Preparation method and application of spinel type oxide catalyst

A spinel-type, oxide-based technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low reserves, low electrochemical activity, power learning slowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

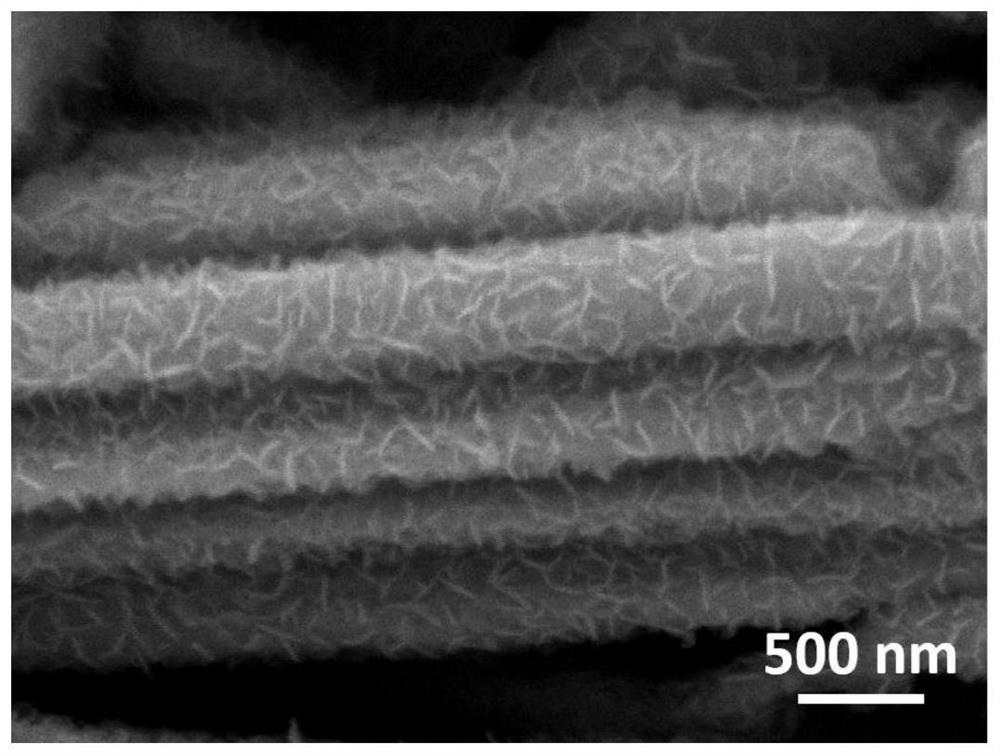

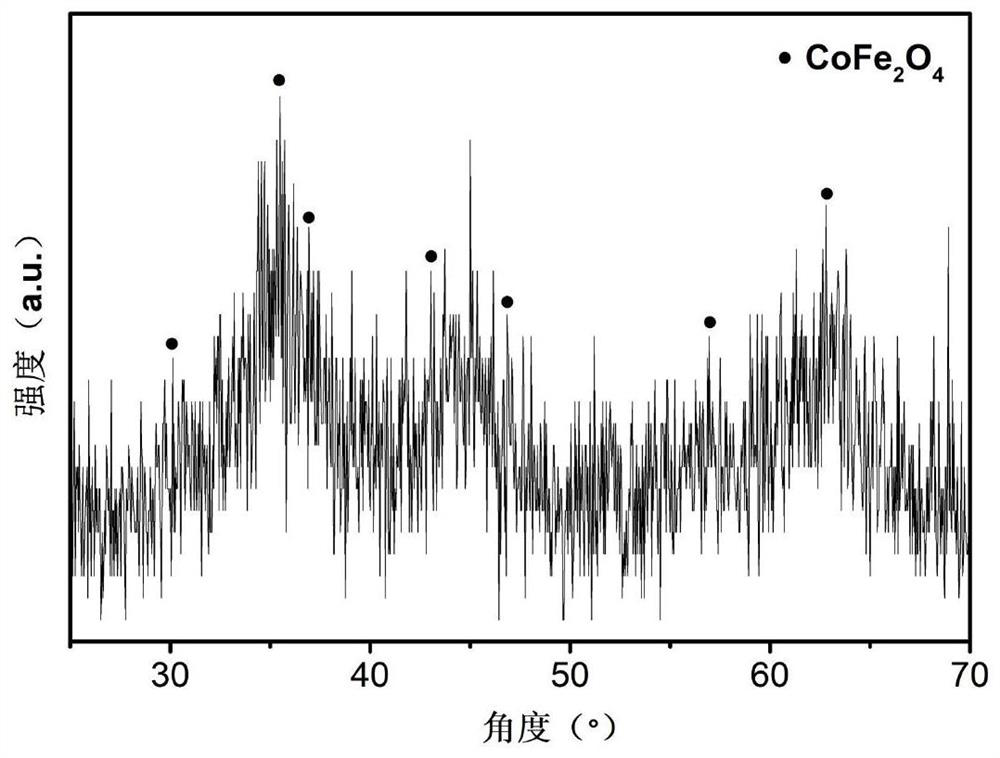

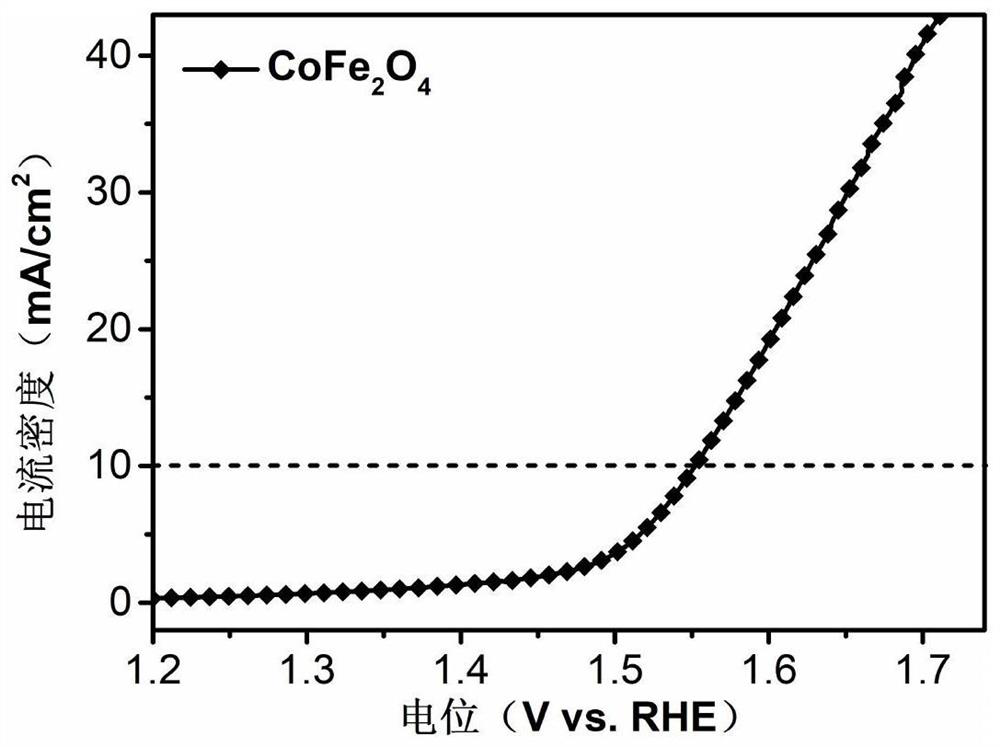

[0056] A preparation method of a spinel-type cobalt-iron oxide catalyst is carried out according to the following steps:

[0057] Step 1: Cobalt, iron and aluminum (atomic ratio: 5:10:85) are jointly heated to a molten state in a vacuum induction melting furnace to obtain an alloy liquid, and the alloy liquid is directly cooled in an argon atmosphere to form a rod-shaped alloy Ingots, and then use a vacuum stripping device to melt the alloy ingots to obtain alloy liquid again, and use the air pressure difference to blow the alloy liquid onto the copper roller with a speed of 1500r / min. After the alloy liquid cools rapidly, it can be blown to form a wide Alloy strips with a diameter of 2 mm and a thickness of 50 μm;

[0058] Step 2. Place the cobalt-iron-aluminum alloy strips obtained in step 1 in a sodium hydroxide solution with a molar concentration of 2 mol / L for dealloying. The reaction time is 36 hours. After being rinsed with ultrapure water for many times, it is dried to...

Embodiment 2

[0062] A preparation method of a spinel type manganese oxide catalyst is carried out according to the following steps:

[0063] Step 1. Use a vacuum induction melting furnace to heat manganese and aluminum (atomic ratio: 10:90) together to a molten state to obtain an alloy liquid, and directly cool the alloy liquid in an argon atmosphere to form a rod-shaped alloy ingot, and then use The vacuum stripping device melts the alloy ingot to obtain the alloy liquid again, and uses the air pressure difference to blow the alloy liquid onto the copper roller with a rotation speed of 1000r / min. After the alloy liquid is cooled rapidly, it can be blow-cast to form a 3mm wide and thick 30μm alloy strip;

[0064] Step 2. Place the manganese-aluminum alloy strip obtained in step 1 in a potassium hydroxide solution with a molar concentration of 6mol / L for dealloying. The reaction time is 12 hours. After being rinsed with ultrapure water for many times, it is dried to obtain manganese Hydrox...

Embodiment 3

[0068] A preparation method of a spinel-type nickel-cobalt oxide catalyst is carried out according to the following steps:

[0069] Step 1. Using a vacuum induction melting furnace to heat nickel, cobalt and aluminum (atomic ratio 10:20:70) together to a molten state to obtain an alloy liquid, and directly cool the alloy liquid in an argon atmosphere to form a rod-shaped alloy Then the alloy ingot is melted with a vacuum stripping device to obtain the alloy liquid again, and the alloy liquid is blown to the copper roller with a speed of 2000r / min by using the air pressure difference. After the alloy liquid is cooled rapidly, it can be blown to form a wide Alloy strips with a diameter of 3 mm and a thickness of 60 μm;

[0070] Step 2. Place the nickel-cobalt-aluminum alloy strip obtained in step 1 in a sodium hydroxide solution with a molar concentration of 4mol / L for dealloying treatment. The reaction time is 24 hours. After repeated washing with ultrapure water, it is dried t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com