Catalyst and preparation method for preparing biodiesel and preparation process of biodiesel

A technology of biodiesel and preparation process, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, biofuels, etc., which can solve the unfavorable biodiesel market competitiveness, increase the difficulty and cost of equipment manufacturing, increase the production cost of biodiesel, etc. problems, to achieve the effect of reducing equipment manufacturing cost and operation difficulty, saving equipment manufacturing cost, and improving price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

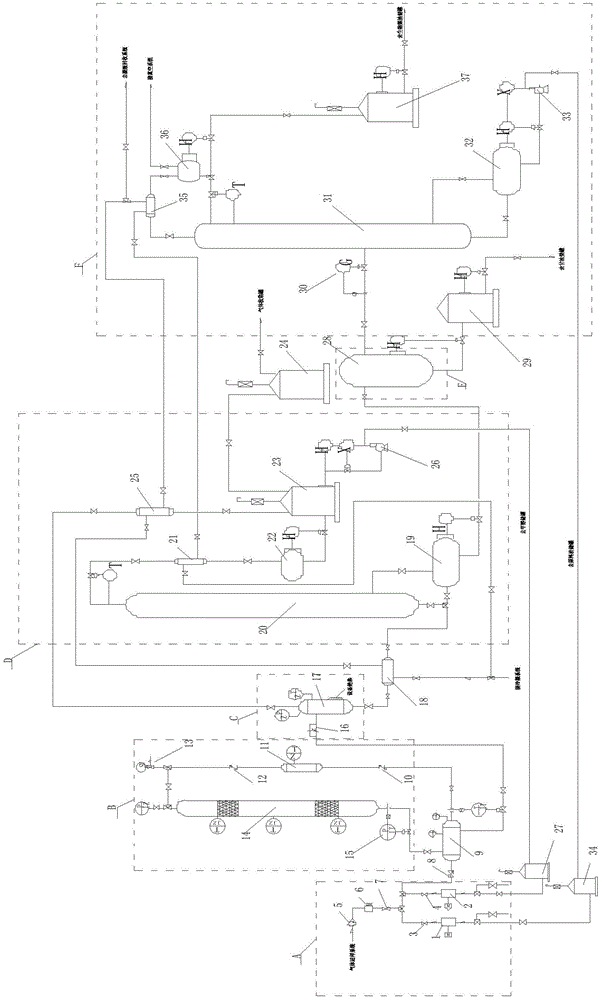

[0040] like figure 1 A biodiesel preparation device shown includes a sampling system A, a reaction system B, a methanol flash system C, a methanol recovery system D, a glycerin separation system E, a fatty acid methyl ester rectification system F and related control systems;

[0041] Sampling system A: includes gas sampling pipeline and liquid sampling pipeline, and the liquid sampling pipeline is divided into oil raw material sampling pipeline and reaction low-carbon alcohol sampling pipeline. The liquid sampling pipeline is connected to the high-pressure metering pumps 1 and 2 through pipelines, and the gas sampling pipeline controls the flow through the rotameter 5 and the electromagnetic flowmeter 6 . And a heat exchanger 9 is set between the sampling system and the reaction system, and is connected to the preheater 11 in the reaction system B through a pipeline to recover heat from the hot material at the lower end of the reactor for heating the upper end of the reactor. ...

Embodiment 1

[0063] Adopt the preparation device of above-mentioned biodiesel and corresponding preparation method to carry out following operations:

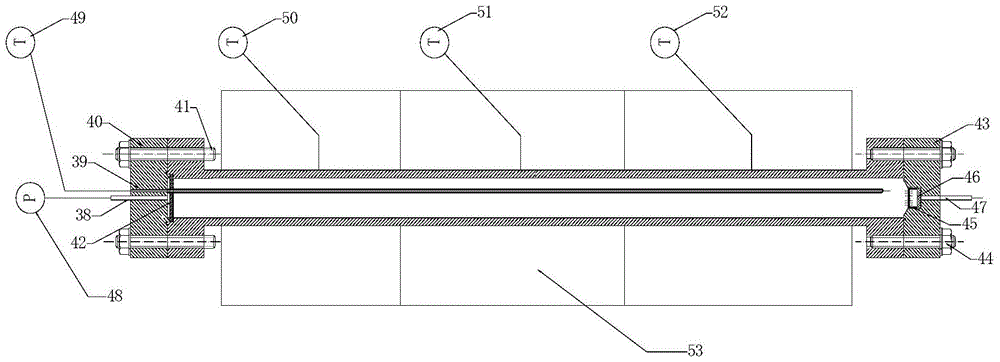

[0064] 1. Press ZrO 2 88.47%, Al 2 o 3 8.22%, TiO 2 3.31% weight ratio weighs ZrO 2 、Al 2 o 3 、TiO 2 powder, put it into a ball mill for 24 hours, add appropriate amount of NaCl, NaHCO 3 Mix the powder and silica sol thoroughly, granulate and shape, dry at 120°C for 12 hours, transfer to a muffle furnace for roasting, heat at 500°C for 1 hour, heat up to 1550°C, hold for 2 hours, and cool to obtain a solid catalyst. The prepared solid catalyst is loaded into the tubular reactor.

[0065] 2. Pump low-carbon alcohol and vegetable oil into the preheater according to the volume ratio of 1:1 through a high-pressure metering pump, preheat to 200°C, and the preheated material enters a static mixer and mixes thoroughly. The vegetable oil is glabra Oil, low carbon alcohol is methanol.

[0066] 3. The mixed material enters the constant t...

Embodiment 2

[0070] Adopt the preparation device of above-mentioned biodiesel and corresponding preparation method to carry out following operations:

[0071] 1. Press ZrO 2 85.38%, Al 2 o 3 9.72% and TiO 2 2.68% weighed ZrO 2 、Al 2 o 3 、TiO 2 Powder, after ball milling for 36 hours, add appropriate amount of NaCl, NaHCO 3 Mix the powder and silica sol thoroughly, granulate and shape, dry at 105°C for 24 hours, transfer to a muffle furnace for roasting, heat at 500°C for 2 hours, heat up to 1800°C, hold for 4 hours, and cool to obtain a solid catalyst. The prepared solid catalyst is loaded into the tubular reactor.

[0072] 2. Pump low-carbon alcohol and vegetable oil into the preheater according to the volume ratio of 5:1 through a high-pressure metering pump, preheat to 230 ° C, and the preheated material enters a static mixer and mixes thoroughly. The vegetable oil is glabra oil , the low carbon alcohol is methanol.

[0073] 3. The mixed material enters the constant temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com