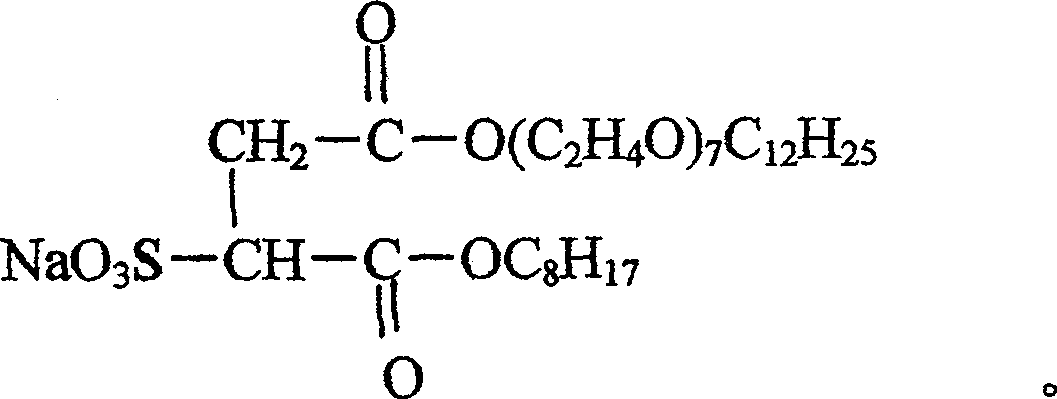

Sodium lauryl polyoxyethylene (7) octyl sulfosuccinate and its preparing process

A technology of lauryl alcohol polyoxyethylene ether and octyl sulfosuccinic acid, which is applied in the directions of chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of complex procedures and unsatisfactory product performance, and achieves compact process. , The effect of reducing equipment requirements and raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

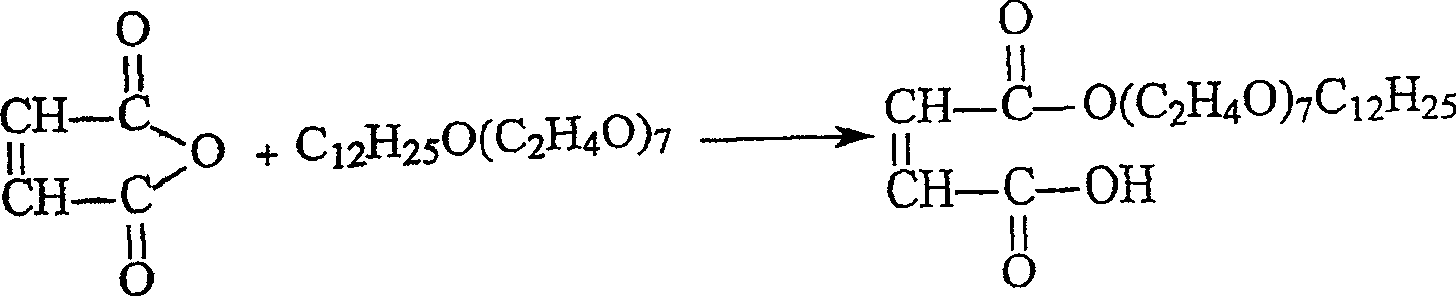

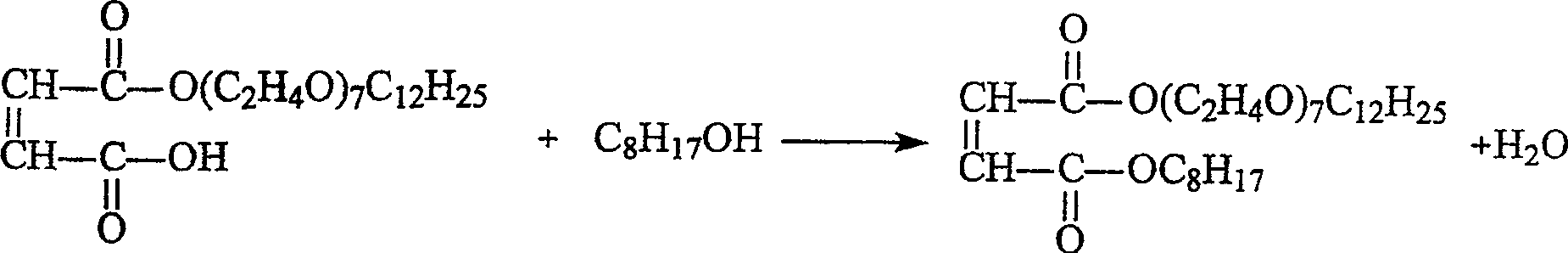

[0017] In a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, the water-treated polyoxyethylene laureth (7) and maleic anhydride were sequentially added at a mass ratio (molar ratio) of 1.00:1.10, and added The alkane sulfonic acid catalyst with 1% of maleic anhydride mass is introduced into nitrogen, and the temperature is raised to 140℃ with stirring within 10-30 minutes (examples 10, 20, 30 minutes); keep this temperature and keep time for 150 minutes in the same reaction Connect a water separator to the device, and add octanol according to the mass ratio (molar ratio) of octanol:maleic anhydride=4.0:1.0 to carry out the double-esterification reaction, and heat it to 200°C according to the above-mentioned single-esterification reaction method Time the temperature, keep the temperature for dehydration, keep the temperature for 300min, cool, neutralize, cool to a temperature of 20~60℃ (for example, 20℃, 40℃, 60℃), and neutralize to a pH of 7±0.5; ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com