Bifunctional biochar-based solid acid catalyst, and preparation method and application thereof

A carbon-based solid acid and bifunctional technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, biofuels, etc., can solve the problems of high requirements for equipment and reaction conditions, poor industrial availability, and time-consuming and energy-consuming reactions. problem, achieve the effect of shortening the reaction time of esterification, stabilizing performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

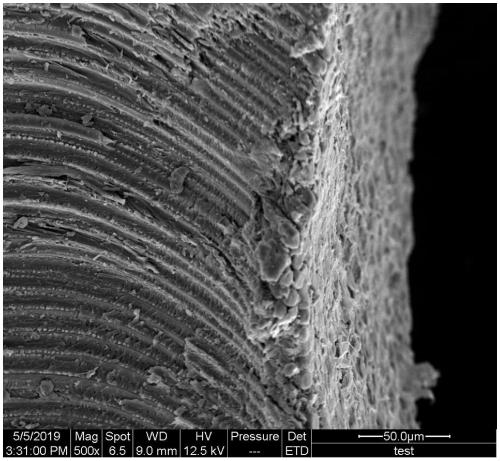

[0018] (1) Take a certain amount of jatropha seed husks, mechanically pulverize them into solid powders of approximately the same size, wash with deionized water, suction filter 3 times, and dry at 80° C. for 8 hours;

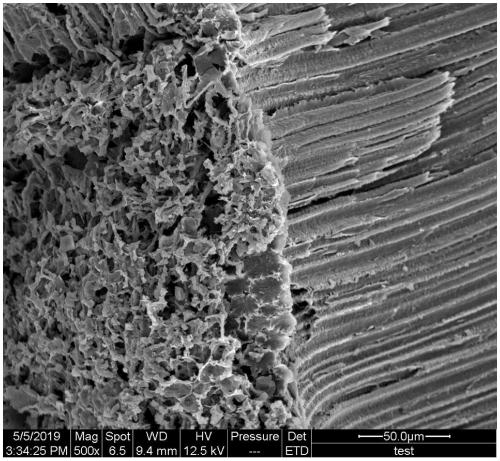

[0019] (2) Mix the washed and dried jatropha seed shells with ammonium lignosulfonate at a mass ratio of 13:1, and then carbonize at 500°C for 2.5 hours under the protection of nitrogen to make a carbon-based precursor loaded with amino groups ;

[0020] (3) Put the carbon-based precursor loaded with amino group and concentrated sulfuric acid at a mass volume ratio of 1g:8mL, add them into a hydrothermal reaction kettle for sulfonation, and heat at 80°C for 2h; The mixture carrier of ammonium lignosulfonate was washed with deionized water until the solution was neutral, and finally it was vacuum-dried at 80° C. for 8 hours to obtain a granular bifunctional biomass carbon-based solid acid catalyst;

[0021] (4) For the preparation of biodiesel, in the process o...

Embodiment 2

[0023] (1) Take a certain amount of jatropha seed husks, mechanically pulverize them into solid powders of approximately the same size, wash with absolute ethanol, suction filter 3 times, and dry at 100° C. for 8 hours;

[0024] (2) Mix the washed and dried jatropha seed shells with ammonium lignosulfonate at a mass ratio of 12:1, and then carbonize at 600°C for 2 hours under the protection of nitrogen to make a carbon-based precursor loaded with amino groups;

[0025] (3) Put the carbon-based precursor loaded with amino groups and oleum at a mass volume ratio of 1g:10mL, add them to the distillation reaction device for sulfonation, and heat at 80°C for 3h; The mixture carrier of ammonium lignosulfonate was washed with deionized water until the solution was neutral, and finally it was vacuum-dried at 80° C. for 8 hours to obtain a granular bifunctional biomass carbon-based solid acid catalyst;

[0026] (4) For the preparation of biodiesel, in the process of catalytic fatty aci...

Embodiment 3

[0028] (1) Take a certain amount of jatropha seed husks, mechanically pulverize them into solid powders of approximately the same size, wash with deionized water, suction filter 3 times, and dry at 80° C. for 8 hours;

[0029] (2) Mix the washed and dried jatropha seed shells with ammonium lignosulfonate at a mass ratio of 8:1, and then carbonize at 400°C for 3 hours under the protection of nitrogen to make a carbon-based precursor loaded with amino groups;

[0030] (3) Put the carbon-based precursor loaded with amino groups and concentrated sulfuric acid at a mass volume ratio of 1g:15mL, add them to the distillation reaction device for sulfonation, and heat at 100°C for 3h; The mixture carrier of ammonium sulfonate was washed with deionized water until the solution was neutral, and finally it was vacuum-dried at 80° C. for 8 hours to obtain a granular bifunctional biomass carbon-based solid acid catalyst;

[0031] (4) In order to prepare biodiesel, in the process of catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com