Esterification device and method for AA and BDO in PBAT production process

A production process and esterification technology, which is applied in the field of AA and BDO esterification equipment, can solve the problems of limited production capacity of a single kettle-type esterification kettle, high investment cost of PBAT, and high cost of separating BDO, so as to improve the efficiency of esterification , reduce energy consumption, and shorten the esterification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

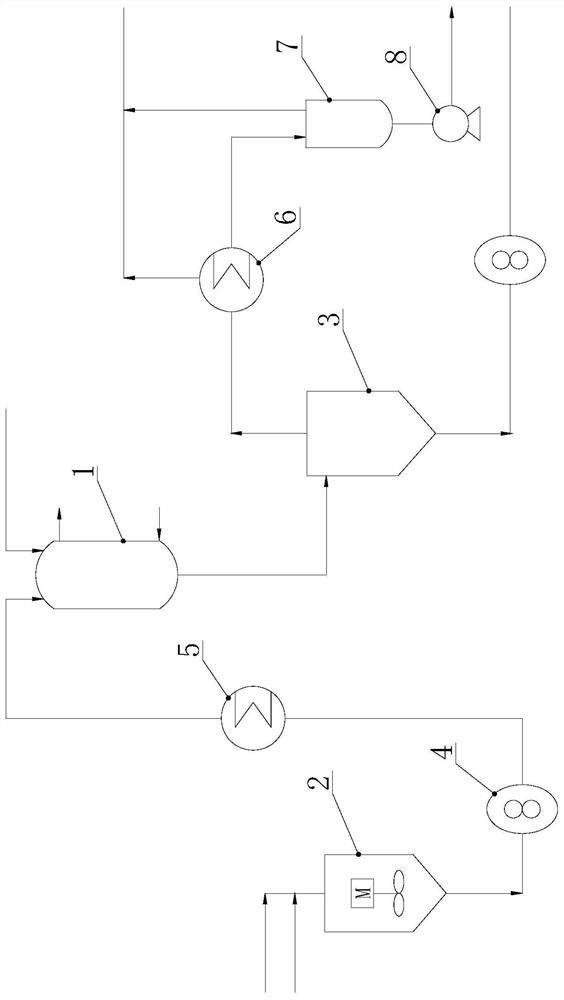

[0042] see figure 1 , is a specific embodiment of the esterification device of AA and BDO in the production process of PBAT. The esterification device of AA and BDO in the production process of PBAT includes a reactor 1, a silo 2, and a vacuum flash tank 3. The silo 2 is formed as a whole by connecting the upper cylindrical section and the lower inverted conical section. The silo is also provided with a coil for heating and keeping warm the AA and BDO in the silo. There is an agitator in the silo. , the feed port of silo 2 is used to connect with AA source and BDO source, wherein AA (adipic acid) is usually a powder, and BDO (1,4-butanediol) is usually an oily liquid. The discharge port of the silo 2 is connected to the material channel inlet of the reactor 1 through the feed pump 4 and the heater 5. Usually, the feed pump adopts a jacketed gear pump, and the heater uses high-temperature heat transfer oil as the heat medium. The outlet of the material channel of the reactor ...

Embodiment 2

[0043] Embodiment 2 produces 300,000 tons / year PBAT

[0044] Adopt the method for the synthetic BSA of the esterification unit of embodiment 1, may further comprise the steps:

[0045] 1) Add BDO (60°C, oily liquid) and AA (30°C, powder) into the silo, stir and mix well, so that the powder AA and the liquid phase BDO are fully mixed to obtain AA / BDO solid-liquid slurry, and control The temperature of the solid-liquid slurry is 40-60°C;

[0046] 2) The AA / BDO solid-liquid slurry is pumped out by the feed pump, and the temperature is raised to 180°C by the heater to obtain the AA / BDO homogeneous slurry, and the catalyst (tetrabutyl titanate, the addition amount is 0.1-0.5kg / t PBAT)

[0047] Enter the material channel of the reactor through the micro-interface generator to carry out esterification reaction. The esterification temperature is 200°C. The time for AA / BDO homogeneous slurry in the material channel is 1h, and BSA and esterification water are discharged from the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com