Patents

Literature

70results about How to "Improve the efficiency of esterification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing bio- diesel oil by two-step catalysis of acid-containing fat

ActiveCN1840612ANo emissionsImprove the efficiency of esterificationBiofuelsLiquid hydrocarbon mixture productionFertilizerPollutant

The provided preparation method for bio-diesel by two-stage catalysis comprises: mixing acid-contained grease, methanol and H2SO4 as 100:15-50:0.5-2 to react in reactor at 40-80Deg; adding BaCO3 to remove residual H2SO4 by filtering solid; with NaOH or KOH as catalyst, adding methanol for further esterification; keeping static for layering with top as coarse product for rectifying to obtain the target and bottom as mixture of glycerine and methyl. This invention has high conversion ratio and no waste release.

Owner:TSINGHUA UNIV

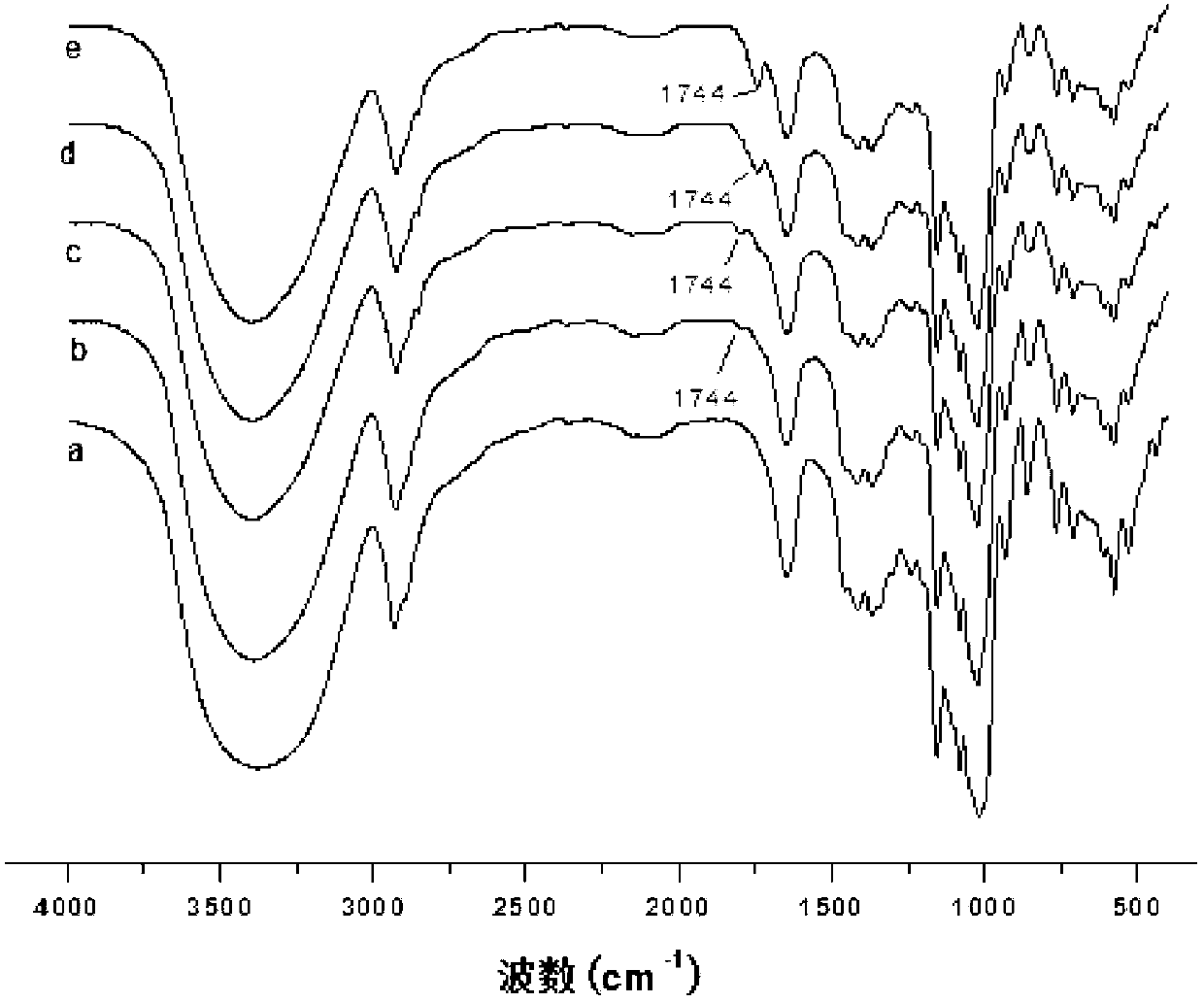

Green preparation method for hydrophobic fatty acid ester of starch (FES)

InactiveCN102732582ACreate pollutionEffective dissolutionFermentationTetrafluoroborateFatty acid methyl ester

The invention discloses a green preparation method for hydrophobic FES. The method comprises the following steps: adding the raw material of dried starch into mixed ionic liquid of 1-butyl-3-methylimidazole acetate and 1-butyl-3-methylimidazole tetrafluoroborate, and carrying out heating and stirring at a constant temperature under a nitrogen atmosphere; cooling an obtained solution, adding lipase and fatty acid methyl ester, wherein the usage amount of lipase accounts for 3 to 15% of the mass of the dry basis of starch and a mol ratio of fatty acid methyl ester to starch is 1:1 to 1: 5, and allowing the solution, lipase and fatty acid methyl ester to undergo a reaction at a temperature of 50 to 80 DEG C for 1 to 5 h; and after the reaction is finished, adding anhydrous ethanol for rinsing and centrifugation after the solution is cooled, removing supernatant, and drying an obtained precipitate at a temperature of 35 to 50 DEG C for 40 to 48 h so as to obtain FES disclosed in the invention. The product of FES has good thermoplasticity, hydrophobicity and biodegradability and has an application value in a wide variety of industries like microcapsule wall materials, biodegradable materials and foodstuffs.

Owner:SOUTH CHINA UNIV OF TECH

Metal-modified cation exchange resin catalyst, preparation method and application thereof

ActiveCN102909077ALow costNo equipment corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemistryN-Butyl acetate

The invention discloses a metal-modified cation exchange resin catalyst, a preparation method and an application thereof. The catalyst employs a cation exchange resin as a matrix and comprises a first metal element modifier selected one or more from Fe, Al and Zn and a second metal element modifier selected one or more from Si, Ni and Pd. The preparation method of the catalyst comprises the steps of loading the first metal element modifier on the cation exchange resin; drying and loading the second metal element modifier on the cation exchange resin. The catalyst is applied in a reaction process for synthesizing sec-butyl acetate, solves the problems that a conventional catalyst for synthesizing sec-butyl acetate erodes equipment, and has high cost and low esterification efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified ion exchange resin catalyst and its application

InactiveCN1887424AHigh activityImprove the efficiency of esterificationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholHydrogen

The present invention relates to modified ion exchange resin catalyst, and is especially one kind of tin dichloride modified cation exchange resin catalyst and its application as ammonium lactate esterifying catalyst. The tin dichloride modified cation exchange resin catalyst is prepared through the following steps: 1. drying hydrogen type strong acid cation exchange resin to constant weight; 2. reaction of the dried hydrogen type strong acid cation exchange resin and tin dichloride inside alcohol solution; and 3. washing the modified resin with anhydrous ethanol for several times, drying in a vacuum drier to eliminate ethanol and obtain the modified cation exchange resin catalyst. The catalyst has high esterification yield and no corrosion to the production apparatus.

Owner:HARBIN INST OF TECH

Method for preparing biomass polyester

The invention discloses a method for preparing biomass polyester, which comprises the following steps of: preparing slurry from terephthalic acid and biomass mixed with polyatomic alcohol according to a molar ratio of 1:1.05 to 1:1.5; then adding the prepared slurry into an esterification reaction kettle to perform the esterification reaction; and finally, performing the condensation polymerization to obtain the biomass polyester, wherein the biomass mixed with the polyatomic alcohol comprises the following components in percentage by weight: 90 to 99.2 percent of ethylene glycol, 0.4 to 5 percent of 1,2-propylene glycol, 0.2 to 2 percent of 1,2-butanediol, 0.1 to 2 percent of pentylene glycol and 0.1 to 1 weight percent of sorbierite. According to the invention, the biomass mixed with the polyatomic alcohol used as a raw material is prepared by a biological fermenting and extracting process and replaces petroleum base ethylene glycol prepared by a conventional method, so that the petroleum using amount and the amount of carbon dioxide discharged outward in the smelting process can be reduced and the phenomenon of shortage of petroleum in China can also be relieved. According to the invention, the design method is reasonable, the energy consumption is reduced, the industrial production is easy to implement and the production cost is reduced.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

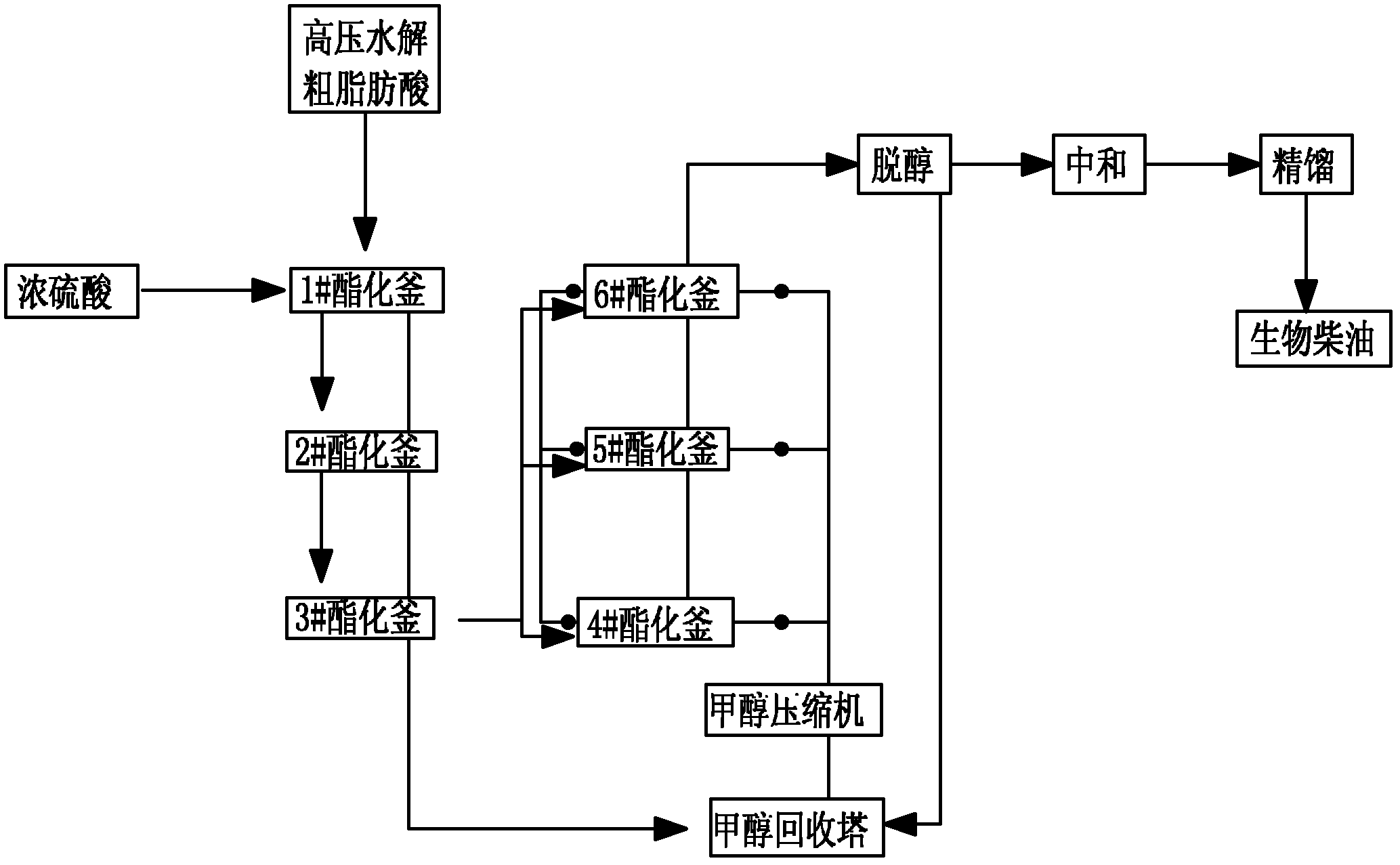

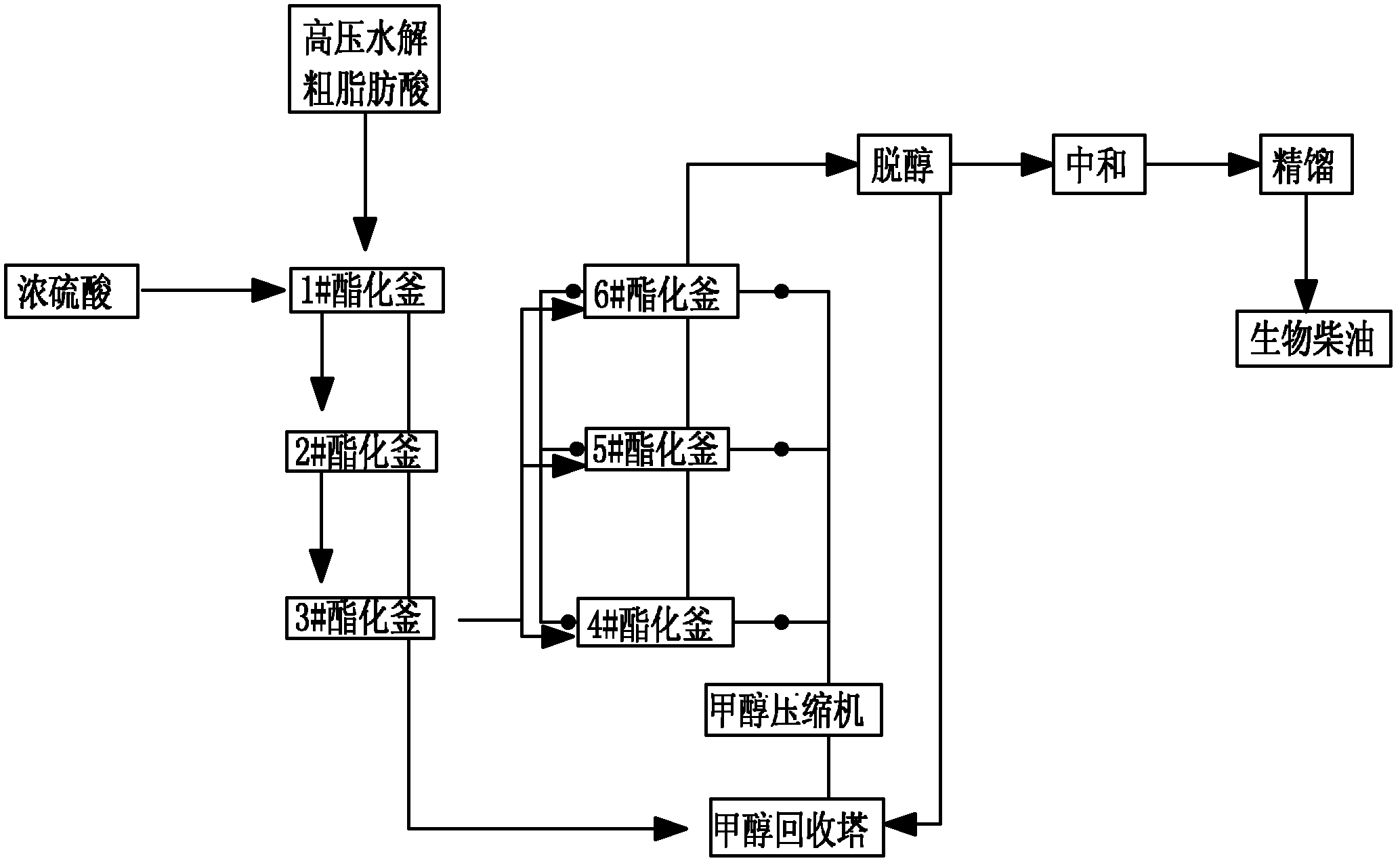

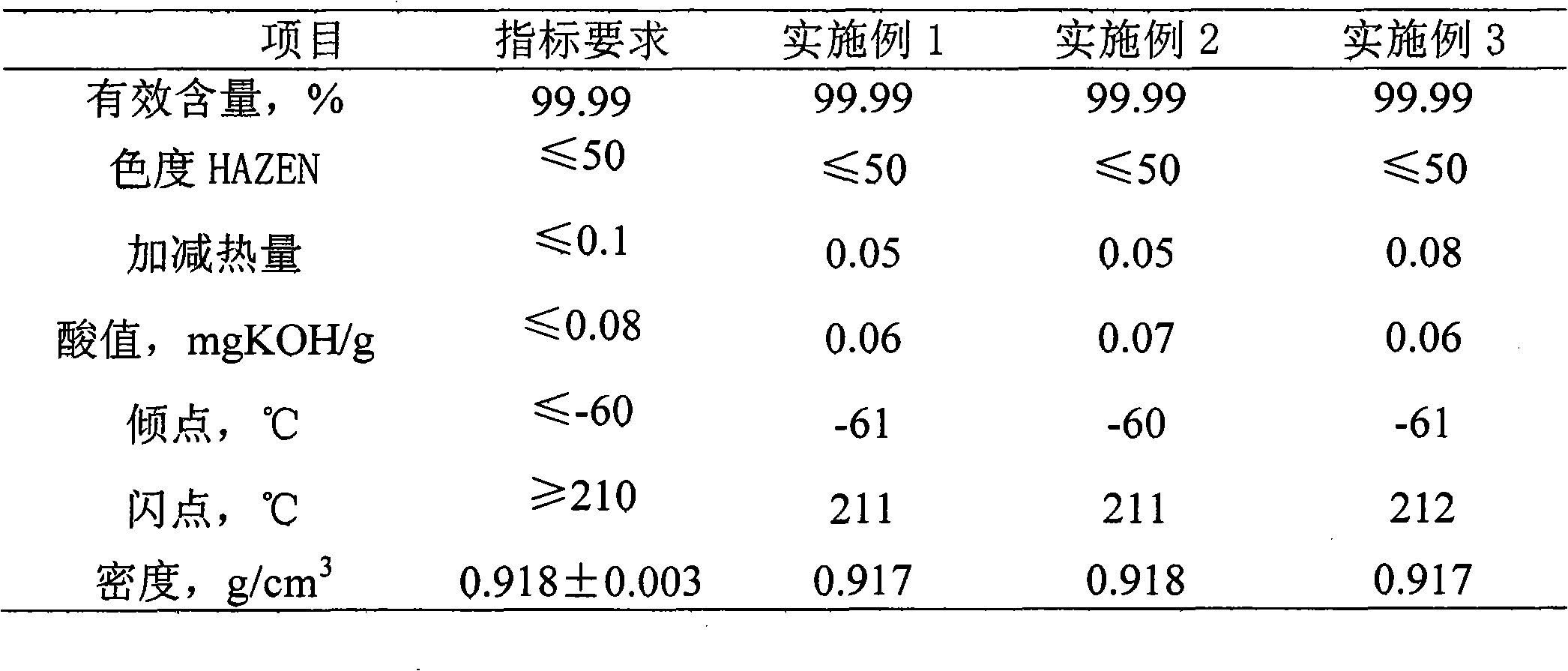

Continuous production method of biodiesel from waste oil/fat

InactiveCN102586027ARealize continuous operationIncrease profitFatty acid chemical modificationFatty acids production/refiningOil and greaseBiodiesel

The invention discloses a continuous production method of biodiesel from waste oil / fat. The method includes mixing waste oil / fat with water at volume ratio of (3-4):1, and hydrolyzing; naturally settling obtained crude fatty acid for 0.5-1.5 hr to remove water and impurities and collect dewatered fatty acid; injecting the dewatered fatty acid and concentrated sulfuric acid into esterification kettle, introducing compressed methanol gas, stepwise esterifying, and alternately removing alcohol after esterification to give crude ester; neutralizing the crude ester with sodium carbonate under stirring; and performing multi-stage distillation to give biodiesel. The method obviates mechanical vacuum distillation for water removal, reduces occurrence of reverse reaction, reduces investment of cooling equipment, improves utilization efficiency, lowers labor intensity, guarantees safe and stable production, and reduces sewage generation.

Owner:潍坊大明生物科技有限公司

Esterification accelerant and method for preparing esterifying liquid by using same

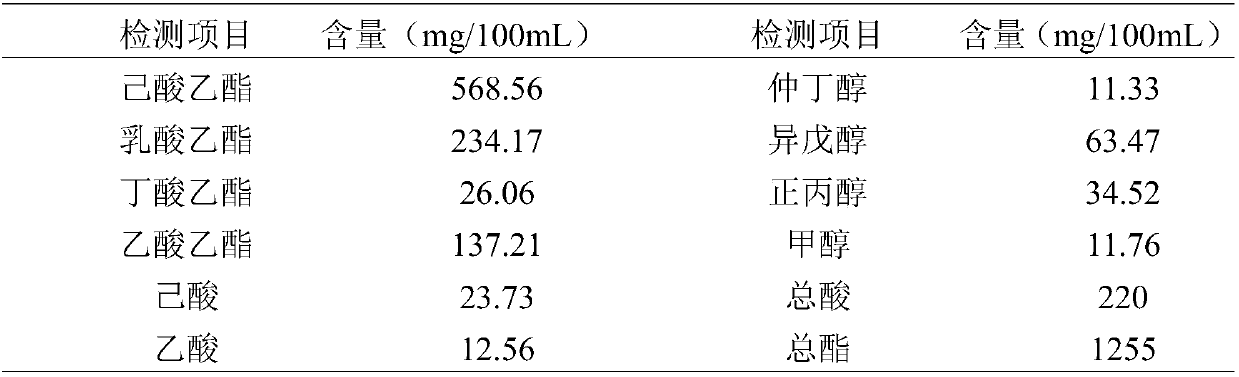

InactiveCN101962607ASignificantly progressiveSolve the problem of hexanoylation inhibitionAlcoholic beverage preparationOrganic acidIsobutyl alcohol

The invention relates to an esterification accelerant consisting of alcohol substances and a method for preparing high-titer esterifying liquid by using the same. The esterification accelerant is one or more selected from n-propanol, isobutyl alcohol, butanol, hexanol and beta phenethanol. After the esterification accelerant of the invention is added during the preparation of the biological esterifying liquid, high-efficiency biological esterification synthesis can be performed on organic acids, such as caproic acid and the like, and simple raw materials, such as foreshot, feint and the like, so as to obtain flavor components, such as ethyl caproate and the like; and the accelerant and the method also have an obvious effect on the synthesis efficiency of esters in a kiln.

Owner:HUBEI UNIV OF TECH

Method for catalyzing synthesizing diisooctyl azelate through load type heteropolyacid

InactiveCN102826998ANo pollutionAvoid pollutionOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholDistillation

The invention discloses a preparation method for producing diisooctyl azelate with load type heteropolyacid served as a catalyst, which is simple in technology, low in cost, and environment-friendly, and has good product quality. The technical scheme is that the method comprises the steps as follows: getting azelaic acid and isooctyl alcohol as the raw materials under the protection of high-purity nitrogen; getting the load type heteropolyacid as a catalyst; carrying out an esterification reaction at a certain temperature, so as to obtain a rough diisooctyl azelate product; processing the rough product by filtering and molecular distillation, and refining, thus obtaining the finished product of the diisooctyl azelate. The method disclosed by the invention is simple in technology, has a mild reaction temperature, good quality of the product, and has no pollution to the environment, and meanwhile, the yield of the product is up to 96%.

Owner:SICHUAN SIPO CHEMICAL CO LTD

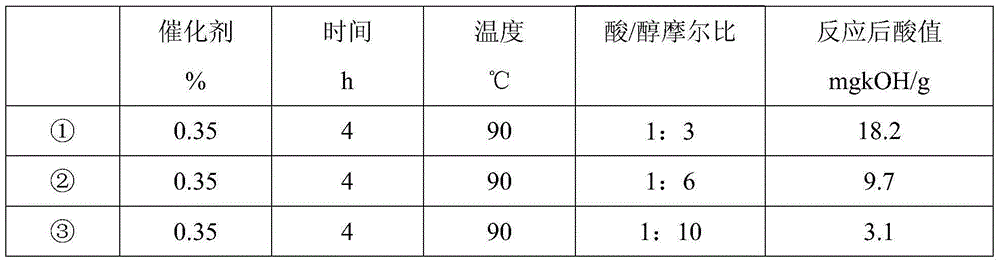

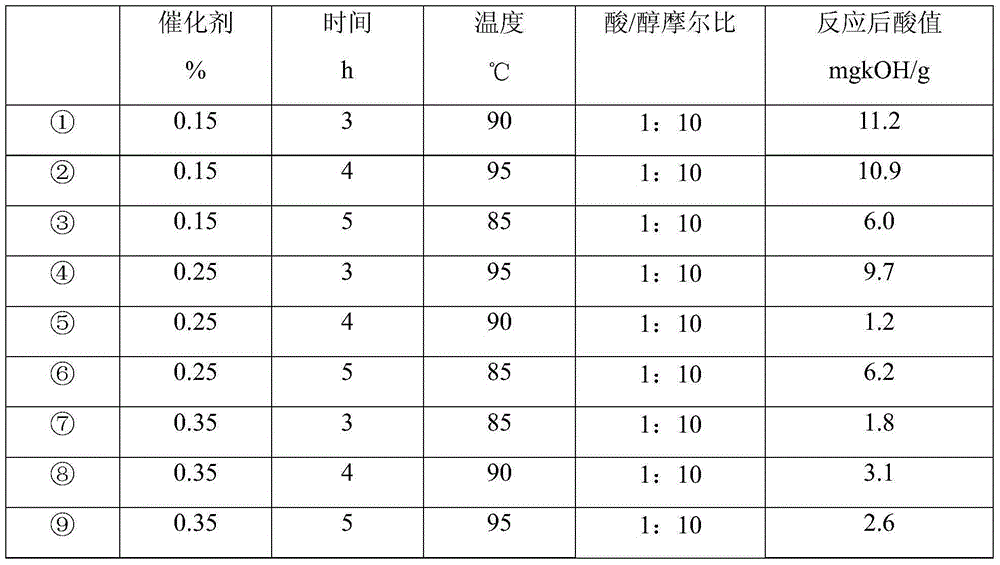

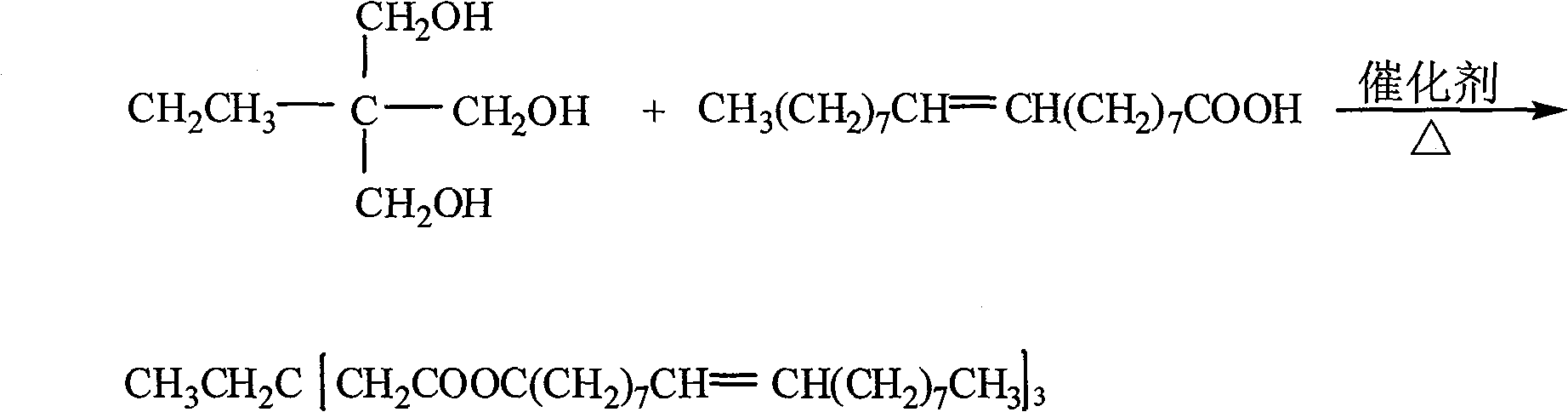

Synthetic method of isopropyl fatty acid ester and application of isopropyl fatty acid ester to special oil

ActiveCN105218364ALow costImprove the efficiency of esterificationOrganic compound preparationCarboxylic acid esters preparationOrganic acidFatty acid ester

The invention discloses a synthetic method of isopropyl fatty acid ester and application of the isopropyl fatty acid ester to special oil. The synthetic method is characterized in that organic acid and isopropanol are used as raw materials and react for 3 to 5 hours at 85 DEG C to 95 DEG C and ordinary pressure under the catalytic action of a catalyst, so as to obtain the isopropyl fatty acid ester, and the catalyst is an N-alkyl pyrrolidone-group methyl phosphate ionic liquid catalyst. The N-alkyl pyrrolidone-group methyl phosphate ionic liquid catalyst is selected for synthesizing the isopropyl fatty acid ester, so that the synthetic method has the characteristics of low reaction temperature, less catalyst addition, no need of water-carrying agent, short reaction time, high esterification rate and the like, and an acid value of a produced product is low.

Owner:NEUFTECH BIOTECH HEFEI

Ferric trichloride modified ion exchange resin catalyzer, method of manufacturing the same and application thereof

InactiveCN101108365AImprove the efficiency of esterificationNo corrosionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholStrong acids

The ferric chloride modification ion exchange resin catalyst and the preparation method and application is provided, which relates to a catalyst and the preparation method and application. In order to solve the problem of the existing ammonium lactate catalyst with complicated preparation techniques, high production cost and low ammonium lactate catalyzing esterification efficiency. The catalyst is made of hydrogenous strong acid cation exchange resin and butanol solution of ferric chloride. The preparation method of the catalyst is realized by the following method: firstly, washing resin and drying; secondly, prepare compound resin; thirdly, proceed alcohol washing and acetone washing to compound resin and then dry, the ferric chloride modification ion exchange resin catalyst can be achieved. The catalyst is used in the ammonium lactate esterification reaction, which has simple preparation techniques, the cost is reduced by 5 to 8 per cent and the ammonium lactate esterification rate can reach 78 to 96 per cent.

Owner:HARBIN INST OF TECH

Synthesis method of ester oil

ActiveCN101775326AReduce dosageHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationAlcoholSynthesis methods

The invention relates to a method for synthesizing ester oil, wherein sulfuric acid and phosphoric acid are adopted in a molar ratio of 1: (2-4) and a composition with the amount thereof accounting for 0.05 to 0.1% of the total weight of alcohol and acid is added into an alcohol-acid reactor as a composite catalyst. The adding method of the composite catalyst comprises the steps of adding the composition in three stages during the alcohol and acid esterification reaction; subjecting the mixture to the reaction for 2 to 6 hours to generate raw ester; blowing epoxy gas into the reactor and then blowing one or more gases selected from nitrogen, steam and argon into the reactor and carrying out chemical deacidification and physical deacidification; then, carrying out reduced pressure distillation, dehydrating and drying under the vacuum condition; and finally, adding polymerization inhibitor into the reactor for precise filter, and obtaining the ester oil with high purity and high quality. The synthesis method has the advantages of rapid reaction speed, high esterification efficiency and greatly improving the purity of the product.

Owner:辽宁海华科技股份有限公司

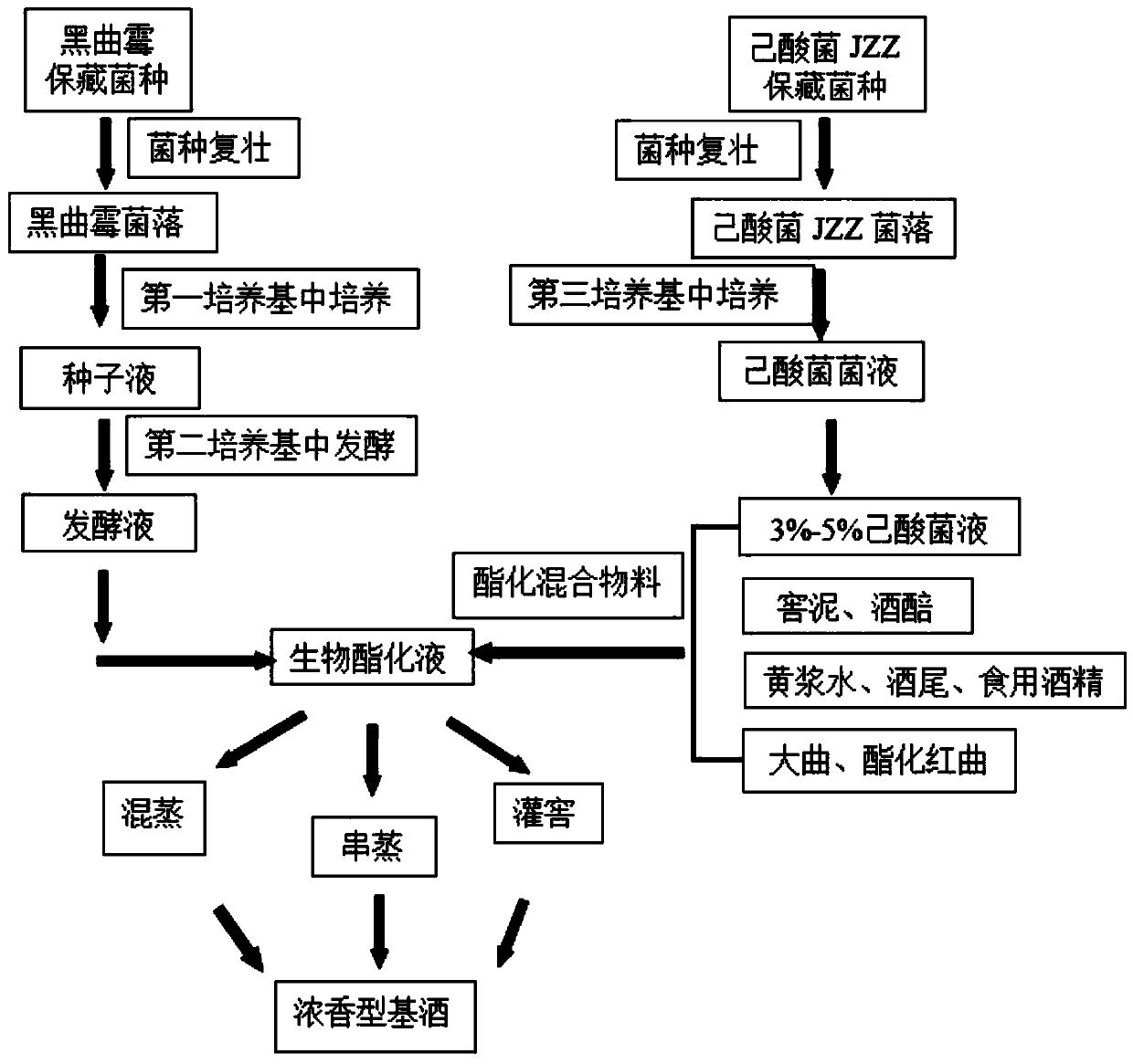

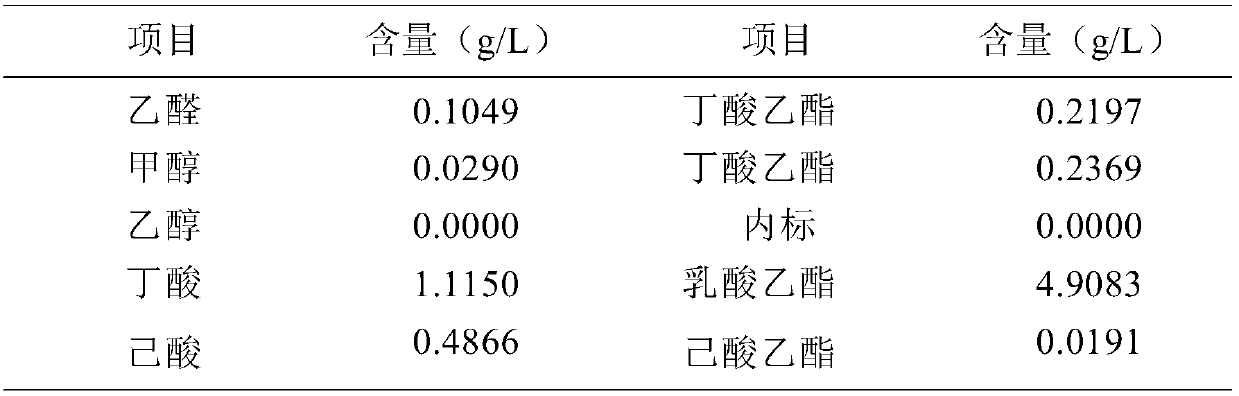

Method for preparing bioesterification liquid by liquid fermentation of aspergillus niger

InactiveCN109628253AImprove the efficiency of esterificationQuality improvementAlcoholic beverage preparationMicroorganism based processesYeastMicrobiology

The invention discloses a method for preparing bioesterification liquid by liquid fermentation of aspergillus niger. The method includes the following steps that 1, preserved strains of aspergillus niger are activated, the activated single bacterial colony is selected and transferred to a first culture medium for culture to obtain seed liquid of aspergillus niger, and the seed liquid is inoculatedinto a fermentation tank containing a second culture medium for enlarged cultivation to obtain aspergillus niger fermentation liquid; 2, the preserved strains JZZ of caproic acid bacteria are inoculated into a third culture medium for anaerobic cultivation for 48-360 h at 25-43 DEG C, and caproic acid bacteria are fermented to obtain caproic acid bacterium liquid; 3, a liquid fermentation mixtureis formed after aspergillus niger fermentation liquid is mixed with an esterification mixture, the pH value of the liquid fermentation mixture is 3.0-5.0, and finally a liquid fermentation method isused for preparing biological esterification liquid. On the basis of adding caproic acid bacterium liquid, esterification red rice, yeast for making hard liquor, pit mud and the like, compound enzymesproduced by aspergillus niger liquid fermentation are also used for promoting esterification, and the esterification efficiency of a liquid fermentation system is improved.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

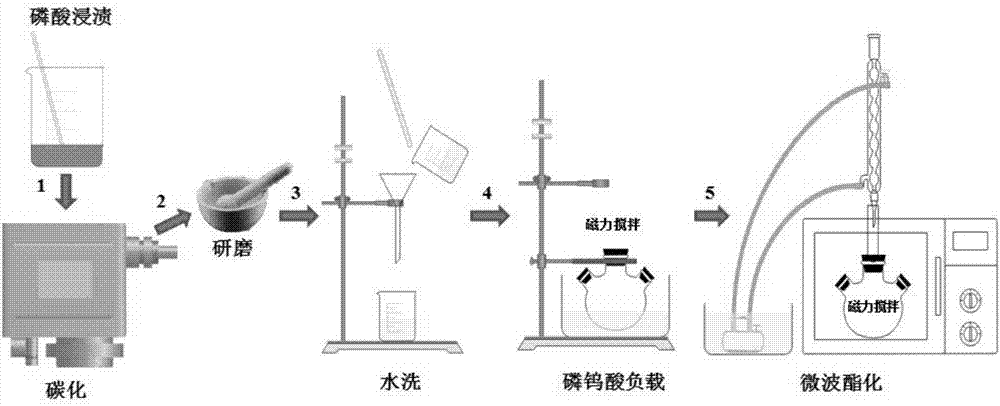

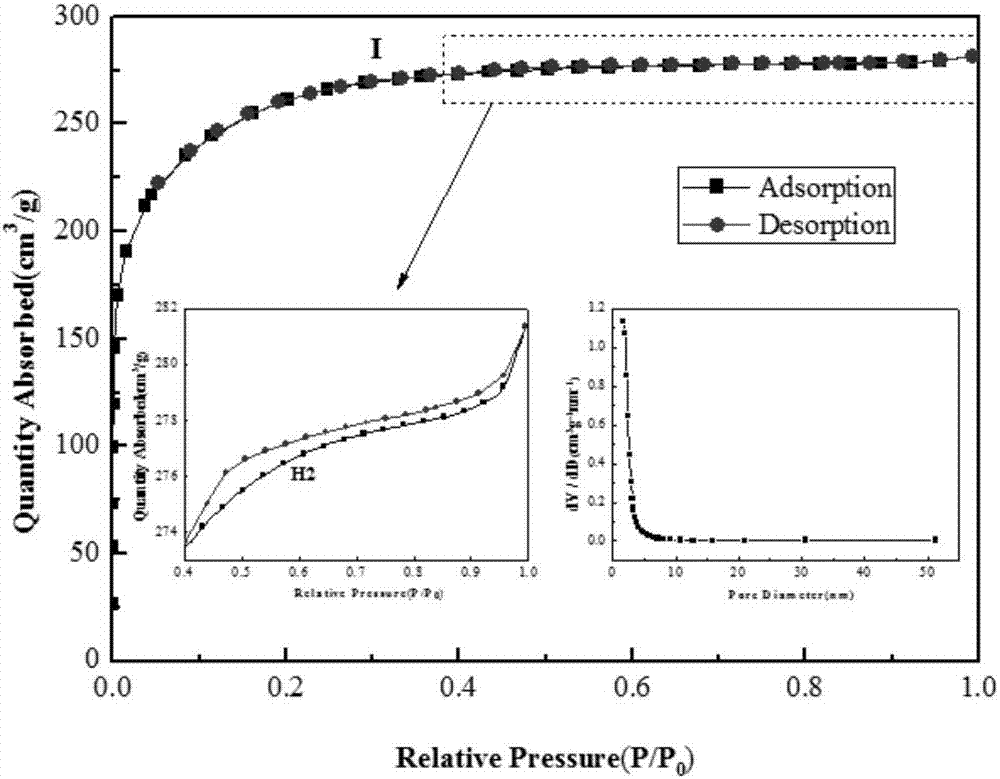

Bamboo-carbon-based solid acid catalyst for biodiesel and preparation method and application of bamboo-carbon-based solid acid catalyst

InactiveCN107999104ALarge specific surface areaPlay the role of hole expansionFatty acid esterificationBiofuelsBiodieselEvaporation

The invention discloses a bamboo-carbon-based solid acid catalyst for biodiesel and a preparation method and application of the bamboo-carbon-based solid acid catalyst. The preparation method includesthe following steps that 1, after being dried, bamboo powder is soaked in a phosphoric acid solution, and after being soaked for a set time, the bamboo powder is dried for standby application; 2, thebamboo powder soaked in the step is heated, carbonized, washed with water to be neutral, and dried for standby application; 3, a carbonized product in the step 2 is mixed with a phosphotungstic acidsolution, the mixture is stirred evenly and dried through evaporation, and the bamboo-carbon-based solid acid catalyst is obtained through preparation. The phosphoric acid solution is used for soaking and activating the bamboo powder, phosphoric acid molecules are used for filling pore structures of the bamboo powder, catalytic degradation is conducted to promote low molecularization of the bamboo powder, a gas escaping material is formed in the carbonation process, the pore expanding effect is achieved, the specific surface area of the prepared bamboo-carbon-based solid acid catalyst is largely increased, and the catalytic esterification efficiency of the catalyst is easily improved.

Owner:山东大学深圳研究院

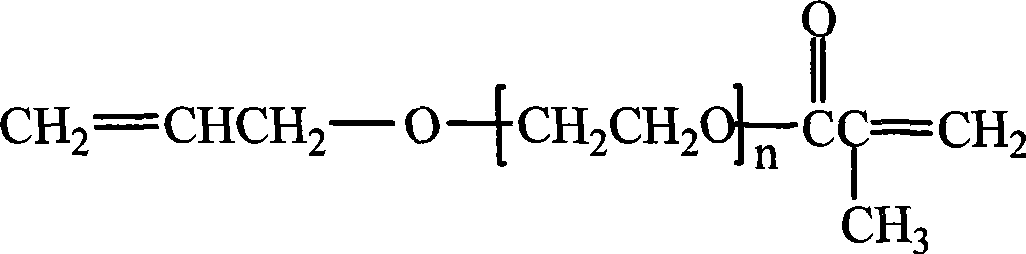

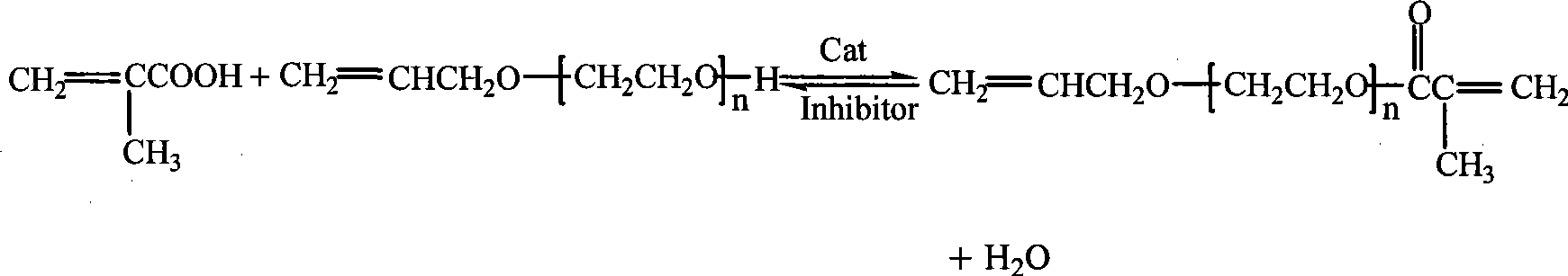

Method for synthesizing allyl alcohol polyethenoxy ether metacrylic acid ester

InactiveCN101497569AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsOrganic compound preparationTest comparisonNitrogen gas

The invention provides a method for synthesizing an allyl alcohol polyethenoxy ether metacrylic acid ester, and belongs to the technical field of synthesizing ester compounds in the organic chemistry. The method comprises that: an allyl alcohol polyethenoxy ether and a methacrylic acid are used as raw materials, a phosphotungstic acid immobilized on active carbon is used as a catalyst, phenothiazine or hydroquinone or a mixture of the phenothiazine and the hydroquinone is used as a polymerization inhibitor, and in the presence of a water-carrying agent and under the condition of continuously filling with nitrogen, the esterification reaction is carried out, after the reaction, the obtained products are refined to obtain the allyl alcohol polyethenoxy ether metacrylic acid ester; and the degree of polymerization of a chain segment of the allyl alcohol polyethenoxy ether is between 1 and 10, and a mol ratio of the allyl alcohol polyethenoxy ether to the methacrylic acid is 1.0:1.0-1.5. According to test comparisons, the method has the advantages of reasonable use of the phosphotungstic acid immobilized on active carbon with good catalytic activity and stability as the catalyst, more advanced and reasonable process, mild reaction conditions and safe and easy operation, and solves the problem of the equipment corrosion.

Owner:ZHEJIANG HUANGMA TECH

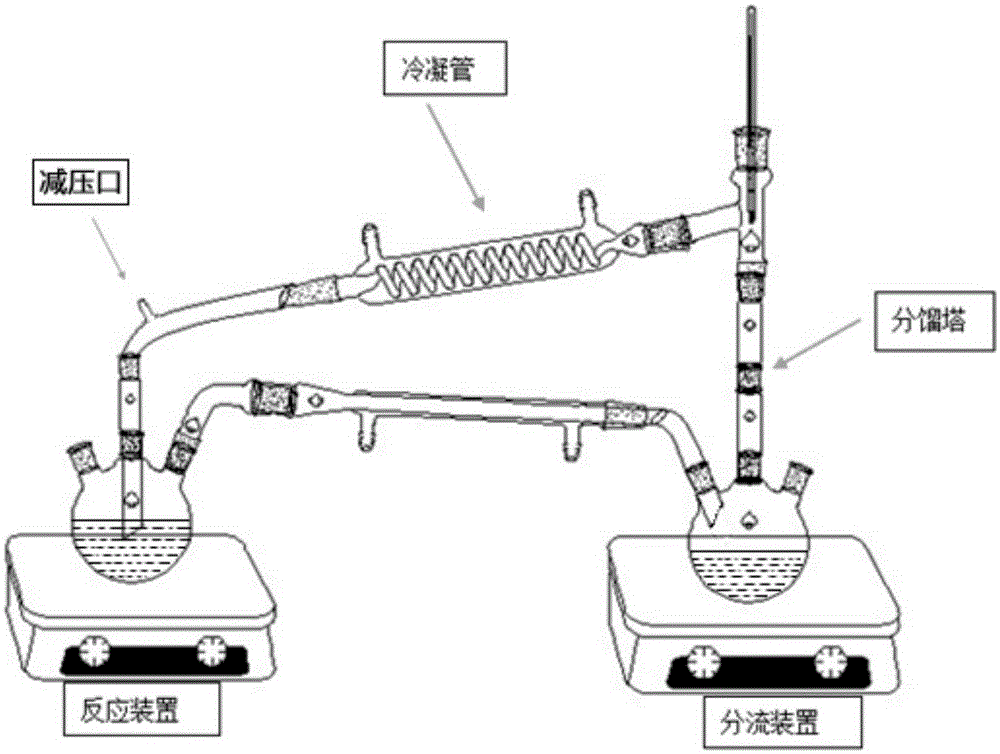

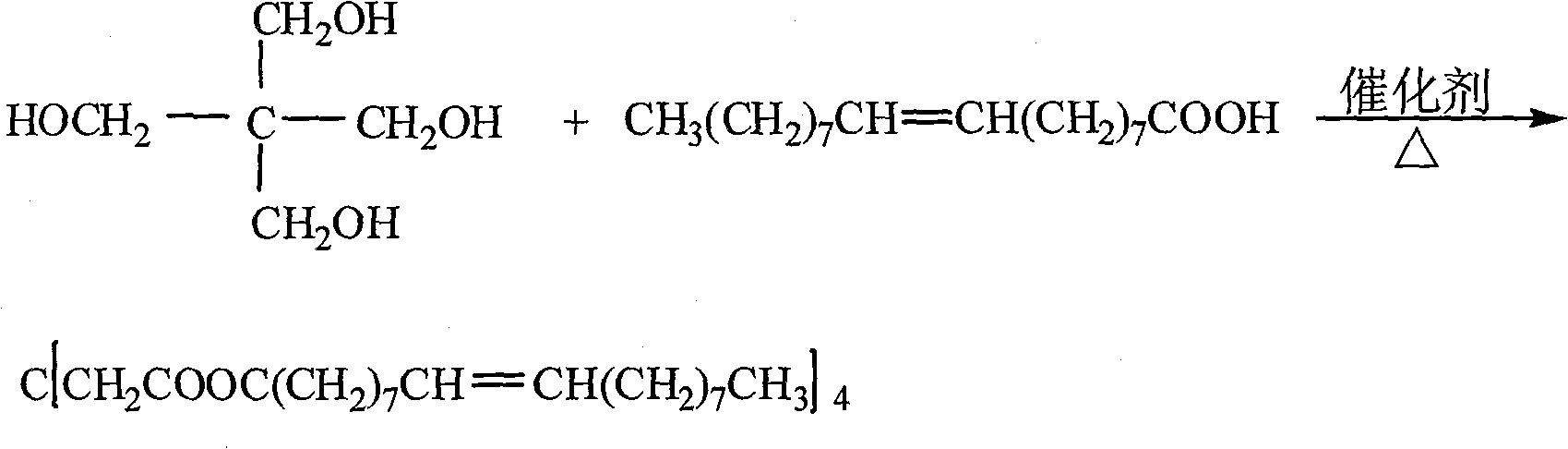

Synthetic method of polyhydroxy alcohol fatty acid ester by scratch film evaporator

ActiveCN105732368AUniform film thicknessSmooth film flowOrganic compound preparationCarboxylic acid esters preparationEvaporatorFatty acid ester

The invention discloses a synthetic method of polyhydroxy alcohol fatty acid ester by a scratch film evaporator as a reactor. The synthetic method comprises the following steps: adopting a scratch film evaporator as a reactor to react polybasic alcohol with fatty acid; mixing the polybasic alcohol and the fatty acid according to a mole ratio that hydroxyl to carboxyl is 1 to (1-1.6), and heating and stirring the mixture, so that the polybasic alcohol and the fatty acid dissolve mutually; inputting the mixed liquid into the scratch film evaporator by a feed pump, so that the mixed liquid is heated by flowing through inner walls of the scratch film evaporator from top to bottom in the form of a liquid film under actions of the scratch film evaporator, and an esterification reaction thereby occurs; pumping water generated in the reaction in a gaseous form out of the scratch film evaporator under vacuum conditions, and collecting the pumped water in the gaseous form by an external condense; and outputting reaction products from a bottom of the scratch film evaporator by a gear pump. By carrying out the esterification reaction adopting the method, the reaction materials are rapidly and uniformly heated, and the water generated by the reaction escapes rapidly, so that the esterification reaction is shifted toward the right side in a balanced way; moreover, the esterification reaction is very high in esterification efficiency. In addition, continuous production can be realized by the synthetic method.

Owner:PETROCHINA CO LTD

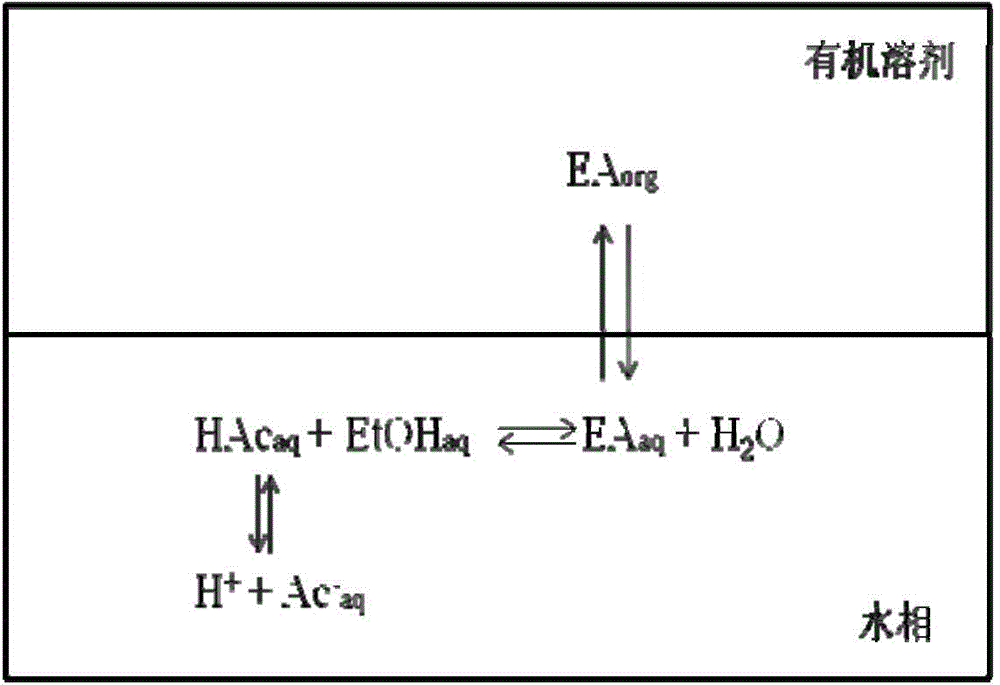

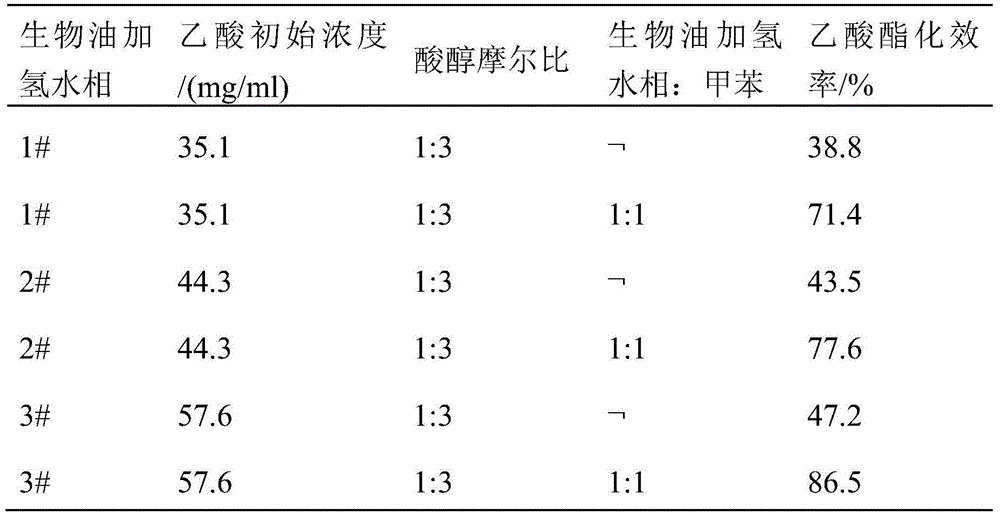

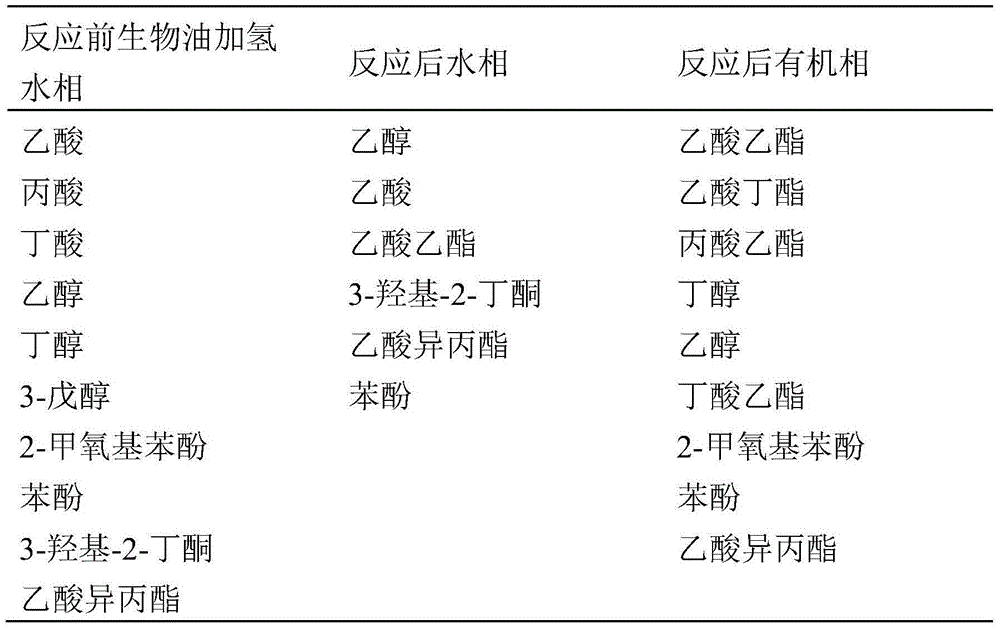

Ultrasonic assistant esterification coupling extraction method of organic acid in bio-oil hydrogenation aqueous phase

ActiveCN104628558ALow costImprove the efficiency of esterificationOrganic compound preparationCarboxylic acid esters preparationOrganic acidPositive direction

The invention discloses an ultrasonic assistant esterification coupling extraction method of an organic acid in a bio-oil hydrogenation aqueous phase, and belongs to the technical field of a treatment method of bio-oil hydrogenation aqueous phases. The method disclosed by the invention is suitable for recycling the organic acid in the bio-oil hydrogenation aqueous phase with lower organic acid concentration. Ethanol, a water-insoluble organic solvent and an acidic esterification catalyst are added in the aqueous phase, the organic acid and the ethanol generate an esterification reaction to generate ester under an ultrasonic condition, and the ester is extracted by the organic solvent into an organic phase to promote the esterification reaction in the aqueous phase to carry out towards a positive direction, so as to effectively improve the esterification efficiency. The ultrasonic assistant esterification coupling extraction method disclosed by the invention is used for recycling the organic acid in the bio-oil hydrogenation aqueous phase and converting the organic acid into the ester with higher value, to increase the economic benefit; the esterification coupling extraction method is used for improving the esterification efficiency of a dilute acid solution with a high water content, and the reaction rate is accelerated by ultrasonic; when the organic acid in the bio-oil hydrogenation aqueous phase is recycled, the aqueous solution is primarily purified, thereby reducing the cost of subsequent water treatment.

Owner:ZHENGZHOU UNIV

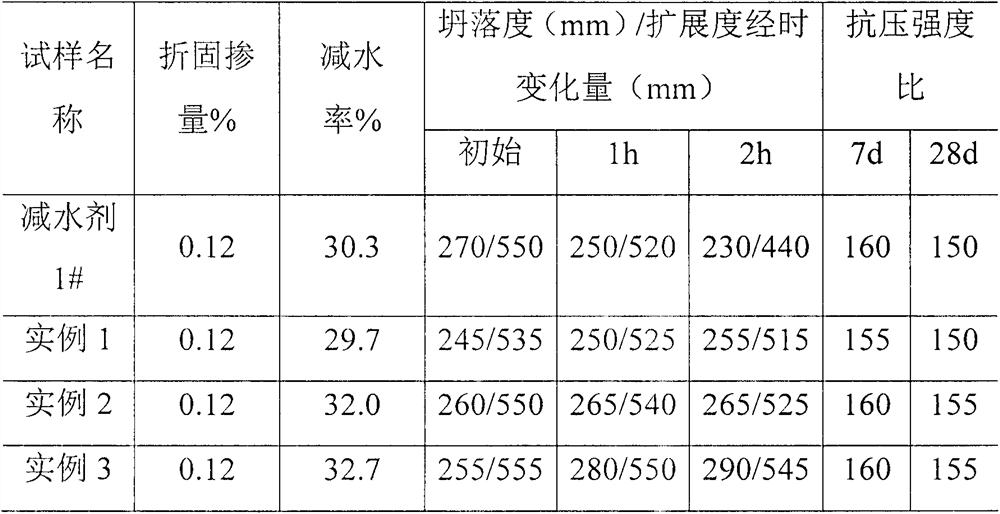

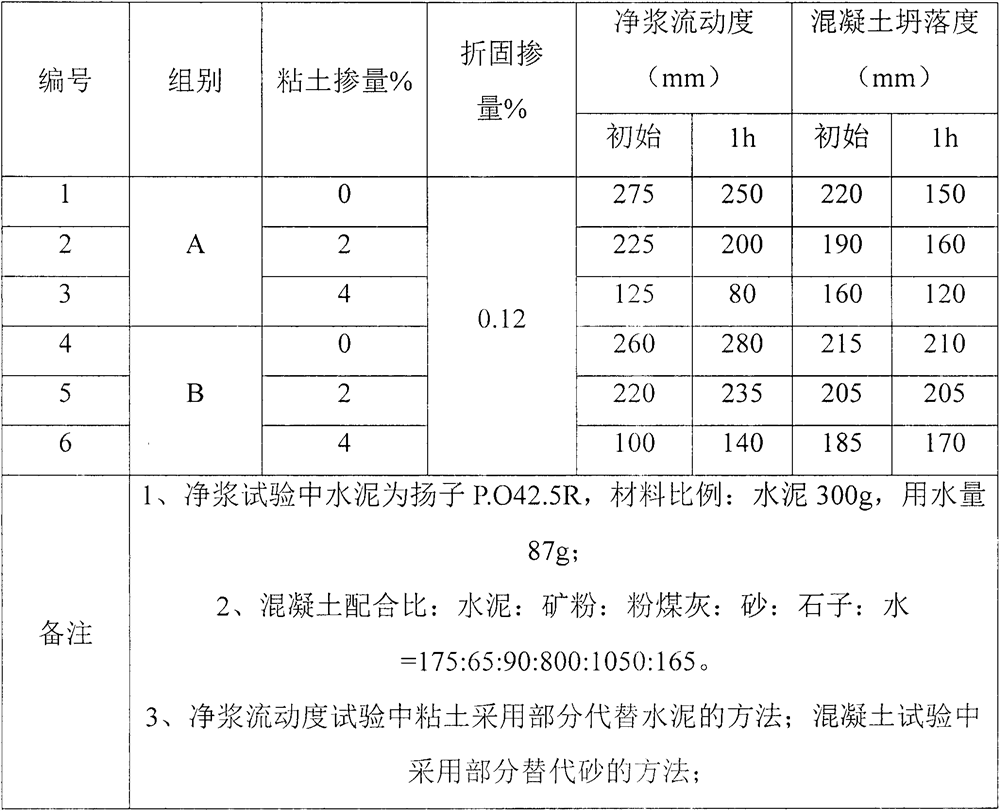

A kind of preparation method of anti-mud type polycarboxylate water reducer

ActiveCN107721233BGood mud resistanceWeaken competitive adsorptionPhosphoric Acid EstersCarboxylic acid

The invention discloses a muddy-resistant polycarboxylate water-reducer and a preparation method thereof. The muddy-resistant polycarboxylate water-reducer comprises the following raw materials: a maleic acid, triethanolamine, polyoxyethylene monomethyl ether, acrylamide, a crylic acid, isoamyl polyoxyethylene ether, a maleic acid grafted glucose phosphate derivative and water. The preparation method for the muddy-resistant polycarboxylate water-reducer is green and environmental, the water reducing dispersibility is good, the muddy-resistant effect is remarkable, the adaptability to mud-containing aggregate is strong, and the cost performance is high. The production process is green and environmental without the three waste emission, and accords with a concept of green and environmental protection and sustainable development.

Owner:南京建高新材料科技有限公司

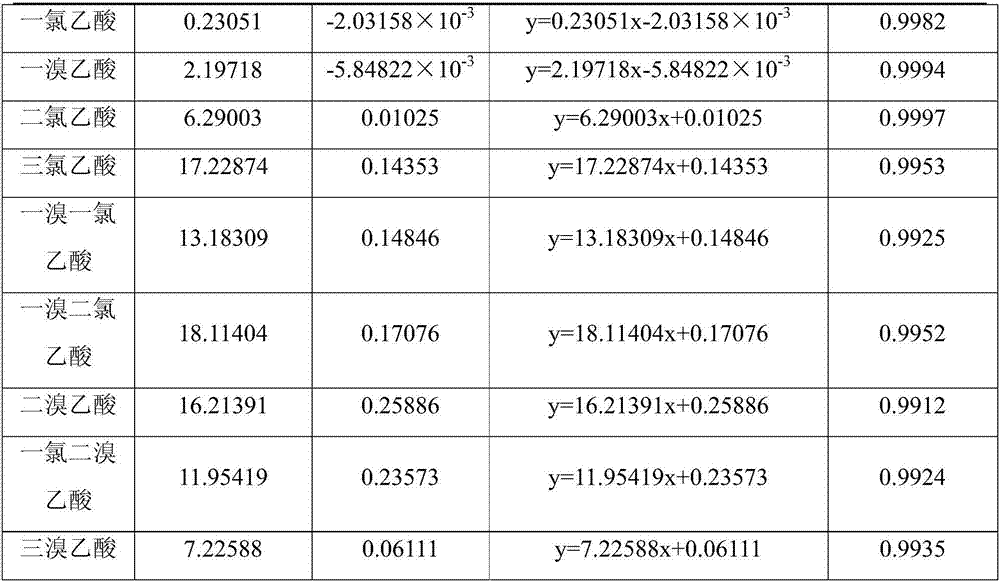

Method for detecting multiple haloacetic acids in air or exhaust gas

ActiveCN107064378AGood water solubilityImprove collection efficiencyComponent separationSolventElectron capture

The invention belongs to the technical field of environment detection and particularly relates to a method for detecting multiple haloacetic acids in air or an exhaust gas. The method comprises the steps of absorbing and sampling the haloacetic acids in the air or the exhaust gas through a porous glass plate absorption bottle containing a NaOH water solution or ultrapure water; extracting the haloacetic acids through methyl tertiary-butyl ether containing an internal standard substance and carrying out esterification reaction on methyl alcohol by adopting the methyl tertiary-butyl ether as a carrier solvent under composite catalysis of a metal catalyst, metalloporphyrin and phenylsulfonate phenolic resin; and measuring the peak area by using a gas chromatograph with an electron capture device and carrying out result measurement. One-off, comprehensive, fast and simultaneous measurement of the multiple haloacetic acids in the air or the exhaust gas is achieved, and the measurement method is high in precision, good in accuracy and low in detection limit.

Owner:肖洋

Bifunctional biochar-based solid acid catalyst, and preparation method and application thereof

InactiveCN110090658AStrong acidEasy to preparePhysical/chemical process catalystsFatty acid esterificationIndustrial wasteFatty acid methyl ester

The invention discloses a bifunctional biochar-based solid acid catalyst, and a preparation method and an application thereof. A mixture of Jatropha curcus seed shells used as a carrier and ammonium lignosulfonate used as an activator is carbonized at a high temperature to form an amino group-supported carbon-based precursor, and carrying out a sulfonation reaction under a heating condition to introduce a sulfonic acid group to the carbon-based precursor in order to prepare the bifunctional biochar-based solid acid containing an amino group and the sulfonic acid group. The catalyst has a yieldreaching up to 93% or above when used to catalyze a methyl esterification reaction of fatty acids under optimal use conditions. The raw material of the solid acid is agricultural and forestry wastesand industrial wastes, the preparation process and the separation operation are simple, the biochar-based solid acid has the advantages of strong acidity, stable performances, low cost, environmentalfriendliness, recyclability and the like, and the two functional groups of the solid acid have synergistic effects in the methy esterification process of the fatty acids to effectively increase the conversion rate, and a new method is provided for preparing biodiesel from high acid value oils.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

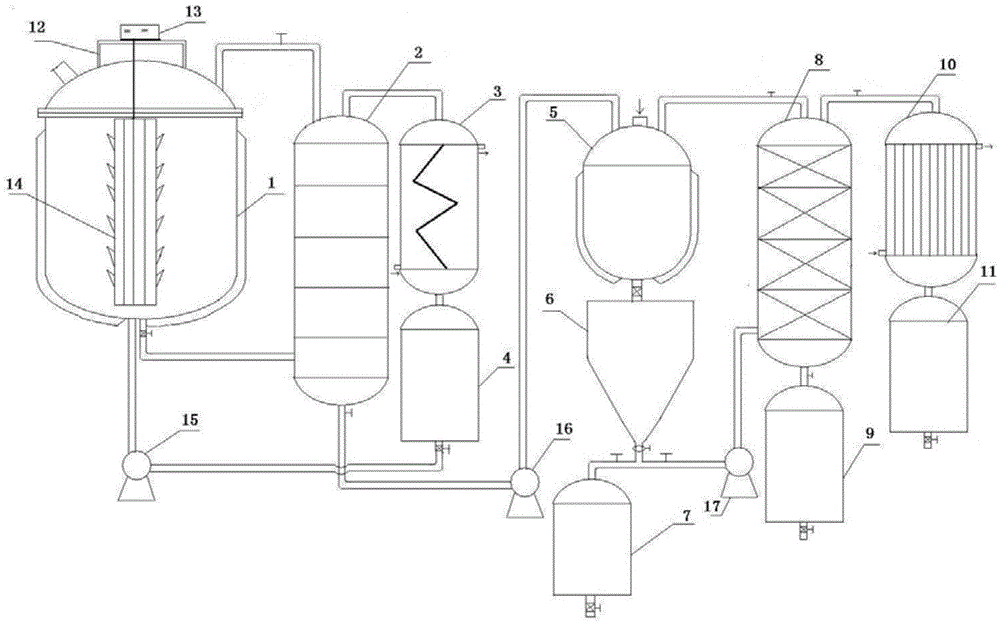

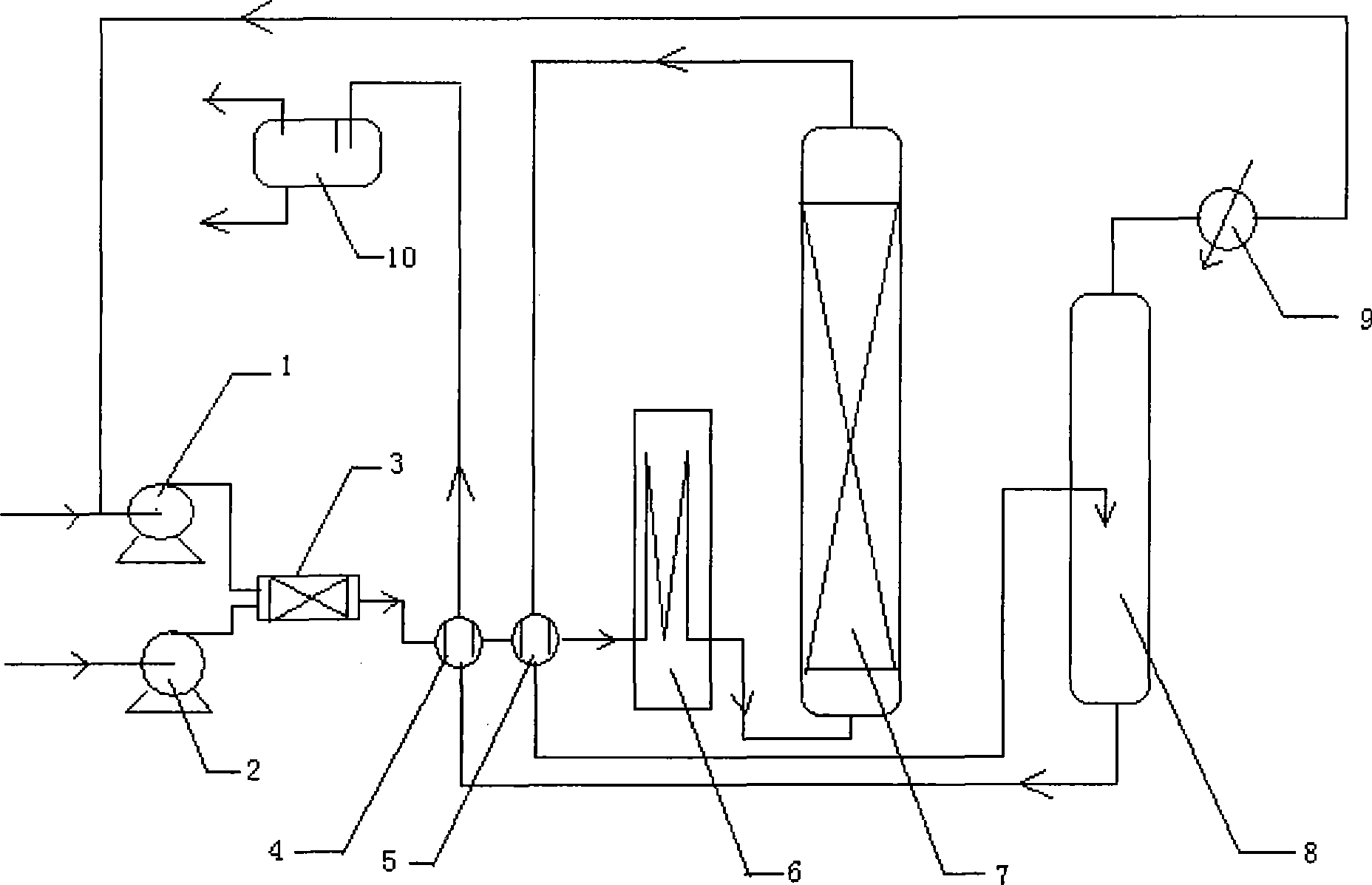

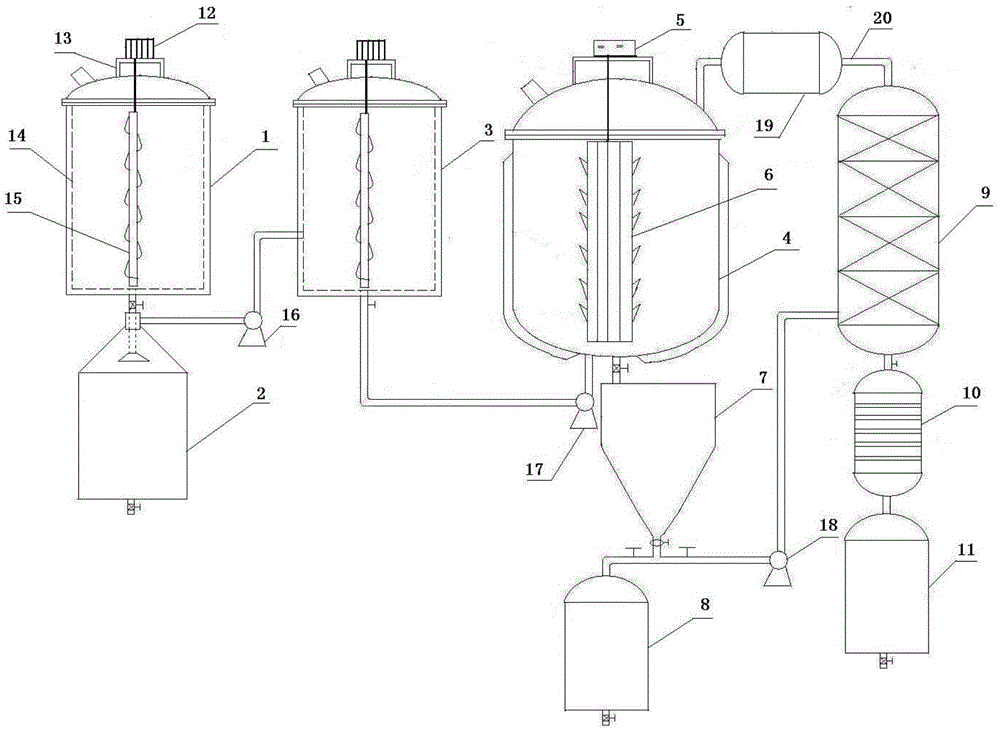

Microalgae biodiesel production device

InactiveCN105647652AHigh extraction rateIncrease productionFatty acid esterificationBiofuelsBiodieselSolvent

The invention discloses a microalgae biodiesel production device. The device comprises an oil extraction tank (1), a rectification tank A (2), an esterification tank (5) and a separator (6), wherein an ultrasonic generator (13) is arranged above the oil extraction tank (1), the lower side of the ultrasonic generator (13) is connected with an ultrasonic oscillation rod (14), the bottom end of the oil extraction tank (1) is connected with the middle-lower section of the rectification tank A (2), the top of the rectification tank A (2) is connected with a condenser A (3), the lower end of the condenser A (3) is connected with a solvent recovery tank (4), the bottom of the rectification tank A (2) is connected with the esterification tank (5) through a liquid pump B (16), the bottom of the esterification tank (5) is connected with the separator (6), the bottom end of the separator (6) is connected with a glycerin collector (10) and a feeding port of a rectification tank B (8), and the bottom end of the rectification tank B (8) is connected with a biodiesel collection tank (11). The device has the advantages that energy consumption is low, the structure is simple, reaction time is short, the microalgae oil extraction rate is high, the biodiesel yield is high, the purity is high, and the like.

Owner:薛晶

Supercritical esterification modification process for bio-oil

ActiveCN101486953ANo consumptionReasonable useFatty acid esterificationBio-feedstockAlcoholOil water

The invention provides bio-oil supercritical esterification modifying technology. After being mixed evenly by a static mixer, the reaction raw materials added in a bio-oil high-pressure pump and a methanol high-pressure pump firstly exchange heat with the modified bio-oil by a secondary heat exchanger, then exchange heat with the esterification reaction mixture by a primary heat exchanger, and then are heated by a heating furnace and enter into a supercritical esterification tower; after heat exchange, the esterification reaction mixture goes through an alcohol recovery tower to get the modified bio-oil and alcohol; the alcohol is recycled to use before being returned to the methanol high-pressure pump; after heat recycle, the modified bio-oil is water-separated by an oil-water separating tank and discharged as product.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of hydroxyethylidene diphosphonic acid

InactiveCN109956969AReduce generationFast esterification reactionGroup 5/15 element organic compoundsAcetic acidMixed materials

The invention discloses a preparation method of hydroxyethylidene diphosphonic acid. The method specifically comprises the following steps: (1) uniformly mixing phosphorus trichloride and glacial acetic acid in a mass ratio of 1:(1.3-3.0); (2) feeding the uniformly mixed materials in the step (1) into a reaction tube, closing the reaction tube, immersing the reaction tube into an oil bath at 130-240 DEG C, and carrying out heating reaction for 15-100 minutes under the pressure of 0.3-0.5 MPa; and (3) after the reaction is finished, moving out an esterification product while hot, feeding the esterification product into a reaction kettle, adding water and a catalyst, and fully stirring and hydrolyzing the esterification product at 125-130 DEG C for 1-2 hours. Under the conditions of increasing reaction pressure and at high temperature, phosphorus trichloride and glacial acetic acid are used as raw materials to complete rapid esterification in a sealed reaction tube in an anhydrous environment; and then carrying out catalytic hydrolysis, rectification purification separation and other treatments to synthesize the hydroxyethylidene diphosphonic acid. According to the method, the esterification reaction time is effectively shortened, side reactions are reduced, and the product yield is increased.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

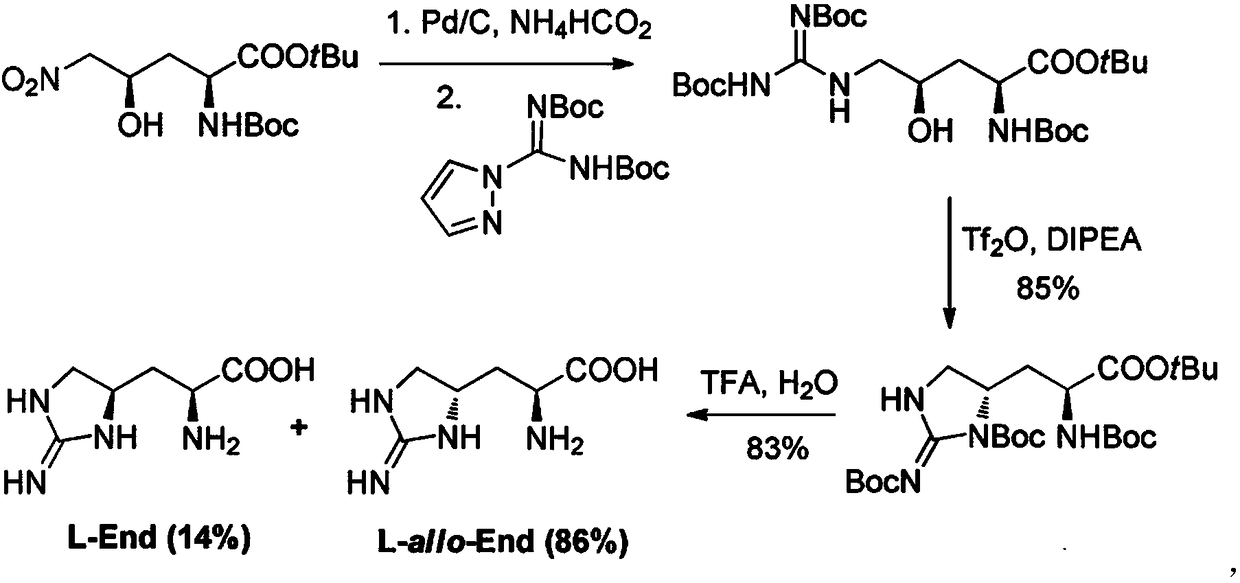

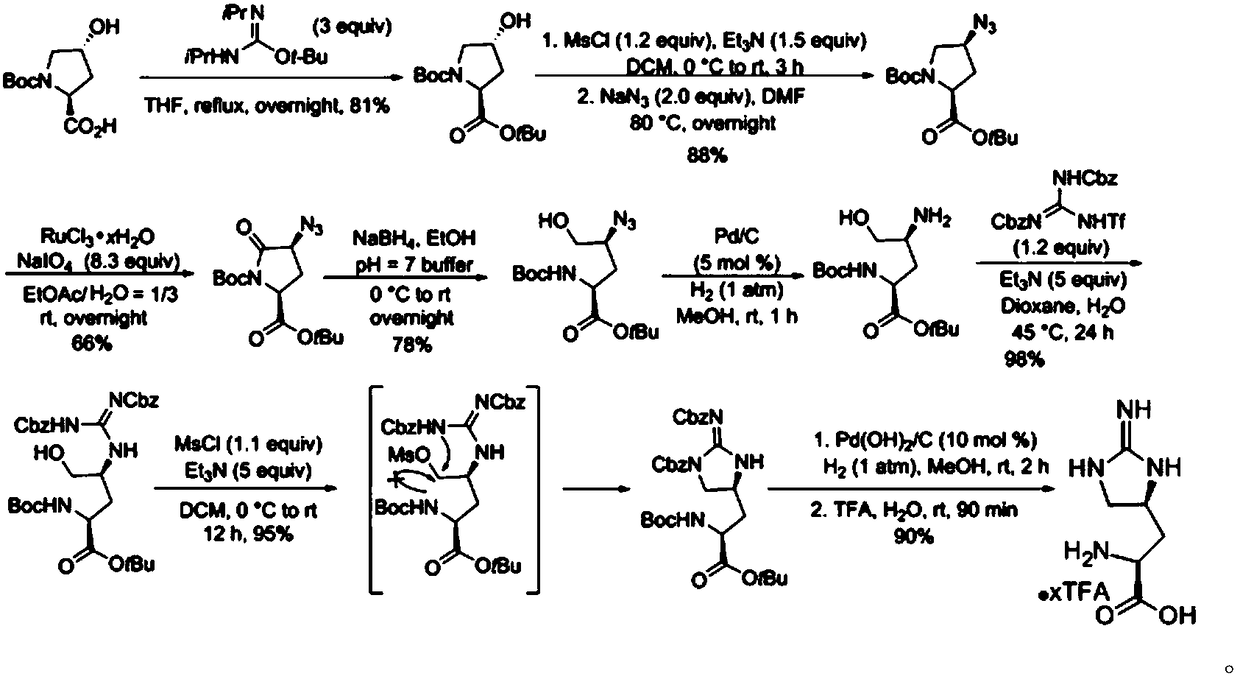

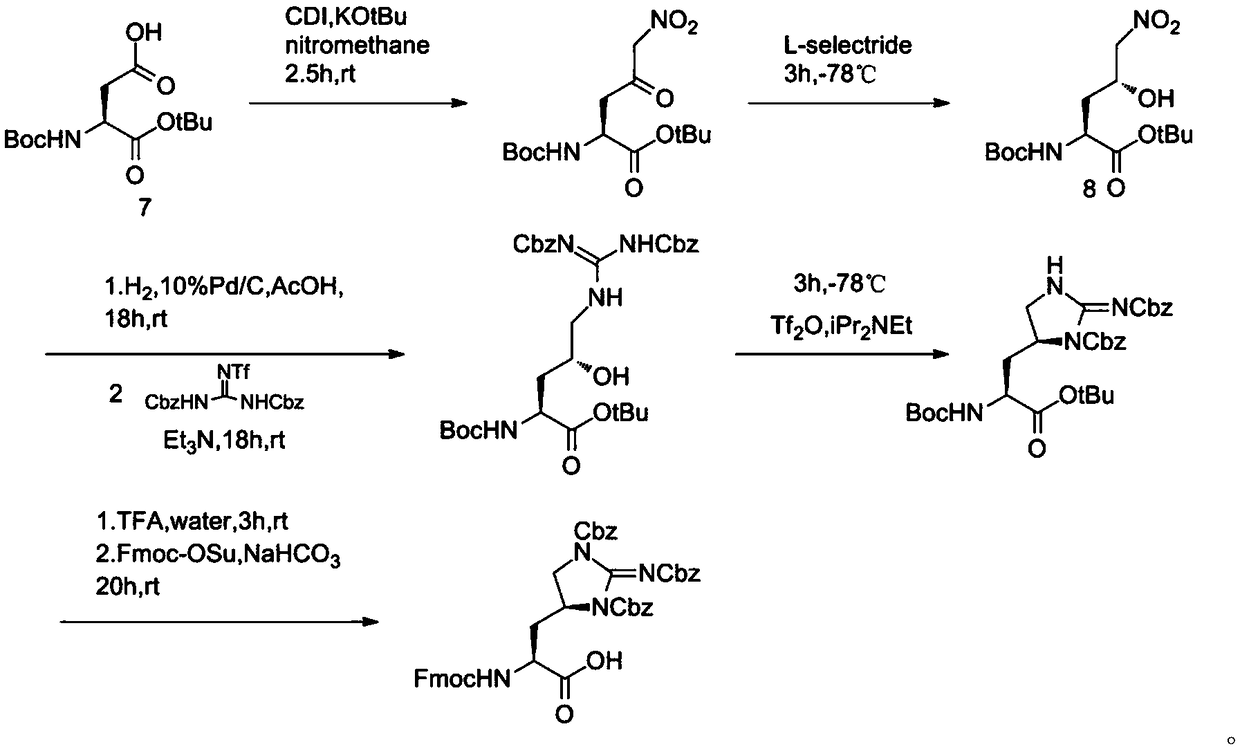

Synthetic route for antibiotic teixobactin and analogs thereof

ActiveCN109320590AImprove the efficiency of esterificationEasy to getPeptide preparation methodsAmino acidTeixobactin

The invention discloses a synthetic route for antibiotic teixobactin and analogs thereof and a method for preparing unnatural amino acids. The method comprises: subjecting a compound shown in a formula (1) to oxidative ring-closing treatment. In the formula, R5 is independently Fmoc, Boc, Phth, or Cbz, and R6 is independently H, Fmoc, Boc, Phth, or Cbz. The method was first proposed by the inventors. By using the oxidative ring-closing reaction, L-allo-Enduracidine (End) unnatural amino acids can be obtained in one step. The method has high yield, few by-products, and simple separation and purification.

Owner:TSINGHUA UNIV

High-efficiency esterification method of trioctyl trimellitate

InactiveCN108586252AIncrease the reaction contact areaImprove the mixing effectProductsOrganic compound preparationChemical industryAcid value

The invention provides a high-efficiency esterification method of trioctyl trimellitate. According to the invention, an esterification liquid is circulated from the bottom of a kettle to the top of the kettle, and is sprayed into the kettle, and the reaction contact area is increased, thereby effectively improving the mixing effect; a stirring system uses a three-layer blade set device to promoteuniform stirring, and can shorten the esterification time by half accordingly, saves energy, and reduces consumption; and after the esterification is completed, the esterification rate is up to 99% orover 99%, and the acid value is relatively low. The method significantly improves the esterification effect of the trioctyl trimellitate, the trioctyl trimellitate can be continuously esterified, theesterification time is shortened, the cost is reduced, and the method is safe and environmentally-friendly, and meets the requirements of green chemical industry and sustainable development. A product has the advantages of light color, good quality and high purity.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Catalyst used for dioctyl terephthalate production and use method thereof

ActiveCN107213914ACatalyticProtectiveOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsooctyl alcoholTitanium metal

The invention discloses a catalyst used for dioctyl terephthalate production in the field of organic chemical industry and application thereof. The catalyst comprises halogenated tributyl quaternary phosphonate and macromolecule modified titanium metal compound, wherein the macromolecule modified titanium metal compound is polyvinyl alcohol modified titanate. The catalyst is used for the catalytic reaction of terephthalic acid and isooctyl alcohol to react to synthesize the dioctyl terephthalate. The catalyst has the advantages of moderate reaction temperature, short reaction time, long catalyst service life, good product color, high terephthalic acid conversion rate and high product yield.

Owner:JIANGSU ZHENGDAN CHEM IND CO LTD

Device for producing biodiesel from waste edible oil

InactiveCN105602737ARealize rational utilizationEase the crisisFatty acid esterificationBiofuelsOil and greaseBiodiesel

The invention discloses a device for producing biodiesel from waste edible oil. The device comprises a solid-liquid separation tank (1), an oil-water separator (2), an impurity removal tank (3), an esterification tank (4), a phase splitter (7) and a rectification tank (9). The oil-water separator (2) is connected to the bottom of the solid-liquid separation tank (1) and connected with the impurity removal tank (3) through a liquid pump I (16), the bottom of the impurity removal tank (3) is connected with the esterification tank (4) through a liquid pump II (17), a phase splitter (7) is connected to the bottom of the esterification tank (4), the bottom of the phase splitter (7) is connected with a glycerinum collection tank (8) and a feed inlet of a vacuum pump (18) through a three-way pipe, a discharge outlet of the vacuum pump (18) is connected with the rectification tank (9), and the bottom of the rectification tank (9) is connected with a biodiesel collection tank (11). According to the device, waste edible oil can be converted into biodiesel, waste materials are changed into things of value, resources are reasonably utilized, and the problem of energy crisis can be effectively relieved.

Owner:薛晶

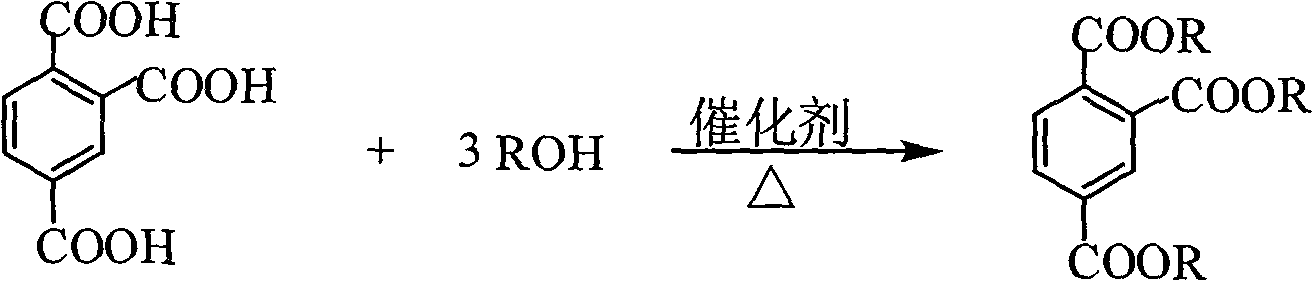

Novel continuous production technique of phthalate plasticizer

InactiveCN105111075AReduce production energy consumptionImprove the efficiency of esterificationOrganic compound preparationCarboxylic acid esters preparationNovel techniquePlasticizer

The invention relates to a novel continuous production technique of a phthalate plasticizer. The technique comprises the following steps: raw materials phthalic anhydride and monobasic alcohol and a catalyst are continuously introduced into a first-stage esterification kettle, and a small amount of monobasic alcohol is continuously introduced into a fifth-stage esterification kettle; liquid-phase materials of all stages of esterification kettles gradually flow to the fifth-stage esterification kettle from the first-stage esterification kettle via a liquid-phase pipeline and flow out of the fifth-stage esterification kettle, thereby obtaining a reaction product; gas-phase materials of all stages of esterification kettles are gradually introduced into the first-stage esterification kettle from the fifth-stage esterification kettle via a gas-phase pipeline and enter a packing tower; and the temperatures of all stages of esterification kettles are kept at 130-230 DEG C, the gage pressures are kept at 0-2atm, and the retention time is kept at 0.2-2 hours. The acid number of the bottom discharge product of the fifth-stage esterification kettle is 0.2-2.5 mg KOH / g. The novel technique for continuously producing the phthalate plasticizer greatly reduces the esterification time and energy consumption, and enhances the economic benefit.

Owner:EAST CHINA UNIV OF SCI & TECH

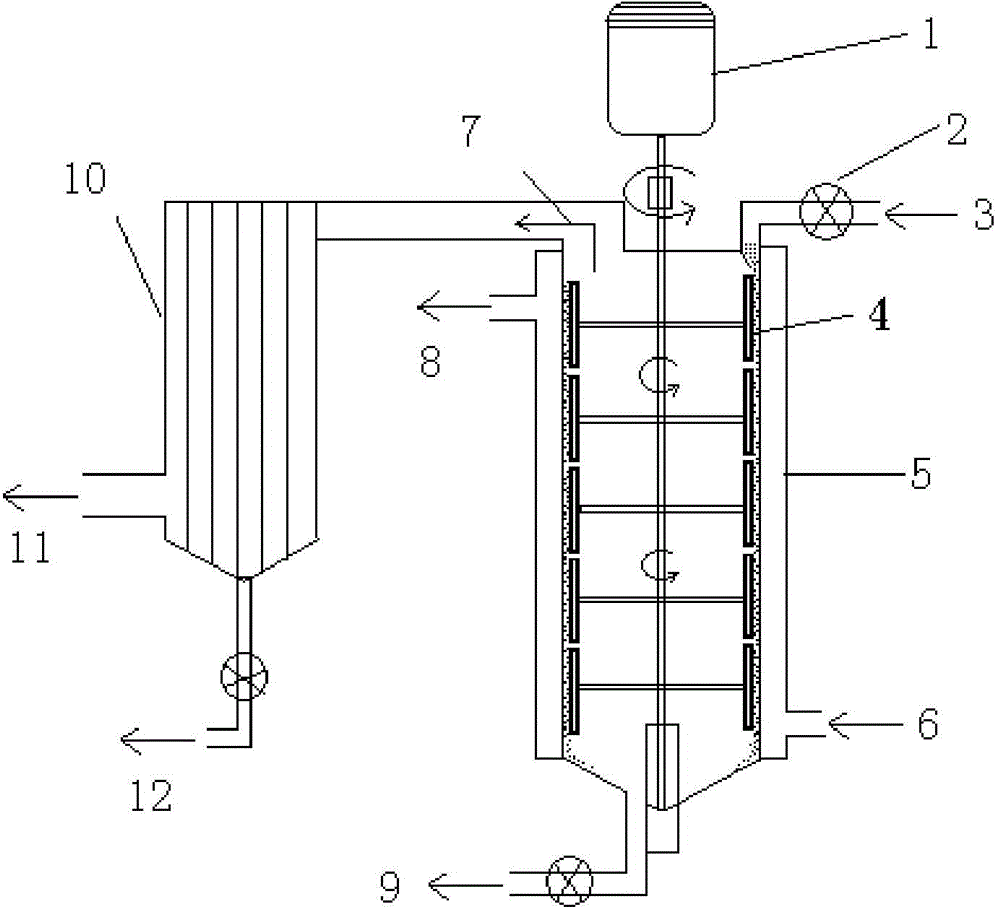

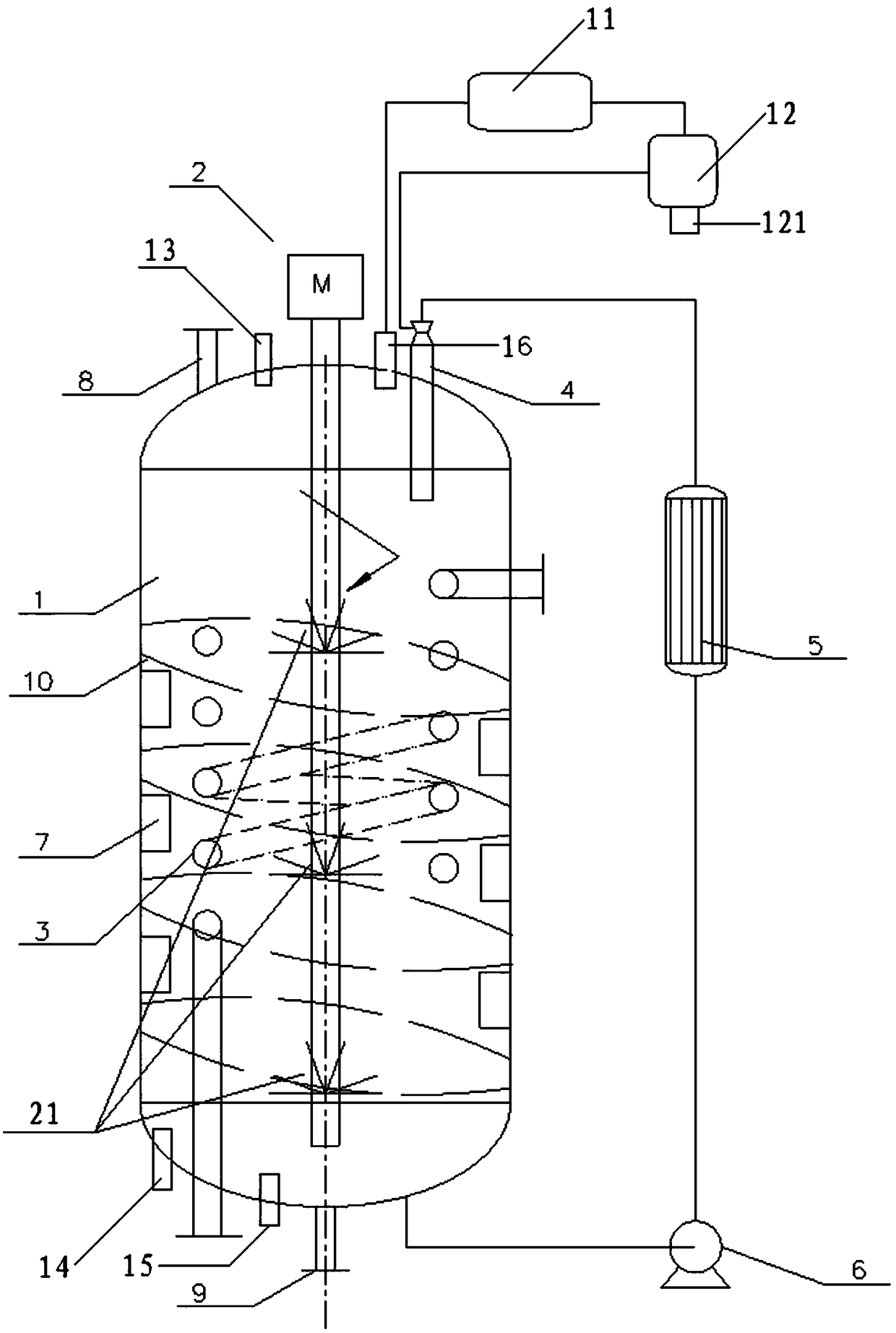

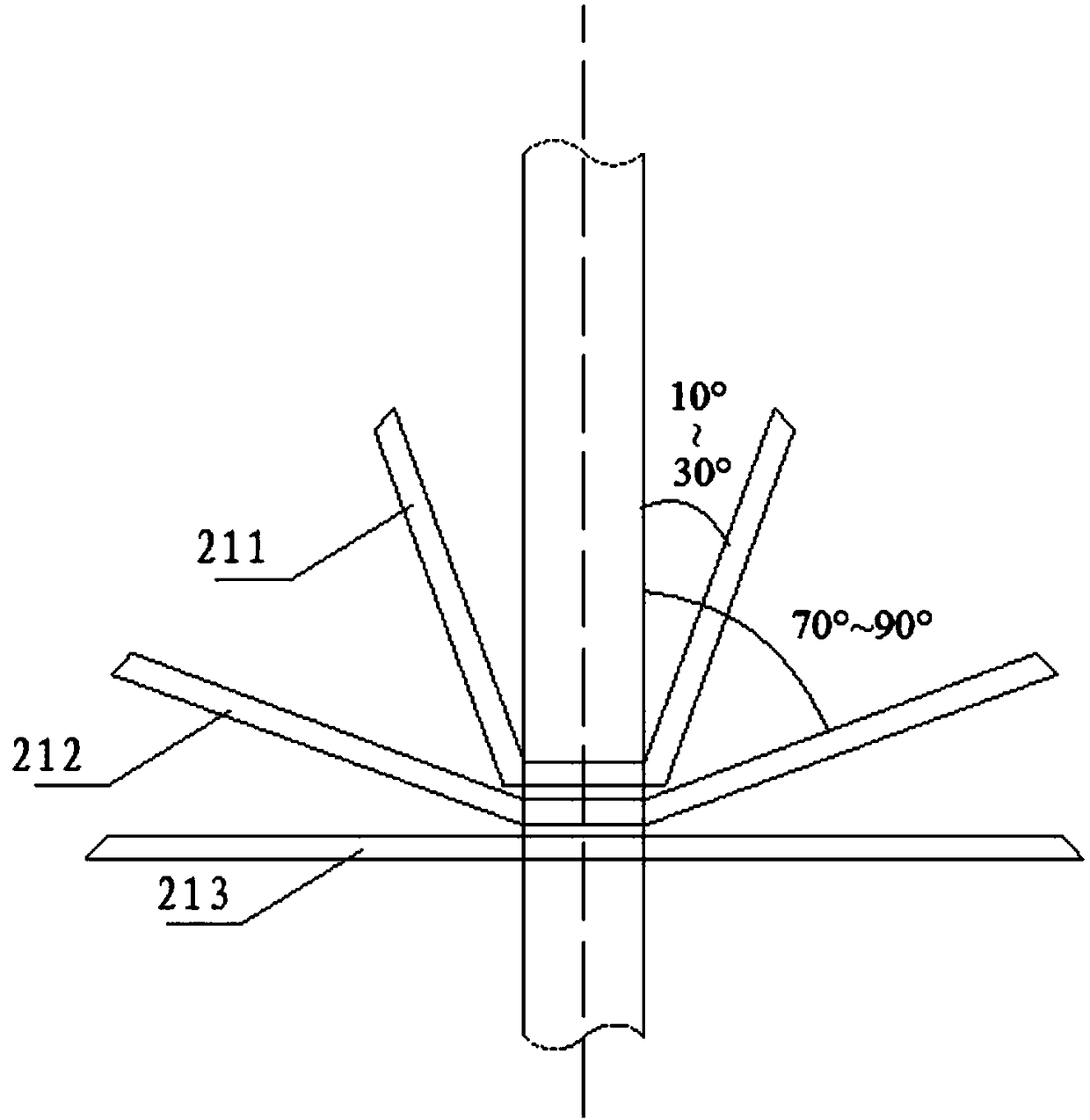

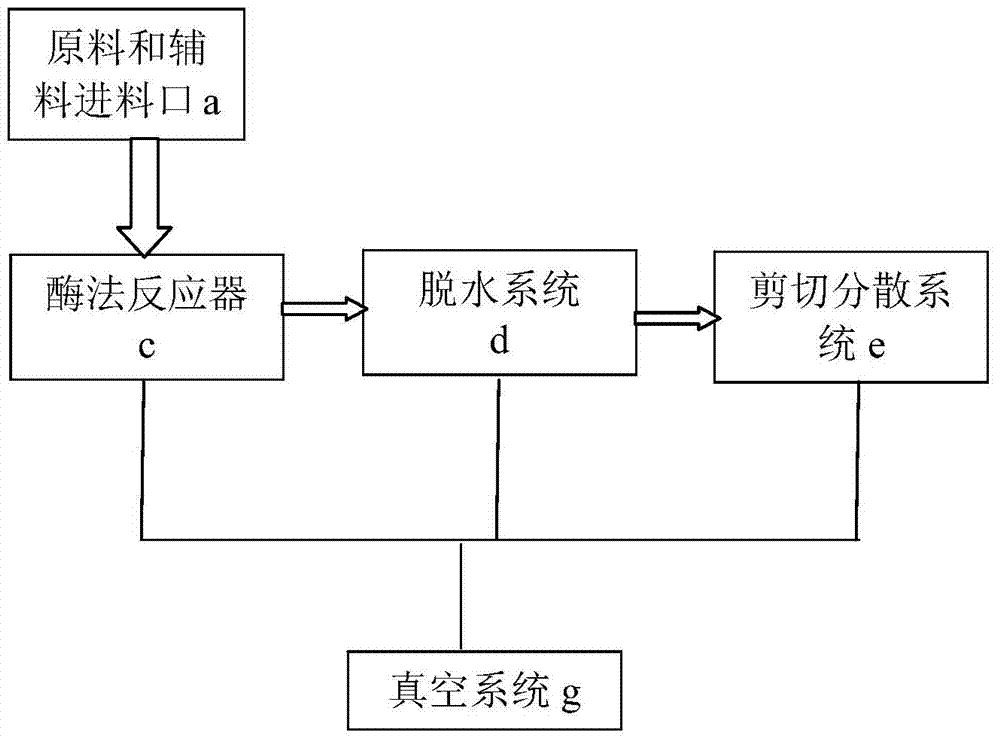

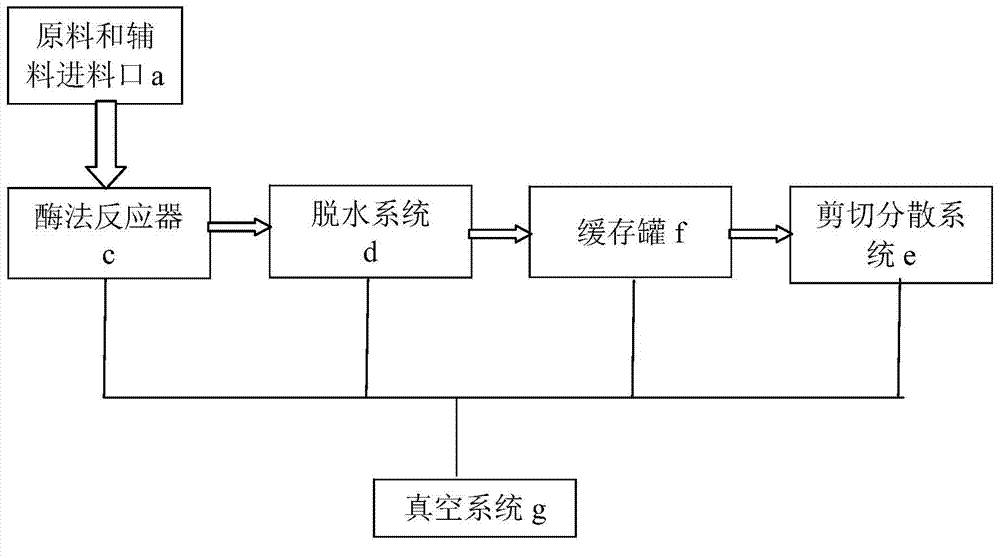

Apparatus for esterifying oils and fats by use of enzymic method

ActiveCN104745646AImprove the efficiency of esterificationBioreactor/fermenter combinationsBiological substance pretreatmentsChemistry

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

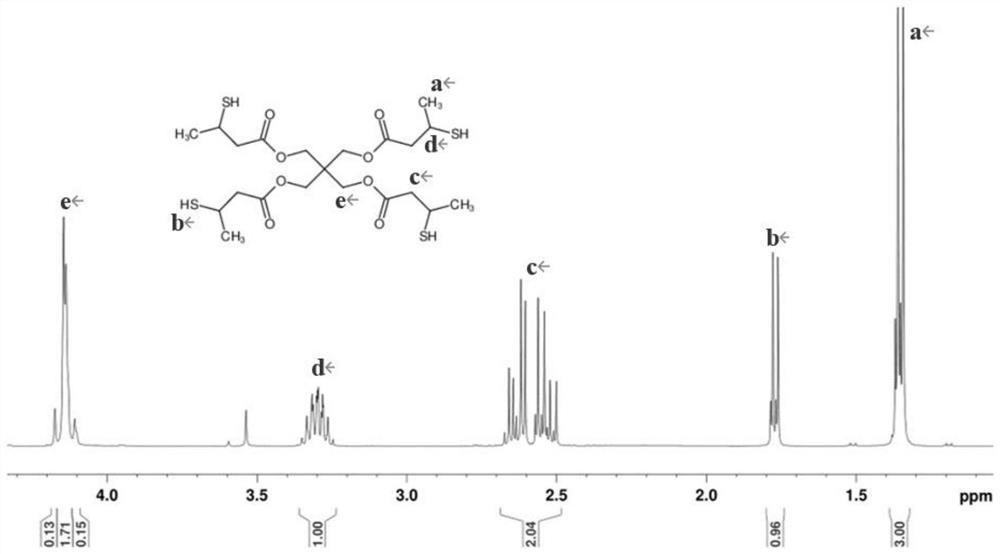

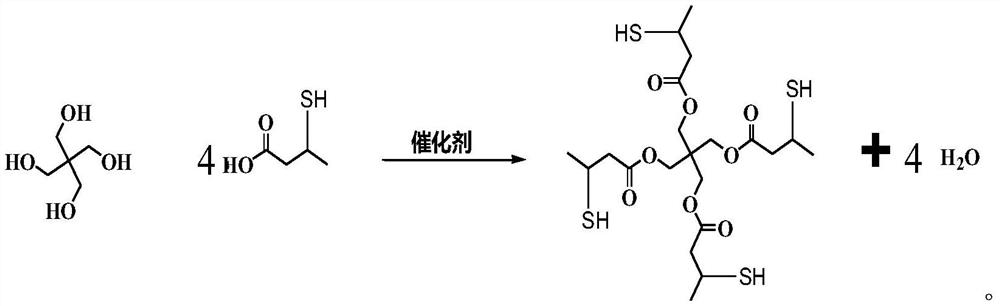

Preparation method of pentaerythritol ester

PendingCN111825579AIncrease acidityHigh catalytic activityThiol preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention provides a preparation method of pentaerythritol ester. The preparation method comprises the following steps: carrying out esterification reaction on pentaerythritol and 3-mercaptobutyric acid under the action of a catalyst to generate pentaerythritol tetra (3-mercaptobutyric acid) ester; the catalyst is prepared by the following method: A) uniformly mixing a template agent and a titanium source compound or a silicon source compound in a solvent to obtain a first mixed solution; B) uniformly mixing the first mixed solution with heteropoly acid and an organic compound with a sulfonic acid group to obtain a second mixed solution; C) removing the solvent from the second mixed solution to obtain gel; and D) carrying out aging treatment on the gel, and roasting to remove the template agent to obtain the catalyst. The supported composite acid catalyst is adopted to synthesize pentaerythritol tetra (3-mercaptobutyric acid) ester, inorganic acid and organic acid catalysts are replaced, the catalyst has higher acidity and catalytic activity, the esterification efficiency can be improved, the reaction time can be shortened, and the catalyst can be repeatedly used and is greener, more environmentally friendly and more economical.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Synthetic method of 1,2,4,5-cyclohexanetetracarboxylic dianhydride

The invention provides a preparation method of 1,2,4,5-cyclohexanetetracarboxylic dianhydride. The method comprises the following steps: pyromellitic acid is reacted with an esterification reagent to prepare pyromellitic acid ester; pyromellitic acid ester is hydrogenated in a fixed-bed reactor to synthesize hydrogenated pyromellitic acid ester; the obtained hydrogenated pyromellitic acid ester is Efficient synthesis of 1,2,4,5-cyclohexanetetracarboxylic dianhydride from tetracarboxylates in strong acids and organic solvents. Compared with the traditional production process, the invention has high esterification reaction efficiency, prolongs the service life of the catalyst, realizes continuous production of hydrogenation reaction, and shortens the process route. The method has the advantages of simple operation, high production efficiency and low cost. The metal ion (sodium, potassium, iron, calcium, aluminum, zinc) content in the obtained 1,2,4,5-cyclohexanetetracarboxylic dianhydride is ≤1ppm, which meets the requirements of electronic grade products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com