Spiral type gas-solid separation device

A gas-solid separation, spiral technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high flight direction requirements, limited gas-solid separation efficiency, large airflow pressure loss, etc. Complete solid separation, low cost and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

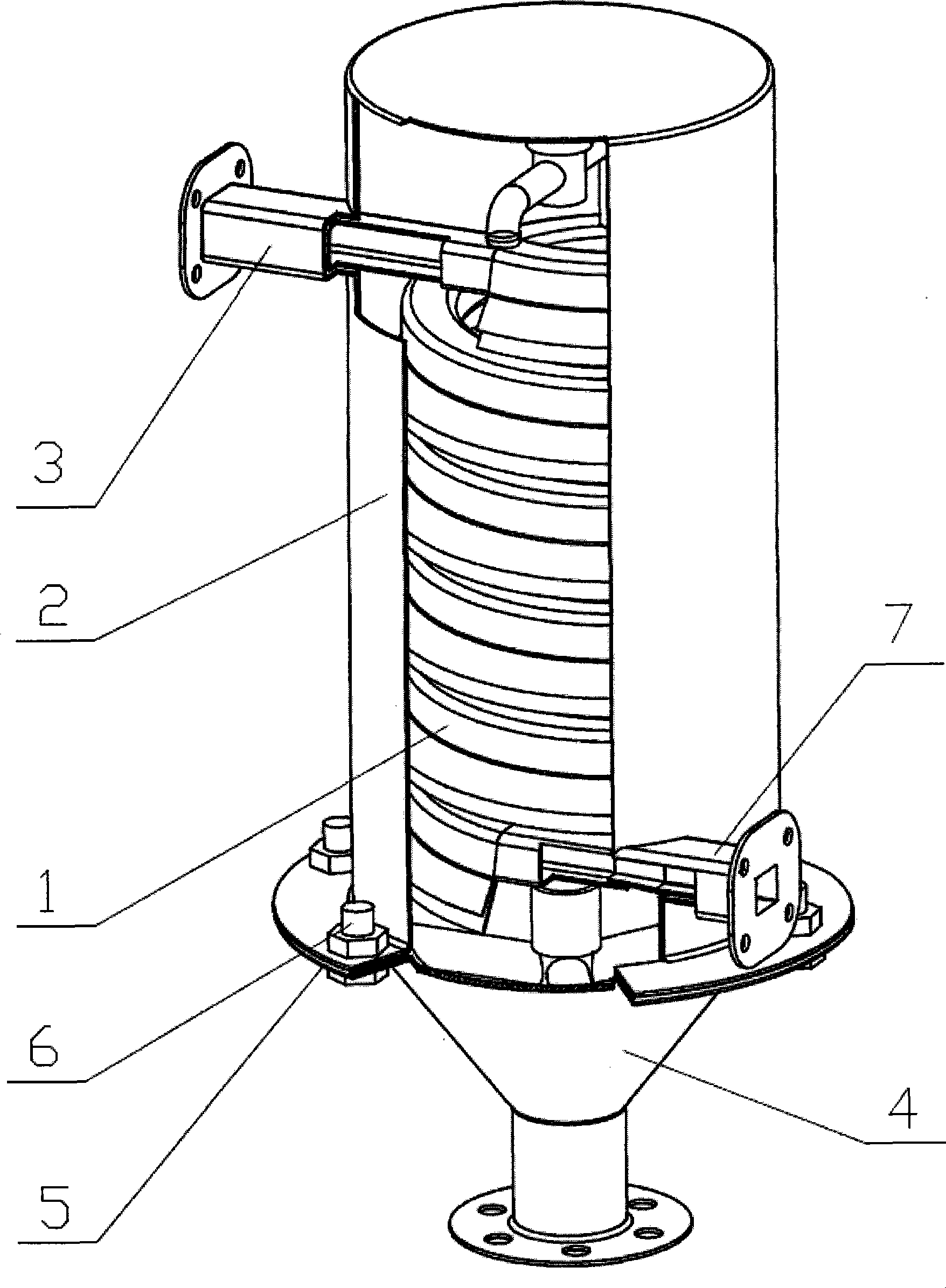

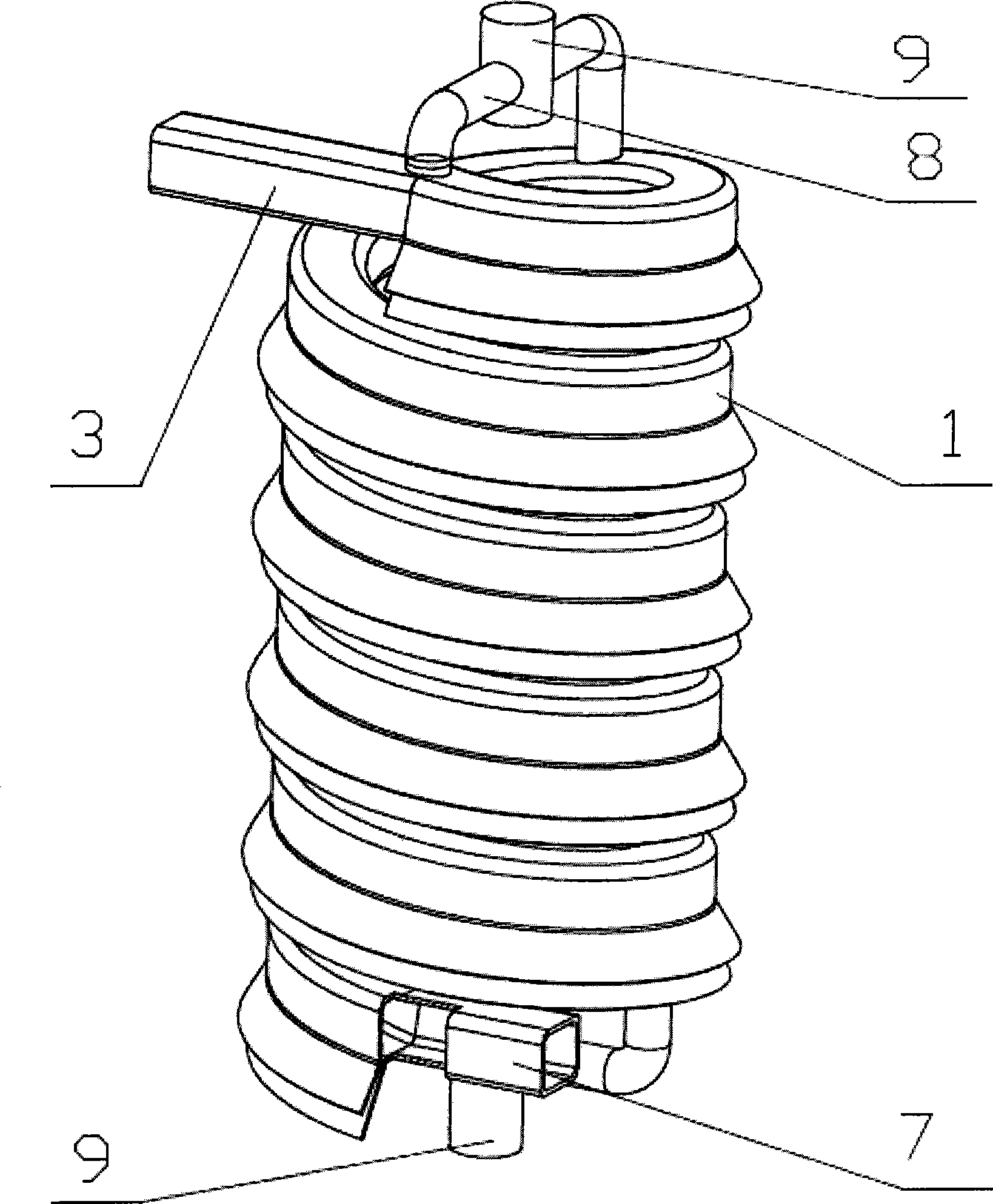

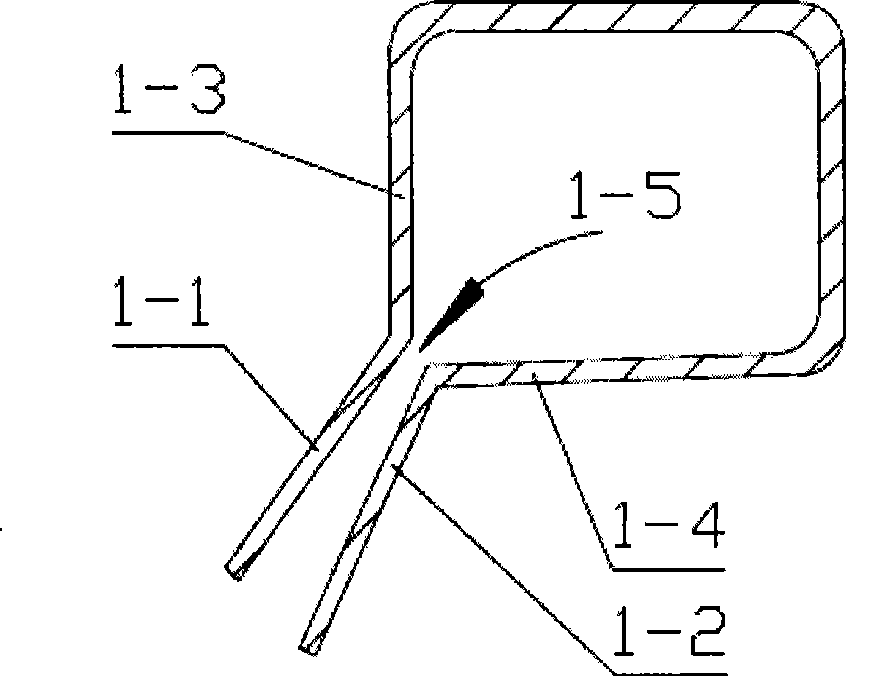

[0020] like figure 1 As shown, the bell mouth of the conical dust collector 4 is connected with the cylindrical sealing cover 2 by the bolt 6, and the spiral air flow channel 1 is coaxially arranged in the cover, and the air flow inlet 7 and the outlet 3 of the channel are connected by the cylindrical sealing cover 2 respectively. The lower and upper side walls protrude. The bolts 6 pass through the bell mouth of the conical dust collector 4 and the flanges 5 at the bottom of the cylindrical sealing cover 2 respectively, and a gasket is arranged between the two flanges 5 . The intersection of the outer wall 1-3 of the spiral air flow passage 1 and the lower wall 1-4 is provided with a slit 1-5, and the outer wall 1-3 and the lower wall 1-4 of the spiral air flow passage 1 on both sides of the slit 1-5 respectively face The oblique downward extension of the side wall of the cylindrical sealing cover 2 forms an upper skirt 1-1 and a lower skirt 1-2 (see image 3 ).

[0021] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com