Bamboo-carbon-based solid acid catalyst for biodiesel and preparation method and application of bamboo-carbon-based solid acid catalyst

A technology of solid acid catalyst and biodiesel, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of high raw material cost and waste of resources, and achieve low carbonization temperature and water washing operation. Effects of improving efficiency and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

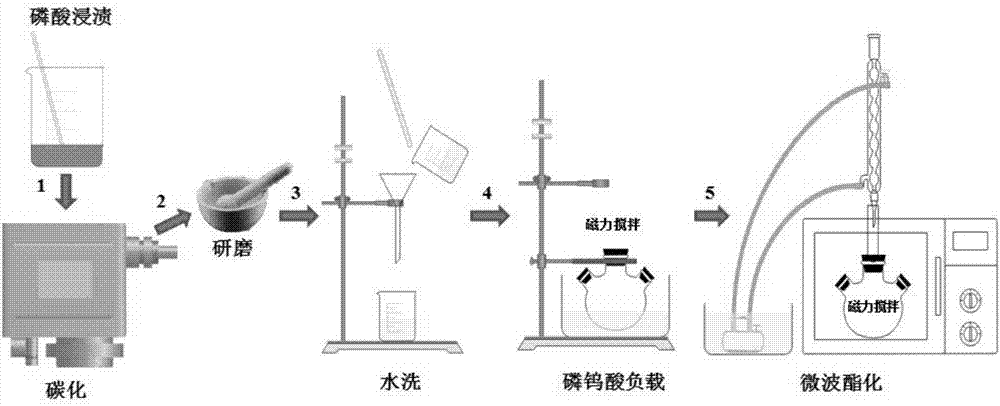

[0033] The specific operation schematic diagram of the preparation method of the present invention is as figure 1 As shown, take 100g of bamboo powder and place it in a blast drying oven to dry for 24 hours for later use; take 47.06g of concentration and mix it with 85% phosphoric acid solution (the quality of pure phosphoric acid is 40g) and mix it with 352.94g of deionized water to prepare a mass concentration of 10% phosphoric acid Dilute solution; weigh 20g of dried bamboo powder and mix it with phosphoric acid solution, stir and impregnate for 5 hours, then dry at 105°C for 12 hours; carbonize the impregnated bamboo powder at 500°C for 2 hours under the protection of nitrogen, and grind and sieve the carbonized product to 200 mesh Finally, wash repeatedly with 80°C deionized water until neutral, and then dry the product at 105°C for 4 hours; take 5g of the dried carbonized product and mix it with 0.556g of phosphotungstic acid, dissolve it in 75mL of deionized water, and p...

Embodiment 2

[0036] Get 100g of bamboo powder and place it in a blast drying oven to dry for 24 hours for subsequent use; take 47.06g of concentration and mix it with 85% phosphoric acid solution (the quality of pure phosphoric acid is 40g) and 86.27g of deionized water to prepare a 30% phosphoric acid dilute solution; Weigh 20 g of dried bamboo powder and mix it with phosphoric acid solution, stir and impregnate for 5 hours, then dry at 105°C for 12 hours; carbonize the impregnated bamboo powder at 600°C for 2 hours under the protection of nitrogen, grind and sieve the carbonized product to 200 mesh, and use Wash with deionized water repeatedly at 80°C until neutral, then dry the product at 105°C for 4 hours; take 5g of the dried carbonized product and mix it with 2.143g of phosphotungstic acid, dissolve it in 75mL of deionized water, and dry it at 65°C under magnetic stirring The water was evaporated to dryness to obtain a bamboo carbon-based solid acid with a loading capacity of phosphot...

Embodiment 3

[0039] Get 100g of bamboo powder and place it in a blast drying oven to dry for 24h for subsequent use; take 47.06g of concentration and mix it with 85% phosphoric acid solution (the quality of pure phosphoric acid is 40g) and 32.94g of deionized water to prepare a 50% phosphoric acid dilute solution; Weigh 20 g of dried bamboo powder and mix it with phosphoric acid solution, stir and impregnate for 5 hours, then dry at 105°C for 12 hours; carbonize the impregnated bamboo powder at 700°C for 2 hours under the protection of nitrogen, and grind and sieve the obtained carbonized product to 200 mesh, then use Wash with deionized water repeatedly at 80°C until neutral, then dry the product at 105°C for 4 hours; take 5g of the dried carbonized product and mix it with 0.556g of phosphotungstic acid, dissolve it in 75mL of deionized water, and dry it at 65°C under magnetic stirring The water was evaporated to dryness to obtain a bamboo carbon-based solid acid with a phosphotungstic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com