Internal circulation anaerobic reactor

An anaerobic reactor and internal circulation technology, which is applied in the field of water treatment, can solve the problems of affecting gas production, water outlet, gas outlet, poor solid-liquid separation in the sedimentation area, etc., to improve impact resistance and reduce sludge loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

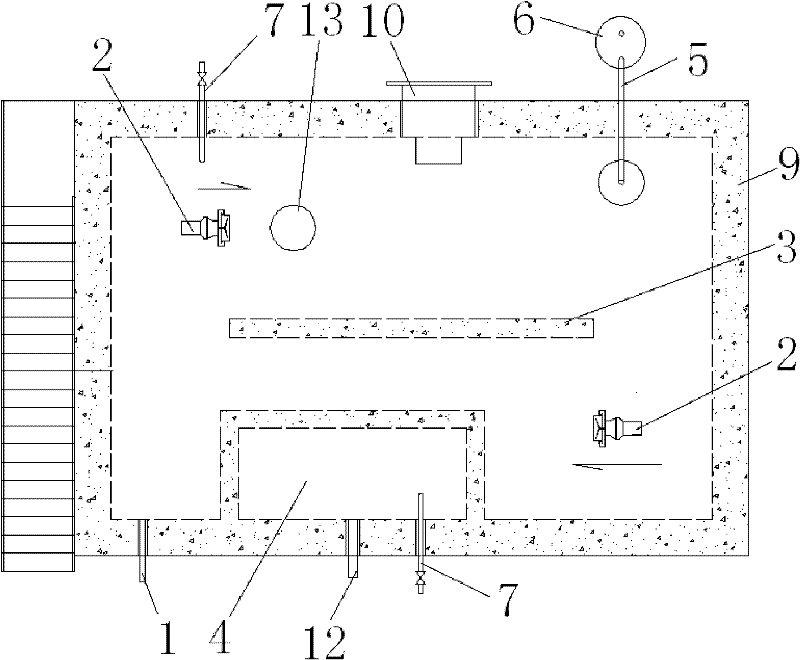

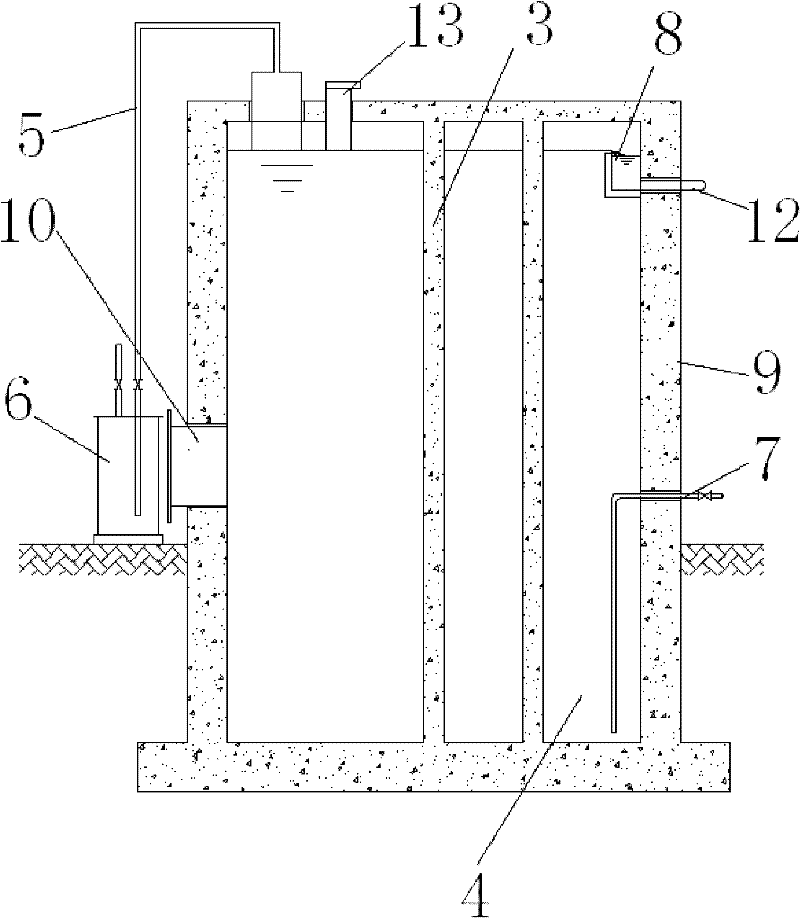

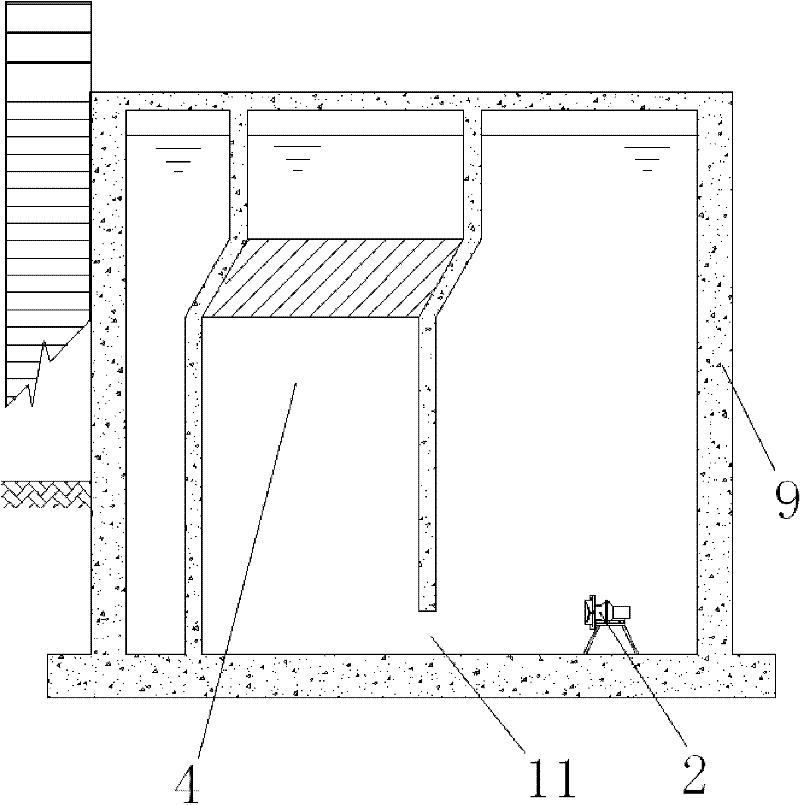

[0026] Such as Figure 1 ~ Figure 3 An internal circulation anaerobic reactor is shown, which includes a pool body 9, a biogas collection pipe 5 connected to the pool body 9, and a water seal tank 6. The internal circulation anaerobic reactor also includes a water inlet pipe 1 and a slanted plate sedimentation tank 4. The middle part of the pool body 9 is provided with a partition wall 3, and the two opposite corners of the pool body 9 are respectively equipped with submersible propellers 2 that push the mixed water in the pool to flow around the partition wall 3, and the inclined plate sedimentation tank 4 is arranged on the pool body 9 On the inner side, the lower end of the inclined plate sedimentation tank 4 is provided with an opening 11 communicating with the inclined plate sedimentation tank 4 and the tank body 9 . The inclined plate settling tank 4 is a closed type, and only the opening 11 is left. The submersible thruster 2 pushes the mixed water body mixed with mudd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com