Synthesis method of ester oil

A synthesis method and technology of ester oil, applied in chemical instruments and methods, petroleum industry, carboxylate preparation, etc., can solve the problems of difficult removal of harmful substances, large amount of catalyst, slow reaction speed, etc., and improve thermal oxidation Stability, fast response, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for synthesizing ester oil, the method comprising the steps of:

[0030] 1) Add the composition of sulfuric acid and phosphoric acid as a combined catalyst to the alcohol and acid reactor; in the combined catalyst of sulfuric acid and phosphoric acid, the molar ratio of sulfuric acid and phosphoric acid is: 1: (2~4); The amount is 0.05-0.1% of the total weight of alcohol and acid.

[0031] 2) Carry out esterification reaction at 160°C-180°C, and generate crude ester after reacting for 2-6 hours;

[0032] 3) Blow ammonia or epoxy gas into the reactor for chemical deacidification; then blow one or more of nitrogen, steam, and argon into the reactor for physical deacidification; the addition of gas can be Quickly and efficiently remove free acid and other reaction by-products and residues in esterification products, and significantly improve the thermal oxidation stability, low temperature fluidity and other important properties of ester synthetic oils.

[0033]...

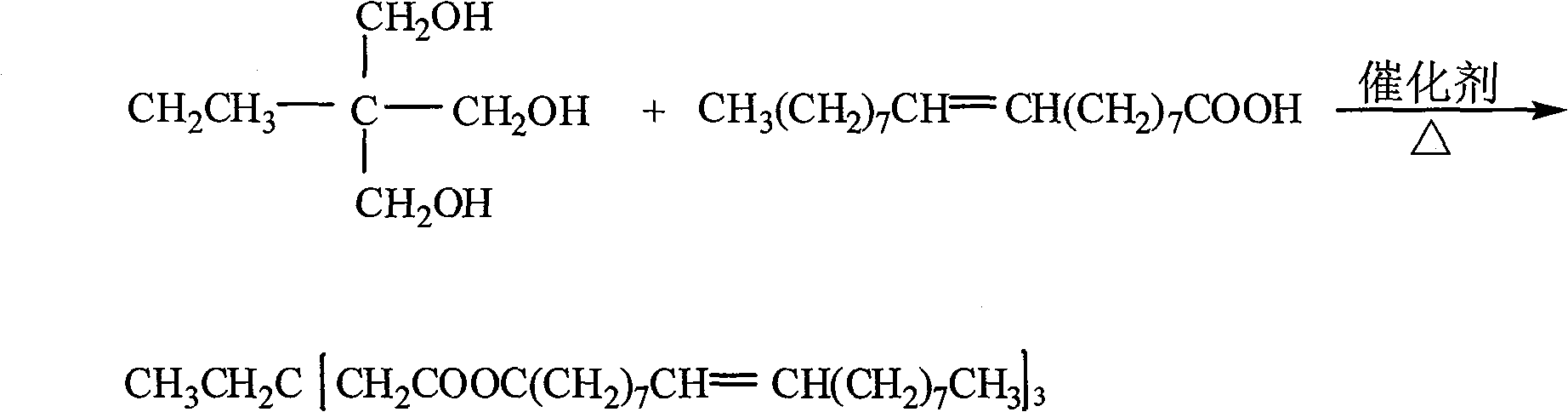

Embodiment 1

[0038] Preparation of Trimethylolpropane Trioleate

[0039] Put trimethylolpropane and oleic acid into the reaction kettle at a molar ratio of 3.2:1, add an appropriate amount of sulfur and phosphoric acid combined catalyst twice under stirring, raise the temperature to 120-130°C, and control the vacuum degree at -0.94MPa, React for 3 hours, then raise the temperature to 170-180°C, add the remaining combined catalyst for the third catalysis, so that the esterification continues to obtain crude ester, continue to react for 2 hours, and then blow epoxy gas into the kettle for a period of time 15h, the flow control is 18L / min, and then nitrogen is blown into the kettle for 20h, and the flow control is 25L / min. Chemical deacidification, further distilling the crude ester under reduced pressure, then dehydrating and drying under vacuum conditions and adding a polymerization inhibitor CPL, precision filtration, adding a polymerization inhibitor to the obtained filtrate to obtain tri...

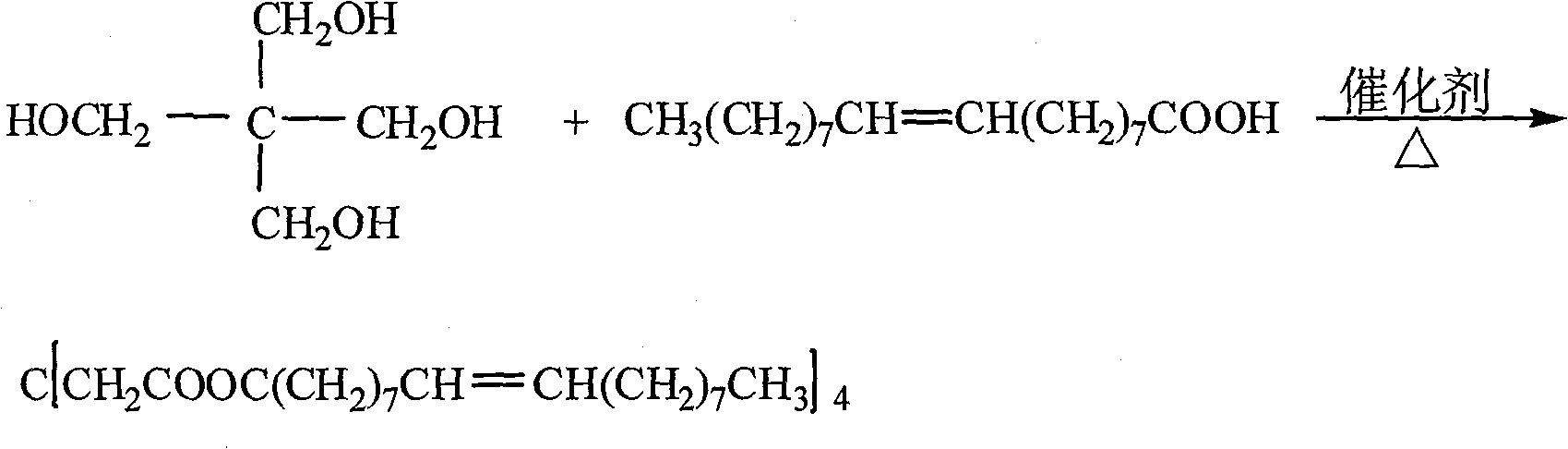

Embodiment 2

[0043] Preparation of Pentaerythritol Tetraoleate

[0044] Put pentaerythritol and oleic acid into the reaction kettle in a molar ratio of 4:1, add an appropriate amount of sulfur and phosphoric acid combined catalyst in two times under stirring, raise the temperature to 120-130°C, control the vacuum degree at -0.94MPa, react for 3 hours, and then Raise the temperature to 170-180°C, add the combined catalyst again for the third catalysis, so that the esterification will continue to occur to obtain the crude ester, and after continuing the reaction for 2 hours, blow epoxy gas into the kettle for 13 hours, and the flow rate is controlled as 15L / min, and then blow nitrogen into the kettle, the feeding time is 20h, and the flow rate is controlled at 13L / min. They interact with the unreacted acid and half ester contained in the crude ester for physical deacidification and chemical deacidification, and further The crude ester was distilled under reduced pressure, then dehydrated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com