Ultrasonic assistant esterification coupling extraction method of organic acid in bio-oil hydrogenation aqueous phase

An ultrasound-assisted, bio-oil technology, applied in the direction of organic chemistry, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low esterification efficiency, limitations, and low concentration of organic acids, so as to purify aqueous solution and improve esterification Efficiency, the effect of speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

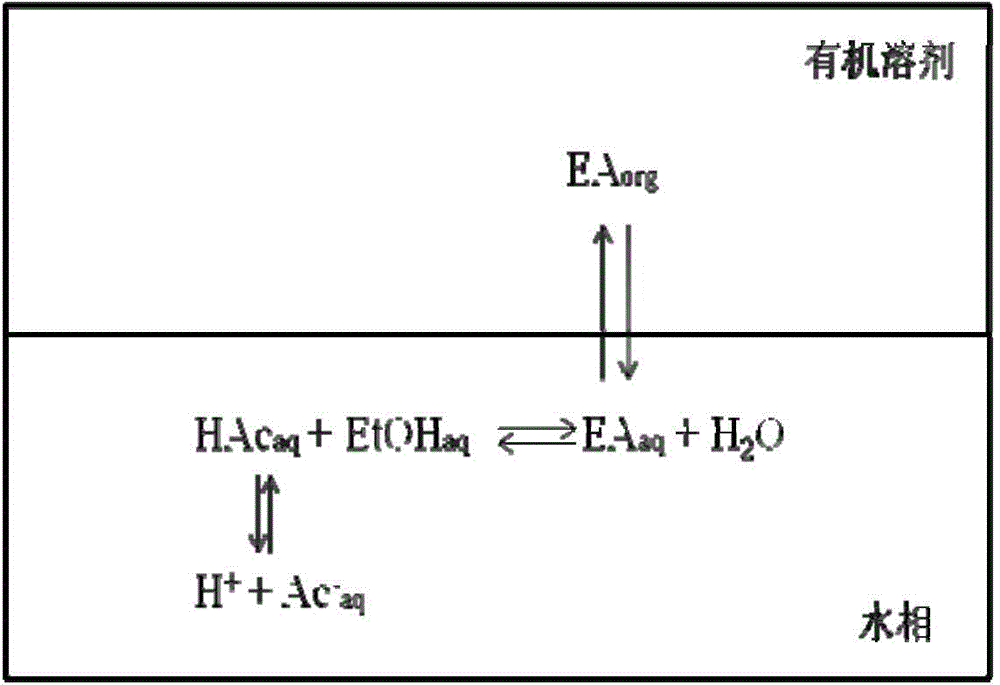

Method used

Image

Examples

Embodiment 1

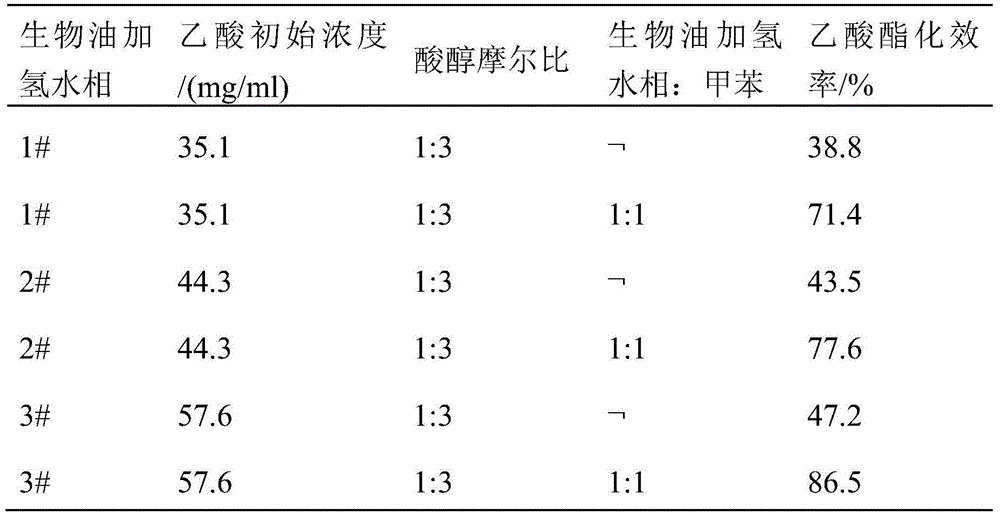

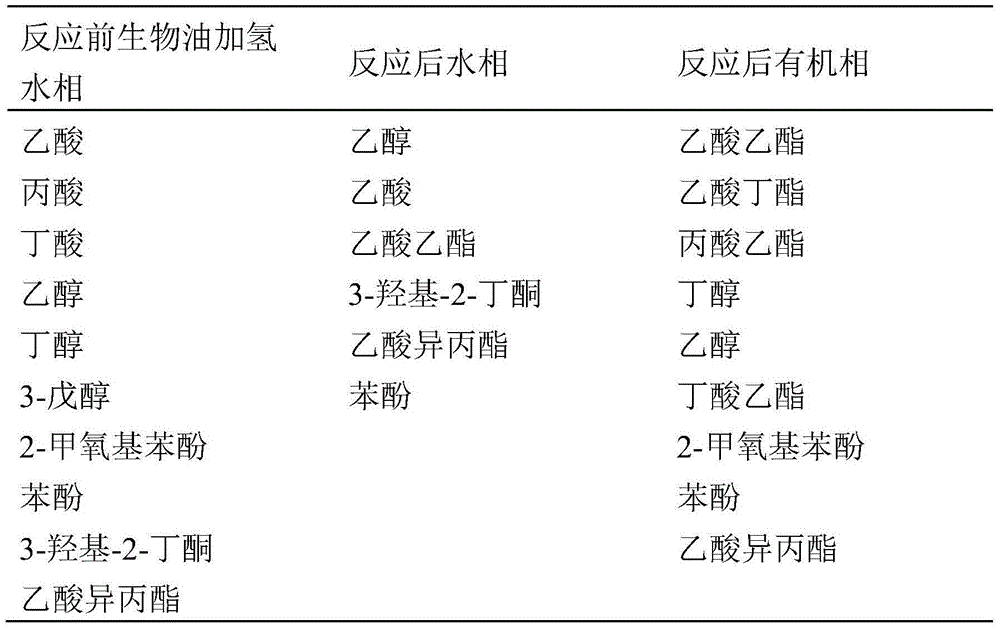

[0024] The bio-oil hydrogenation aqueous phase with the initial acetic acid concentration of 35.1mg / ml (1#), 44.3mg / ml (2#) and 57.6mg / ml (3#) was used as the raw material, and the molar ratio of acid to alcohol was 1:3. The organic solvent is toluene, and ultrasonic-assisted esterification coupling extraction is performed to recover acetic acid in the bio-oil hydrogenation aqueous phase. The specific steps are as follows:

[0025]Add the same quality bio-oil hydrogenation aqueous phase and toluene into a 250ml Erlenmeyer flask with a stopper (at the same time, a control group without toluene is provided), place the flask in an ultrasonic cleaner, and add organic acid when the water bath is heated to 60°C Anhydrous ethanol with an equimolar amount of 3 times, the amount of concentrated sulfuric acid is 10% of the molar amount of acetic acid; the reaction conditions set the ultrasonic frequency to 40kHz, the ultrasonic power to 80%, react for 3h to reach equilibrium, keep at 60°...

Embodiment 2

[0037] Using 63.5 mg / ml acetic acid aqueous solution as the simulated bio-oil hydrogenation aqueous phase, the acetic acid in it was recovered by ultrasonic-assisted esterification coupling extraction method, and the organic solvent was screened. The specific steps are as follows:

[0038] Add 63.5mg / ml acetic acid aqueous solution and organic solvent of the same mass into a 250ml Erlenmeyer flask with a stopper, place the flask in an ultrasonic cleaner, and add dehydrated alcohol in an equimolar amount to acetic acid when the water bath is heated to 60°C. The amount of sulfuric acid is 10% of the molar amount of acetic acid; the reaction conditions set the ultrasonic frequency to 40kHz, the ultrasonic power to 80%, react for 3h to reach equilibrium, keep at 60°C until the end of the reaction; take a small amount of uniform reaction solution, and separate the reaction solution by standing The water layer and the organic layer after the reaction were obtained, and the contents o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com