Atomization air purifier

A technology for atomizing air and air purification, applied in chemical instruments and methods, using liquid separation agents, separation devices, etc., can solve the problems of high price, complicated installation, air pollution, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

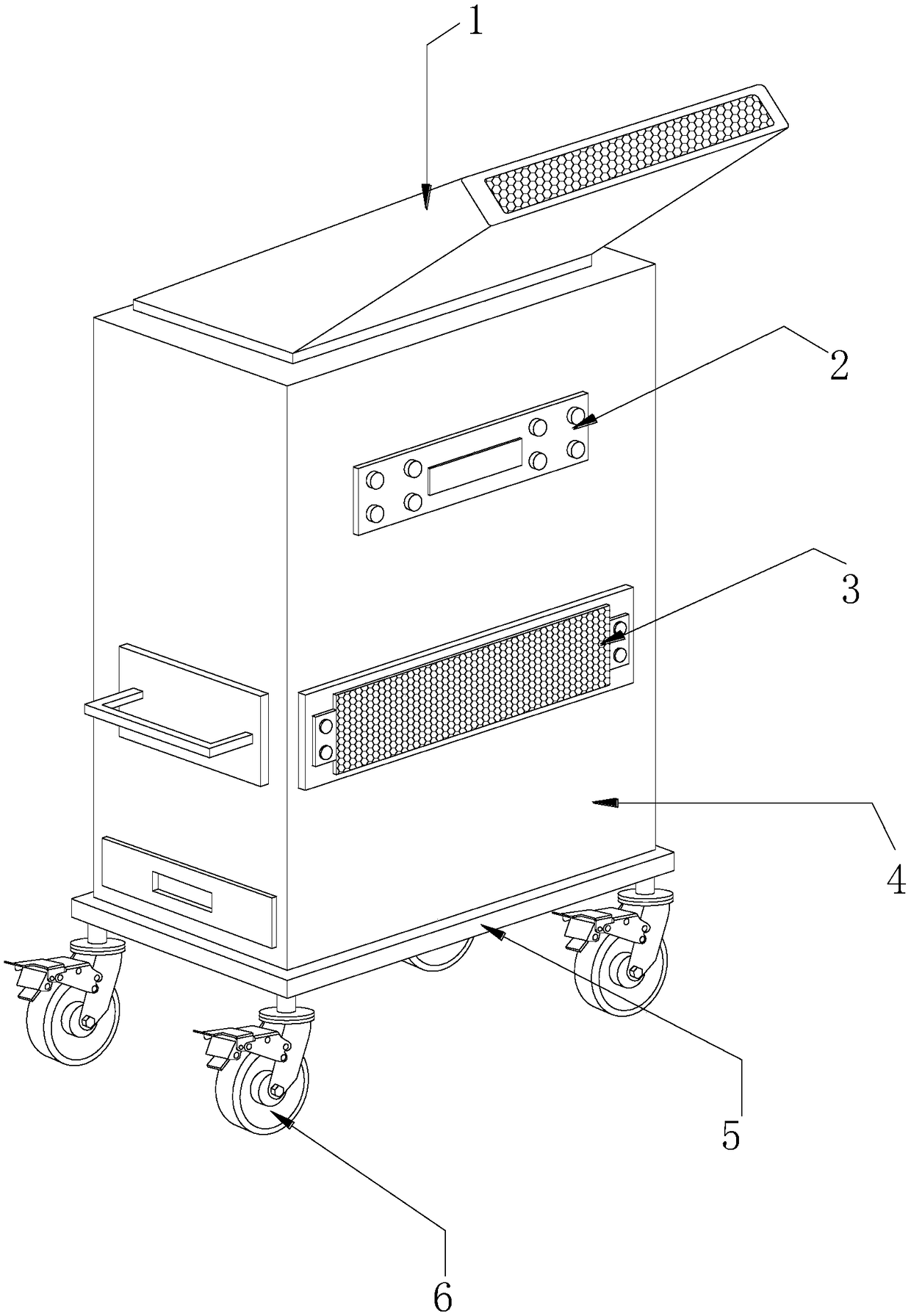

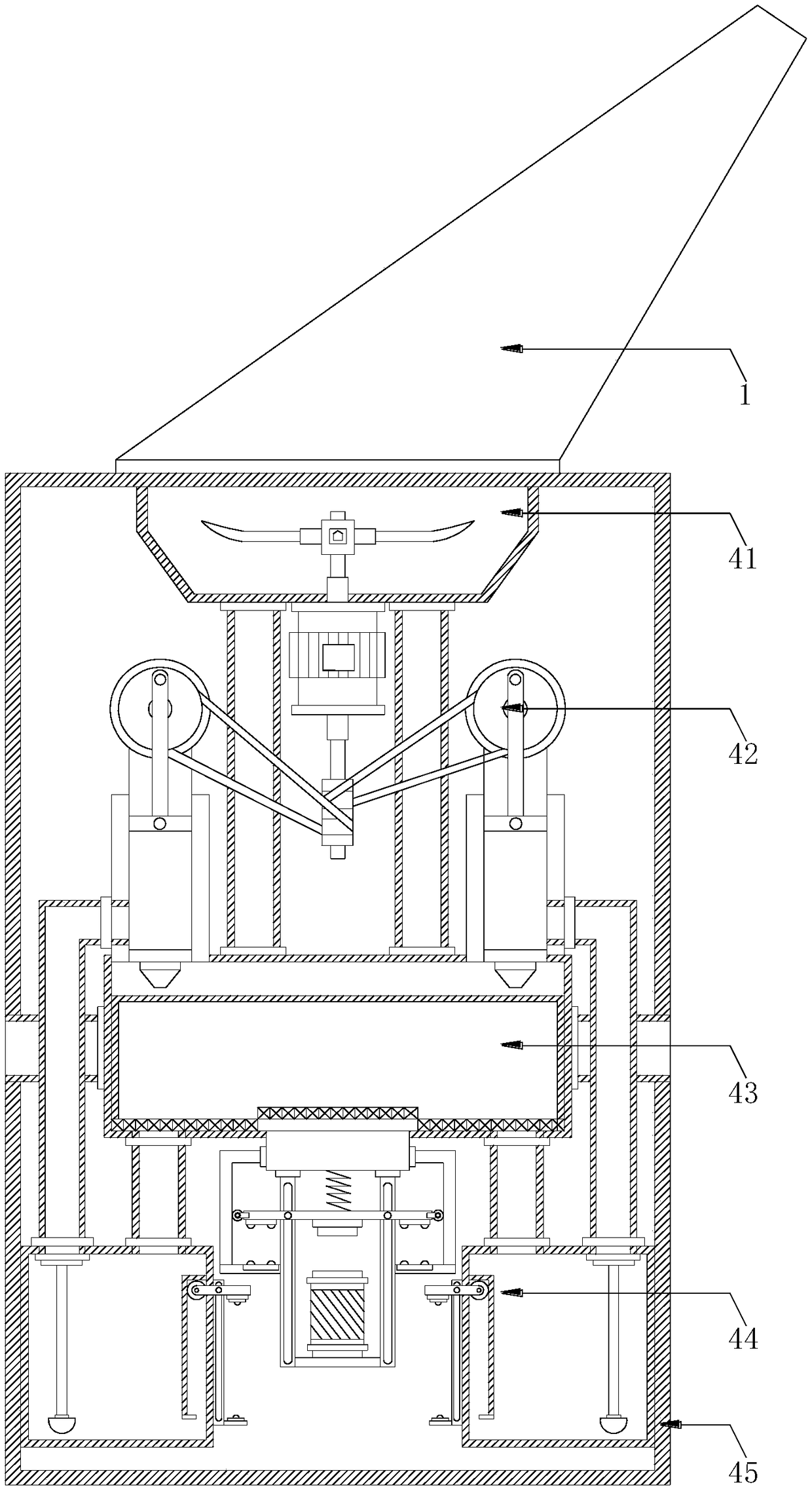

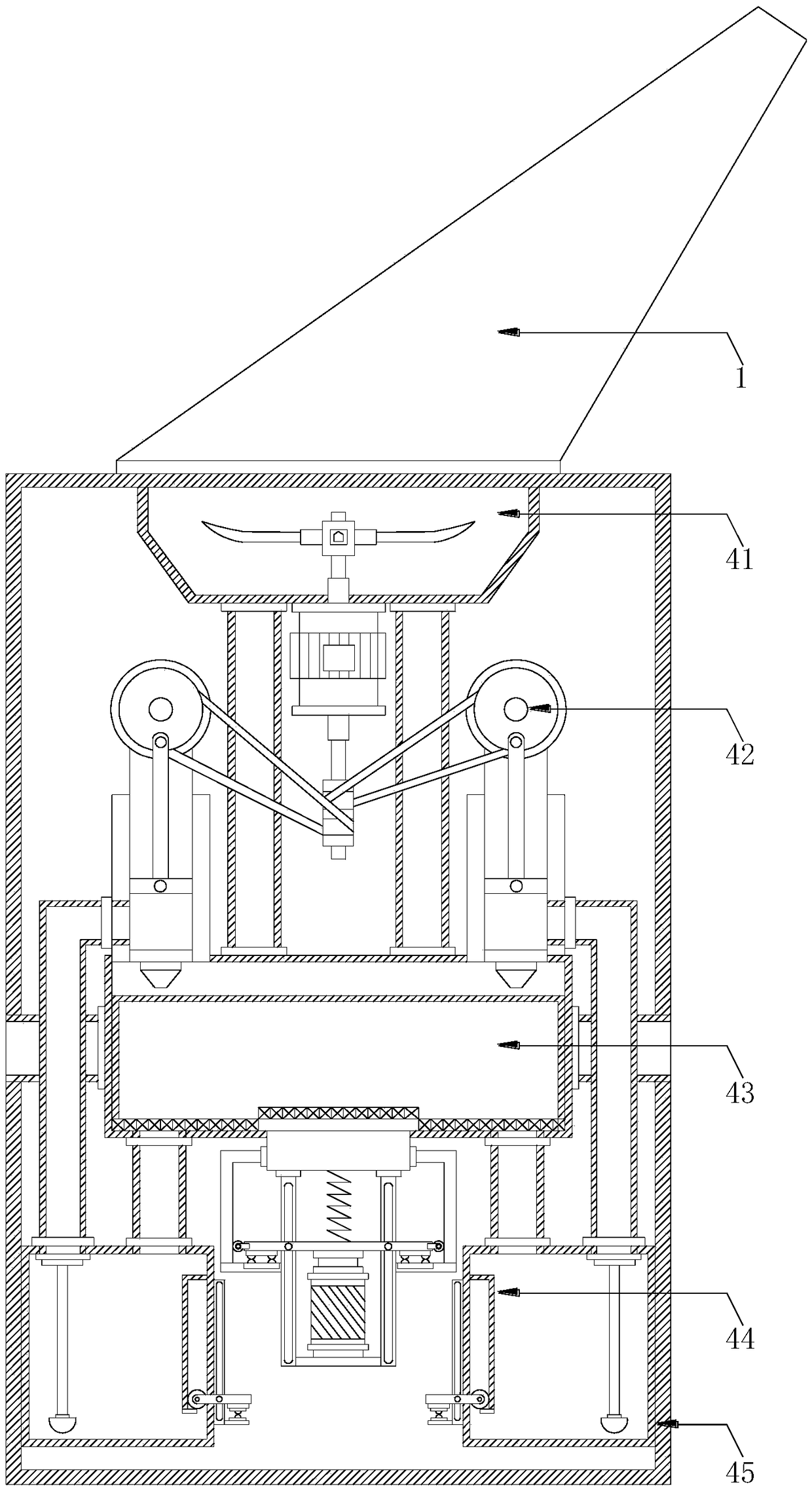

[0024] see Figure 1-Figure 5 , the present invention provides an atomizing air purifier, the structure of which includes an air intake duct 1, a control panel 2, an air outlet filter water screen cover 3, an atomizing air purification device 4, a bottom frame 5, and swivel casters 6. The bottom Four swivel casters 6 are evenly spaced at the bottom of the frame 5, and the swivel casters 6 are screwed to the bottom frame 5, and the top of the bottom frame 5 is provided with an atomizing air purification device 4 and the two are interlocked. , the front and rear ends of the atomized air purification device 4 are provided with an air outlet water filter screen cover 3, and the described air outlet water filter screen cover 3 is fixed on the surface of the atomization air purification device 4 by screws, and the described The top of the atomizing air purification device 4 is provided with an air intake duct 1 and the two adopt an interference fit. A control panel 2 is provided bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com