Green preparation method for hydrophobic fatty acid ester of starch (FES)

A technology for fatty acid methyl esters and fatty acids is applied in the field of green preparation of hydrophobic fatty acid starch esters, which can solve problems such as toxicity, restriction, and difficulty in product separation, and achieve the effects of mild reaction conditions, improved esterification efficiency, and simple process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

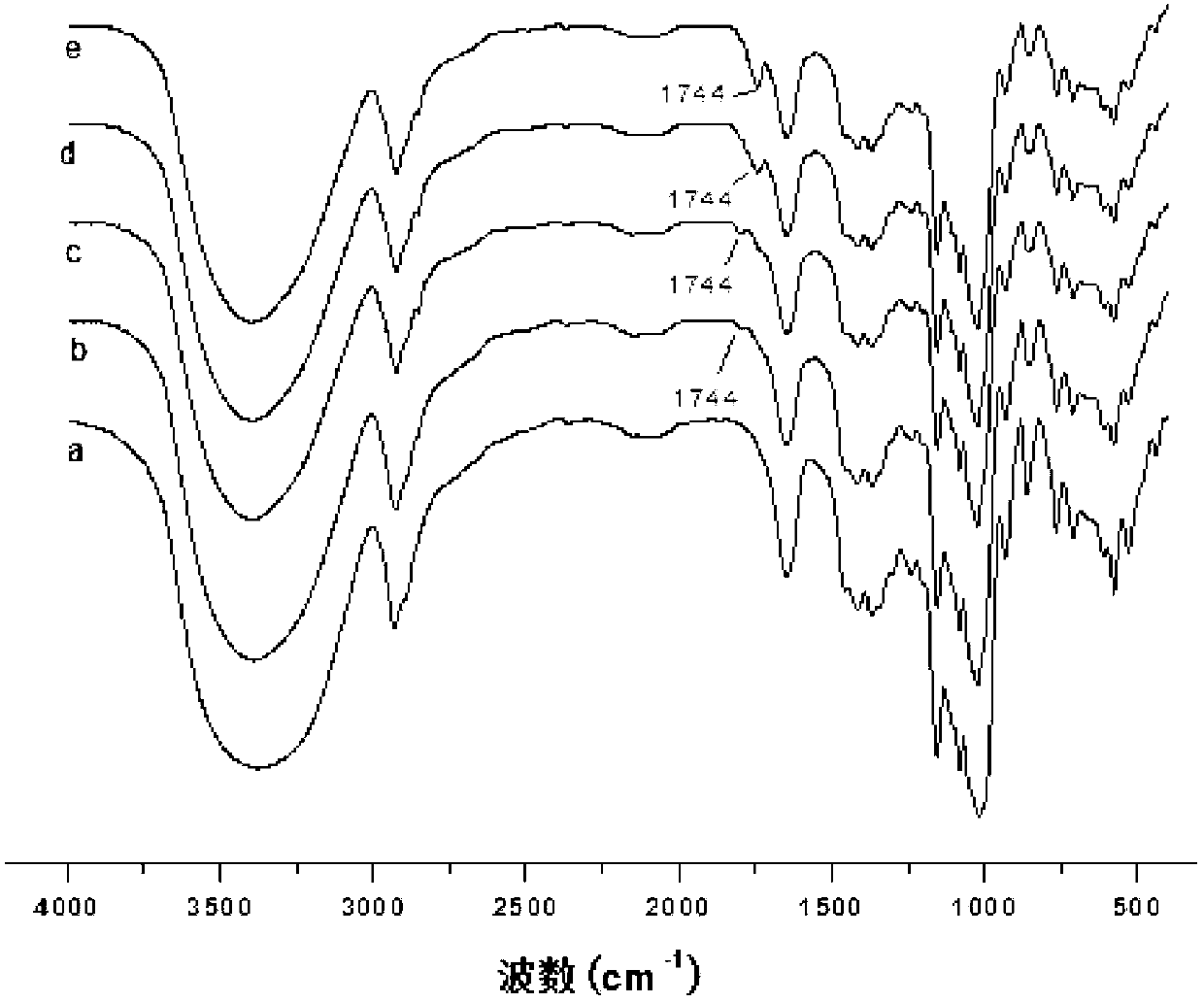

Image

Examples

Embodiment 1

[0023] The first step is to dry high-amylose corn starch VII (produced by National Starch Chemical Co., Ltd. of the United States, the amylose content in the starch is about 70%, which is a commercial starch) at 50°C until the moisture content is lower than 3%;

[0024] In the second step, the starch obtained in the first step is made into starch milk with a mass percentage of 5% by using an ionic liquid mixture, and the ionic liquid is 1-butyl-3-methylimidazole acetate and 1-butyl-3-methylimidazole The imidazolium tetrafluoroborate was mixed according to the mass ratio of 1:3, under the protection of nitrogen, heated and stirred at a constant temperature of 120°C for 2 hours;

[0025] In the third step, the temperature of the resulting solution is lowered to 60°C, and lipase (Candida rugosa lipase, Type VII, Sigma-Aldrich Company), methyl stearate is added, and the amount of lipase is 3% of the dry weight of starch, stearin The molar ratio of methyl ester to starch is 1:1, re...

Embodiment 2

[0031] The first step is to dry high-amylose corn starch V (produced by American National Starch Chemical Co., Ltd., the amylose content in the starch is about 50%, which is a commercial starch) at 60°C until the moisture content is lower than 3%;

[0032] In the second step, the starch obtained in the first step is made into starch milk with a mass percentage of 7% by using an ionic liquid mixture, and the ionic liquid is 1-butyl-3-methylimidazole acetate and 1-butyl-3-methylimidazole The imidazolium tetrafluoroborate was mixed according to the mass ratio of 1:6, under the protection of nitrogen, heated and stirred at a constant temperature of 120°C for 3 hours;

[0033] In the third step, the temperature of the resulting solution is lowered to 50°C, and lipase (Candida rugosa lipase, Type VII, Sigma-Aldrich Company), methyl palmitate is added, and the amount of lipase is 9% of the dry weight of starch, methyl palmitate The molar ratio of ester to starch is 1:3, react at cons...

Embodiment 3

[0037] The first step is to dry the tapioca starch at 50°C until the moisture content is lower than 3%;

[0038]In the second step, the starch obtained in the first step is made into starch milk with a mass percentage of 10% by using an ionic liquid mixture, and the ionic liquid is 1-butyl-3-methylimidazole acetate and 1-butyl-3-methylimidazole The imidazolium tetrafluoroborate was mixed according to the mass ratio of 1:5, under the protection of nitrogen, heated and stirred at a constant temperature of 120°C for 4 hours;

[0039] In the third step, the temperature of the resulting solution is lowered to 80°C, and lipase (Candida rugosa lipase, Type VII, Sigma-Aldrich Company), methyl myristate is added, and the amount of lipase is 7% of the dry weight of starch, and myristate The molar ratio of methyl ester to starch is 1:5, and the reaction is carried out at a constant temperature for 1 hour;

[0040] The fourth step is to cool the obtained solution to room temperature, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com