Low-melting-point copolyester and preparation method thereof

A copolyester, low melting point technology, applied in the field of polymers, can solve the problems of polyester thermal properties, poor mechanical properties, impact on practical properties, destruction of crystalline properties, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

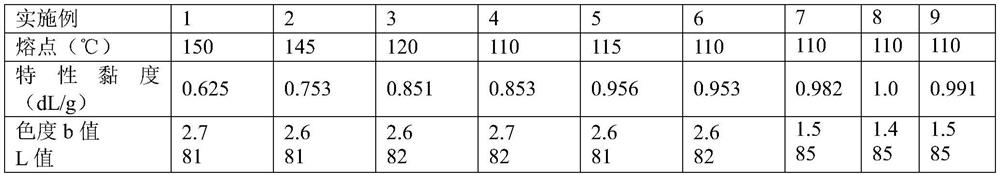

Examples

preparation example Construction

[0019] A kind of preparation method of low melting point copolyester, reaction steps are as follows: (1) esterification reaction: mixed acid IPA / PTA, EG and Sb 2 EG 3 Weighing according to the formula (in the mixed acid composed of IPA and PTA, the PTA mass accounts for 80-90%, the molar ratio of EG and the mixed acid is the alkyd ratio 1:1.2-1.5, Sb 2 EG 3 The quality is 300-400ppm based on the mixed acid quality), first pour half of the weighed EG into the 50L polymerization kettle, turn on the stirring and then add the evenly mixed powder IPA, PTA and Sb 2 EG 3 , and then pour the remaining EG, open the kettle to heat, and after beating for 30-40 minutes, use nitrogen to perform three-way and three-release, discharge the air in the kettle, pay attention to keep the pressure in the kettle at 0.2-0.3MPa for esterification, and control the pressure in the kettle. The temperature is between 240°C and 250°C, and the esterification ends when the water output reaches 85% to 95%...

Embodiment 1

[0022] A kind of preparation method of low melting point copolyester, reaction steps are as follows: (1) esterification reaction: take mixed acid IPA / PTA, EG and Sb 2 EG 3 , wherein the mass of PTA in the mixed acid accounts for 90%, the molar ratio of EG to the mixed acid is the alkyd ratio of 1:1.2, Sb 2 EG 3 The mass is 300ppm of the mass of the mixed acid. Pour half of the weighed EG into a 50L polymerization kettle, turn on the stirring and then add the evenly mixed powder IPA, PTA and Sb 2 EG 3 , and then pour the remaining EG, open the kettle to heat, after beating for 30 minutes, use nitrogen to carry out three connections and three releases, discharge the air in the kettle, keep the pressure in the kettle at 0.2-0.3MPa for esterification, and control the temperature in the kettle at 240 ~250°C, after 50 minutes, the water output reaches 90% of the theoretical value, and the esterification is completed;

[0023] (2) polycondensation reaction: in the reaction soluti...

Embodiment 2

[0025] A kind of preparation method of low melting point copolyester, reaction steps are as follows: (1) esterification reaction: take mixed acid IPA / PTA, EG and Sb 2 EG 3 , wherein the mass of PTA in the mixed acid accounts for 80%, the molar ratio of EG to the mixed acid is the alkyd ratio of 1:1.2, and the Sb 2 EG 3 The mass is 350ppm of the mass of the mixed acid. Pour half of the weighed EG into a 50L polymerization kettle, turn on the stirring and then add the evenly mixed powder IPA, PTA and Sb 2 EG 3 , and then pour the remaining EG, open the kettle to heat, after beating for 30 minutes, use nitrogen to carry out three connections and three releases, discharge the air in the kettle, keep the pressure in the kettle at 0.2-0.3MPa for esterification, and control the temperature in the kettle at 240 ~250°C, after 50 minutes, the water output reaches 90% of the theoretical value, and the esterification is completed;

[0026](2) polycondensation reaction: in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com