Apparatus for esterifying oils and fats by use of enzymic method

An enzymatic esterification and oil technology, which is applied in the field of oil processing, can solve the problems of long reaction time, low conversion rate, and great influence on oil quality, and achieve the effect of improving the efficiency of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

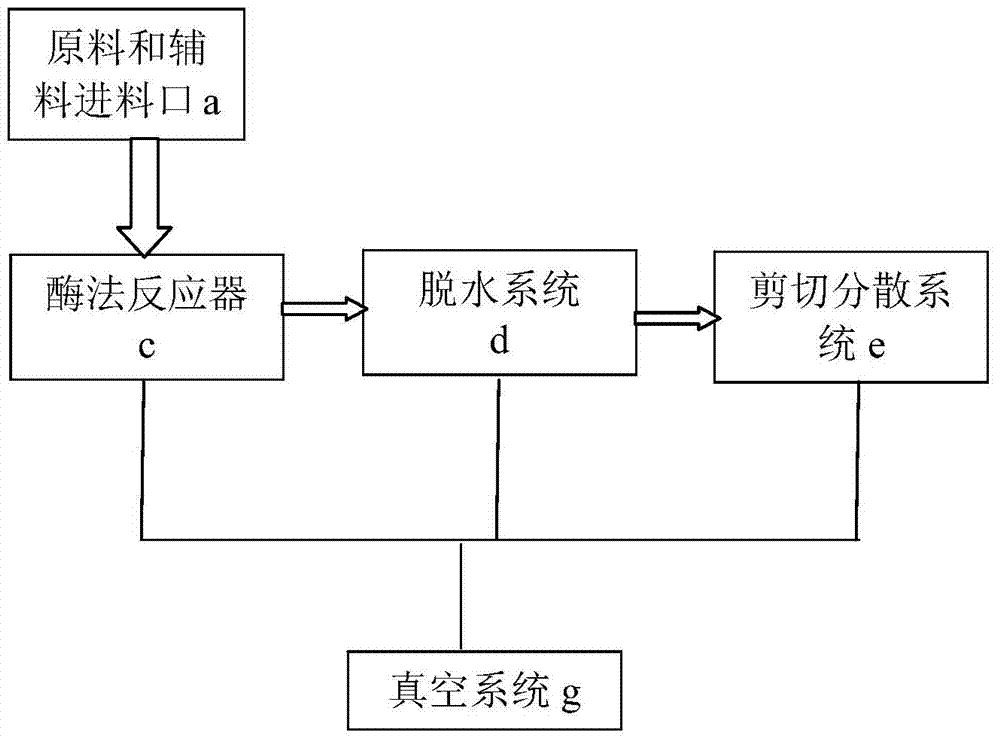

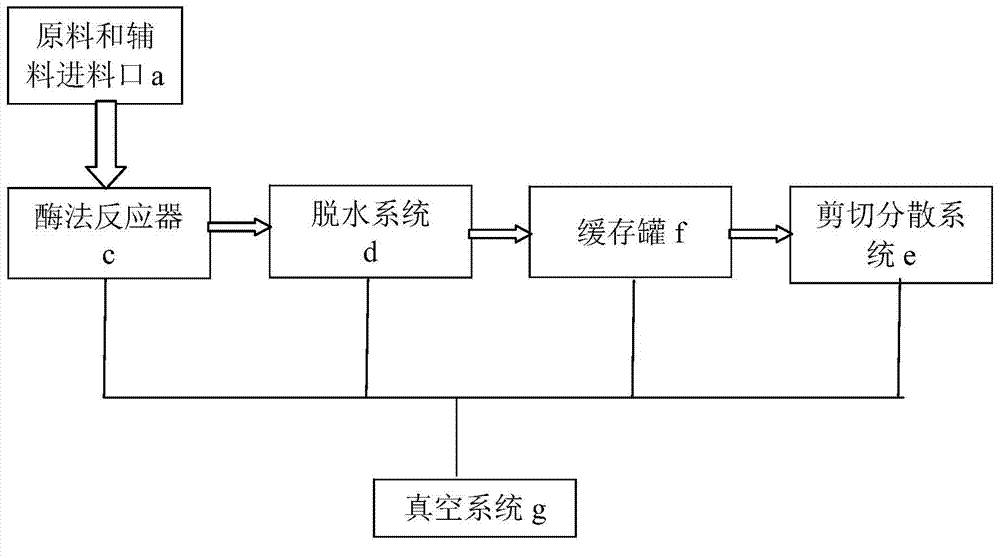

Method used

Image

Examples

Embodiment 1

[0070] Example 1. Enzymatic esterification reaction of rice oil and glycerol mixture with dispersed particle diameter below 1000 nanometers

[0071] Take 1000g of degummed rice oil and 20g of glycerin and mix them for 20min, and control the shear line velocity to 25m / s. Take a 50-gram sample, let it stand for 24 hours, and detect the particle size of glycerin by a polarizing microscope. The results are shown in Table 1.

[0072] Heat the pretreated and sheared degummed rice oil to 70°C, add 47.5g of immobilized enzyme preparation NOVOZYM435, and react at 75°C for 8 hours. During the reaction, use a vacuum system to evacuate to maintain the vacuum degree <10mbar. Sampling was performed every 2 hours, centrifuged at 10,000 rpm for 5 min, and the upper oil phase was collected to measure the acid value. The acid value of the obtained samples at different sampling points was detected.

Embodiment 2

[0073] Example 2 Enzymatic esterification reaction of rice oil and glycerin mixture with dispersed particle size of 5-15 microns

[0074] Mix 1000g of degummed rice oil and 20g of glycerol, shear and mix for 5min, and control the shear line speed to 20m / s, and obtain the pretreated and sheared degummed rice oil sample. Take a 50-gram sample, let it stand for 24 hours, and detect the particle size of glycerin by a polarizing microscope. The results are shown in Table 1.

[0075] Heat the pretreated and sheared degummed rice oil sample to 70°C, add 47.5g of immobilized enzyme preparation NOVOZYM435, and react at 75°C for 8 hours. During the reaction, use a vacuum system to maintain vacuum <10mbar. Sampling was performed every 2 hours, centrifuged at 10,000 rpm for 5 min, and the upper oil phase was collected to measure the acid value. The acid value of the obtained samples at different sampling points was detected.

Embodiment 3

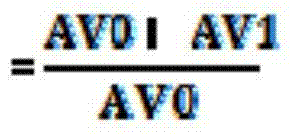

[0082] Embodiment 3, the impact of adding nitrogen on the rate of esterification of rice oil

[0083] Weigh 1000g degummed rice oil sample, heat to 75°C, add 20g glycerol, shear at 10000rpm for 3min; add 50g immobilized enzyme preparation NovoZYM435, react at 75°C for 8h. During the reaction process, nitrogen gas was charged from the bottom of the reactant, and its flow rate was adjusted, while a vacuum pump was used to evacuate to maintain a vacuum degree of <10mbar. Samples were taken every 2 hours, centrifuged at 10,000 rpm for 5 minutes, and the upper oil phase was collected to measure the acid value and DAG content, and the esterification rate was calculated. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com