A kind of preparation method of anti-mud type polycarboxylate water reducer

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture, and can solve the problems of affecting the effect of water reducing and dispersing, poor effect of sulfonic acid groups, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

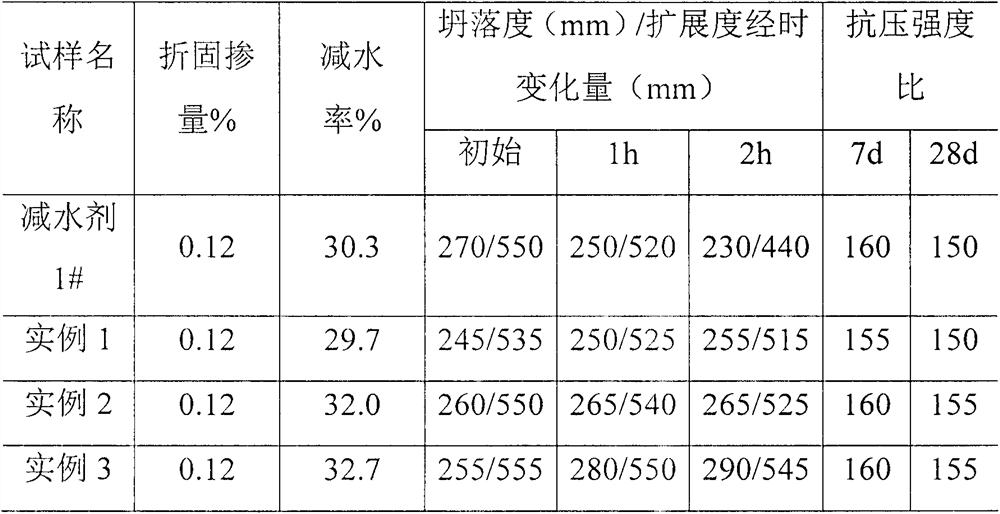

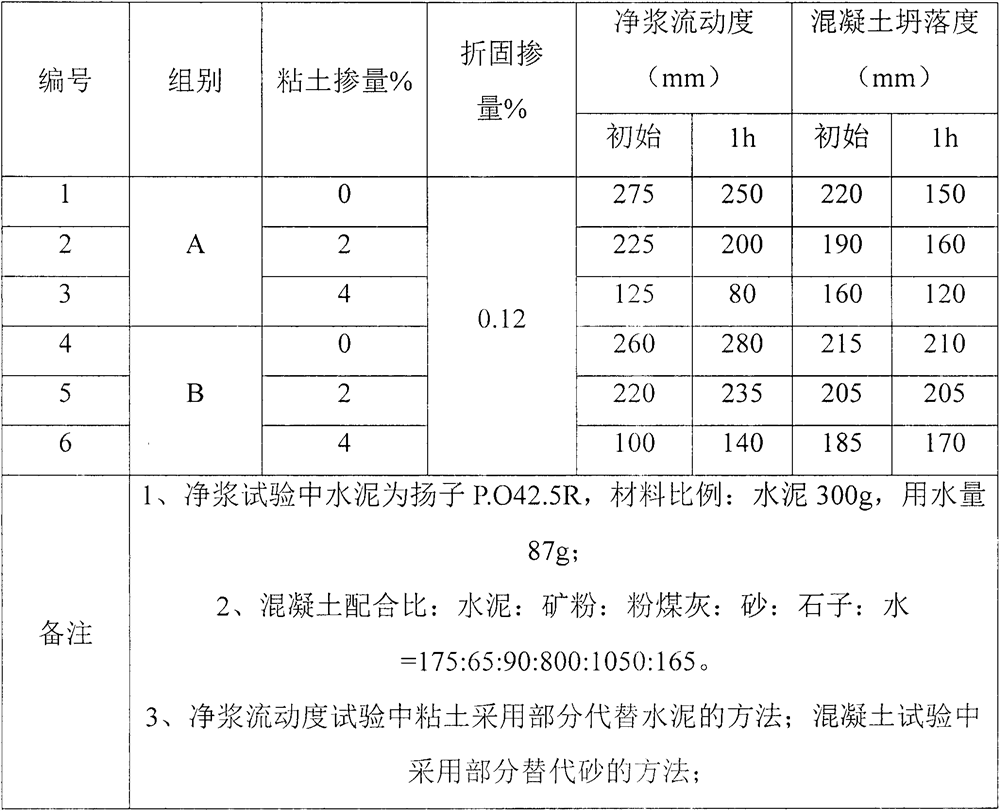

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method of anti-mud type polycarboxylate superplasticizer comprises the following steps:

[0025] (1) After grinding 3.1g maleic anhydride, add it to 5.5g dry powdered glucose, form a solution with 1g concentrated sulfuric acid, 0.1g inhibitor and 1.2g deionized water, and add the solution to the After aging for 15 minutes in the mixture of maleic anhydride and glucose, put it into an oven and react at 120 degrees Celsius for 2 hours to fully evaporate and dry the water to obtain the mixture I. Grind the mixture I, then add 2.57g of 50% phosphoric acid aqueous solution, stir and mix evenly, after aging for 15 minutes, put it in an oven, heat and react at 120 degrees Celsius for 1.5 hours to obtain the mixture II.

[0026] (2) Mix 6.5g maleic anhydride, 4.5g triethanolamine, 0.2g polymerization inhibitor and 9g polyethylene glycol monomethyl ether evenly, under the catalysis of 0.2g p-toluenesulfonic acid, under the condition of heating...

Embodiment 2

[0029] Embodiment 2: a kind of preparation method of anti-mud type polycarboxylate superplasticizer comprises the following steps:

[0030] (1) Grind 5.8g maleic anhydride and add it to 1( ).2g dry powdered glucose, form a solution with 1.7g concentrated sulfuric acid, 0.2g polymerization inhibitor and deionized water, and make the solution under stirring condition Add it into the mixture of maleic anhydride and glucose, age for 15 minutes, put it in an oven, react at 120 degrees Celsius for 2 hours, make the water fully evaporate and dry, and obtain the mixture I. Grind the mixture I, then add 4.8g of 50% phosphoric acid aqueous solution, stir and mix evenly, after aging for 15 minutes, put it in an oven, heat and react at 120 degrees Celsius for 1.5 hours to obtain the mixture II.

[0031] (2) Mix 6.7g maleic anhydride, 4.8g triethanolamine, 0.2g polymerization inhibitor and 10.2g polyethylene glycol monomethyl ether, under the catalysis of 0.2g p-toluenesulfonic acid, heat ...

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of anti-mud type polycarboxylate superplasticizer comprises the following steps:

[0035] (1) After grinding 7.6g maleic anhydride, add it to 13.4g dry powdered glucose, form a solution with 4.5g phosphoric acid, 1.9g concentrated sulfuric acid, 0.2g inhibitor and deionized water, and stir the The solution was added to a mixture of maleic anhydride and glucose, aged for 15 minutes, put into an oven, and reacted at 120 degrees Celsius for 2 hours to fully evaporate and dry the water to obtain mixture I. Grind the mixture I, then add 6.3g of 50% phosphoric acid aqueous solution, fully stir and mix evenly, after aging for 20 minutes, put it in an oven, heat and react at 120 degrees Celsius for 1.5 hours to obtain the mixture II.

[0036] (2) Mix 7.2g maleic anhydride, 5g triethanolamine, 0.25g polymerization inhibitor and 12.3g polyethylene glycol monomethyl ether, under the catalysis of 0.5g p-toluenesulfonic acid, under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com