Supercritical esterification modification process for bio-oil

An esterification modification, bio-oil technology, applied in the direction of biological raw materials, fatty acid esterification, etc., can solve the problems of high processing costs, large investment and operating costs, and harsh reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

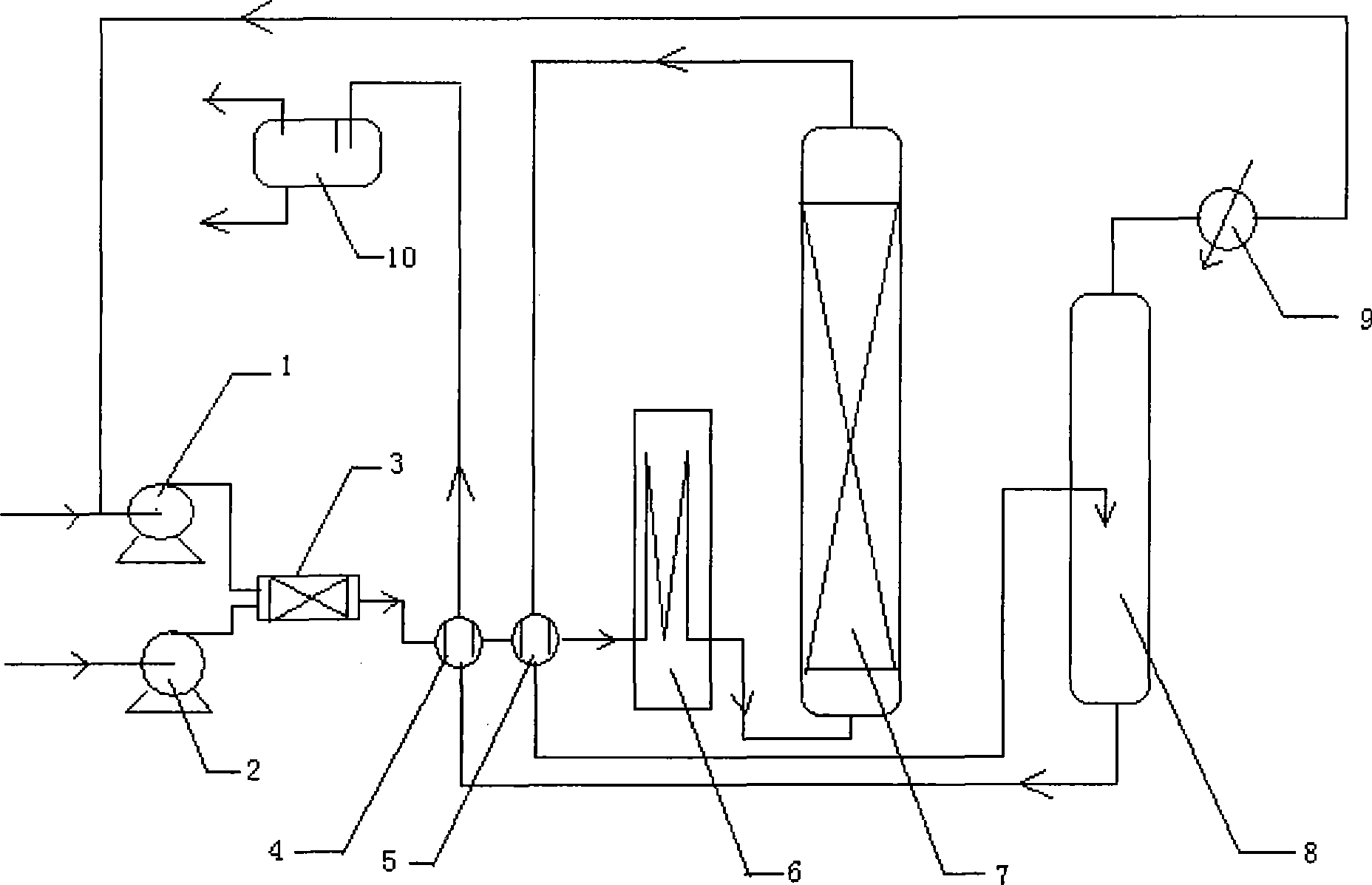

[0008] Below in conjunction with accompanying drawing, the present invention is described in detail: figure 1 As shown, according to the oil-alcohol ratio of 1:1.1-3, the bio-oil high-pressure pump (1) and the methanol high-pressure pump (2) add bio-oil and alcohol with a pressure of not less than 8MPa and mix them uniformly through a static mixer (3). First pass through the secondary heat exchanger (5) to exchange heat with the modified bio-oil, then pass through the primary heat exchanger (4) to exchange heat with the esterification reaction mixture, and then heat the alcohol under the pressure by the heating furnace (6). Enter the supercritical esterification tower (7) reaction after the saturation temperature; The esterification reaction mixture is separated by the alcohol recovery tower (8) after heat exchange, and the methanol vapor at the top of the tower is condensed by the condenser (9) to obtain modified bio-oil and alcohol The alcohol returns to the methanol high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com