Continuous production method of biodiesel from waste oil/fat

A technology for waste oil and biodiesel, which is applied in the production of fatty acids, biofuels, and fats, etc., can solve the problems of affecting the esterification rate and product yield, etc., so as to improve the utilization rate of heat energy, improve the efficiency of esterification, and stabilize production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

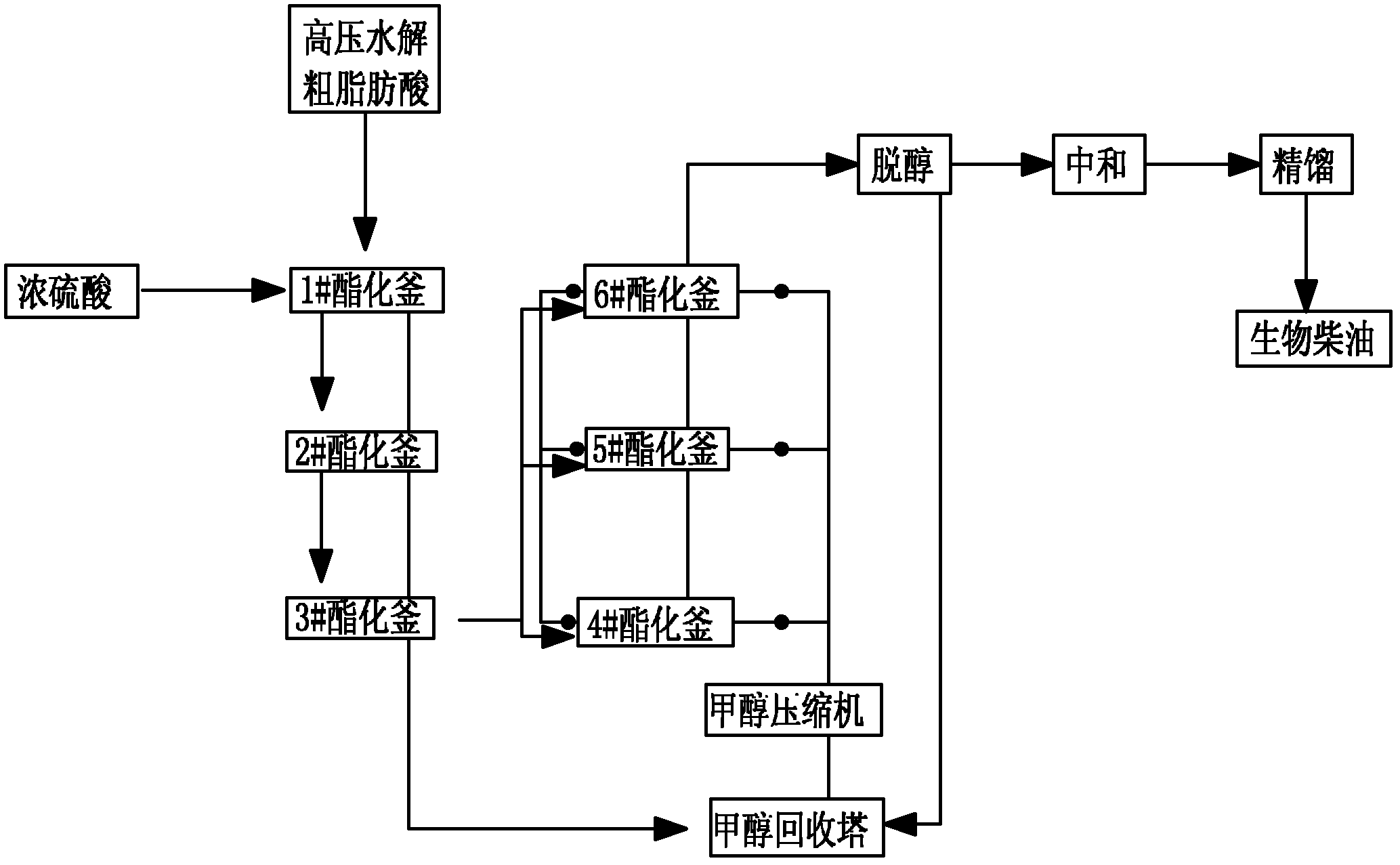

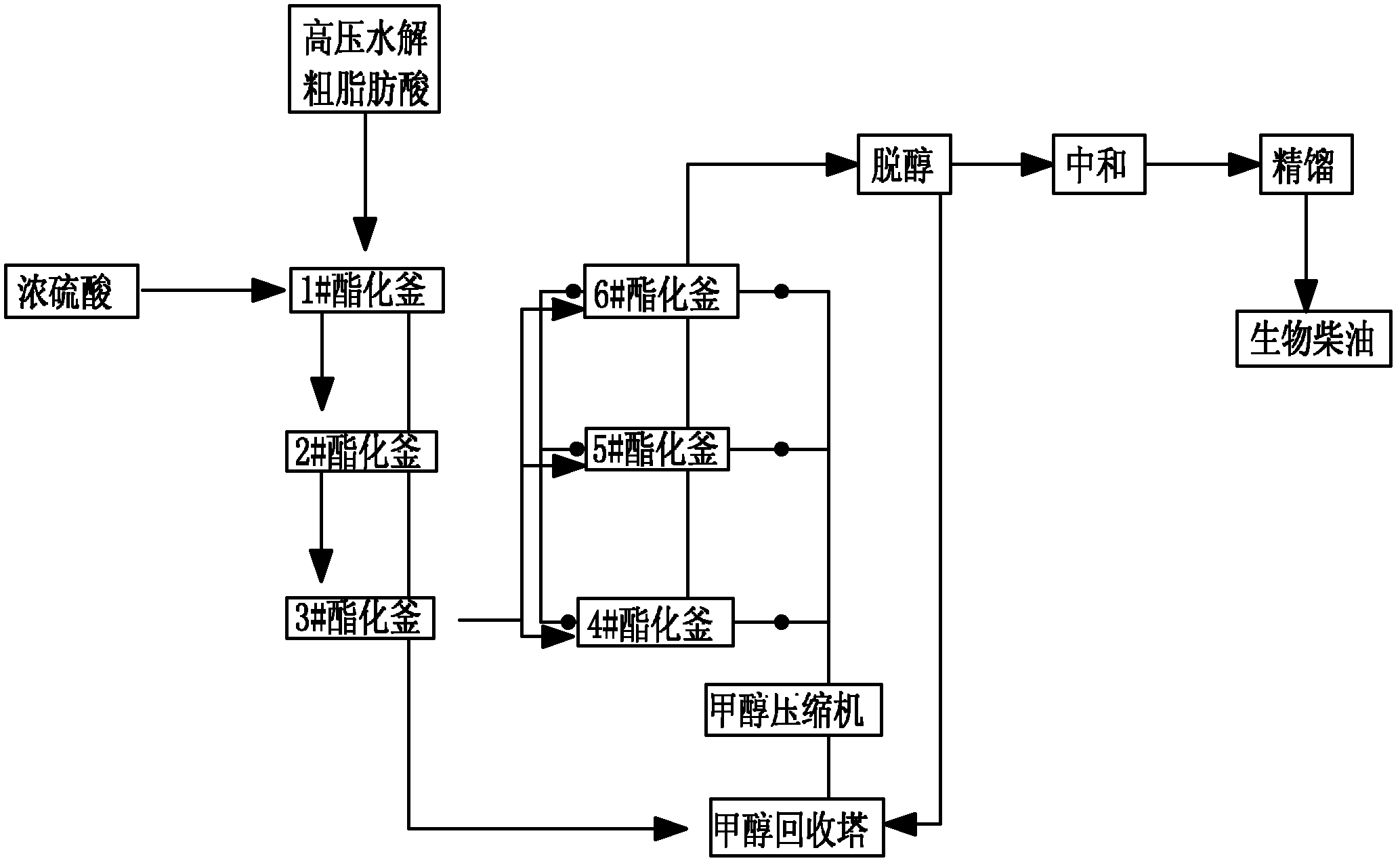

Method used

Image

Examples

Embodiment 1

[0026] 1. High-pressure hydrolysis of acidified vegetable oil bottoms to prepare fatty acids: acidified vegetable oily bottoms and hot water are injected into the hydrolysis tower in a proportion of 4:1, and the temperature is increased by 2.0MPa steam to obtain crude fatty acids with a hydrolysis rate of more than 98%, which naturally occur in the settling tank. Settling for 0.5h to remove water impurities.

[0027] 2. Esterification and dealcoholization: Dewatered fatty acid and concentrated sulfuric acid are injected into the esterification kettle, and compressed methanol gas is introduced. Under the pressure of 0.08MPa, the esterification is carried out step by step.

[0028] 3. Neutralization: After dealcoholization, the crude ester is transferred to a neutralization kettle and cooled to 70°C. Under stirring, soda ash powder is added to neutralize to the specified acid value, and the alkali residue is removed by sedimentation.

[0029] 4. Rectification: The neutralized cr...

Embodiment 2

[0031] 1. High-pressure hydrolysis of the mixture of acidified vegetable oil and waste oil to prepare fatty acid: the acidified vegetable oil and hot water are injected into the hydrolysis tower in a proportion of 3:1, and 3.0 MPa steam is used to pressurize and heat up to obtain a crude fatty acid with a hydrolysis rate of more than 96%. Natural sedimentation in the settling tank for 1h to remove water impurities.

[0032] 2. Esterification and dealcoholization: Dewatered fatty acid and concentrated sulfuric acid are injected into the esterification kettle, and compressed methanol gas is introduced to esterify step by step under the pressure of 0.55MPa. After esterification, alternate dealcoholization.

[0033] 3. Neutralization: After dealcoholization, the crude ester is transferred to a neutralization kettle and cooled to 80°C. Soda ash powder is added under stirring to neutralize to the specified acid value, and the alkali residue is removed by sedimentation.

[0034] 4. R...

Embodiment 3

[0036] 1. High-pressure hydrolysis of acidified vegetable oil bottoms to prepare fatty acids: acidified vegetable oily bottoms and hot water are injected into a hydrolysis tower in a proportion of 3.5:1, and 3.5 MPa steam is used to pressurize and heat up to obtain crude fatty acids with a hydrolysis rate of more than 98%. Settling for 1.5h to remove water impurities.

[0037] 2. Esterification and dealcoholization: Dewatered fatty acid and concentrated sulfuric acid are injected into the esterification kettle, and compressed methanol gas is introduced. Under the pressure of 1.5MPa, esterification is carried out step by step.

[0038] 3. Neutralization: After dealcoholization, the crude ester is transferred to a neutralization kettle to cool down to 90°C. Under stirring, soda ash powder is added to neutralize to the specified acid value, and the alkali residue is removed by sedimentation.

[0039] 4. Rectification: The neutralized crude ester enters the secondary rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com