High-efficiency esterification method of trioctyl trimellitate

A technology of trioctyl trimellitate and trimellitic anhydride, which is applied in the field of efficient esterification of trioctyl trimellitate, can solve the problems of long esterification time, incomplete esterification, low conversion rate and the like, and achieves improved esterification. effect, shortened esterification time, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

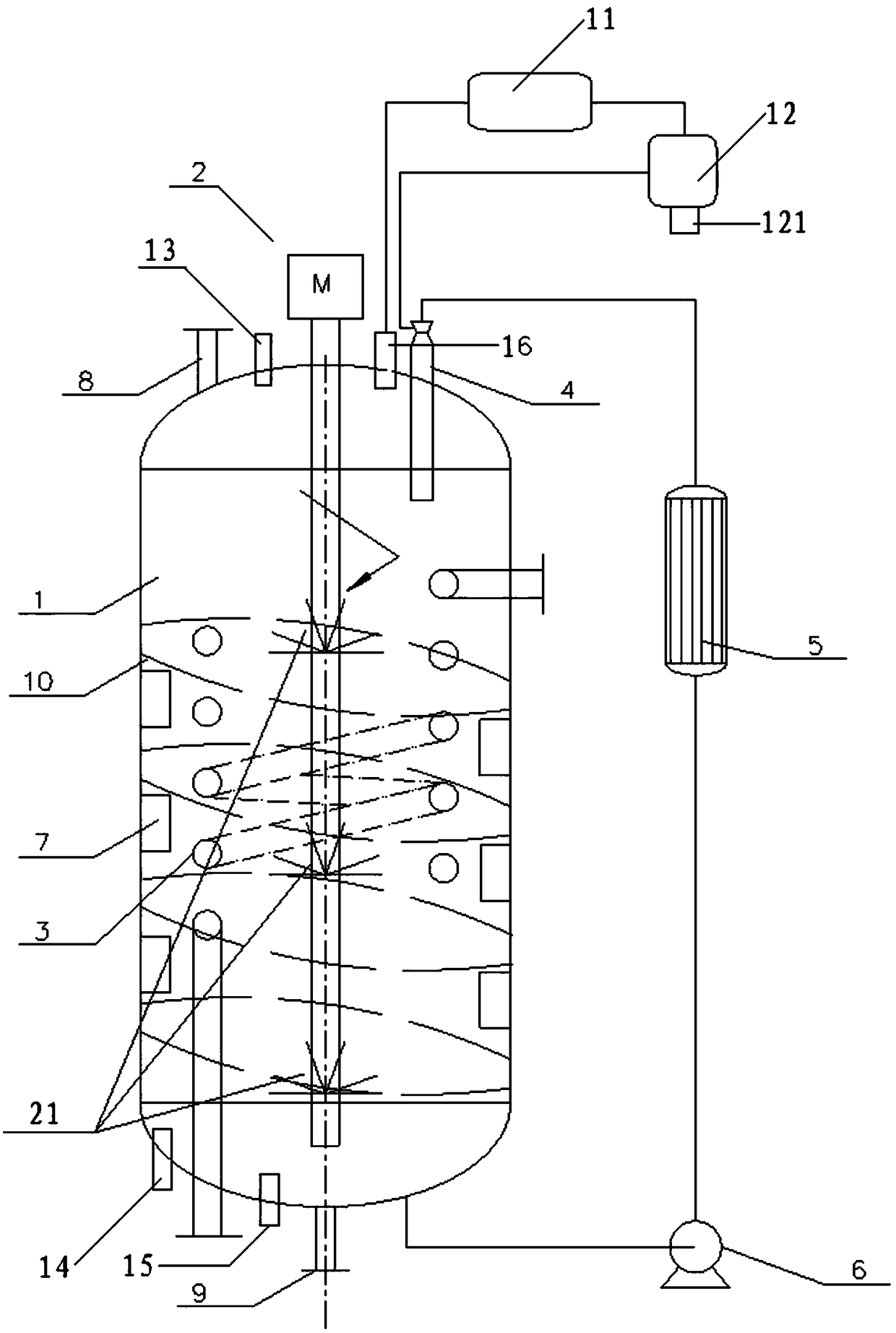

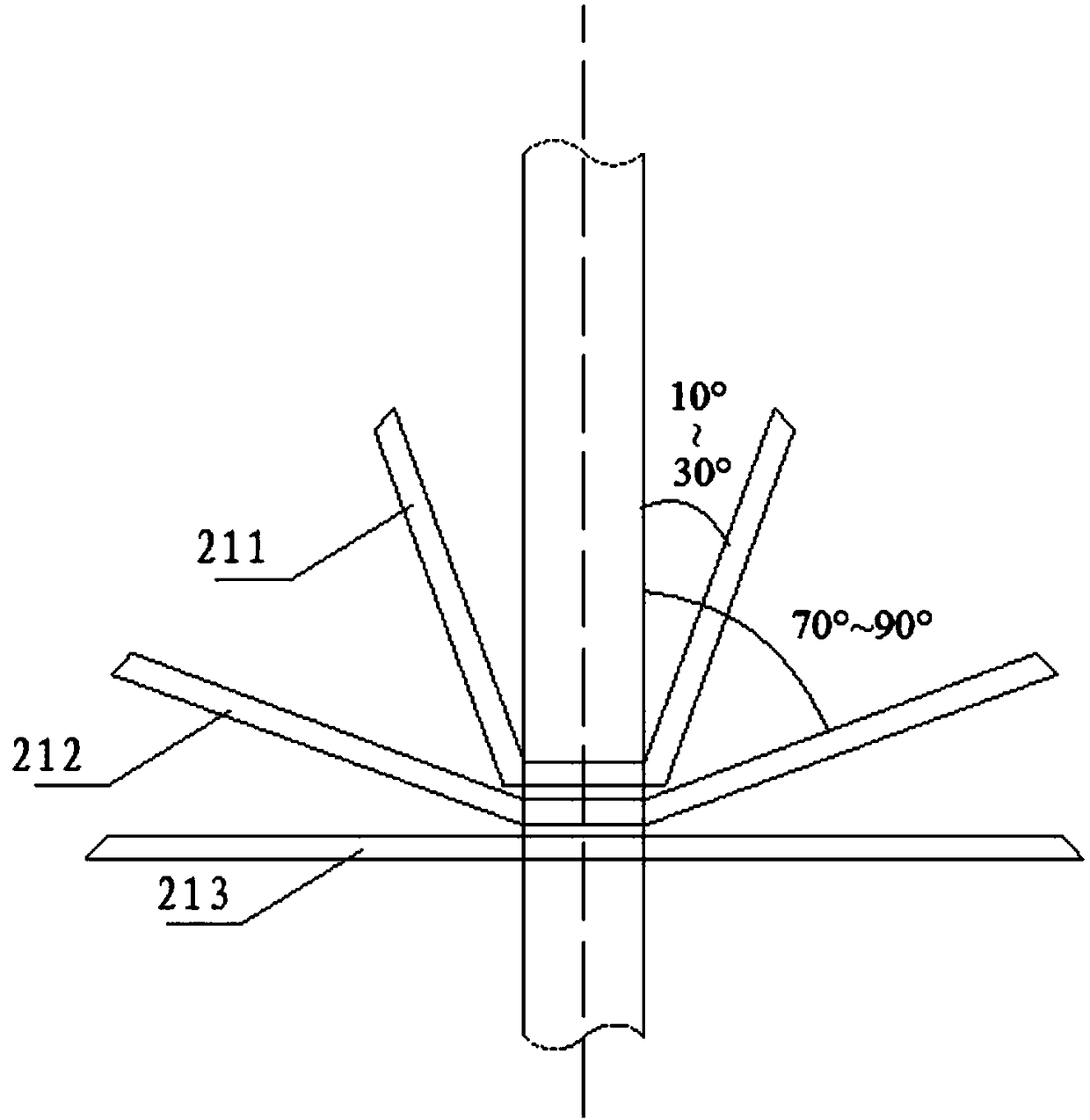

[0062]A kind of high-efficiency esterification method of plasticizer trioctyl trimellitate, described high-efficiency esterification method comprises the following steps: S1, put trimellitic anhydride and octanol into the high-efficiency esterification reactor in molar ratio for pre-mixing, Under the conditions of stirring and nitrogen blanketing, preheat to 120-150°C, the absolute pressure is 0.04-0.3MPa, and the slow stirring speed is 35r / min; S2, after trimellitic anhydride is completely dissolved in octanol, raise the temperature to 150-180 After ℃, add a mass ratio of liquid inorganic acid ester catalyst to carry out catalytic esterification reaction; S3, the esterification liquid is from the bottom of the high-efficiency esterification reactor, and after the circulation pump heats up in the heat exchanger, it is circulated to the top for injection The device enters the high-efficiency esterification reactor by spraying to form the circulation of the esterification liquid....

Embodiment 2

[0064] A kind of high-efficiency esterification method of plasticizer trioctyl trimellitate, described high-efficiency esterification method comprises the following steps: S1, put trimellitic anhydride and octanol into the high-efficiency esterification reactor in molar ratio for pre-mixing, Under the conditions of stirring and nitrogen blanketing, preheat to 120-150°C, the absolute pressure is 0.04-0.3MPa, and the slow stirring speed is 35r / min; S2, after trimellitic anhydride is completely dissolved in octanol, raise the temperature to 150-180 After ℃, add a mass ratio of liquid inorganic acid ester catalyst to carry out catalytic esterification reaction; S3, the esterification liquid is from the bottom of the high-efficiency esterification reactor, and after the circulation pump heats up in the heat exchanger, it is circulated to the top for injection The device enters the high-efficiency esterification reactor by spraying to form the circulation of the esterification liquid...

Embodiment 3

[0066] A kind of high-efficiency esterification method of plasticizer trioctyl trimellitate, described high-efficiency esterification method comprises the following steps: S1, put trimellitic anhydride and octanol into the high-efficiency esterification reactor in molar ratio for pre-mixing, Under the conditions of stirring and nitrogen blanketing, preheat to 120-150°C, the absolute pressure is 0.04-0.3MPa, and the slow stirring speed is 35r / min; S2, after trimellitic anhydride is completely dissolved in octanol, raise the temperature to 150-180 After ℃, add a mass ratio of liquid inorganic acid ester catalyst to carry out catalytic esterification reaction; S3, the esterification liquid is from the bottom of the high-efficiency esterification reactor, and after the circulation pump heats up in the heat exchanger, it is circulated to the top for injection The device enters the high-efficiency esterification reactor by spraying to form the circulation of the esterification liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com