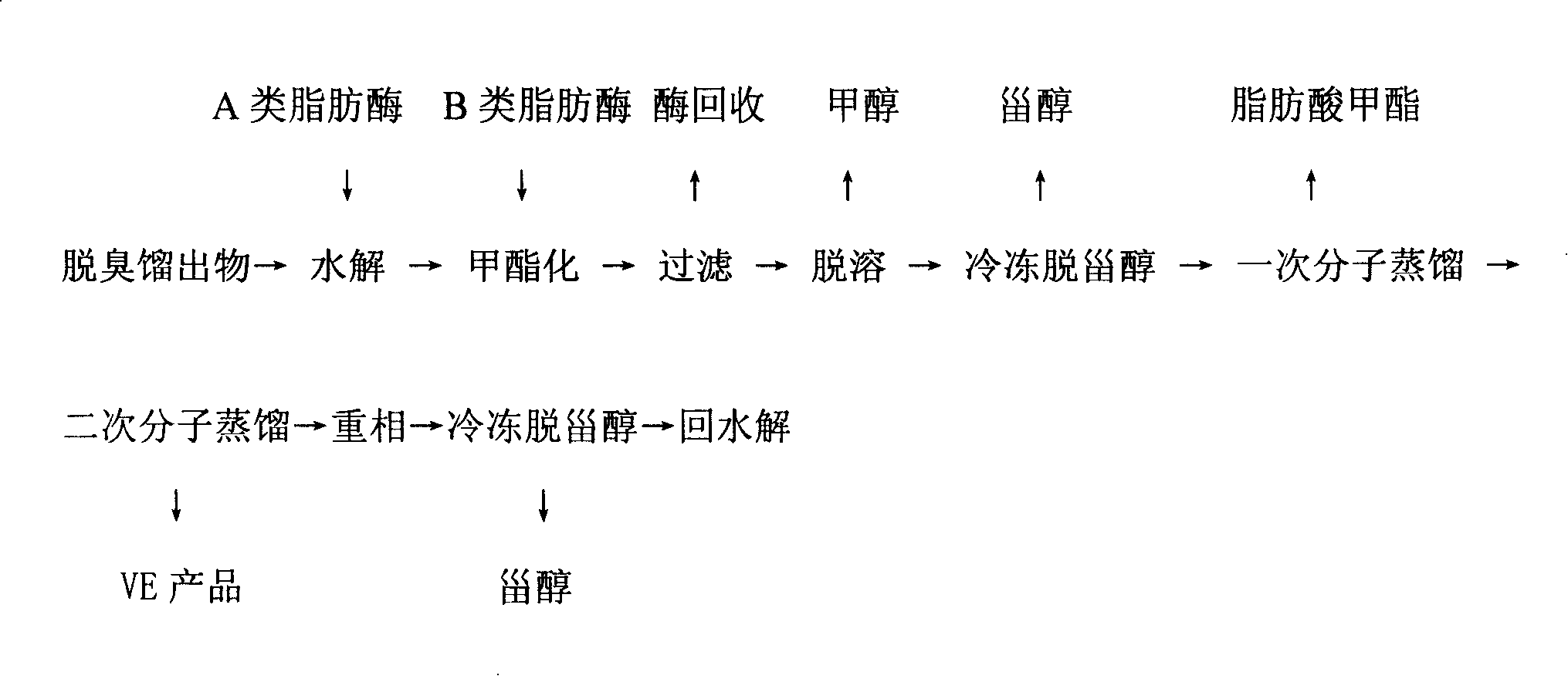

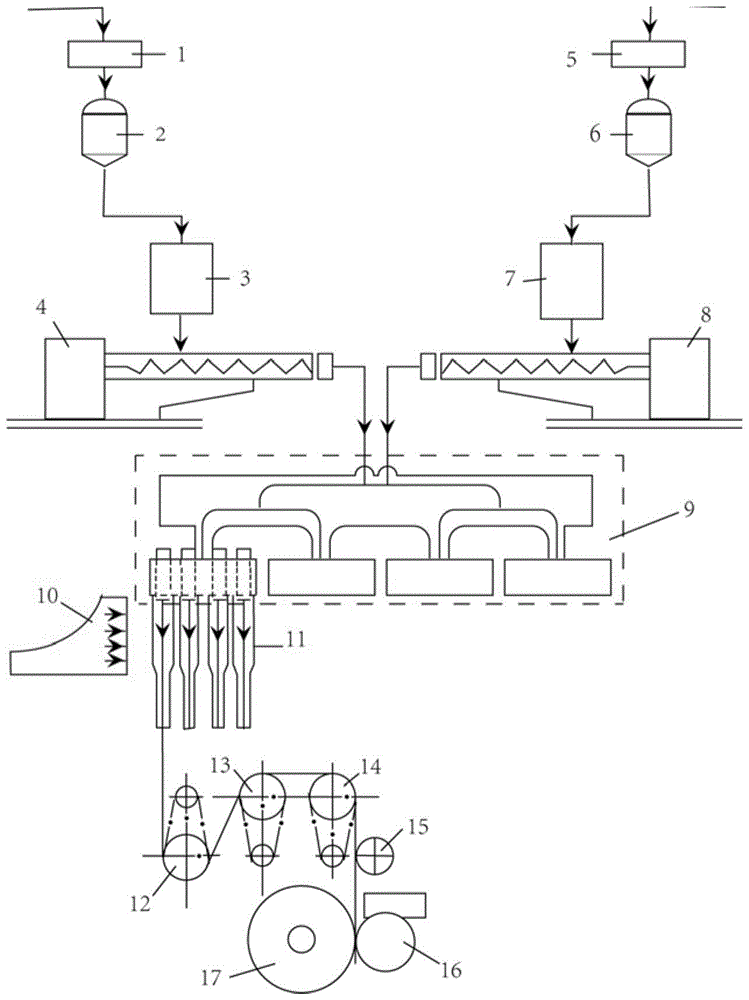

Novel method for extracting natural vitamin E, phytosterol, fatty acid methyl ester by enzyme catalysis and molecular distillation

The invention relates to a method to extract a natural vitamin E, a phytosterin, and a fatty acid methyl ester by the enzyme catalysis and the molecular distillation, which is characterized in that a triglyceride in a distillate which is deodorized from a vegetable oil is hydrolyzed into a fatty acid through a lipase, a methanol is catalyzed by the lipase and the fatty acid is esterified and generated into a fatty acid methyl ester, and the natural vitamin E and the phytosterin are produced when the methanol and the fatty acid methyl ester are processed by filtering, desolventizing, freezing and removing the phytosterin, and removing the fatty acid methyl ester through the secondary molecular distillation. The the extraction method of natural vitamin E, phytosterin, and fatty acid methyl este, compared with the prior art, has the advantages of adopting the process that the oil is catalyzed and hydrolyzed first and then the enzyme catalyzes the fat to be esterified and to be processed by the secondary molecular distillation, no producing wastewater, shortening the esterification time, increasing the natural vitamin E content, deploying the secondary freezing and crystallization to remove the phytosterin with high recovery rate of phytosterin, and beneficially increasing the purity of the vitamin E.

Owner:唐河金海生物科技有限公司

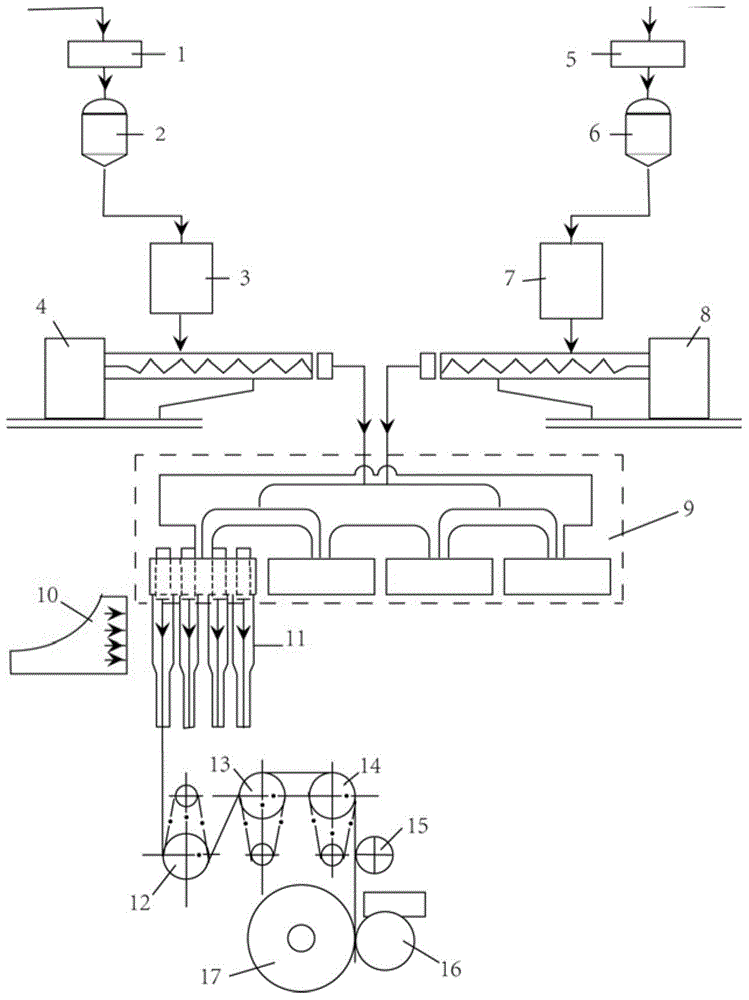

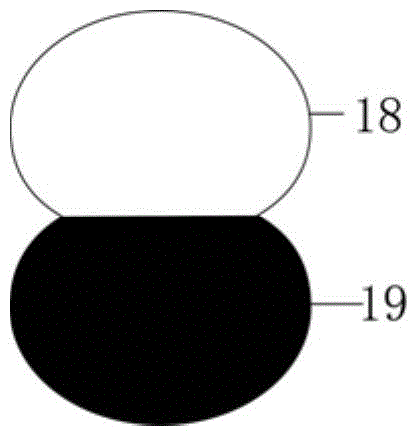

Polyester elastomer/PET composite elastic fiber and preparation method thereof

ActiveCN104831417AIncrease elasticityImprove performanceMelt spinning methodsConjugated synthetic polymer artificial filaments1,4-ButanediolElastomer

The invention discloses a polyester elastomer / PET composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of firstly carrying out reduced-pressure direct esterification on terephthalic acid, 1,4-butanediol and double-ended hydroxyl polyether in a certain proportion in the presence of catalysts, carrying out melt polycondensation to obtain a polyester elastomer, and carrying out a spin-draw-winding one-step process on the prepared polyester elastomer and PET, so as to obtain the polyester elastomer / PET composite elastic fiber, wherein the breaking strength of the polyester elastomer / PET composite elastic fiber is 2.8cN / dtex-3.56cN / dtex, the elongation at break is 16.9%-30.4%, the curling degree is 60%-75%, the curling elasticity rate is 97%-99%, the capillary water absorption height is 9.7cm / 30min-14.1cm / 30min. Compared with normal composite elastic fibers, the polyester elastomer / PET composite elastic fiber has relatively excellent elasticity and relatively soft hand feeling, and the fabric capillary suction effect of the polyester elastomer / PET composite elastic fiber is even higher than those of cotton fabrics; the preparation method is short in production process, high in spinning speed and low in cost, and the prepared composite elastic fiber can be directly used in subsequent weaving without being processed into interlaced yarns.

Owner:SICHUAN UNIV +1

Method for synthesizing citric acid ester type compound

InactiveCN101830803AHigh catalytic activityShorten the esterification timeOrganic compound preparationCarboxylic acid esters preparationChemical synthesisBenzene

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

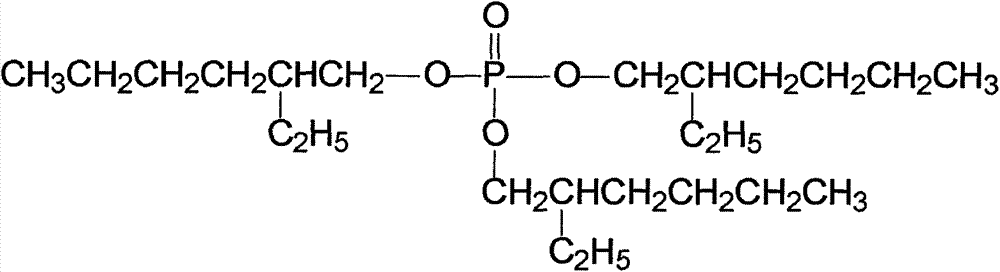

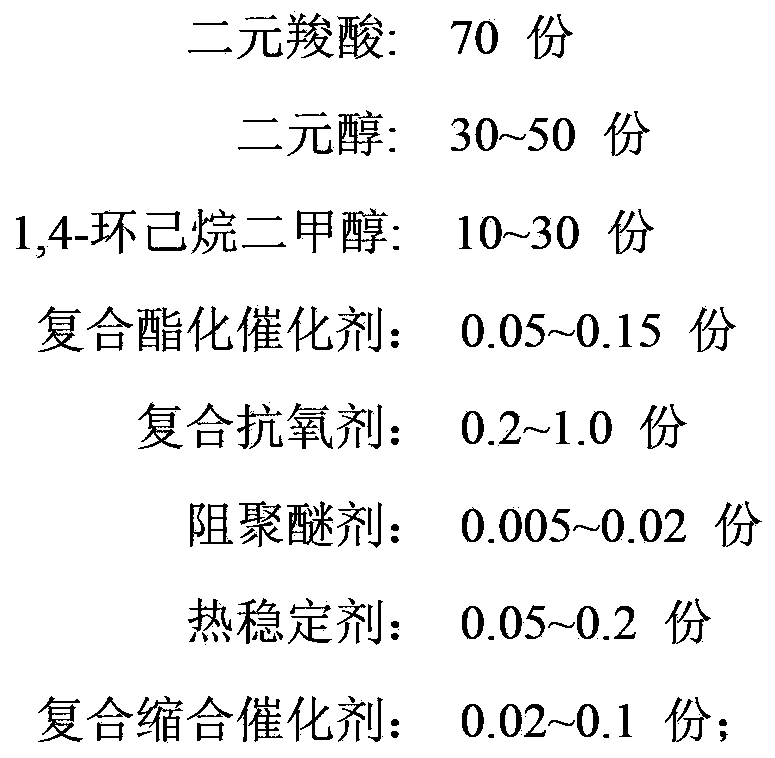

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

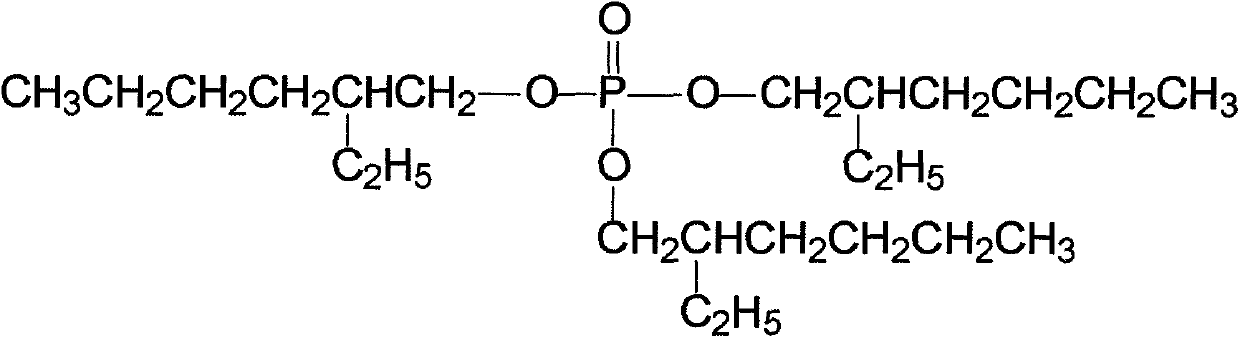

Production method of trioctyl phosphate

ActiveCN103435642AImprove conversion rateReduce usageGroup 5/15 element organic compoundsIsooctyl alcoholFiltration

The invention relates to a production method of trioctyl phosphate. The trioctyl phosphate is obtained by reacting phosphorus oxychloride and isooctyl alcohol under the action of titanium tetrachloride; the integral production process comprises the following process steps of: mixing; esterifying; neutralizing, and washing; dealcoholizing; carrying out refining treatment; carrying out dewatering pressure filtration, and the like. The synthetic method disclosed by the invention can be used for adding the phosphorus oxychloride in batches under a production process condition, controlling the temperature of a mixing process, greatly reducing the generation of side reaction and enhancing the purity of products; the synthetic method disclosed by the invention can be used for furthest improving the transformation ratio of the phosphorus oxychloride by utilizing the proportion, namely the mole ratio of the phosphorus oxychloride and octanol at 1:(3.10-3.15), saving the usage amount of the octanol and saving the cost, thereby being favorable to industrial large-scale production.

Owner:HANGZHOU QIANYANG TECH

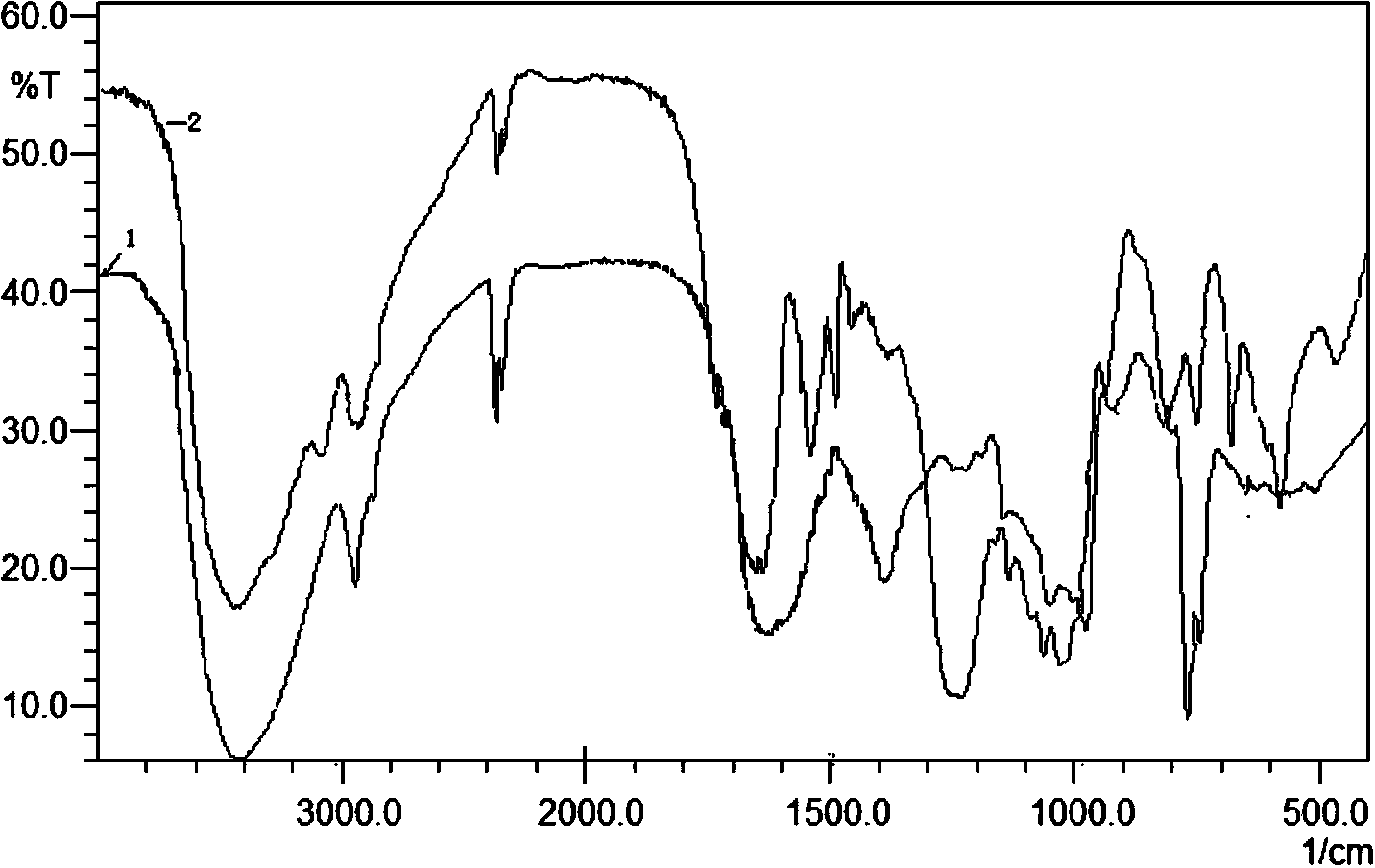

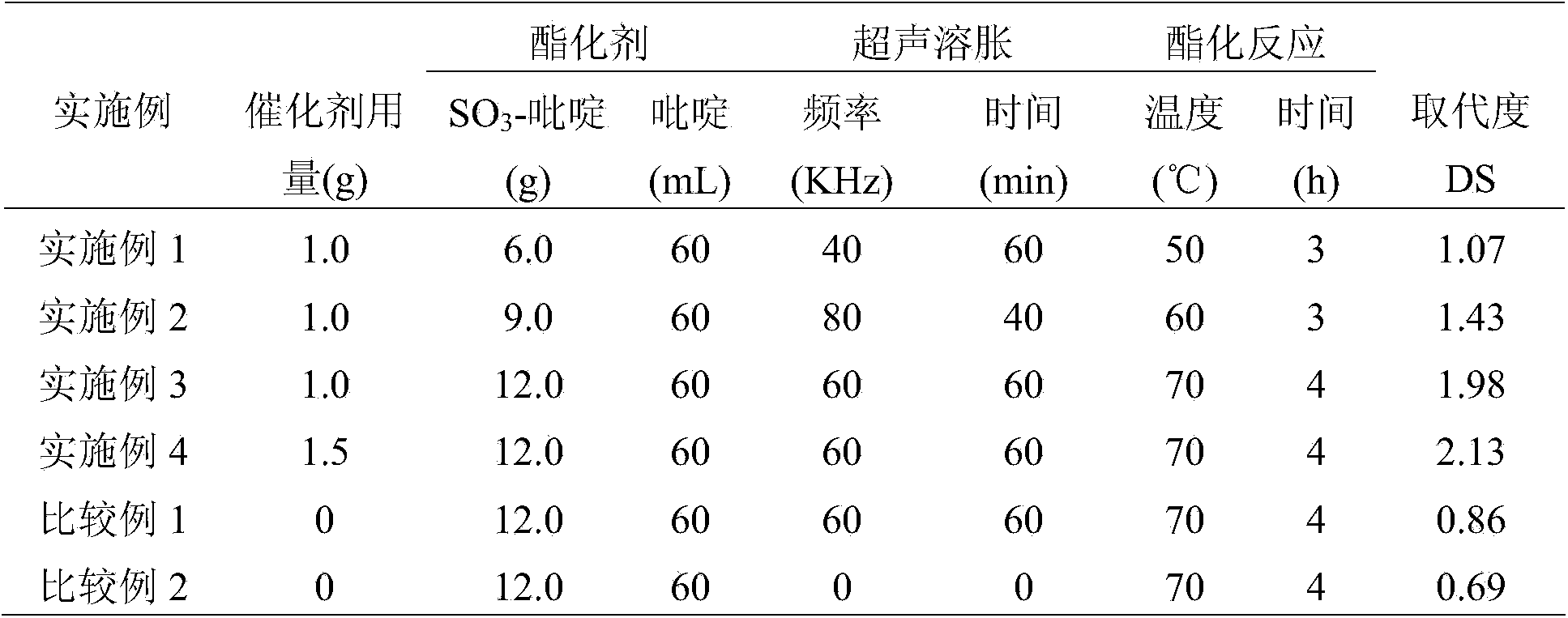

Ultrasonic wave assistant-catalyzed synthesis of grifolan sulphate

InactiveCN103819573AHigh degree of substitutionLower the esterification temperatureSulfur trioxidePyridine

The invention discloses a method for ultrasonic wave assistant-catalyzed synthesis of grifolan sulphate. According to the method, the grifolan is used as a raw material, and sulfur trioxide-pyridine is used as a sulfonating agent, under the catalytic action of 4-dimethylaminopyridine, the grifolan sulphate can be prepared, further, the method includes the step of ultrasound swelling of grifolan in N,N-dimethylformamide. According to the method, as the synthesis of grifolan sulphate is realized through the ultrasonic wave assistant-catalysis method, the esterification temperature is reduced, the esterification time is shortened, and the degree of substitution of sulfuric acid groups is improved by 1.07-2.13; with the adoption of the method provided by the invention, the reaction condition is safe and controllable, and the reaction speed is higher.

Owner:BEIJING UNION UNIVERSITY

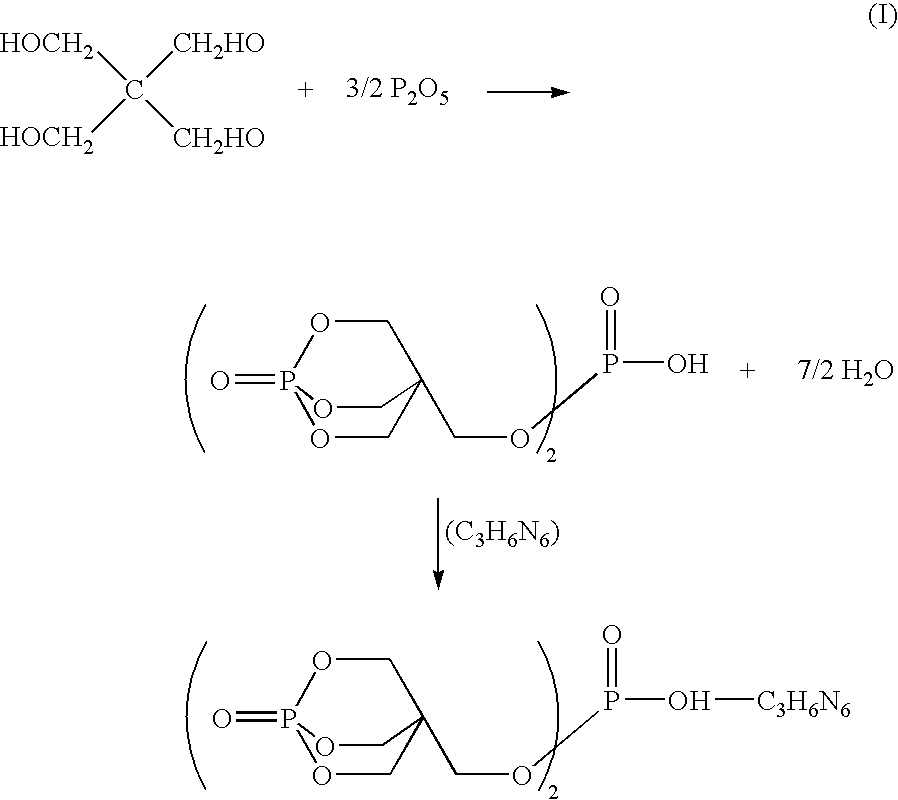

Method for preparing melamine salt of bis(pentaerythritol phosphate) phosphoric acid

InactiveUS20080255353A1Shorten the esterification timeOptimize the reaction systemOrganic chemistryPentaerythritolO-Phosphoric Acid

A method for producing a melamine salt of bis(pentaerythritol phosphate) phosphoric acid is proposed. The method includes the steps of reacting and mixing pentaerythritol and diphosphorous pentaoxide in an extruder to carry out esterification to produce bis(pentaerythritol phosphate) phosphoric acid; and mixing bis(pentaerythritol phosphate) phosphoric acid with melamine or a derivative thereof to carry out quaternization in the presence of a solvent, followed by removing water to obtain a melamine salt of bis(pentaerythritol phosphate) phosphoric acid. Diphosphorous pentaoxide is used in the method as a reactant, so that no hydrogen chloride is produced and it is not necessary to recollect trichlorophosphoric acid. Moreover, in the method of the present invention, such that esterification time can be shortened and a high pressure in a closed reaction system that causes explosion can be avoided.

Owner:CHANG CHUN PLASTICS

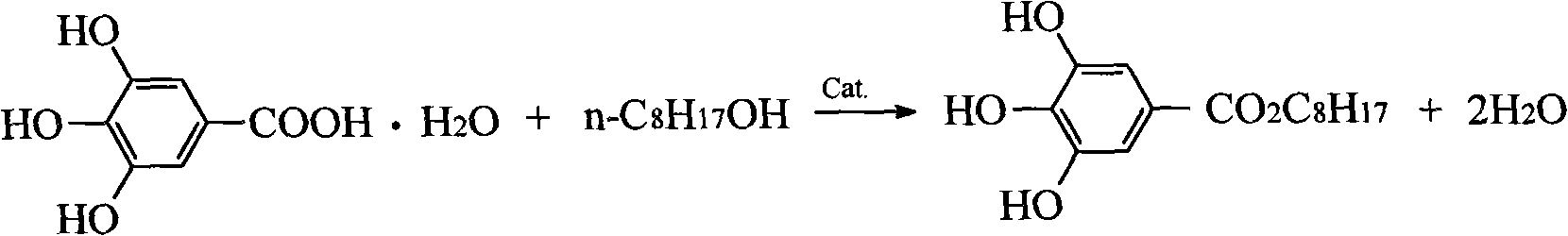

Overdosed esterification production technology for n-octyl gallate

InactiveCN101781214AShorten the reaction time of esterificationHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationGallic acid esterDistillation

The invention discloses overdosed esterification production technology for n-octyl gallate, which comprises the following steps: reacting gallic acid raw materials with n-octyl alcohol for an esterification reaction in the presence of an organic sulfonic acid catalyst; vaporizing and concentrating the filtrate under reduced pressure; adding cyclohexane for recrystallization; washing the filtrate by using purified water until the PH is between 6.0 and 7.0; and performing vacuum drying to obtain the end product of n-octyl gallate. The overdosed esterification production technology for the n-octyl gallate has the advantages of obviously shortening the esterification reaction time, having high reaction conversion rate, saving the high temperature distillation process under reduced pressure and reducing the damage to reaction products due to high temperature. The n-octyl alcohol is a reactant and a solvent used for the reaction, and the production cost is reduced.

Owner:JIURUI BIOLOGY & CHEM CO LTD

Preparation method of glyceryl triacetate

ActiveCN105218366AHigh yieldHigh purityPhysical/chemical process catalystsOrganic compound preparationActivated carbonPtru catalyst

The invention discloses a preparation method of glyceryl triacetate. The preparation method comprises the following steps: 1, mixing and stirring concentrated sulfuric acid and activated carbon, wherein the pH value of the activated carbon is 1, the mass ratio of the sulfuric acid to the activated carbon is 1: 0.5-2, raising the temperature to 150-190 DEG C, preserving the temperature for 10-30 minutes, conducting natural cooling, then placing the mixture at the normal temperature, and obtaining a catalyst; 2, mixing the catalyst obtained in step 1 with glycerin, acetic acid and dehydrating agents, raising the temperature to 100-150 DEG C, getting the mixture to react, and obtaining glyceryl triacetate through post-treatment, wherein the volume mass ratio of glycerin to the catalyst is 1: 0.004-0.10. According to the preparation method, a novel catalytic reaction is adopted, esterification time is shortened by about 10 hours, energy is saved, and the cost is lowered; compared with a method in which concentrated sulfuric acid serves as a catalyst, the novel catalyst is used for preparing glyceryl triacetate, side reaction polymerization products are reduced, and product purity is raised to above 99.7% from 98.0-99.0%.

Owner:MILE KANGHE GLYCERIDE CO LTD

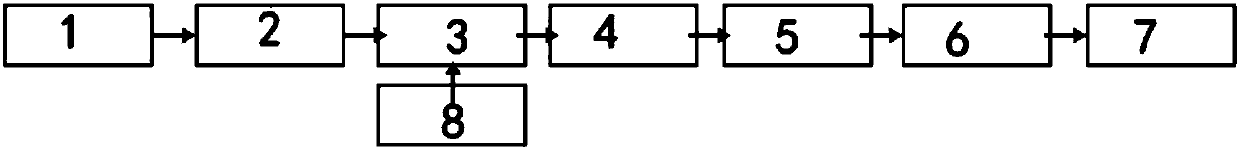

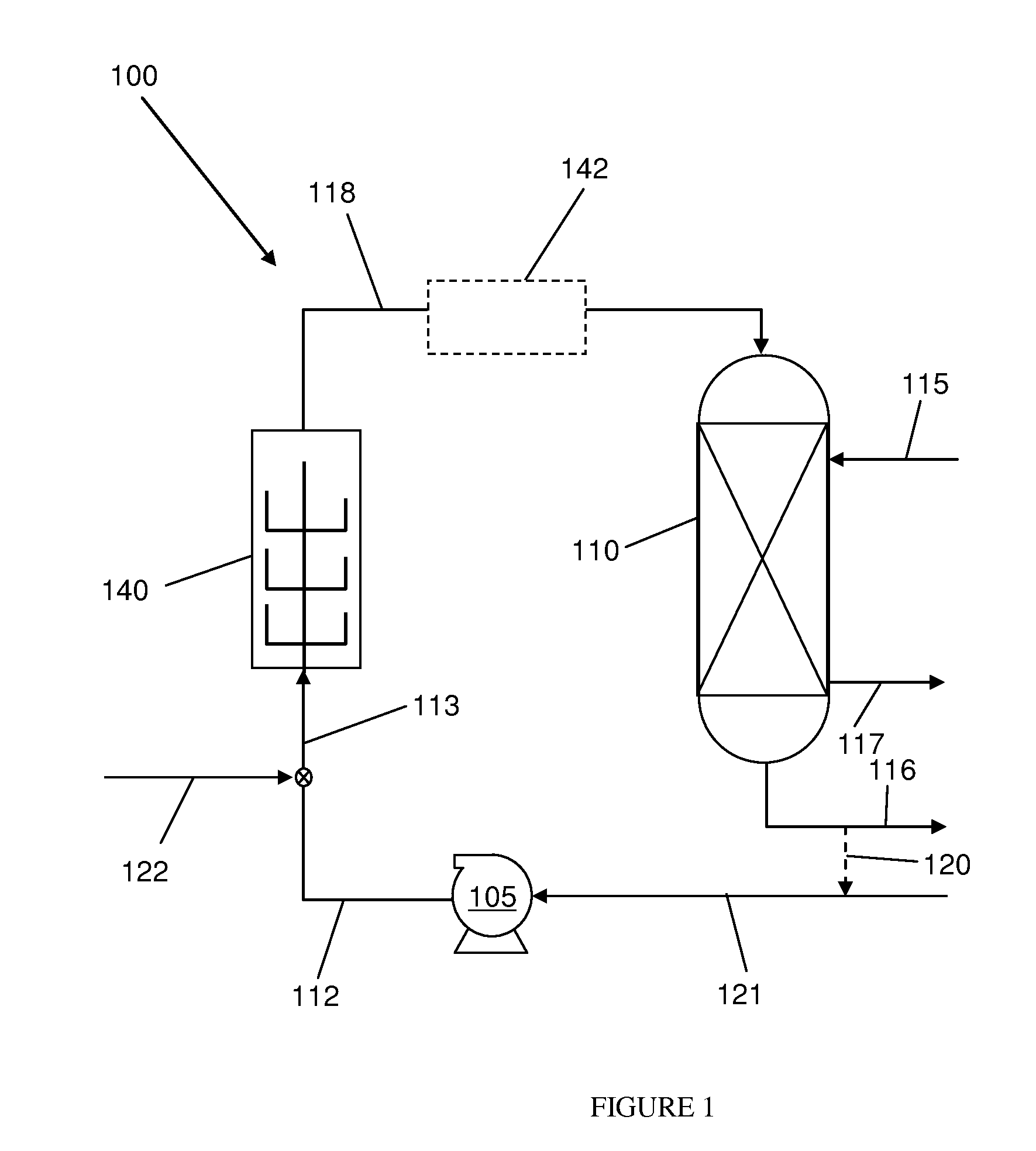

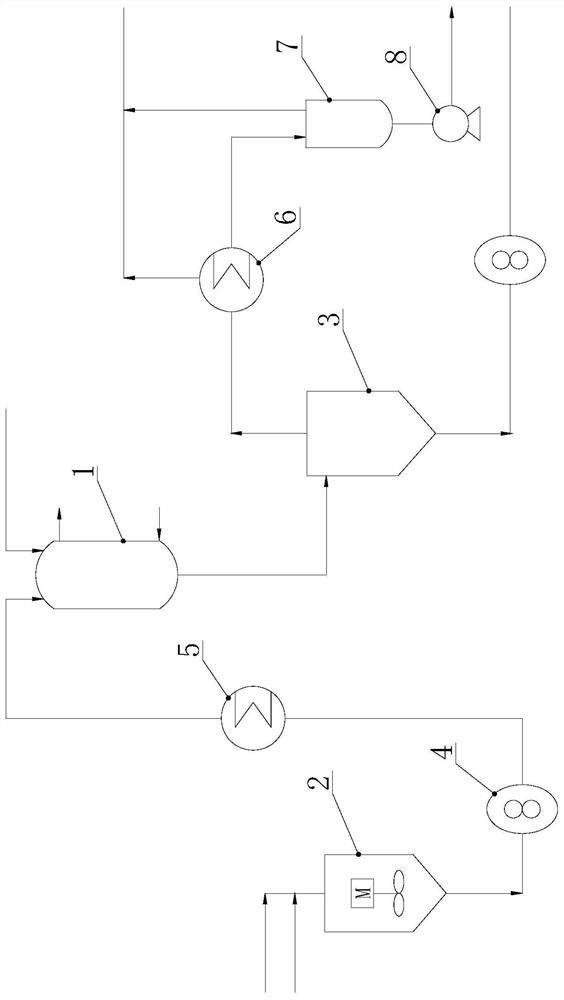

Esterification catalyst, esterification catalysis system and method for preparation of esterification catalyst and esterification catalyst reaction

PendingCN107837811AReduce manufacturing costSolve the problem of pollutionCatalyst carriersFatty acid esterificationBiodieselSilica gel

The invention provides an esterification catalyst, an esterification catalysis system and a method for preparation of the esterification catalyst and esterification catalyst reaction. The esterification catalyst is prepared from silica gel, and iron, zirconium, titanium, tin, scandium and sulfuric acid which are adsorbed on the silica gel; the mass percent of the iron, the zirconium, the titanium,the tin, the scandium and the sulfuric acid in the silica gel is respectively as follows: 9-30% of the iron, 0.009-0.015% of the zirconium, 9-30% of the titanium, 0.3-3% of the tin, 0.003-0.009% of the scandium and 59% of the sulfuric acid. The esterification catalysis system comprises a stock solution pool, a chemical filter pool, an adsorption area, a drying dehydration area, a roasting furnace, an esterification reaction pool, a deacidification oil tank and C-shaped macropore silica gel; the stock solution pool, the chemical filter pool, the adsorption area, the drying dehydration area, the roasting furnace, the esterification reaction pool and the deacidification oil tank are successively connected, and the C-shaped macropore silica gel is connected with the adsorption area. Accordingto the esterification catalyst, the esterification catalysis system and the method for the preparation of the esterification catalyst and the esterification catalyst reaction, the production cost ofbiodiesel is reduced, the sulfur content and acid value of a product achieve the purpose of meeting GB (V) diesel oil standard, the defect that traditional process causes environmental pollution easily is solved, and the esterification catalyst, the esterification catalysis system and the method for the preparation of the esterification catalyst and the esterification catalyst reaction make contributions to production of biodiesel, energy conservation, emission reduction and environmental protection.

Owner:广西锟德能源科技有限公司

Preparation method of base oil of drilling fluid

InactiveCN103865641AEasy dosageReduce dosageFatty acid esterificationFatty-oils/fats refiningPtru catalystDistillation

The invention belongs to the technical field of petroleum industry, and particularly relates to a preparation method of base oil of a drilling fluid. The method prepares the base oil of the drilling fluid through the steps: impurity removal; water removal; enzymatic pre-esterification; alkali catalytic esterification; distillation and the like. The method is environment-friendly and pollution-free in reaction and mild in reaction condition. As the pre-esterification time is shorter, the use level of alcohol is less, so that the alcohol has less influence on the activity of enzymes. The enzymatic catalyst can be repeatedly used, so that the cost is lowered, the reaction time is saved, and the production efficiency and the ester conversion ratio are improved. The base oil of the drilling fluid prepared by the invention is safe and energy-saving biological oil which is high in flash point and ignition point. The ignition point is higher than 93 DEG C, and the flash point is not lower than 130 DEG C. The base oil of the drilling fluid is safe to transport and use.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing sulfated apple pomace polysaccharide through twin-screw extrusion

The invention discloses a method for preparing sulfated apple pomace polysaccharide through twin-screw extrusion, and belongs to the technical field of food processing. The method comprises the following steps: (1) carrying out extrusion modification on apple pomace subjected to moisture adjustment by adopting a double-screw extruder, and performing drying, crushing and sieving to obtain modifiedapple pomace; (2) adding distilled water into the modified apple pomace, performing leaching in a water bath, removing filter residues, concentrating under reduced pressure, carrying out alcohol precipitation, standing, centrifuging, removing supernatant, and drying the precipitate to obtain apple pomace polysaccharide; and (3) dispersing the apple pomace polysaccharide in dimethylformamide, adding sulfamic acid under a stirring condition, uniformly mixing, carrying out esterification reaction under an ultrasonic condition, cooling to room temperature, regulating the pH value until the solution is neutral, carrying out alcohol precipitation, dissolving the obtained precipitate in distilled water, performing dialyzing, and drying the obtained product to obtain the sulfated apple pomace polysaccharide. The method has the advantages of high production efficiency, high yield, safety and no toxicity of the product, and high yield of the obtained product.

Owner:SHAANXI UNIV OF SCI & TECH

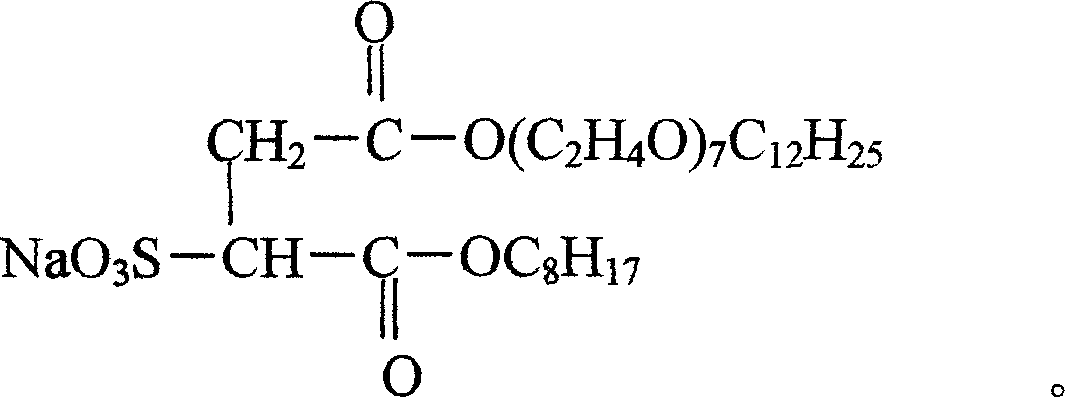

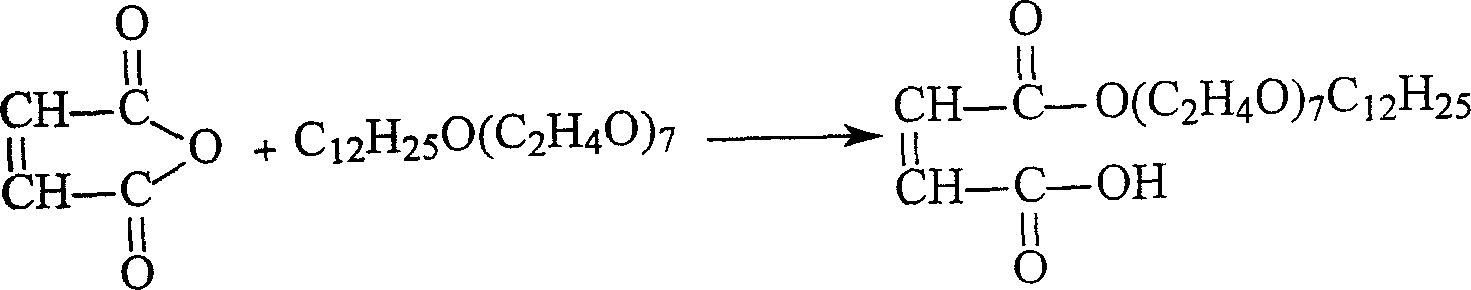

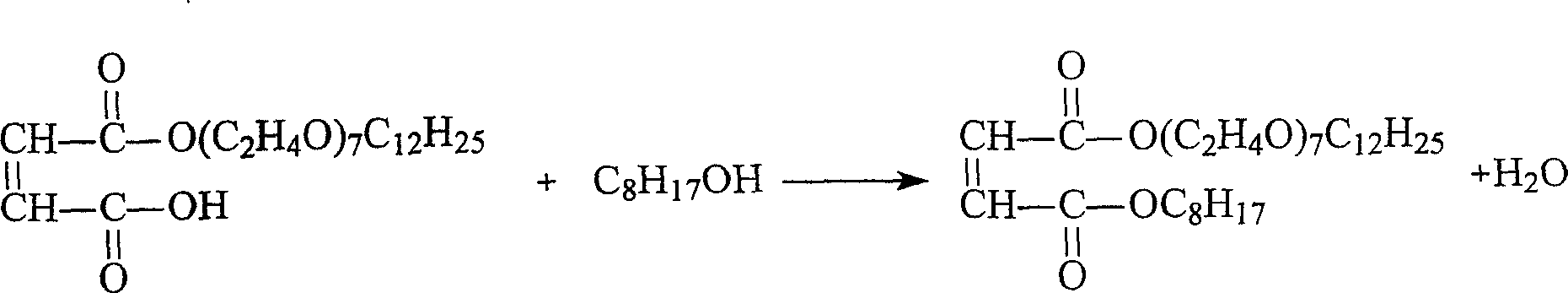

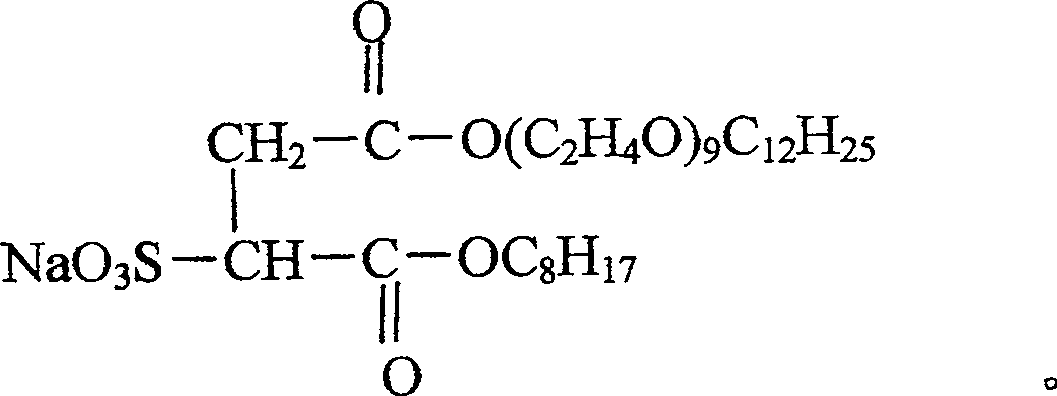

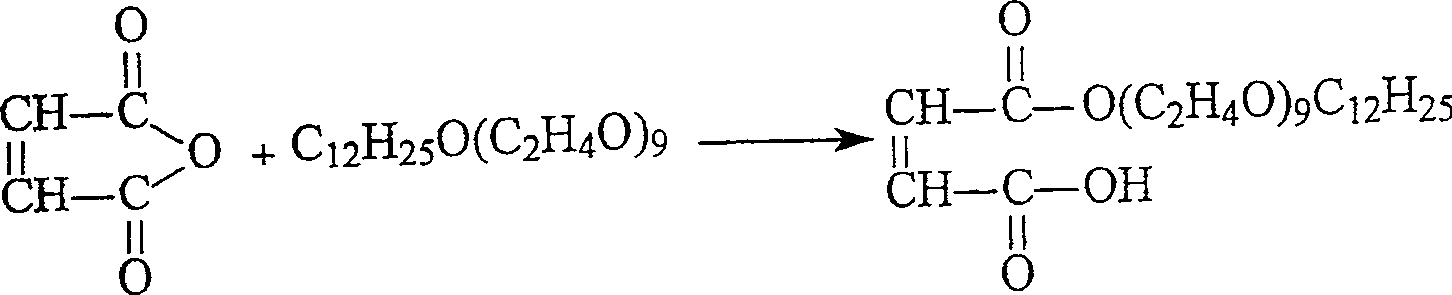

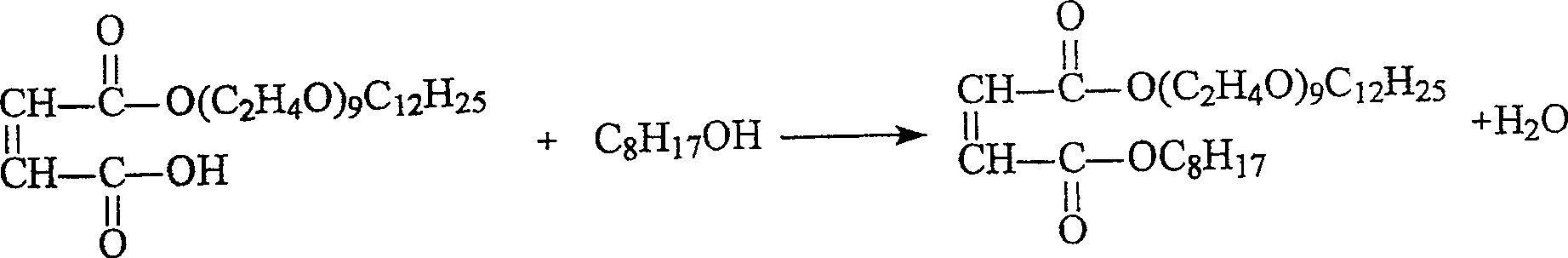

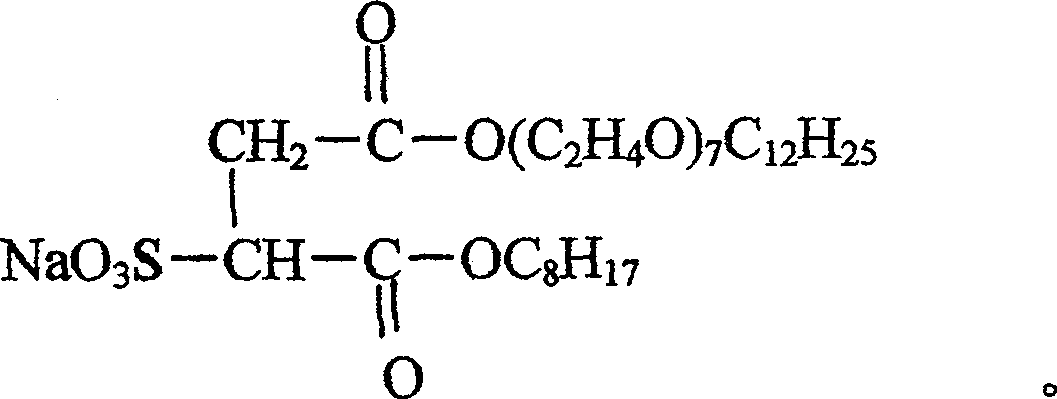

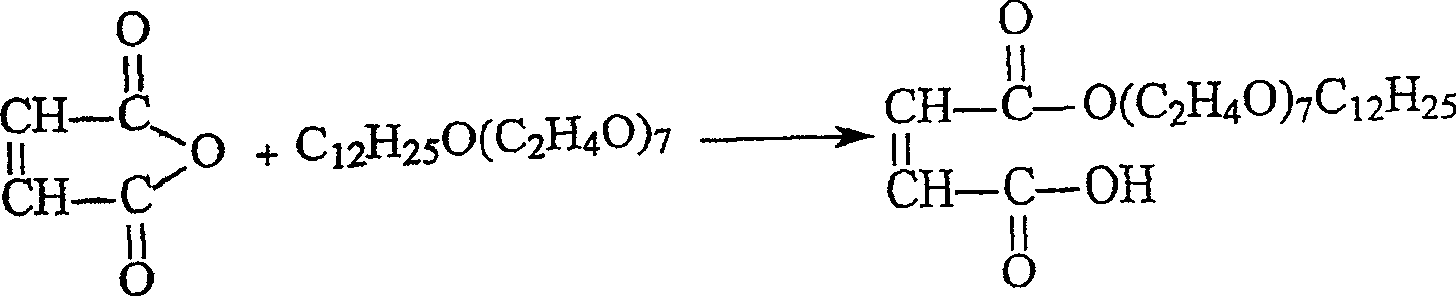

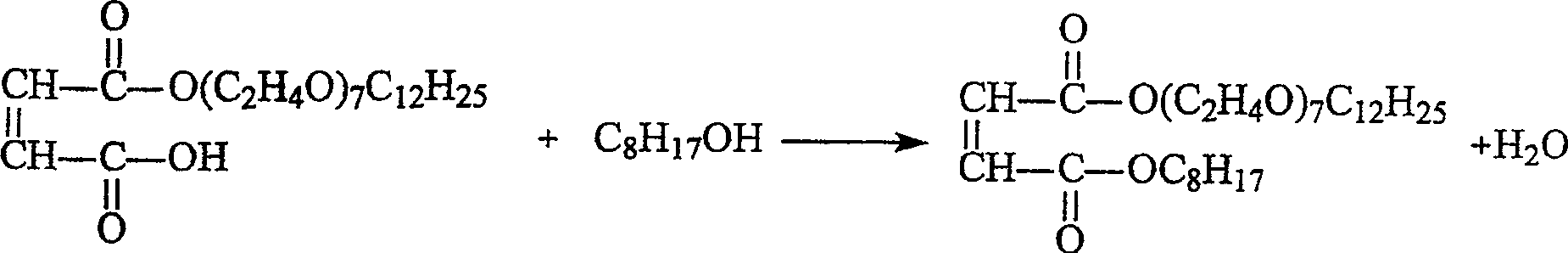

Sodium lauryl polyoxyethylene (7) octyl sulfosuccinate and its preparing process

InactiveCN101015779AReduce consumptionIncrease profitTransportation and packagingMixingEtherSodium bisulfite

The invention discloses a lauryl alcohol polyvinyl ether (7) octyl sulfo succinic mixed diester sodium and relative preparation, comprising that processing monoester reaction between maleic anhydride and lauryl alcohol polyvinyl ether (7), and processing diester reaction between the reaction product of monoester reaction and octanol, and processing conjugate addition reaction between the reaction product of diester reaction and sodium bisulfite to obtain final product. The invention has high-quality property and simple process.

Owner:NANTONG UNIVERSITY

High-efficiency esterification method of trioctyl trimellitate

InactiveCN108586252AIncrease the reaction contact areaImprove the mixing effectProductsOrganic compound preparationChemical industryAcid value

The invention provides a high-efficiency esterification method of trioctyl trimellitate. According to the invention, an esterification liquid is circulated from the bottom of a kettle to the top of the kettle, and is sprayed into the kettle, and the reaction contact area is increased, thereby effectively improving the mixing effect; a stirring system uses a three-layer blade set device to promoteuniform stirring, and can shorten the esterification time by half accordingly, saves energy, and reduces consumption; and after the esterification is completed, the esterification rate is up to 99% orover 99%, and the acid value is relatively low. The method significantly improves the esterification effect of the trioctyl trimellitate, the trioctyl trimellitate can be continuously esterified, theesterification time is shortened, the cost is reduced, and the method is safe and environmentally-friendly, and meets the requirements of green chemical industry and sustainable development. A product has the advantages of light color, good quality and high purity.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Production method of trioctyl phosphate

ActiveCN103435642BImprove conversion rateReduce usageGroup 5/15 element organic compoundsIsooctyl alcoholFiltration

The invention relates to a production method of trioctyl phosphate. The trioctyl phosphate is obtained by reacting phosphorus oxychloride and isooctyl alcohol under the action of titanium tetrachloride; the integral production process comprises the following process steps of: mixing; esterifying; neutralizing, and washing; dealcoholizing; carrying out refining treatment; carrying out dewatering pressure filtration, and the like. The synthetic method disclosed by the invention can be used for adding the phosphorus oxychloride in batches under a production process condition, controlling the temperature of a mixing process, greatly reducing the generation of side reaction and enhancing the purity of products; the synthetic method disclosed by the invention can be used for furthest improving the transformation ratio of the phosphorus oxychloride by utilizing the proportion, namely the mole ratio of the phosphorus oxychloride and octanol at 1:(3.10-3.15), saving the usage amount of the octanol and saving the cost, thereby being favorable to industrial large-scale production.

Owner:HANGZHOU QIANYANG TECH

Novel continuous production technique of phthalate plasticizer

InactiveCN105111075AReduce production energy consumptionImprove the efficiency of esterificationOrganic compound preparationCarboxylic acid esters preparationNovel techniquePlasticizer

The invention relates to a novel continuous production technique of a phthalate plasticizer. The technique comprises the following steps: raw materials phthalic anhydride and monobasic alcohol and a catalyst are continuously introduced into a first-stage esterification kettle, and a small amount of monobasic alcohol is continuously introduced into a fifth-stage esterification kettle; liquid-phase materials of all stages of esterification kettles gradually flow to the fifth-stage esterification kettle from the first-stage esterification kettle via a liquid-phase pipeline and flow out of the fifth-stage esterification kettle, thereby obtaining a reaction product; gas-phase materials of all stages of esterification kettles are gradually introduced into the first-stage esterification kettle from the fifth-stage esterification kettle via a gas-phase pipeline and enter a packing tower; and the temperatures of all stages of esterification kettles are kept at 130-230 DEG C, the gage pressures are kept at 0-2atm, and the retention time is kept at 0.2-2 hours. The acid number of the bottom discharge product of the fifth-stage esterification kettle is 0.2-2.5 mg KOH / g. The novel technique for continuously producing the phthalate plasticizer greatly reduces the esterification time and energy consumption, and enhances the economic benefit.

Owner:EAST CHINA UNIV OF SCI & TECH

Polymerizing production method for transparent amorphous copolyester

The invention discloses a polymerizing production method for transparent amorphous copolyester. The method has the advantages of low esterification temperature, short esterification time and high esterification rate. The method comprises the following steps of: carrying out an esterification reaction and a condensation reaction on dihydric alcohol and dicarboxylic acid to obtain the transparent amorphous copolyester, wherein the esterification reaction comprises the following specific procedures of: breaking various materials into pulp by using a pulping machine and carrying out the esterification reaction on the pulp at the temperature of 220-240DEG C for 1.0-1.5 hours to obtain an esterified product; the condensation reaction comprises the following specific procedures of: polymerizing the esterified product obtained by the esterification reaction at the reaction pressure of 0.2-0.5MPa and the temperature of 250-260DEG C for 1.5-2 hours; then reducing the pressure to be less than 200MPa within 0.5 hour; raising the condensation reaction temperature to be 275DEG C from 260DEG C; adding a thermal stabilizer; and after the condensation reaction, obtaining a polyester copolymer with the inherent viscosity of greater than 0.75dL / g and the carboxyl content of less than 10mol / t.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

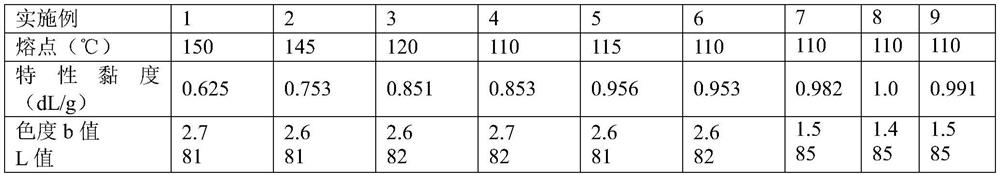

Low-melting-point copolyester and preparation method thereof

The present invention relates to the field of polymers. In view of the problem that existing low-melting-point polyester is poor in thermal performance and mechanical performance, the invention provides a low-melting-point copolyester which has the intrinsic viscosity of 0.6-1.0 dL / g and the melting point of 110-150 DEG C, has the characteristics of low melting point, good crystallinity, high intrinsic viscosity and difficulty in bonding, and is suitable for spinning filaments, short fibers and non-woven fabrics. The invention further provides a preparation method of the low-melting-point copolyester, MPO is used as a main modifier, and a PEG2000, 3000 and 4000 blend is used as an auxiliary modifier. Primary hydroxyl in an MPO molecular chain enables MPO to have high reaction activity, theesterification time is shortened, by-products are few, and the prepared polyester is extremely light in color and luster and high in stability and weather resistance. The larger the addition amount of MPO is, the larger the reduction of the melting point is. A crystallization nucleating agent is introduced into a polyester macromolecular structure, so that crystallization property damage caused by MPO is improved, and the melting point is reduced.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

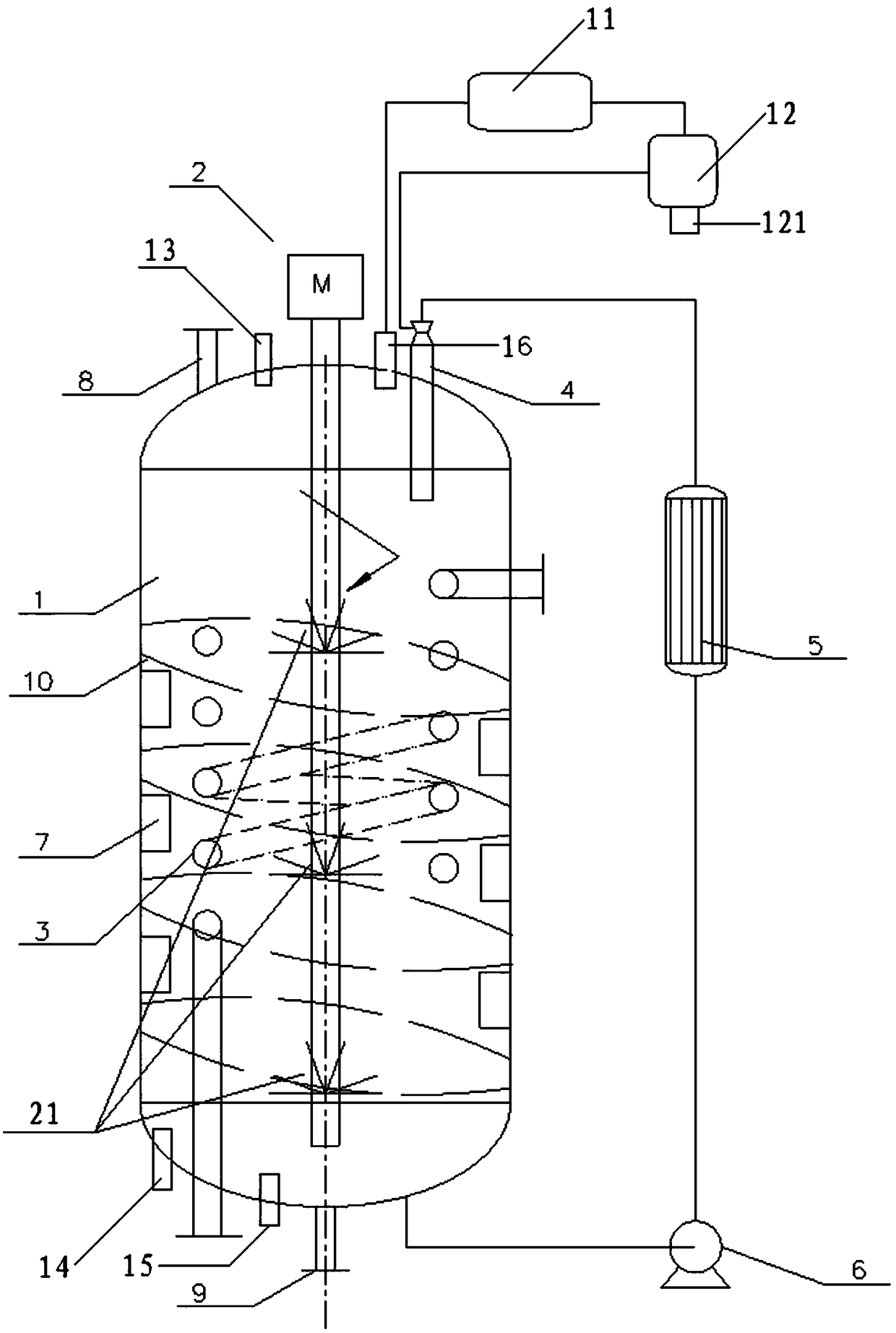

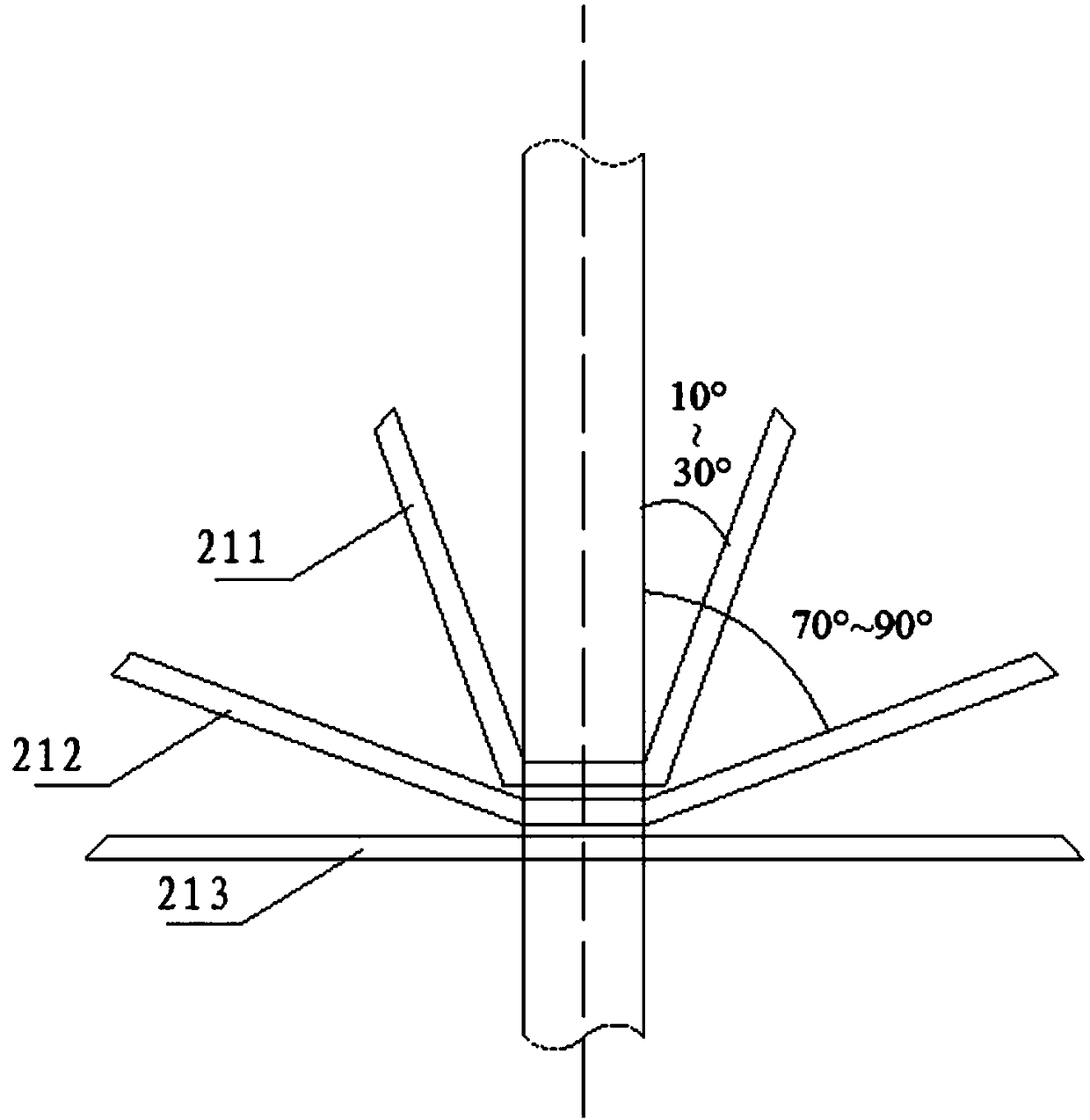

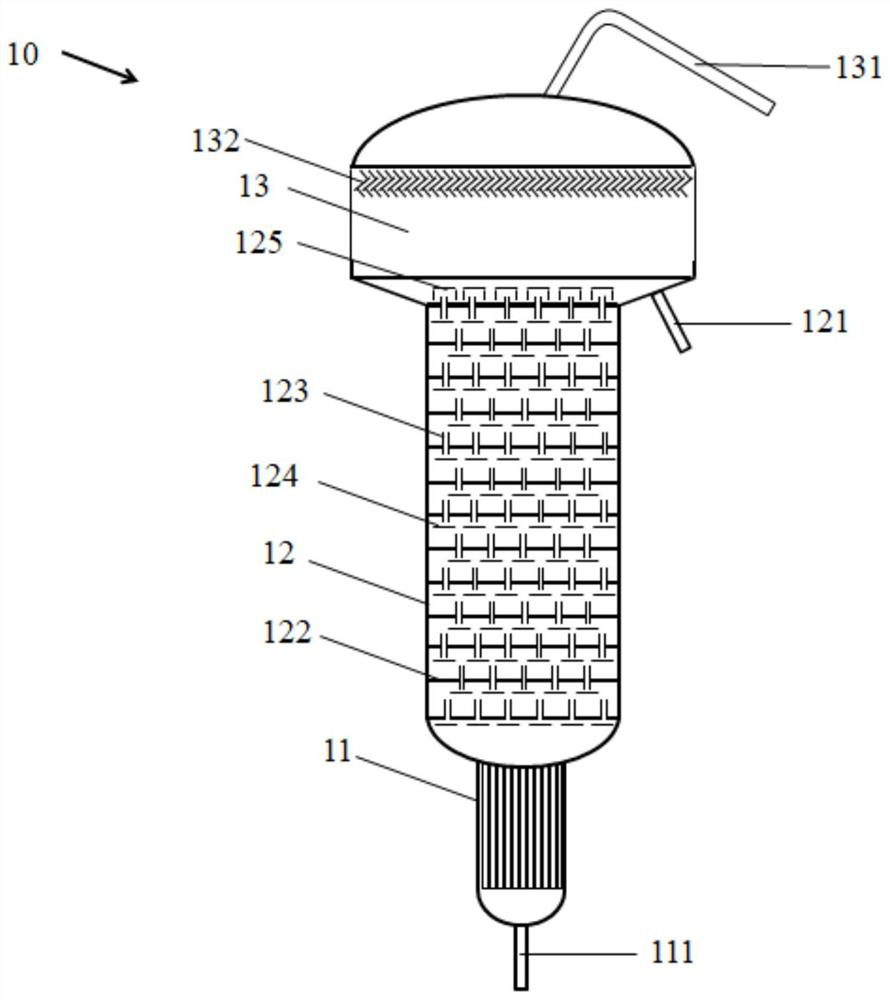

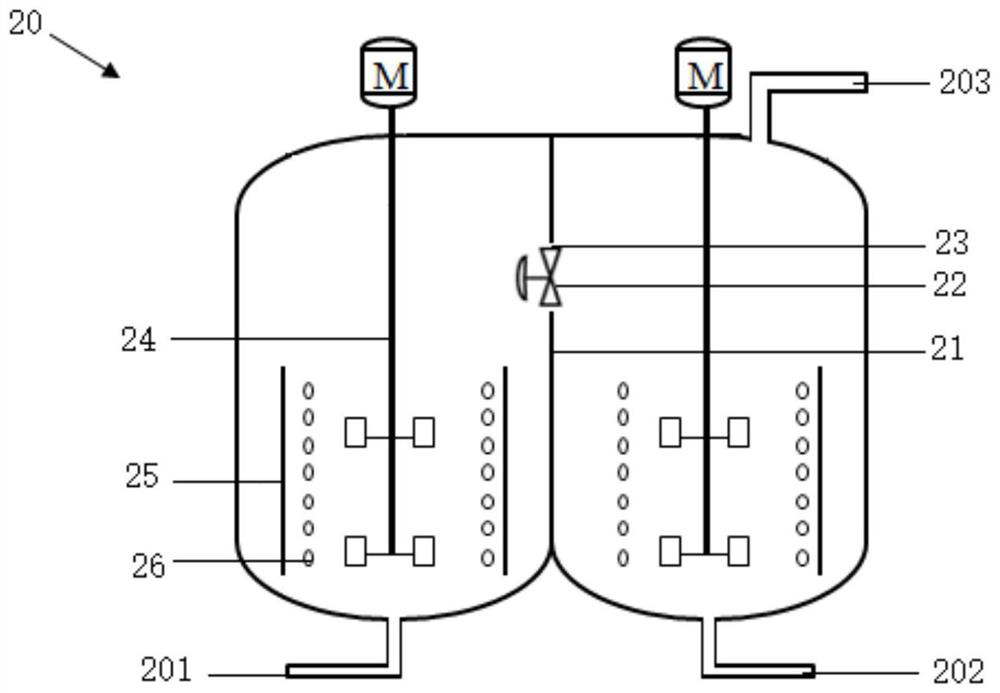

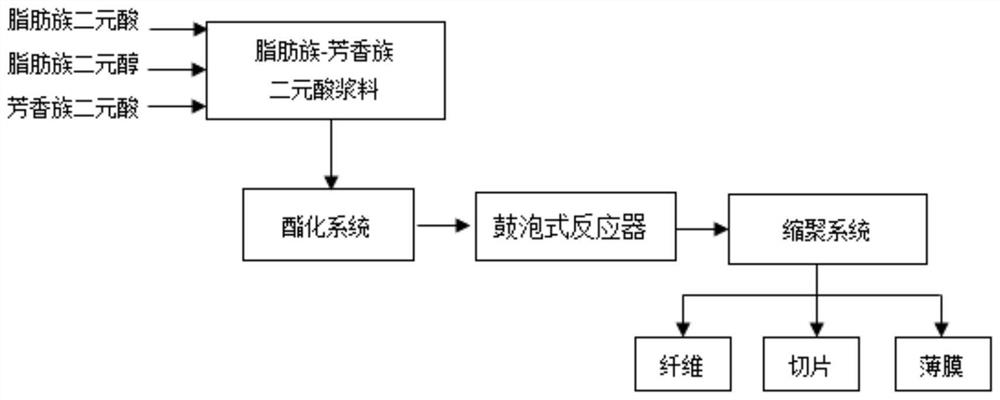

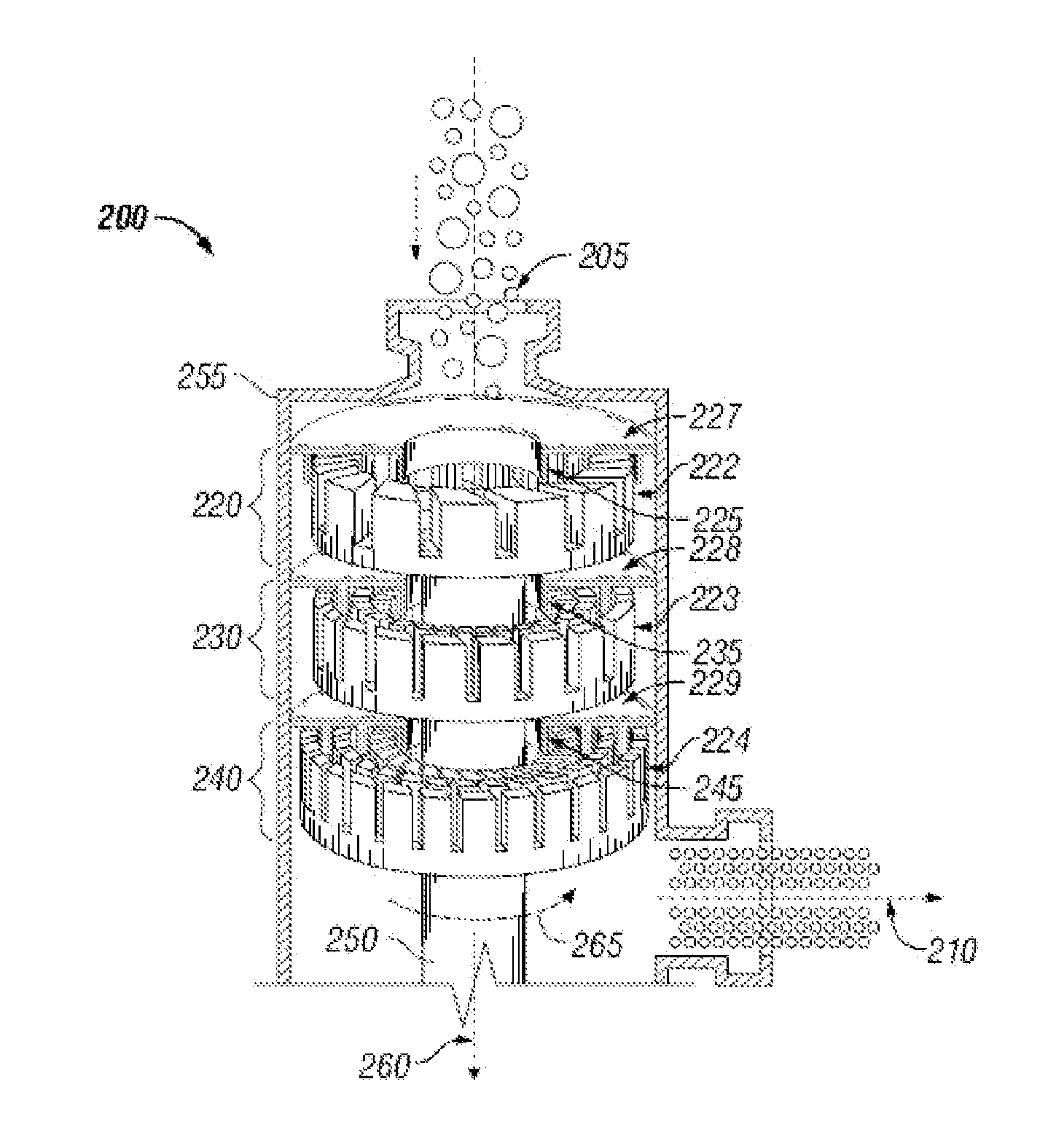

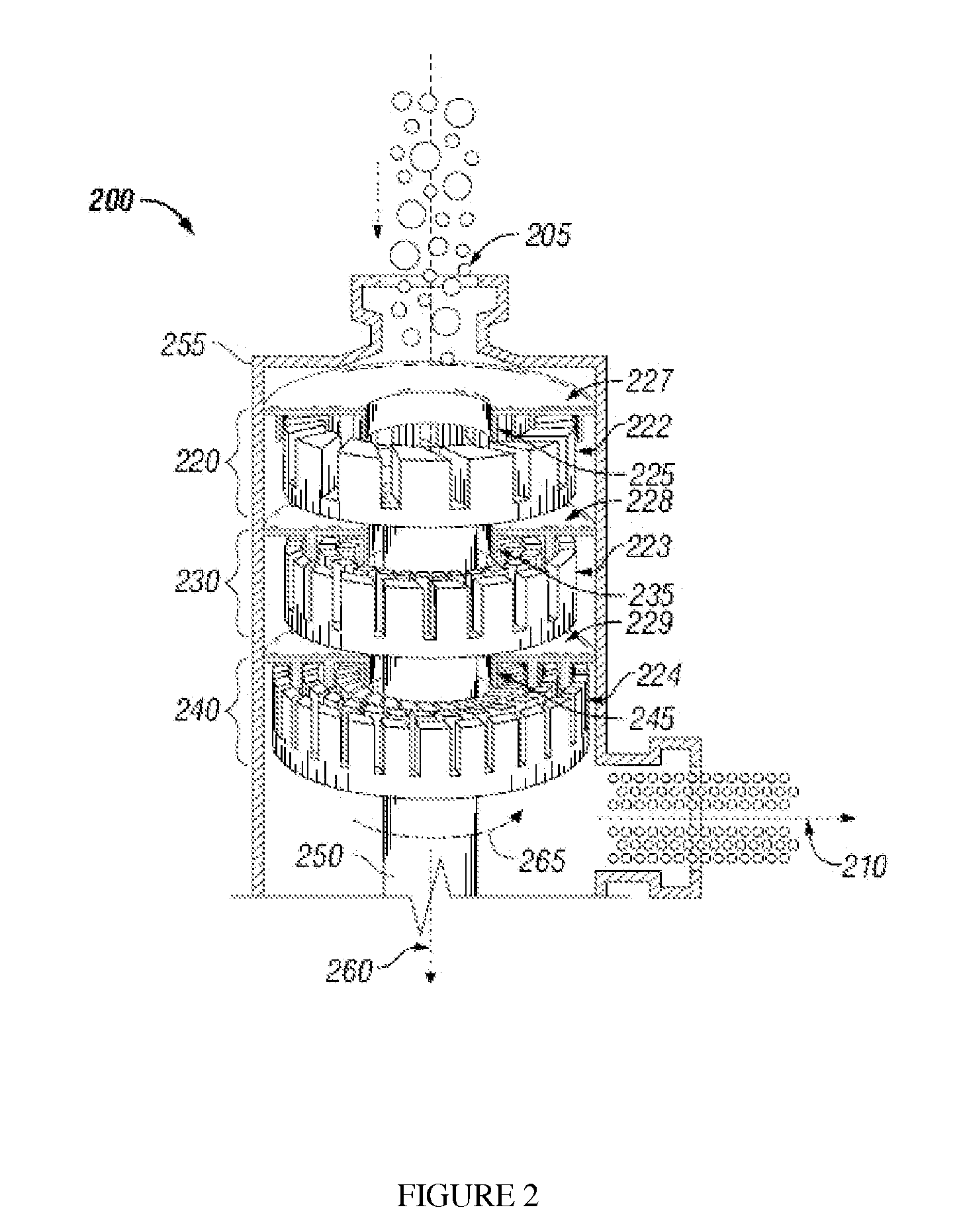

Preparation system and preparation method of biodegradable copolyester and copolyester thereof

ActiveCN112794996AEfficient DepthEfficient melt polycondensationBio-packagingChemical/physical/physico-chemical stationary reactorsPolymer scienceCopolyester

The invention discloses a preparation system and a preparation method of biodegradable copolyester and the copolyester thereof. The preparation system comprises an esterification system and a polycondensation system which are connected in sequence, and a bubbling type reactor is further arranged between the esterification system and the polycondensation system. Materials flowing out of the esterification system are subjected to deep esterification and pre-polycondensation through the bubbling type reactor and then are fed into the polycondensation system. According to the preparation system of the biodegradable copolyester, the simultaneous occurrence of efficient deep esterification and melt polycondensation of aliphatic-aromatic copolyester ester is realized, and the esterification time of aliphatic-aromatic binary acid slurry is greatly shortened; the aliphatic-aromatic copolyester prepolymer meeting the requirements of a subsequent final polycondensation reaction is prepared; the aliphatic-aromatic copolyester continuously produced by using the system has the characteristics of good biodegradability, low terminal carboxyl group content and good hue.

Owner:CHINESE TEXTILE ACAD

Method of making phthalic acid diesters

InactiveUS20110027140A1Promote dispersion and solubilityIncrease shearGaseous chemical processesPhysical/chemical process catalystsAlcoholReaction temperature

Owner:HRD CORP

A kind of polyester elastomer/pet composite elastic fiber and preparation method thereof

ActiveCN104831417BIncrease elasticityImprove performanceMelt spinning methodsConjugated synthetic polymer artificial filamentsElastomerBreaking strength

The invention discloses a polyester elastomer / PET composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of firstly carrying out reduced-pressure direct esterification on terephthalic acid, 1,4-butanediol and double-ended hydroxyl polyether in a certain proportion in the presence of catalysts, carrying out melt polycondensation to obtain a polyester elastomer, and carrying out a spin-draw-winding one-step process on the prepared polyester elastomer and PET, so as to obtain the polyester elastomer / PET composite elastic fiber, wherein the breaking strength of the polyester elastomer / PET composite elastic fiber is 2.8cN / dtex-3.56cN / dtex, the elongation at break is 16.9%-30.4%, the curling degree is 60%-75%, the curling elasticity rate is 97%-99%, the capillary water absorption height is 9.7cm / 30min-14.1cm / 30min. Compared with normal composite elastic fibers, the polyester elastomer / PET composite elastic fiber has relatively excellent elasticity and relatively soft hand feeling, and the fabric capillary suction effect of the polyester elastomer / PET composite elastic fiber is even higher than those of cotton fabrics; the preparation method is short in production process, high in spinning speed and low in cost, and the prepared composite elastic fiber can be directly used in subsequent weaving without being processed into interlaced yarns.

Owner:SICHUAN UNIV +1

A kind of preparation method of sulfated apple water-soluble dietary fiber

The invention discloses a preparation method of sulfated apple water-soluble dietary fiber. The preparation method comprises the following steps: (1) extruding and modifying apple dietary fiber, and then extracting the water-soluble dietary fiber by adopting water extraction and alcohol precipitation; and (2) fast and efficiently preparing the sulfated apple water-soluble dietary fiber under ultrasonic-assisted conditions by adopting sulfamic acid-N,N-dimethylformamide method. The preparation method has the advantages that the reaction conditions are mild, the operation is simple, the toxicity of a product is low and the like, the substitution degree of the prepared sulfated apple water-soluble dietary fiber is 0.23-0.97, and the sulfated apple water-soluble dietary fiber has excellent oxidization resistance and anti-tumor activity.

Owner:SHAANXI UNIV OF SCI & TECH

Esterification device and method for AA and BDO in PBAT production process

PendingCN113499596ANo backmixingReduce circulationVacuum distillation separationChemical/physical/physico-chemical stationary reactorsEngineeringProcess engineering

An esterification device for AA and BDO in the PBAT production process comprises a micro-interface wound tube type reactor, a stock bin and a vacuum flash tank. A feeding port of the stock bin is used for being connected with an AA source and a BDO source, a discharging port of the stock bin is connected with a material channel inlet of the reactor through a feeding pump and a heater, and a material channel outlet of the reactor is connected with the vacuum flash tank. A micro-interface generator is arranged at an inlet of the material channel, a liquid outlet in the bottom of the vacuum flash tank is used for discharging BSA, a steam outlet in the top of the vacuum flash tank is connected with a vacuum separator through a condenser, and non-condensable gas outlets of the condenser and the vacuum separator are both connected with a negative pressure source. The device is simple in structure and convenient to operate, the operation efficiency is greatly improved, the production requirement of large-scale production of PBAT can be met at low cost, the esterification reaction can be carried out in the forward direction without adopting an excessive BDO mode, the esterification rate of AA and BDO can be effectively improved and reaches 98.5% or above, material backmixing can be effectively avoided, the circulation amount of BDO is reduced by 95%, and energy consumption is greatly reduced.

Owner:华峰集团上海工程有限公司

Method for synthesizing citric acid ester type compound

InactiveCN101830803BHigh catalytic activityRich sourcesOrganic compound preparationCarboxylic acid esters preparationChemical synthesisSynthesis methods

The invention discloses a method for synthesizing a citric acid ester type compound, which belongs to the technical field of chemical synthesis. The method comprises the following steps of: using citric acid and fatty alcohol as main raw materials, and using benzene sulfonic acid or amino benzene sulfonic acid as a catalyst; and performing esterification and the purification processes of acetylation, neutralization, washing, drying, distillation and the like. The catalyst has rich sources, a low cost and high activity, can be separated from an esterification liquid easily after the neutralization, is coke-free during the distillation, has less corrosion to equipment, and is safe and environment-friendly; the water generated by the esterification is separated out by adopting a binary heterogeneous separation technique, and no water separating agent is additionally added; and acetyl citric acid ester is produced by adopting an esterification-acetylation continuous synthesis method, the flow is greatly simplified, and a synthesis process is shortened. The citric acid ester prepared by the method has the advantages of high quality, high purity, low degree of color and wide applicationrange.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for continuously and rapidly producing polyester product and application thereof

PendingCN114621422AReduce the esterification rateShorten the esterification timePolyesterPolymer chemistry

The invention relates to the field of polyester, in particular to a method for continuously and rapidly producing a polyester product and application of the method, and the method comprises the following steps: 1, pumping out an esterification melt from an esterified substance by a melt metering gear pump, and injecting a chain extender into the esterification melt after a melt pipeline is cooled; 2, the esterified melt and a chain extender enter a melt mixing device together to be uniformly mixed and then enter a homogenizer, a chain extension homogenization reaction is performed in the homogenizer, and a first polyester melt is obtained; 3, the first polyester melt enters a pre-polymerization kettle to be subjected to a pre-polymerization reaction, and a second polyester melt is obtained; 4, the second polyester melt enters a polycondensation kettle to be subjected to a polymerization reaction, and a third polyester melt is obtained; 5, the third polyester melt enters a tackifying kettle to be subjected to tackifying reaction, and a fourth polyester melt is obtained; and 6, cooling the fourth polyester melt, and granulating to obtain polyester product slices.

Owner:江苏睿安应用生物技术股份有限公司

Sodium polyoxyethylene fatty alcohol ether (9) octyl sulfosuccinate and its preparing process

The invention discloses a fatty alcohol polyvinyl ether (9) octyl sulfo succinic mixed diester sodium and relative preparation, comprising that processing monoester reaction between maleic anhydride and fatty alcohol polyvinyl ether (9), and processing diester reaction between the reaction product of monoester reaction and octanol, and processing conjugate addition reaction between the reaction product of diester reaction and sodium bisulfite to obtain final product. The invention has high-quality property and simple process.

Owner:NANTONG UNIVERSITY

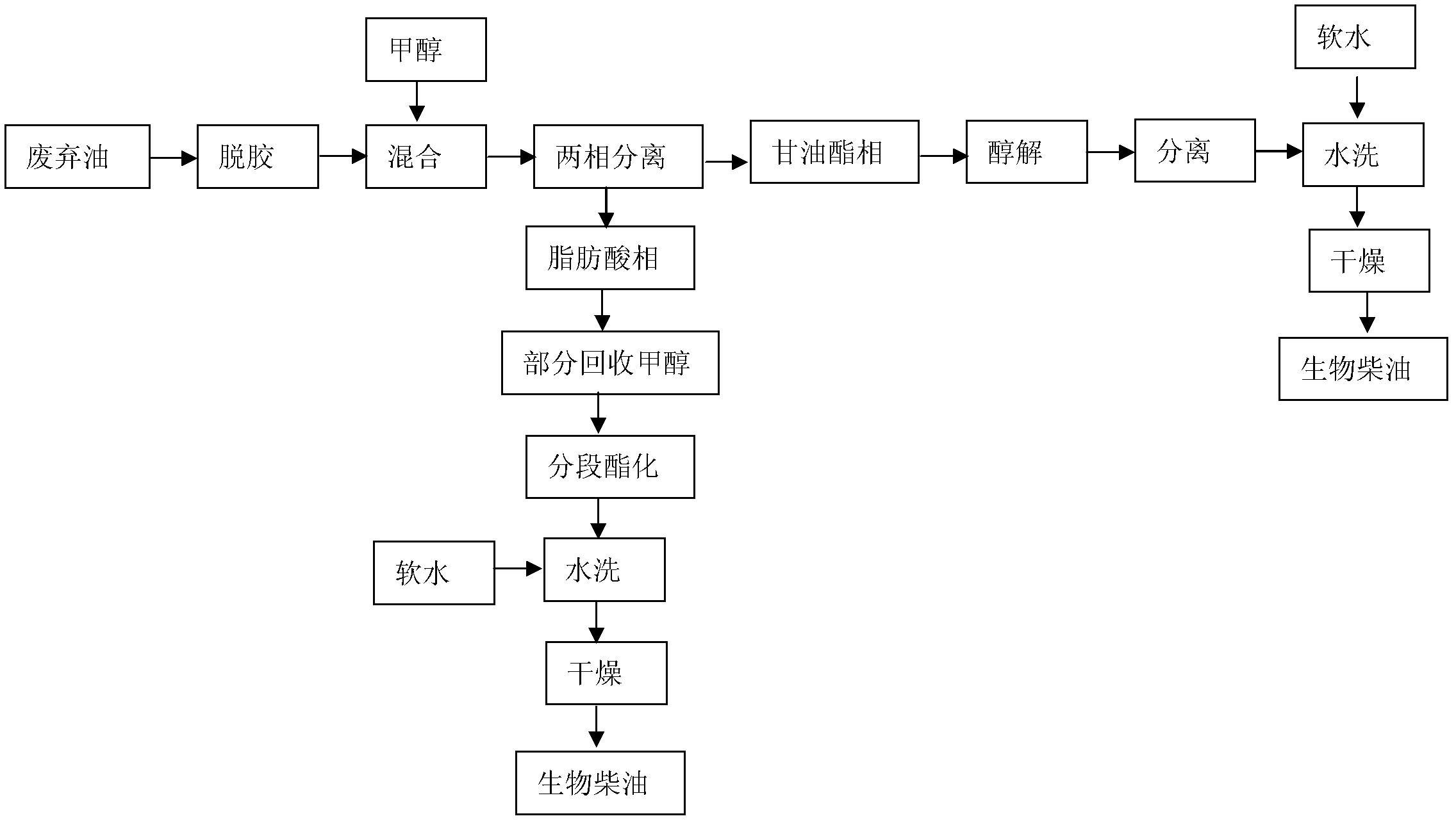

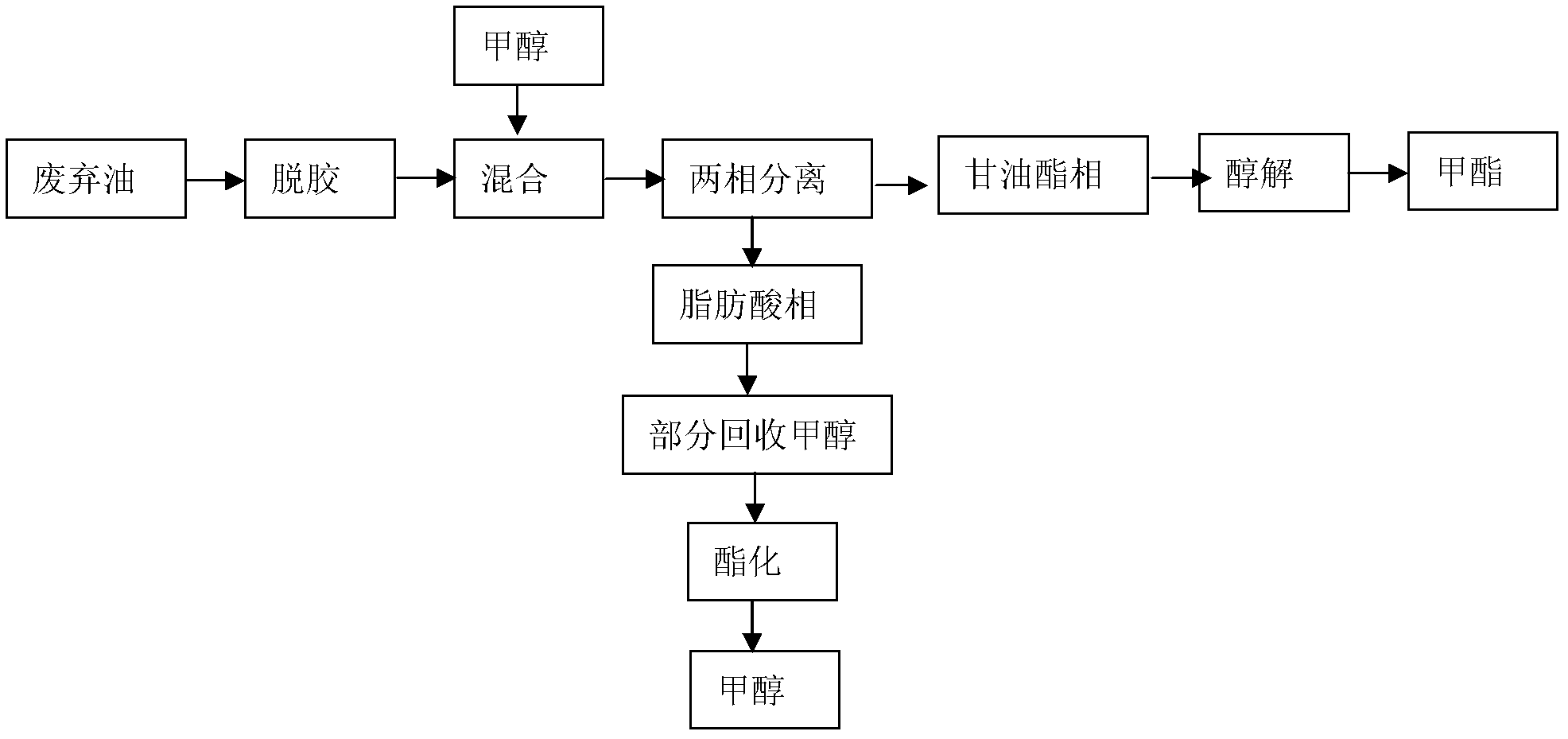

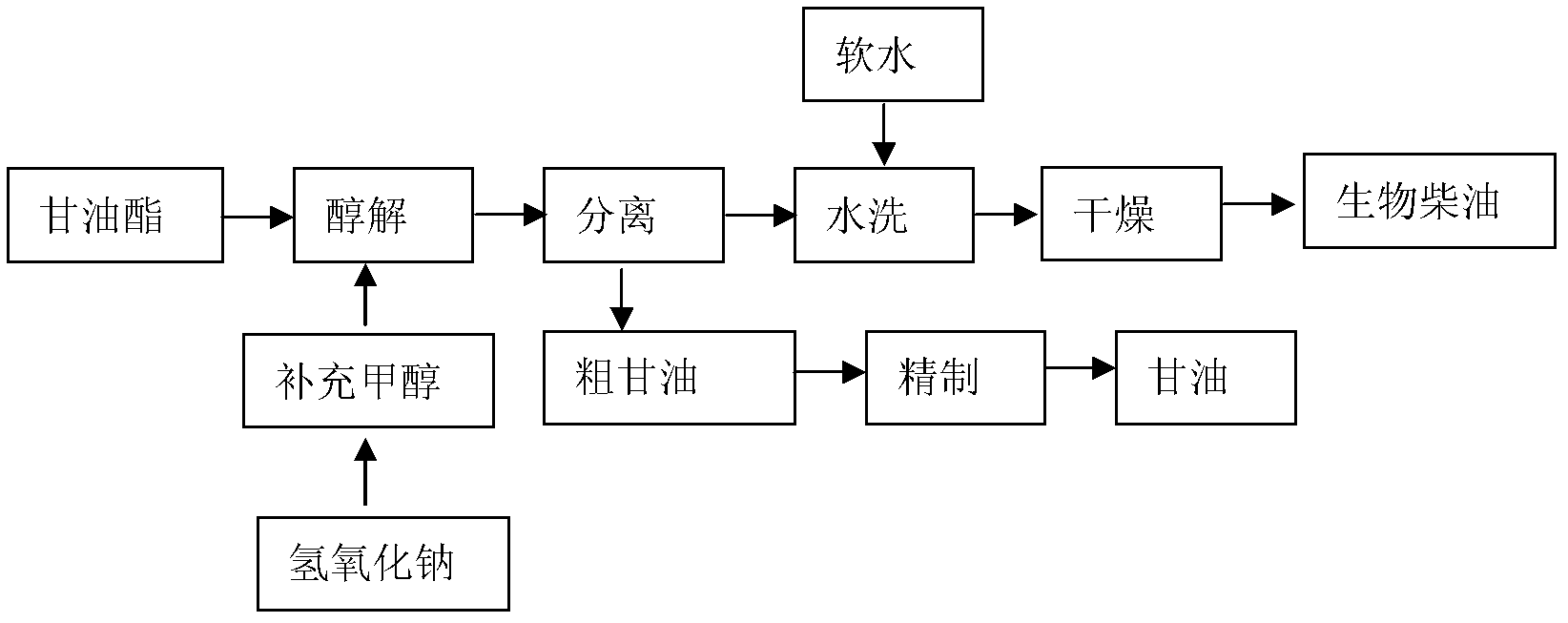

Method for preparing biodiesel by using waste grease split-phase method

ActiveCN102618390BImprove use valueNo pollution in the processFatty acid esterificationBiofuelsSaline waterBiodiesel

The invention provides a method for preparing biodiesel by using a waste grease split-phase method, which comprises the following steps of: firstly, heating waste grease to 80 DEG C; adding concentrated sulfuric acid which accounts for 0.3 percent of the weight of the grease and is 98 percent in concentration and stirring for 20min; then, adding high-salt-hot water which accounts for 5 percent of the weight of the grease and is 2 percent in concentration; stirring for 30min; performing centrifugal separation to obtain degummed waste grease; adding methanol to the degummed waste grease in proportion that the molar ratio of the grease to the methanol is 1:1.5; stirring for 30min at the temperature of 30 DEG C; standing to separate glyceride from fatty acid; adding the methanol to the glyceride in proportion that the molar ratio of the glyceride to the methanol is 1:4.5; meanwhile, adding solid sodium hydroxide which accounts for 0.8 percent of the weight of the glyceride and stirring; reacting for 1h under at the temperature of 70 DEG C; standing to separate a glycerine layer in a reaction mixture; then separating to obtain crude biodiesel, crude glycerine and sodium sulfate; washing, drying and filtering the separated crude biodiesel to prepare the biodiesel; adding the methanol to the fatty acid; then, adding H2SO4 for catalysis, wherein the weight ratio of the fatty acid to the methanol to the H2SO4 is 1:0.45:0.03; performing esterification at the temperature of 60-65 DEG C stage by stage for 30min respectively; performing vacuum dealcoholization and dewatering between the two stages of reaction; and finally cooling and filtering to prepare the biodiesel.

Owner:国粮武汉科学研究设计院有限公司

Anti-oxidation dietary fiber preparation method

InactiveCN106852504AImprove physiological activityMild in natureNatural extract food ingredientsFood ingredient functionsOxidation ActivityChemistry

The invention relates to an anti-oxidation dietary fiber preparation method, which comprises: (1) carrying out extrusion modification treatment on pumpkin dietary fiber, and extracting water-soluble dietary fiber by using a water extraction and alcohol precipitation method; and (2) using a sulfamic acid-N,N-dimethylformamide method to rapidly and efficiently prepare the sulfated pumpkin water-soluble dietary fiber under an ultrasonic wave-assisted condition. According to the present invention, the preparation method has advantages of mild reaction condition, simple operation, low product toxicity and the like, and the prepared sulfated pumpkin water-soluble dietary fiber has a fiber substitution degree of 0.23-0.97, and has good anti-oxidation activity and good anti-tumor activity.

Owner:CHONGQING DOUHAO BIOTECH

Sodium lauryl polyoxyethylene (7) octyl sulfosuccinate and its preparing process

InactiveCN100471552CReduce consumptionIncrease profitTransportation and packagingMixingEtherSodium bisulfite

The invention discloses a lauryl alcohol polyvinyl ether (7) octyl sulfo succinic mixed diester sodium and relative preparation, comprising that processing monoester reaction between maleic anhydride and lauryl alcohol polyvinyl ether (7), and processing diester reaction between the reaction product of monoester reaction and octanol, and processing conjugate addition reaction between the reaction product of diester reaction and sodium bisulfite to obtain final product. The invention has high-quality property and simple process.

Owner:NANTONG UNIVERSITY

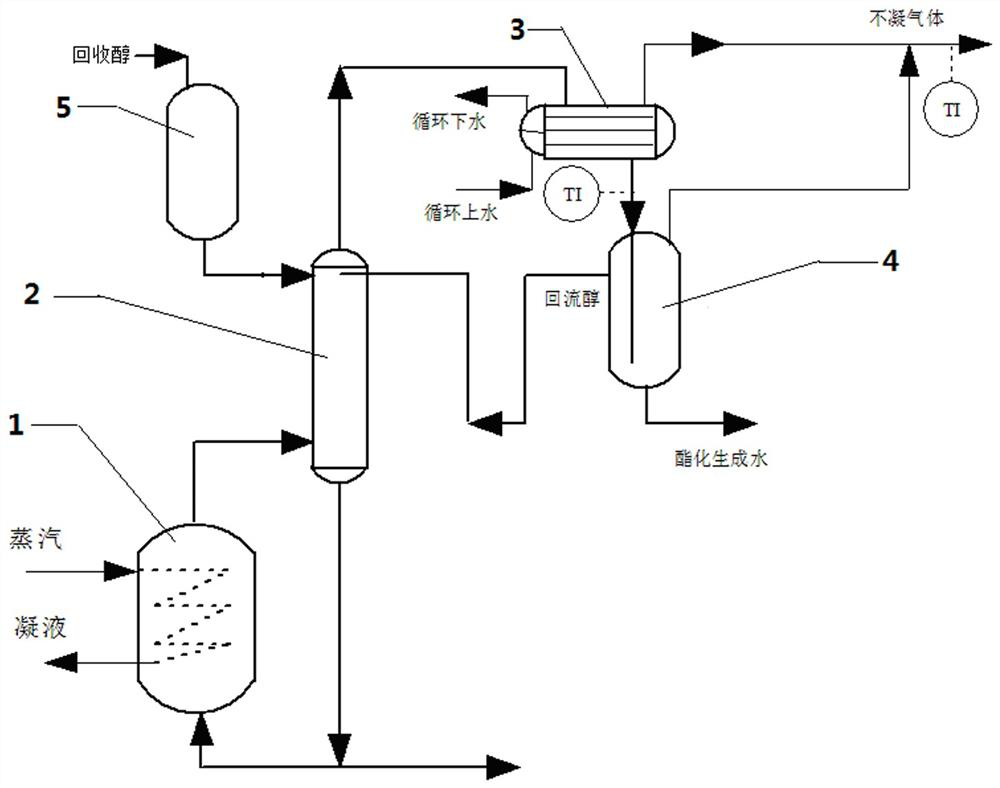

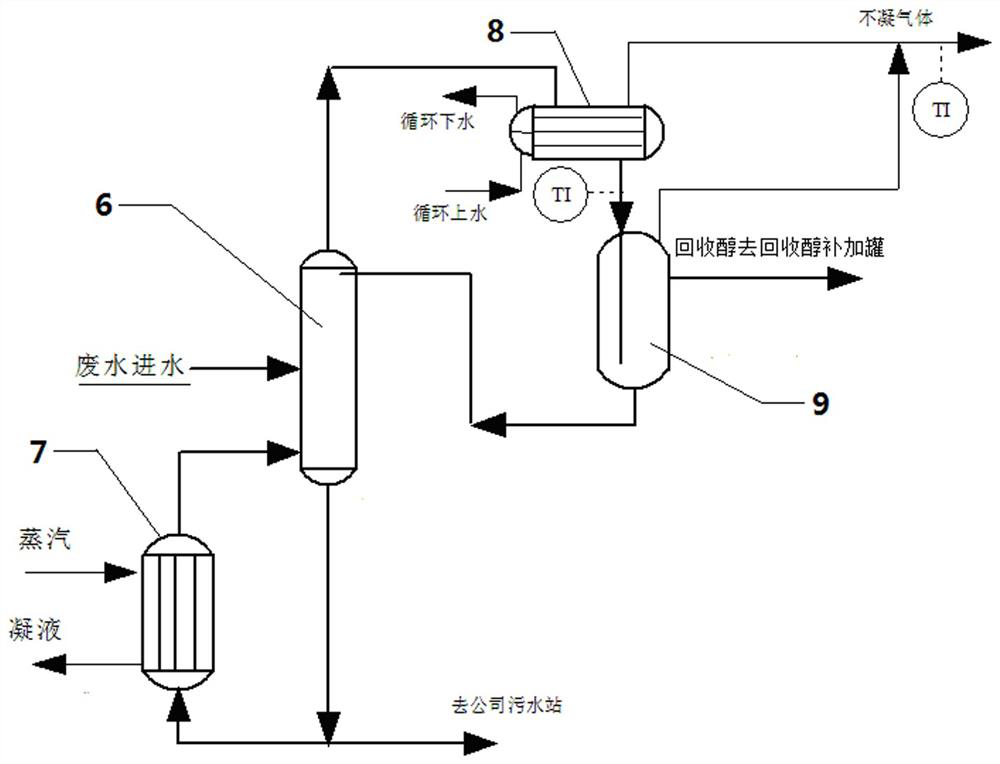

Dibutyl phthalate production process capable of preventing crystallization in esterification kettle

PendingCN111620779AImprove heating efficiencyShorten the esterification timeOrganic compound preparationCarboxylic acid esters separation/purificationEngineeringDibutyl phthalate

The invention discloses a dibutyl phthalate production process capable of preventing crystallization in an esterification kettle. Raw materials are sequentially added into the esterification kettle for heating reaction, steam evaporated from the top of the esterification kettle enters an esterification tower and then enters an alcohol-water separation tank (1) for alcohol-water separation after being condensed by a condenser (1), and separated reflux alcohol is added from the top of the esterification kettle, is in reverse contact with the steam evaporated from the esterification kettle and then flows into the esterification kettle; after completion of esterification reaction, the product is introduced into a neutralization kettle for neutralization; the neutralized wastewater is added from a wastewater tower and then flows into a reboiler to be heated; steam evaporated from the reboiler enters the wastewater tower, is condensed by a condenser (2) and then enters an alcohol-water separation tank (2) for alcohol-water separation, the separated recycled alcohol is introduced into a recycled alcohol supplementing tank, and the recycled alcohol is added from the top of the esterification tower, is in reverse contact with the steam evaporated from the esterification kettle and then flows into the esterification kettle for esterification reaction. According to the production process,crystals in the esterification kettle can be remarkably reduced, and the production efficiency is improved.

Owner:福建春达化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com